The introduction of fibre laser cutting machines has significantly changed the landscape of modern manufacturing. In an industry where speed, точность, and versatility are paramount, fibre lasers have emerged as one of the most advanced technologies for cutting and engraving metal materials.

В этой статье, we will explore the workings of fibre laser cutting machines, их ключевые преимущества, and why they have become a preferred choice in industries ranging from automotive to aerospace.

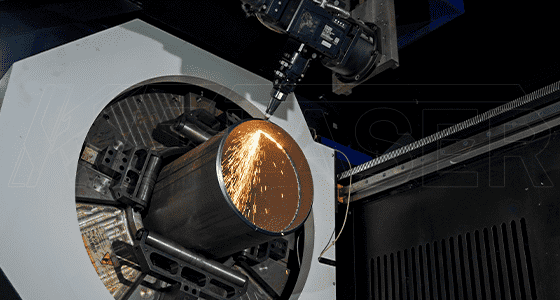

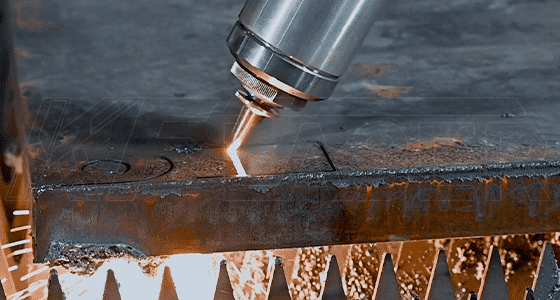

По своей сути, а fibre laser cutting machine uses a highly focused laser beam to cut through metal materials with incredible precision. The laser beam is generated using an optical fiber, which makes the system more efficient and powerful compared to traditional cutting methods.

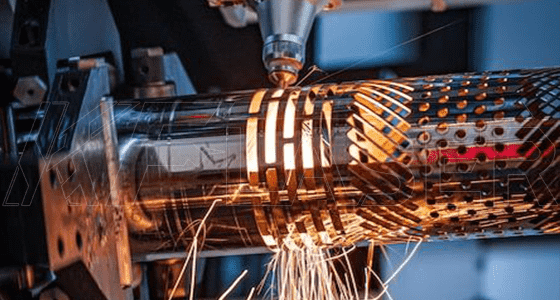

Fibre lasers typically use a laser source made from a solid-state laser diode that is pumped into an optical fiber, generating a laser beam with a very small spot size and high energy density. This allows the laser to cut through a wide range of materials, from thin sheets of metal to thicker metals like stainless steel, алюминий, and carbon steel.

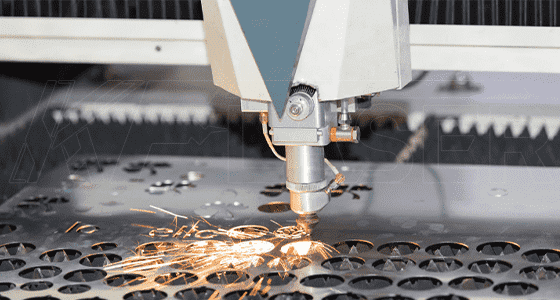

Fibre laser cutting is known for its impressive cutting speeds, especially when compared to other types of lasers, например, CO2-лазеры. The concentrated laser beam produced by the fibre laser allows for faster cutting and better efficiency, making it an ideal option for high-volume production environments. This increased speed helps reduce overall production time and costs.

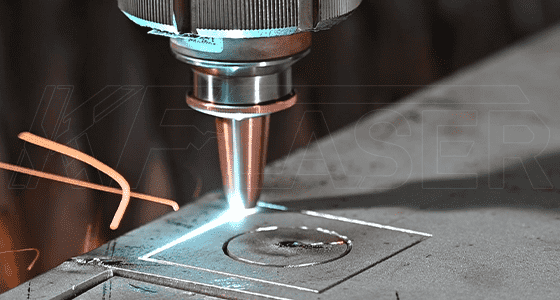

Precision is critical in industries where tight tolerances are required. Fibre laser cutting machines can achieve high levels of accuracy, often down to 0.1mm. The focused beam ensures clean cuts with minimal kerf (ширина разреза), which is especially important for intricate designs and complex shapes. The ability to maintain accuracy over extended periods also reduces the need for rework, Экономия как времени, так и денег.

One of the standout features of fibre laser cutting is its precision, which leads to minimal material wastage. The machine’s precise cutting ability reduces scrap material, which is an important consideration in industries that deal with expensive materials. Кроме того, the smaller heat-affected zone (ЗТВ) ensures less deformation and discoloration on the workpiece, improving the final product quality.

Fibre lasers are more energy-efficient than their CO2 counterparts. Since they use solid-state diode pumps, the energy conversion efficiency is much higher, meaning less power is needed to generate the same cutting effect. This efficiency translates into lower operating costs and a more environmentally friendly process, as fibre lasers use less electricity to perform the same task.

Fibre laser cutting machines can handle a broad range of materials and thicknesses. They are particularly well-suited for cutting metals such as stainless steel, мягкая сталь, алюминий, и латунь, making them an indispensable tool for manufacturers across industries. The versatility of these machines makes them suitable for small-scale custom projects as well as large-scale mass production.

Fibre lasers require significantly less maintenance compared to CO2 lasers. The lack of mirrors and the use of fiber optics means there are fewer parts that need to be maintained or replaced. This results in lower downtime and fewer service costs, improving the overall cost-efficiency of the cutting process.

The working principle of a fibre laser cutting machine revolves around the generation of high-intensity light through fiber optics. Here’s a simplified breakdown of the process:

The versatility and efficiency of fibre laser cutting machines make them ideal for use in a variety of industries:

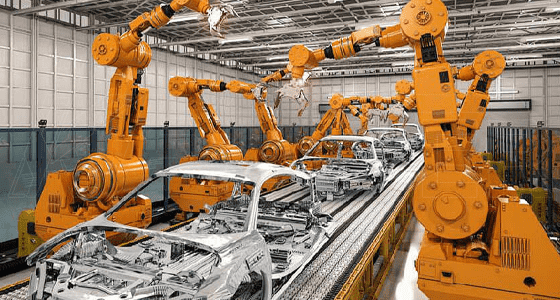

The automotive sector relies heavily on fibre laser cutting for manufacturing parts like body panels, структурные компоненты, и выхлопные системы. The machine’s ability to cut high-strength steel and other metals with precision helps manufacturers produce lightweight, durable components that meet safety and performance standards.

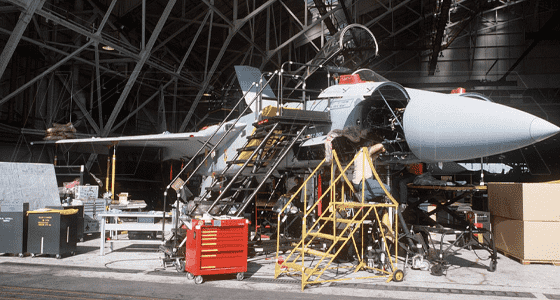

В аэрокосмическом производстве, materials need to be cut with extreme accuracy and minimal waste. Fibre laser cutting is perfect for producing parts like engine components, fuselage panels, and brackets. The technology also ensures that the parts meet stringent quality standards required for safety-critical applications.

Fibre laser cutting machines are commonly used in sheet metal fabrication, where high-volume, high-precision cutting is necessary. The ability to cut through thin to medium-thick sheets of metal at high speeds allows manufacturers to produce a wide range of products, from metal enclosures to structural frames.

В электронике, fibre lasers are used to cut delicate metal components such as connectors, heatsinks, and circuit board components. The precision and speed offered by fibre laser cutting ensure that the parts are produced with the required tolerances for optimal performance.

Fibre laser cutting is also popular in the creation of custom signs, скульптуры, and decorative metal art. The ability to cut intricate designs and patterns in a variety of metals makes it ideal for creating visually appealing and unique designs.

Precision is crucial in the production of medical devices, and fibre laser cutting is often used to cut stainless steel and titanium components for instruments and implants. The accuracy of fibre laser machines ensures that the components meet the exact specifications required for medical applications.

Выбор правильного fibre laser cutting machine depends on several factors, включая:

Тип и толщина материала: Different machines are better suited for specific materials and thicknesses. Ensure the machine can handle the types of metals you work with and the material thickness you need.

Требования к питанию: The power of the fibre laser determines its cutting capacity. Higher wattage lasers can cut through thicker materials more efficiently, but they may be more expensive. Consider the power requirements based on your cutting needs.

Скорость резания: Speed is an important consideration for mass production. Fibre lasers can cut metal much faster than traditional methods, but the cutting speed may vary based on the material, толщина, and complexity of the design.

Совместимость программного обеспечения: Many fibre laser cutting machines come with advanced software that helps with programming, path generation, and optimizing cutting efficiency. Make sure the machine’s software is compatible with your existing design files and production workflow.

Обслуживание и поддержка: Opt for a fibre laser cutting machine that offers reliable after-sales support and low maintenance costs. Machines with fewer moving parts tend to require less upkeep, which can save you both time and money in the long run.

Fibre laser cutting machines have set a new benchmark for speed, точность, and versatility in manufacturing. Whether you’re working with thin sheets of metal or cutting intricate parts for the aerospace or automotive industries, fibre lasers offer a range of benefits that make them an essential tool in modern production environments. Their ability to provide high-quality cuts with minimal waste, более низкое энергопотребление, and reduced maintenance costs makes them an ideal investment for businesses aiming to stay competitive in today’s fast-paced manufacturing world.