Новости

Раскрытие всего потенциала станка для лазерной резки мощностью 1500 Вт

В быстро развивающемся мире производства, точность и скорость важны как никогда. Если вы ищете способ оставаться впереди конкурентов, а станок лазерной резки 1500 Вт может быть это просто решение. Эта мощная технология резки меняет отрасли промышленности, позволяя предприятиям создавать сложные конструкции с беспрецедентной точностью и скоростью..

Лазерная резка уже давно стала фаворитом в отраслях, требующих высокой точности.. Работаете ли вы с металлами, пластмассы, или даже текстиль, тот станок лазерной резки 1500 Вт предлагает значительные преимущества, которые трудно игнорировать. Но что именно делает станок лазерной резки мощностью 1500 Вт таким важным инструментом в современном производстве??

Основы станков лазерной резки

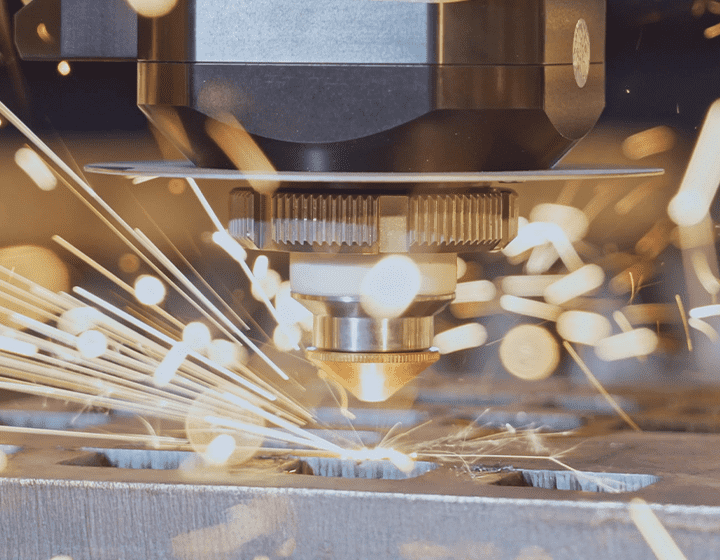

Прежде чем погрузиться в мощность и возможности станка для лазерной резки мощностью 1500 Вт., важно понимать основной принцип работы лазерной резки.. Эта технология использует мощный лазерный луч для резки материалов., благодаря теплу лазерного луча, плавящему или испаряющему материал. Интенсивность лазера, в сочетании со скоростью и точностью луча, делает его идеальным для создания сложных форм и детальных разрезов с минимальными отходами..

Почему стоит выбрать станок для лазерной резки мощностью 1500 Вт?

Более высокая мощность для более прочных материалов:

Мощность 1500 Вт позволяет резать более толстые материалы, например, нержавеющую сталь., алюминий, и другие металлы, требующие более высокой энергии для точной резки.. Благодаря этой дополнительной силе, вы можете легко работать с приложениями промышленного уровня без ущерба для качества.

Точность и детализация:

Одним из наиболее заметных преимуществ станка для лазерной резки мощностью 1500 Вт является его способность обеспечивать чрезвычайно точную резку.. С высококачественным лазером, путь резки узкий и чистый, что сводит к минимуму необходимость в постобработке и сокращает отходы материала.

Более высокая скорость резки:

Повышенная мощность приводит к более высокой скорости резки.. Станок лазерной резки мощностью 1500 Вт позволяет быстро обрабатывать даже самые сложные конструкции., значительное повышение производительности при сохранении точности. Это ключевое преимущество для таких отраслей, как автомобилестроение., где важны быстрые сроки производства.

Универсальность в приложениях:

В то время как станок лазерной резки мощностью 1500 Вт известен для обработки более толстых материалов., он также превосходно режет широкий спектр материалов, включая пластик., текстиль, древесина, и цветные металлы. Независимо от того, производите ли вы прототипы, компоненты для машин, или замысловатые дизайны, эта машина справится со всем этим.

Снижение эксплуатационных расходов:

По сравнению с традиционными методами резки, лазерная резка — более энергоэффективное решение. Точность станка лазерной резки мощностью 1500 Вт снижает количество отходов и лома материалов., что в свою очередь помогает компаниям экономить на материальных затратах. Кроме того, машина требует меньше обслуживания, сокращение долгосрочных эксплуатационных затрат.

Основные характеристики станка для лазерной резки мощностью 1500 Вт

Передовые системы охлаждения:

Лазерная резка выделяет значительное количество тепла., что может повлиять на производительность и долговечность. Многие современные машины мощностью 1500 Вт оснащены встроенными системами охлаждения, которые поддерживают оптимальную производительность и продлевают срок службы машины..

Автоматизированная работа:

Для дальнейшего повышения производительности, 1500Станки для лазерной резки W часто оснащены автоматизированными системами загрузки и разгрузки.. Это сводит к минимуму вмешательство человека, уменьшает ошибки, и обеспечивает непрерывную работу без частых перерывов.

Улучшенное управление лучом:

Интенсивность лазерного луча можно точно регулировать., обеспечивает большую гибкость при резке материалов различной толщины и материалов.. Это делает машину невероятно адаптируемой к различным производственным требованиям..

Основные характеристики станка для лазерной резки мощностью 1500 Вт

Передовые системы охлаждения:

Лазерная резка выделяет значительное количество тепла., что может повлиять на производительность и долговечность. Многие современные машины мощностью 1500 Вт оснащены встроенными системами охлаждения, которые поддерживают оптимальную производительность и продлевают срок службы машины..

Автоматизированная работа:

Для дальнейшего повышения производительности, 1500Станки для лазерной резки W часто оснащены автоматизированными системами загрузки и разгрузки.. Это сводит к минимуму вмешательство человека, уменьшает ошибки, и обеспечивает непрерывную работу без частых перерывов.

Улучшенное управление лучом:

Интенсивность лазерного луча можно точно регулировать., обеспечивает большую гибкость при резке материалов различной толщины и материалов.. Это делает машину невероятно адаптируемой к различным производственным требованиям..

Применение станков для лазерной резки мощностью 1500 Вт

Автоматизированная индустрия:

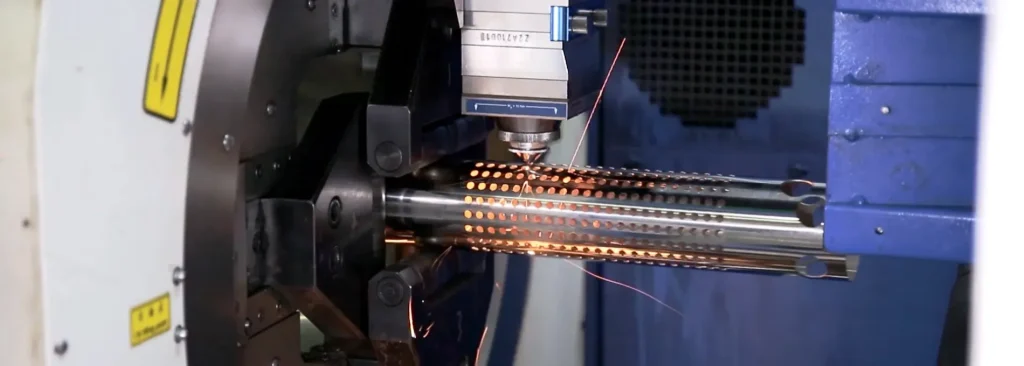

Лазерная резка играет важную роль в автомобильном секторе., там, где важна точность и скорость. От резки сложных деталей кузовов автомобилей до изготовления компонентов двигателей., Станок лазерной резки мощностью 1500 Вт позволяет производить высококачественные компоненты с минимальными отходами..

Аэрокосмическая промышленность:

Производителям аэрокосмической отрасли требуется точная резка, чтобы обеспечить легкий вес и точность их компонентов.. Станок лазерной резки мощностью 1500 Вт — идеальный инструмент для создания детализированных и надежных деталей, соответствующих строгим отраслевым стандартам..

Производство медицинского оборудования:

В секторе медицинского оборудования, Точность является ключевым. Станки лазерной резки используются для изготовления мелких деталей, таких как хирургические инструменты., имплантаты, и диагностическое оборудование, требующее строгих допусков.. Станок мощностью 1500 Вт гарантирует, что каждый компонент будет обработан до совершенства..

Вывески и произведения искусства:

За пределами промышленного применения, Станок лазерной резки мощностью 1500 Вт — мощный инструмент для создания вывесок., логотипы, и художественные проекты. Его способность прорезать толстые материалы, такие как акрил., древесина, и металл делают его идеальным решением как для дизайнеров, так и для художников..

Оптимизация инвестиций в станок для лазерной резки мощностью 1500 Вт

Инвестиции в станок лазерной резки 1500 Вт требует тщательного рассмотрения. Такие факторы, как тип материала, толщина, и сложность конструкций, которые вы собираетесь вырезать, будут играть роль в определении того, станет ли эта конкретная машина лучшим выбором для вашего бизнеса..

Более того, регулярное техническое обслуживание и надлежащее обучение вашего персонала необходимы для обеспечения долговечности машины.. Поддерживая оборудование в отличном состоянии и обеспечивая квалификацию ваших операторов, вы можете максимизировать эффективность машины и поддерживать стабильно высокое качество продукции..

Двигаясь вперед с технологией лазерной резки

Поскольку отрасли продолжают развиваться, роль мощных станков для лазерной резки, таких как станок лазерной резки 1500 Вт будет только становиться более важным. Его способность резать быстрее, точнее, и более эффективно революционизирует производственные процессы по всему миру. Занимаетесь ли вы автомобильным производством, аэрокосмический, или даже производство вывесок, инвестиции в станок для лазерной резки мощностью 1500 Вт окупятся увеличением производительности., снижение затрат, и улучшение качества продукции.

Тщательно учитывая ваши конкретные потребности и интегрируя технологию лазерной резки в вашу деятельность., вы можете не только удовлетворить, но и превзойти требования современной промышленности.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина