Технология лазерной резки произвела революцию в обрабатывающей промышленности., обеспечение точности, скорость, и гибкость для бизнеса по всему миру. Поскольку отрасли продолжают требовать более высоких стандартов производства, выбор производитель станков для лазерной резки становится решающим. В этом руководстве подробно рассматриваются факторы, которые следует учитывать при выборе производителя., помогая вам принять обоснованное решение, соответствующее вашим операционным целям.

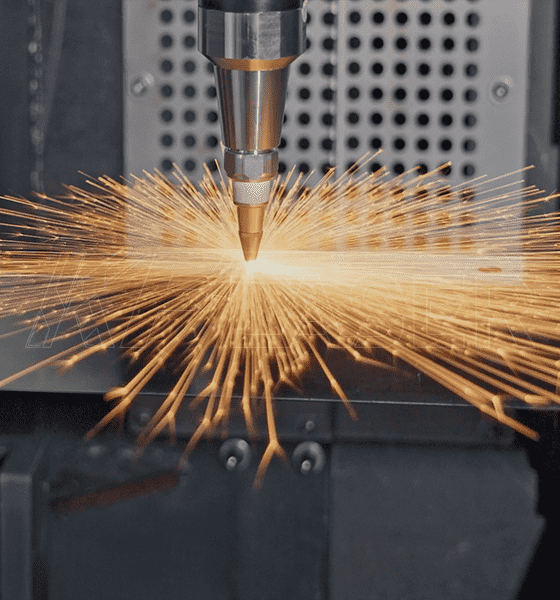

Прежде чем углубиться в то, как выбрать лучшего производителя, важно понимать, что такое станки для лазерной резки и почему они так важны. В станках лазерной резки используется мощный лазер для резки таких материалов, как металл., древесина, пластмассы, и многое другое. Эти машины широко используются в таких отраслях, как автомобилестроение., аэрокосмический, Электроника, и архитектура благодаря своей точности, чистые порезы, и минимальные потери материала.

Основная технология, лежащая в основе этих машин, включает в себя СО2-лазеры, волоконные лазеры, и твердотельные лазеры, каждый со своими уникальными преимуществами. Производители в этой области часто предлагают различные типы станков для лазерной резки, исходя из конкретных потребностей своих клиентов..

Выбор подходящего производителя станков для лазерной резки предполагает оценку множества аспектов бизнеса и технологий, которые они предлагают.. Ниже приведены наиболее важные факторы, которые следует учитывать перед совершением покупки..

Первым и главным фактором является качество станков лазерной резки. Высококачественные станки необходимы для обеспечения точности., долголетие, и эффективность вашего производственного процесса. Надежный производитель предоставит машины, изготовленные из первоклассных материалов., передовые технологии, и компоненты, соответствующие отраслевым стандартам.

При изучении производителей, проверьте сертификаты их продукции, меры контроля качества, и отзывы клиентов. Высокопроизводительные производители обычно используют самые современные технологии для повышения производительности машин., обеспечение бесперебойной работы и минимального времени простоя.

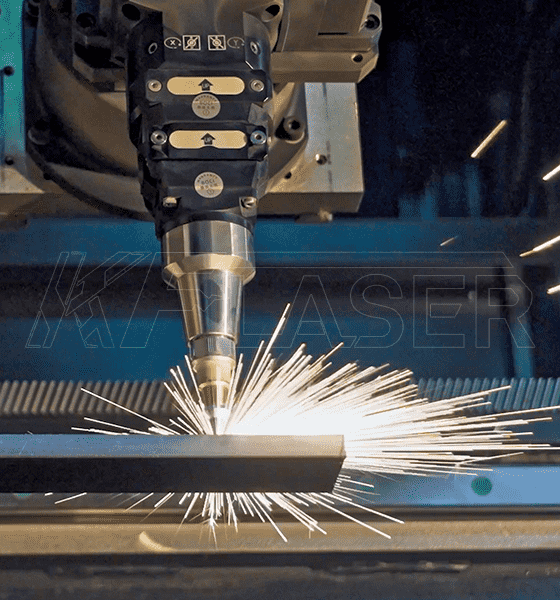

Индустрия лазерной резки быстро развивалась за последнее десятилетие., с такими инновациями, как волоконная лазерная резка, многоосевая лазерная резка, и автоматизация лазерной резки становится все более популярным. В зависимости от ваших производственных потребностей, очень важно сотрудничать с производителем, который предлагает передовые технологии, соответствующие вашим требованиям..

Например, если вы в основном режете металлы тонкой и средней толщины, Станок для резки волоконным лазером может быть более эффективным и экономичным по сравнению с лазером CO2.. Некоторые производители предлагают гибридные машины, сочетающие в себе разные технологии., давая вам больше гибкости в производстве.

У каждого бизнеса есть уникальные производственные потребности, поэтому важно искать производителя, который предлагает настраиваемые решения. Надежный производитель должен быть готов тесно сотрудничать с вами, чтобы понять ваши конкретные требования и предложить индивидуальные станки для лазерной резки, подходящие для обработки ваших материалов., толщина, и объемы производства.

Нужно ли вам специализированное программное обеспечение, комплексные системы автоматизации, или способность обрабатывать определенные материалы, Хороший производитель предоставит индивидуальные решения, которые улучшат ваш рабочий процесс и повысят общую эффективность производства..

Станок для лазерной резки — это значительная инвестиция., и обеспечение того, чтобы у вас было достаточно послепродажная поддержка необходим для поддержания его работоспособности. Ищите производителей, которые предоставляют комплексные обучение, Поиск неисправностей, обслуживание, и ремонт услуги.

Лучшие производители предлагают долгосрочную поддержку клиентов., включая удаленную диагностику, онлайн-помощь, и ремонт на месте, чтобы вы могли быстро решить любые проблемы, которые могут возникнуть. Надежная гарантия и быстрый доступ к запасным частям также помогут минимизировать время простоя и обеспечить бесперебойную работу вашего производства..

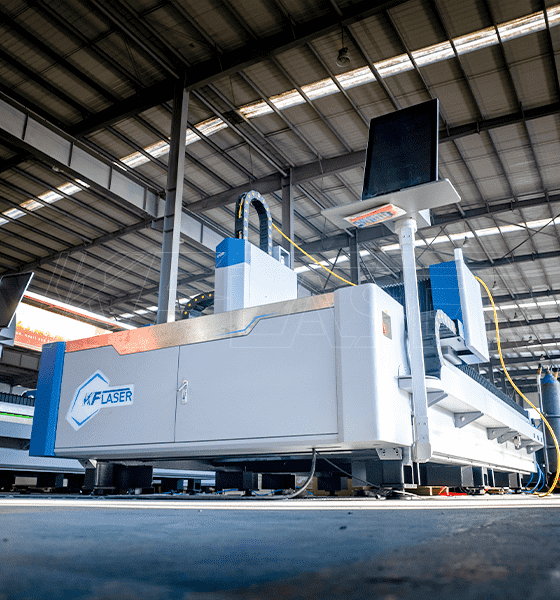

В зависимости от масштаба вашего бизнеса и срочности ваших потребностей, тот производственная мощность производителя имеет решающее значение. У некоторых производителей могут быть более длительные сроки выполнения заказов., специально для высококачественных или нестандартных станков для лазерной резки. Прежде чем принять решение, важно обсудить график времени на доставку и установку.

Если вам необходимы крупномасштабные производственные циклы или быстрые сроки выполнения работ, убедитесь, что производитель может удовлетворить ваши требования. Обсудите ожидаемые сроки доставки, а также потенциальные задержки и способность производителя масштабировать производство по мере роста вашего бизнеса..

Хотя качество всегда должно быть приоритетом, экономическая эффективность остается важным фактором для большинства предприятий. Разные производители предлагают разные модели ценообразования., и стоимость может существенно варьироваться в зависимости от возможностей машины, технология, и настройки.

Очень важно сбалансировать цену и ценность, хотя выбор недорогой машины может показаться привлекательным., снижение качества может привести к увеличению долгосрочных затрат из-за технического обслуживания, ремонт, и время простоя. Выбирайте производителя, который предлагает конкурентоспособную цену без ущерба для качества и производительности..

Производитель репутация является отличным показателем уровня обслуживания и качества продукции, которую они предоставляют.. Изучите онлайн-обзоры, тематические исследования, и отзывы других предприятий, которые использовали машины производителя. Кроме того, проверьте наличие каких-либо отраслевых наград или признаний, которые могут указывать на их положение на рынке..

Хорошо зарекомендовавший себя производитель с хорошей репутацией с большей вероятностью предложит надежные машины и исключительное обслуживание клиентов.. Также важно запросить рекомендации у существующих клиентов, которые могут поделиться своим опытом работы с производителем..

The лазерная резка постоянно развивается, с новыми функциями и технологиями, появляющимися регулярно. При выборе производителя, важно учитывать, насколько они привержены инновации и поддерживать свои машины в курсе последних достижений в области технологий лазерной резки..

Ищите производителей, которые инвестируют в исследования и разработки., а также тех, кто предлагает машины, которые можно легко модернизировать или интегрировать с будущими достижениями.. Это гарантирует, что ваше оборудование останется актуальным и эффективным на долгие годы..

При поиске производителя станков для лазерной резки, существует несколько всемирно признанных брендов, известных своими передовыми технологиями и надежными продуктами.. Некоторые из ведущих производителей включают в себя:

ТРАМП: Известные своим высоким качеством, Немецкие системы лазерной резки., TRUMPF предлагает широкий выбор станков для резки волоконным и CO2-лазером., а также решения по автоматизации.

Любимый: Мировой лидер в области технологий лазерной резки и изготовления листового металла., Amada предлагает современные волоконные лазерные станки с высокой точностью и скоростью..

Быстроник: Предлагаем станки для резки как волоконным, так и CO2-лазером., Bystronic славится своим удобным интерфейсом., высокоскоростная резка, и отличное обслуживание клиентов.

Лазер Хана: Китайская компания, предлагающая широкий ассортимент станков для лазерной резки., включая волоконные лазерные системы с высокой эффективностью и точностью.

Мазак Оптоника: Mazak предлагает современные станки для резки волоконным лазером, обеспечивающие высокую производительность и качество., что делает их популярными в таких отраслях, как автомобилестроение и аэрокосмическая промышленность..

Выбор правильного производитель станков для лазерной резки является важным решением, которое повлияет на эффективность, точность, и общая продуктивность вашего бизнеса. Оценивая такие факторы, как качество машины, технологические возможности, варианты настройки, и послепродажная поддержка, вы можете принять обоснованное решение, соответствующее потребностям вашего бизнеса.

Не забудьте провести исследование и получить рекомендации от других специалистов отрасли, чтобы убедиться, что вы сотрудничаете с производителем, который обеспечивает наилучшее соотношение цены и качества., технология, и обслуживание для ваших потребностей в лазерной резке.