Новости

Освоение оборудования для лазерной резки металла: Все, что вам нужно знать

Вы можете поделиться этой статьей:

The world of metal cutting machinery laser is a fascinating blend of innovation, точность, и эффективность. As industries evolve to meet growing demands for accuracy and sustainability, laser technology has emerged as a game-changer, redefining how metal is processed across sectors like automotive, аэрокосмический, и производство.

Imagine a single machine capable of slicing through dense metal sheets with pinpoint precision, creating intricate designs, and delivering results at lightning speed. This isn’t the future—it’s the present, made possible by advancements in laser cutting technology. В этом комплексном руководстве, we’ll dive deep into the world of laser metal cutting, exploring its mechanics, Приложения, преимущества, and much more.

1.What is Laser Metal Cutting?

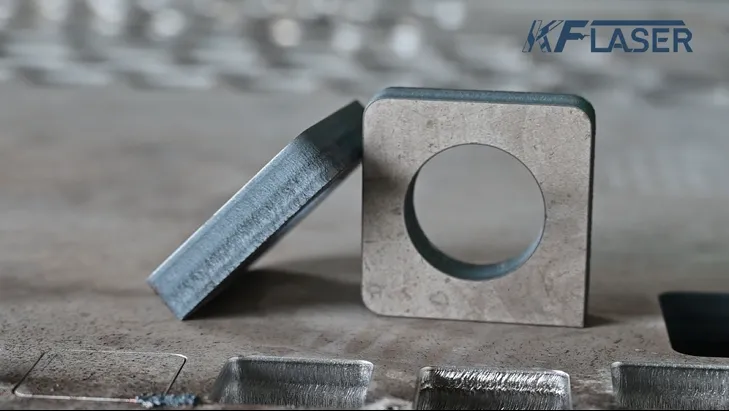

Laser metal cutting is a high-precision process that uses a focused laser beam to cut, melt, or vaporize metal materials. В отличие от традиционных методов резки, laser cutting offers unmatched precision, allowing manufacturers to achieve intricate designs and seamless edges. It is widely adopted in industries that demand both speed and accuracy.

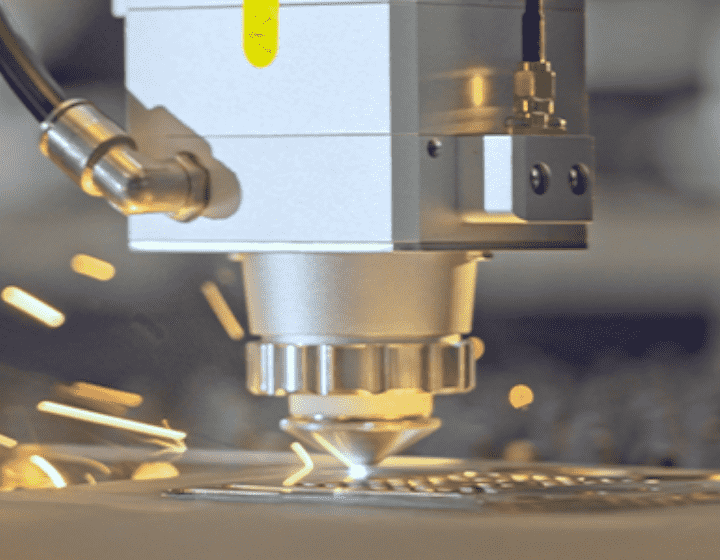

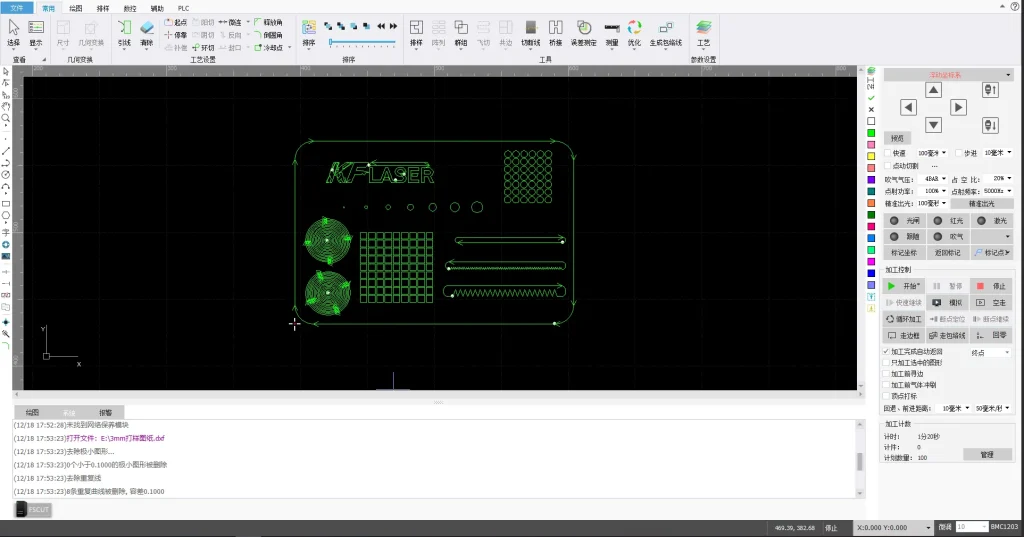

По своей сути, laser cutting works by concentrating light energy into a highly focused beam. This beam is directed at the metal surface, heating it to extreme temperatures that cause it to melt or vaporize. The process is guided by advanced CNC (Компьютерное числовое управление) системы, ensuring precision down to the micrometer level.

☟ The following video will help you understand laser metal cutting more intuitively.

2.Why is Laser Metal Cutting a Game-Changer?

Traditional metal cutting techniques like sawing, фрезерование, and plasma cutting often fall short in terms of precision, скорость, и универсальность. Metal cutting machinery laser offers several distinct advantages:

1.Непревзойденная точность:

Achieve cuts as fine as 0.1mm with minimal material wastage.

2.Универсальность:

From stainless steel to aluminum, медь, and even titanium, lasers can handle a wide range of materials.

3.Скорость и эффективность:

Laser cutting machines can process complex designs at speeds that outpace traditional methods.

4.Экологические преимущества:

Reduced material wastage and energy efficiency make laser cutting a more sustainable option.

5.Automation-Friendly:

Integration with CNC systems allows for automated, high-volume production with minimal human intervention.

3.How Does Metal Laser Cutting Work?

To fully appreciate the capabilities of metal cutting machinery laser, it’s essential to understand its operation:

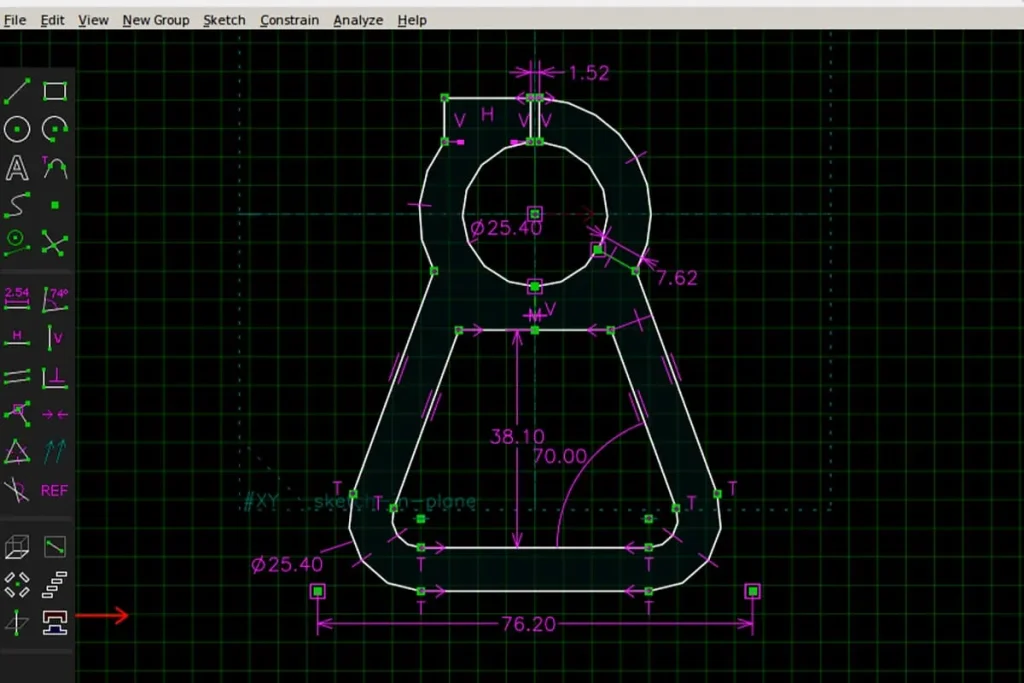

1.Preparation: The metal sheet is secured on the cutting bed, and the desired design is uploaded to the CNC system.

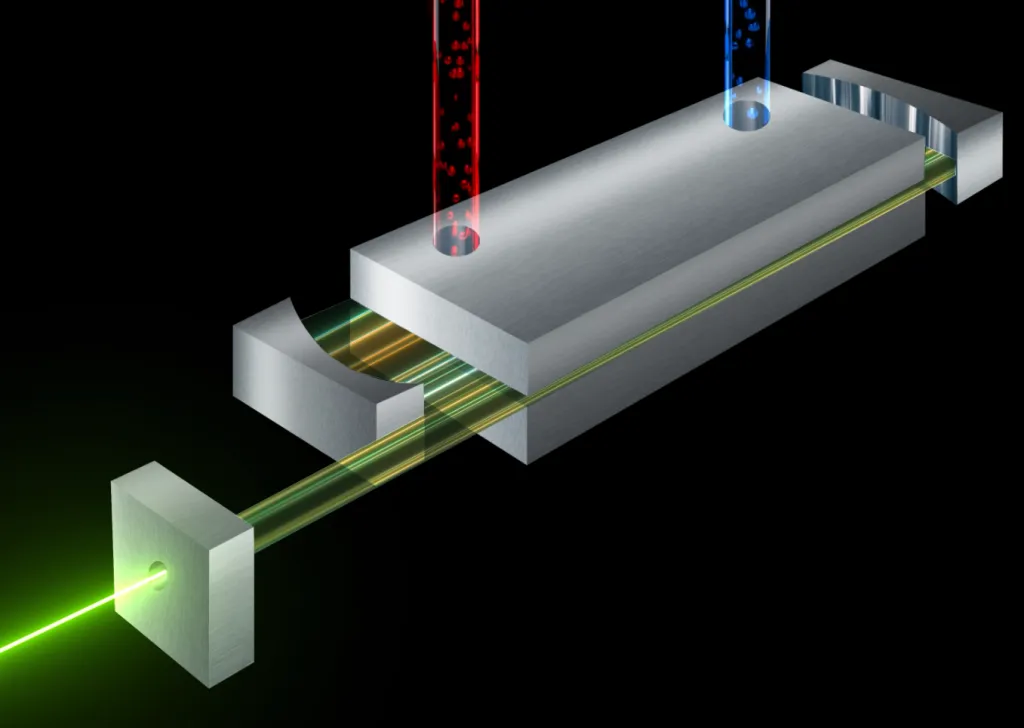

2.Лазерная активация: A laser beam, generated by either a fiber or CO2 source, is focused on the metal surface.

3.Material Removal: The intense heat melts or vaporizes the material, while assist gases (like nitrogen or oxygen) blow away debris.

4.Precision Control: The CNC system guides the laser head along the programmed path, ensuring accurate cuts.

5.Post-Processing: The cut metal is cooled, cleaned, and prepared for further use.

4.Типы лазерных режущих машин

Choosing the right laser cutting machine depends on your specific needs. Here are the most commonly used types:

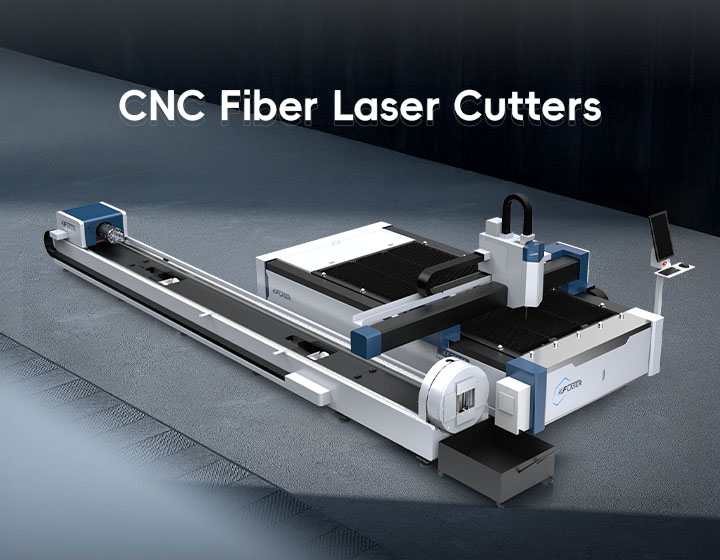

1. Волоконные станки для лазерной резки

Fiber lasers are the gold standard for metal cutting. They use a solid-state laser source, offering higher precision and efficiency compared to other types.

Преимущества:

◆Ideal for cutting reflective metals like aluminum and copper.

◆Higher cutting speeds and energy efficiency.

◆Minimal maintenance requirements.

Приложения:

◆Aerospace components.

◆Automotive parts.

◆Electronics.

2.Станки для лазерной резки CO2

CO2 lasers are versatile machines suitable for cutting both metals and non-metals. They operate by exciting a gas mixture to generate the laser beam.

Преимущества:

◆Lower initial investment.

◆Suitable for cutting non-metallic materials like wood and acrylic.

◆Proven technology with decades of use.

Приложения:

◆Signage and decorative items.

◆Furniture components.

◆Thin metal sheets.

3. Прямые диодные лазеры

Direct diode lasers are a newer technology, offering compact designs and energy efficiency.

Преимущества:

◆High-speed cutting for thin metals.

◆Long operational lifespan.

◆Suitable for mobile applications.

Приложения:

◆Automotive manufacturing.

◆Consumer electronics.

◆Light fabrication.

5.Metals Commonly Processed with Laser Technology

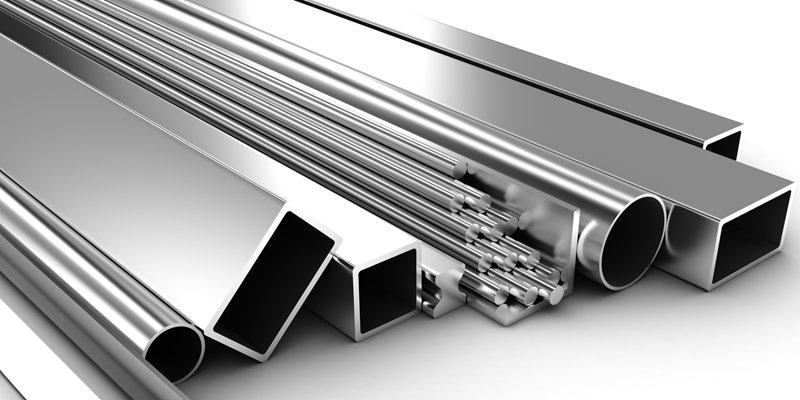

Металлические лазерные системы могут обрабатывать широкий спектр металлов, каждый с уникальными характеристиками:

1. Мягкая сталь

◆Affordable and durable.

◆Used in automotive frames and structural components.

2. Нержавеющая сталь

◆Corrosion-resistant and strong.

◆Common in kitchenware, медицинское оборудование, and architectural elements.

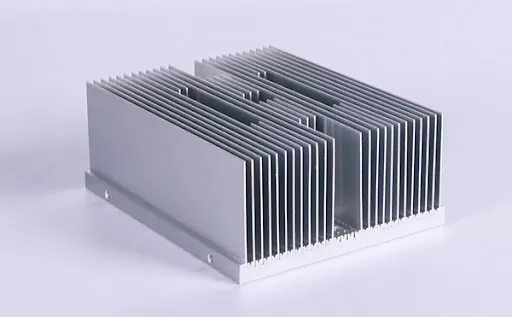

3. Алюминий

◆Lightweight and versatile.

◆Ideal for aerospace and automotive applications.

4. Медь и латунь

◆Highly conductive metals.

◆Used in electrical components and decorative items.

5. Титан

◆Strong and lightweight.

◆Essential for aerospace and medical industries.

6.Advantages of Laser Cutting for Metal Fabrication

1. Точность и аккуратность

Laser cutting delivers consistent results with tolerances as tight as ±0.1mm. This level of precision is crucial for industries like aerospace, where even minor deviations can have significant consequences.

2. Скорость и эффективность

Со скоростью резания до 500 дюймы в минуту, laser systems significantly reduce production times. This speed translates into higher throughput and cost savings.

3. Flexibility

Whether you’re cutting intricate designs or large structural components, laser machines adapt seamlessly to various requirements.

4. Уменьшенные отходы

Laser cutting minimizes material wastage, сделать это экологически чистым вариантом. Усовершенствованное программное обеспечение для гнездования оптимизирует использование материалов, further reducing costs.

5. Safety and Automation

Laser systems are highly automated, снижение необходимости ручного вмешательства. Built-in safety features, например, защитные кожухи, ensure a secure working environment.

7.Emerging Trends in Metal Laser Cutting

The field of laser metal cutting is constantly evolving. Some of the latest trends include:

1.AI-Driven Systems:

Artificial intelligence is being integrated into CNC systems for predictive maintenance and real-time optimization.

2.Зеленые лазеры:

New laser technologies focus on energy efficiency and reduced carbon footprints.

3.3D Лазерная резка:

Advanced systems now allow for three-dimensional cuts, expanding the possibilities for complex designs.

Главные новости

-

Революция лазерного резака мощностью 4 кВт: Резка металла как технология завтрашнего дня сегодня31 октябрь 2025

Революция лазерного резака мощностью 4 кВт: Резка металла как технология завтрашнего дня сегодня31 октябрь 2025 -

6000w Объяснение мощности лазера28 октябрь 2025

6000w Объяснение мощности лазера28 октябрь 2025 -

8Революция в станке для лазерной резки кВт24 октябрь 2025

8Революция в станке для лазерной резки кВт24 октябрь 2025 -

Автоматизированные системы волоконной лазерной резки21 октябрь 2025

Автоматизированные системы волоконной лазерной резки21 октябрь 2025 -

Лучшие волоконные лазерные резаки с ЧПУ17 октябрь 2025

Лучшие волоконные лазерные резаки с ЧПУ17 октябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина