In the realm of modern manufacturing and fabrication, metal laser cutters have revolutionized the way industries process and shape metals. These sophisticated machines utilize high-powered lasers to precisely cut through various types of metals with unparalleled accuracy and speed. Whether for small-scale workshops or large industrial facilities, understanding the capabilities and benefits of metal laser cutters is crucial for optimizing production efficiency and maintaining high standards of quality.

A metal laser cutter is a specialized tool designed to cut through metals using a focused laser beam. This technology is preferred over traditional cutting methods for its ability to produce clean, precise cuts without physical contact, reducing the risk of material contamination or damage. The laser beam is generated by amplifying light through optical resonators and directed through mirrors or fiber optics to the cutting head, where it is focused on the workpiece.

Metal laser cutters find application across a spectrum of industries:

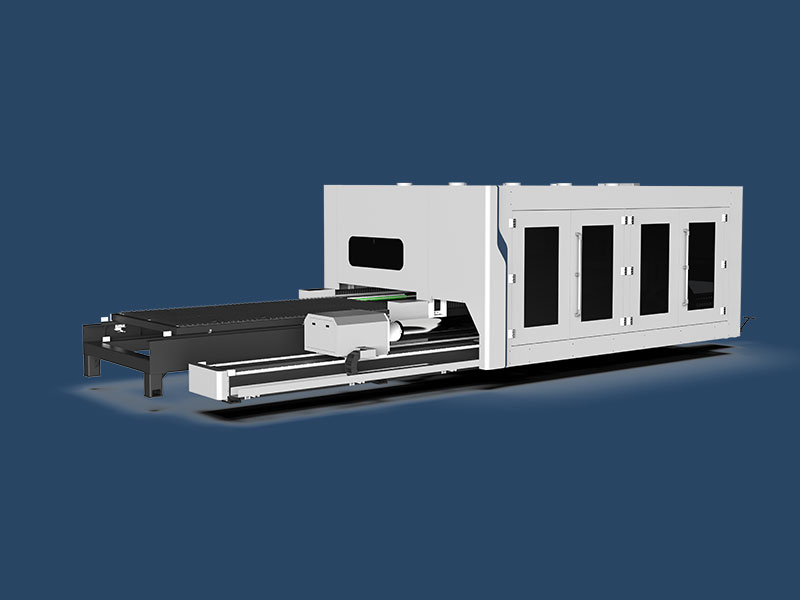

When selecting a metal laser cutter, several factors should be considered to ensure it meets specific production needs: