В мире современного производства, stainless laser cutting has become a key process for producing high-precision components. With its ability to create intricate designs and handle complex geometries, this cutting-edge technique has gained widespread adoption across various industries, от автомобилестроения до аэрокосмической отрасли, architecture, and beyond. The combination of speed, точность, and versatility makes stainless laser cutting an invaluable tool for businesses looking to streamline production while maintaining the highest standards of quality.

This article delves into the benefits and applications of stainless steel laser cutting, shedding light on why it’s becoming an indispensable technique in contemporary metalworking.

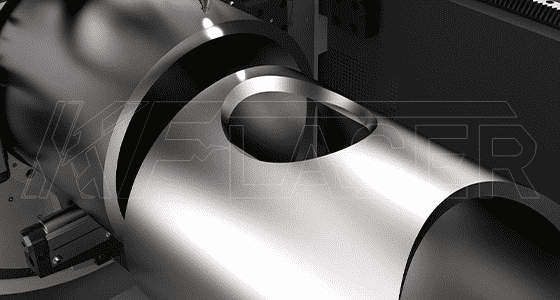

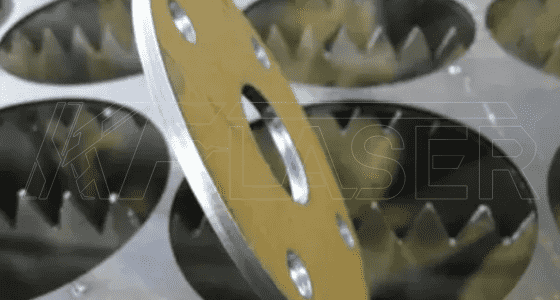

Stainless laser cutting refers to the process of using a focused laser beam to cut through stainless steel. The laser emits intense energy that melts or vaporizes the material at the point of contact, enabling a clean and precise cut. This process is particularly effective for cutting stainless steel sheets and plates, allowing for intricate shapes and sharp edges that would be difficult or impossible to achieve with traditional mechanical methods.

The key advantage of laser cutting is the fine control it offers. The laser beam’s focus can be adjusted for varying material thicknesses and cutting depths, ensuring accurate cuts even on thick stainless steel plates.

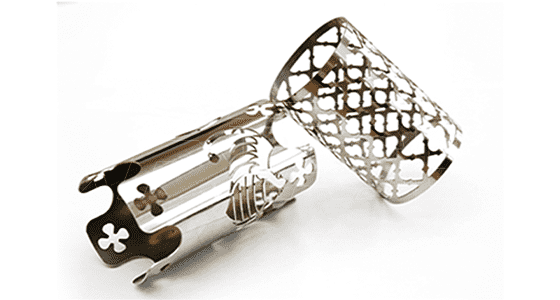

One of the primary reasons stainless laser cutting is so popular is its ability to produce extremely precise cuts. The laser’s fine beam ensures that there are minimal deviations from the intended cutting path, allowing for highly detailed designs. This level of accuracy is essential for applications where precision is critical, such as in the aerospace and medical industries.

В отличие от традиционных методов резки, which may cause the material to warp or distort, лазерная резка produces smooth, clean edges with minimal thermal impact. This is especially important for stainless steel, as the material can be prone to discoloration or oxidation if exposed to excessive heat. The low heat-affected zone (ЗТВ) also means that there is less need for post-processing, making the entire cutting process more efficient.

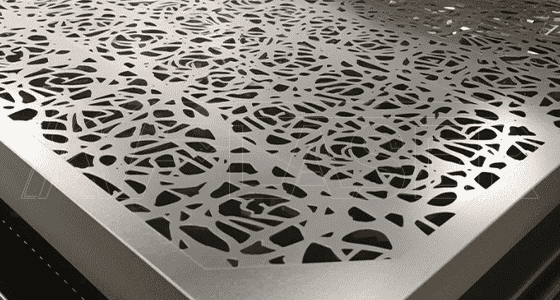

Laser cutting is known for its versatility, capable of producing complex shapes, дыры, and patterns in stainless steel with high precision. This flexibility makes it ideal for industries that require custom designs or intricate detailing. From delicate engravings to heavy-duty structural cuts, stainless laser cutting can handle a variety of applications.

The efficiency of stainless steel laser cutting contributes to reduced lead times. Unlike mechanical cutting methods that require tool changes and frequent maintenance, laser cutters operate quickly and with minimal downtime. This is particularly beneficial for manufacturers who need to meet tight production deadlines or who require high-volume production runs.

Another notable advantage of stainless laser cutting is its efficiency in terms of material usage. The precision of the cuts ensures minimal wastage, which can significantly reduce material costs. In industries where stainless steel is a high-cost material, reducing waste can have a considerable impact on the bottom line.

The process of cutting stainless steel with a laser involves several key stages:

В автомобильном секторе, stainless laser cutting is used to produce high-precision parts, such as brackets, структурные компоненты, и кузовные панели. The ability to cut complex shapes ensures that manufacturers can meet the exact specifications required for vehicle assembly.

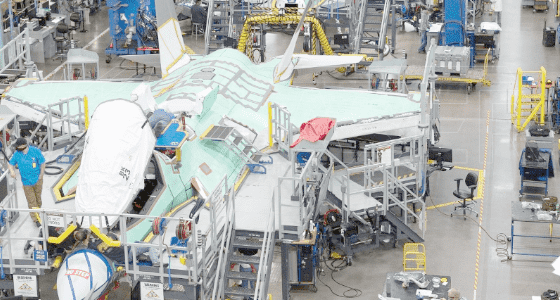

В аэрокосмической отрасли, stainless laser cutting is essential for creating lightweight and durable components that must meet stringent performance standards. From turbine blades to fuselage components, laser cutting ensures that the parts are both precise and structurally sound.

Laser cut stainless steel is often used in architectural applications for decorative facades, перила, and cladding. The precision and aesthetic quality of the cuts make it a popular choice for high-end architectural designs, where both functionality and appearance are important.

В медицинской сфере, stainless laser cutting plays a crucial role in the production of surgical instruments, имплантаты, и диагностическое оборудование. The need for absolute precision and the ability to handle complex geometries make laser cutting ideal for medical device manufacturers.

Stainless steel is widely used in the creation of durable, attractive signage for both indoor and outdoor applications. Laser cutting allows for the creation of logos, letters, and graphics with sharp edges, ensuring that the signage is both legible and visually appealing.

From kitchen appliances to electronics, stainless laser cutting is used to produce parts for a wide range of consumer goods. The precision offered by laser cutting ensures that components fit together perfectly, resulting in high-quality finished products.

When deciding whether to use stainless laser cutting, there are several factors to keep in mind:

The thickness of the stainless steel affects both the cost and the complexity of the cutting process. While laser cutting is efficient for materials of various thicknesses, thicker stainless steel requires more powerful lasers and may take longer to cut. Be sure to choose a cutting machine capable of handling the specific thicknesses you need.

Лазерная резка производит гладкую, polished edges, but the final finish can vary depending on the laser type and settings. For applications that require specific finishes, such as brushed or mirror-like surfaces, additional post-processing may be needed.

For small to medium production runs, laser cutting is ideal, as it does not require special tooling or setup. Однако, for very large production volumes, other methods like punching or stamping may be more cost-effective. Discuss production volume with your supplier to determine the best method.

While laser cutting is highly efficient, it can be more expensive than traditional cutting methods, especially for large quantities. Однако, the advantages in precision, скорость, and reduced material waste often justify the higher upfront cost.

The minimal waste produced during stainless laser cutting is an environmental benefit, as it reduces the need for disposal of scrap material. Кроме того, the use of clean energy sources to power laser cutters can further reduce the environmental footprint of the process.

Поскольку технологии продолжают развиваться, stainless laser cutting is expected to become even more advanced. Инновации в лазерных источниках, cutting speeds, and automation are likely to further improve the efficiency and versatility of this technique. With increasing demand for precision and customization in various industries, stainless steel laser cutting will continue to play a pivotal role in modern manufacturing processes.

With its ability to handle complex geometries, produce clean edges, and minimize waste, stainless laser cutting is sure to remain at the forefront of metalworking technology. The continuous advancements in this field will only serve to expand its applications, making it an even more valuable tool for industries worldwide.