Новости

3KW Fiber Laser Rutch Guide | Преимущества & Советы

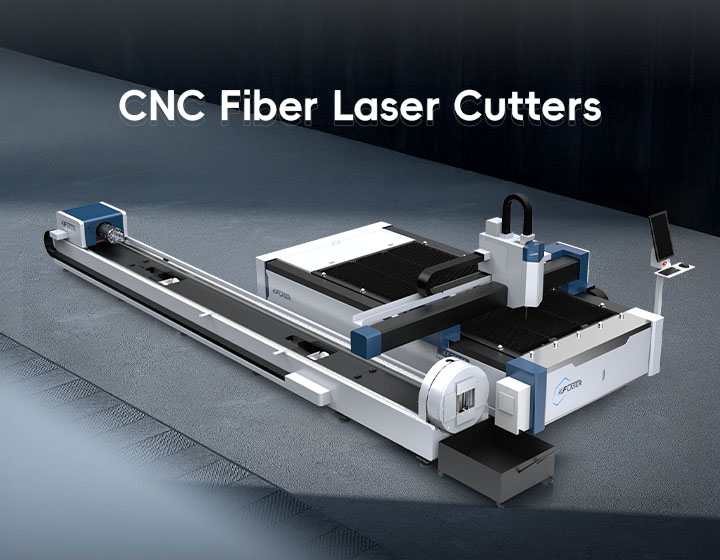

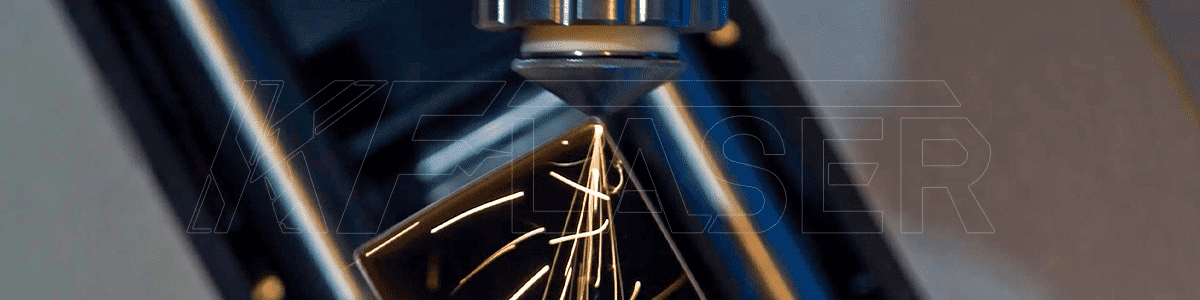

Точность, власть, и производительность — три столпа, определяющие революционные возможности 3Станок для лазерной резки с оптоволоконным кабелем. Эти системы не просто разрезают металл.; они переопределяют эффективность производства благодаря микронной точности и невероятной скорости. Для инженеров, стремящихся устранить узкие места в производстве, или производителей, требующих безупречных кромок нержавеющей стали., эта технология стала бесспорной основой современной промышленной резки..

Почему промышленность переходит на станок для волоконной лазерной резки мощностью 3 кВт

Переход от традиционных CO₂-лазеров или плазменных резаков к волоконным системам мощностью 3 кВт не является постепенным — он преобразует. Исследования компании Industrial Laser Solutions выявили 40% среднее снижение энергопотребления по сравнению с эквивалентными единицами CO₂. Операторы сообщают, что скорость резки превышает 25 метров в минуту на мягкой стали толщиной 1 мм., сокращение сроков производства вдвое. Секрет? Длина волны сфокусированного луча (1.06 мкм) что металлы поглощают в 5 раз эффективнее, чем CO₂ 10.6 Выход мкм. Это преимущество поглощения приводит к более чистому резанию меди., латунь, и светоотражающие материалы, которые ранее бросали вызов лазерным системам.

Материальное мастерство: Что это может сократить?

- Нержавеющая сталь (1–20 мм): Почти зеркальная обработка листов толщиной 10 мм со скоростью 1,2 м/мин., с вспомогательным газом азотом.

- Алюминий (1–25 мм): Заусенцы с нулевой кромкой на авиационной стали толщиной 15 мм при скорости 3,5 м/мин..

- Углеродистая сталь (1–30 мм): Прокалывание пластины диаметром 25 мм с помощью кислорода. 1.8 секунды.

- Медь/латунь (0.5–12 мм): Отражающая оптика предотвращает рассеивание луча на проводящих листах толщиной 8 мм..

Реальные данные от производителя & Журналы по металлообработке показывают 92% сокращение трудозатрат на вторичную чистовую обработку при обработке углеродистой стали толщиной более 5 мм — доказывая, что скорость — не единственное преимущество.

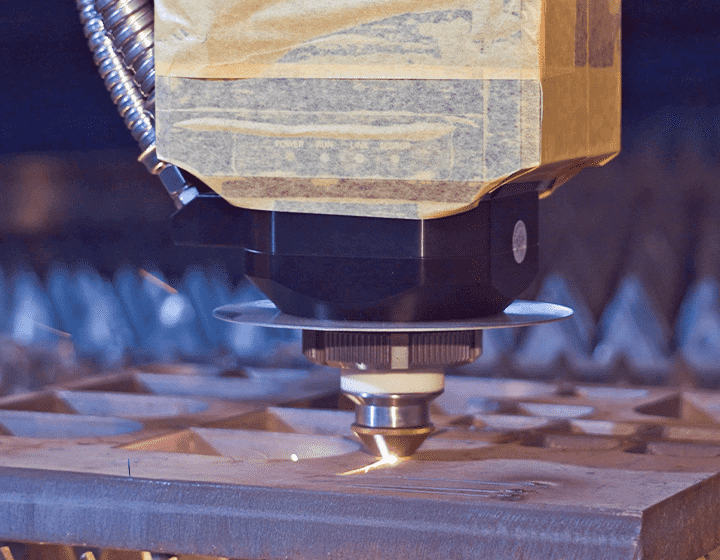

Внутри технологии: Оптика & Интеллект

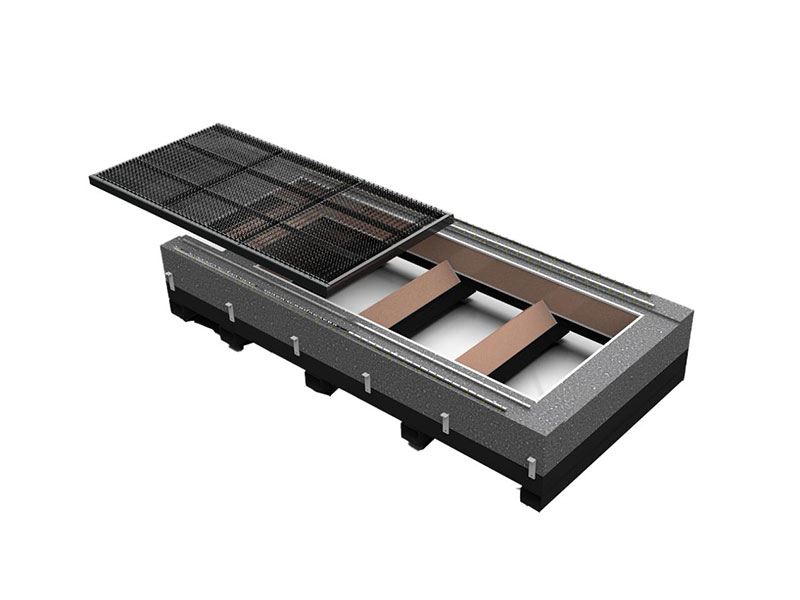

А 3Станок для лазерной резки с оптоволоконным кабелемВеликолепие проистекает из его упрощенной архитектуры. Диоды накачки возбуждают стеклянные волокна, легированные иттербием, генерирование лазерного луча, направляемого через гибкие кабели доставки. В отличие от CO₂-лазеров, требующих выравнивания зеркал, волоконно-оптические системы сохраняют качество луча независимо от вибраций окружающей среды. Современные модели объединяют функции, управляемые искусственным интеллектом.:

- Датчики предотвращения столкновений останавливают движение внутри 0.01 секунды

- Линзы с автофокусом регулируют ±5 мм в реальном времени для деформированных материалов

- Алгоритмы профилактического обслуживания прогнозируют деградацию оптики 80 часов до провала

Эти инновации минимизируют время простоя, обеспечивая при этом ширину пропила всего 0,15 мм, что критически важно для сложных компонентов аэрокосмической отрасли..

Анализ затрат: Факторы рентабельности инвестиций, которые нельзя игнорировать

Фактор | CO₂-лазер (4кВт) | 3KW Fiber Laser |

Стоимость энергии/час | $6.20 | $2.10 |

Замена объектива | Каждый 6 месяцы ($1,800) | Каждый 2 годы ($1,200) |

Использование газа для резки | 30% выше | Оптимизированное управление потоком |

Техническое обслуживание | 15 часов/месяц | 4 часов/месяц |

Данные получены из 2024 Отчет IMTS об эффективности производства

Производители переходят на 3Станок для лазерной резки с оптоволоконным кабелем обычно окупают инвестиции за 14–18 месяцев только за счет экономии электроэнергии. В сочетании с 30% более высокая производительность при обработке тонких металлов, общая рентабельность инвестиций резко возрастает.

Отраслевые преобразования

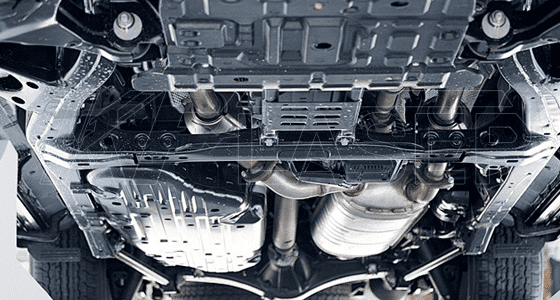

Поставщики автомобильной продукции

Один завод по резке кронштейнов шасси достиг 22-часовой непрерывной работы за счет исключения замены расходных материалов.. Срок службы диода волоконного лазера — 8000 часов — позволил работать в три смены с <0.1отклонение допуска в мм.

Архитектурные Металлоконструкции

Производитель из Техаса снизил процент брака декоративных бронзовых ширм с 12% к 0.7% с помощью лазера “мягкий пирсинг” режим, что предотвращает разбрызгивание на деликатных поверхностях.

Выбор вашей системы: 5 Необоротные вопросы

- Качество луча (Бпп): Потребность ≤2,0 мм·мрад для равномерных резов толщиной 30 мм.

- Точность охлаждения: Чиллеры, поддерживающие ±0,5°C, предотвращают колебания мощности.

- Программное обеспечение управления: Ищите автономное программирование с предустановками библиотеки материалов.

- Сертификаты безопасности: МЭК 60825-1 Сорт 1 соответствие требованиям корпуса

- Сервисная сеть: Проверять <48гарантия времени ответа персонала в вашем регионе

Развенчание мифов о техническом обслуживании

Миф: “Волоконные лазеры нуждаются в еженедельной оптической очистке.”

Реальность: Герметичные траектории балок требуют только ежеквартального осмотра окон при нормальных условиях..

Миф: “Более высокая мощность всегда означает более быструю резку.”

Реальность: Толщина более 20 мм, Выбор вспомогательного газа влияет на скорость больше, чем на мощность. Чистота азота выше 99.95% оказывается критически важным для резки нержавеющей стали без окисления.

Будущее: Что будет дальше с 3KW Tech?

Новые разработки замечены на LASYS 2024 включать:

- Гибридные присадочные головки: Создание износостойких покрытий толщиной 0,8 мм на режущих кромках во время пауз.

- Прогнозируемый контроль ширины реза: Тепловизионные камеры упреждающе регулируют фокус луча при обнаружении отклонений в материале

- Зеленые лазеры: 515Прототипы с длиной волны нанометра, режущие чистую медь со скоростью, в два раза превышающей скорость тока

Эти инновации не заменят системы мощностью 3 кВт, но расширят их доминирование в многопрофильном производстве..

Голоса с завода

“Перед нашим 3Станок для лазерной резки с оптоволоконным кабелем, мы передали на аутсорсинг все алюминиевые компоненты толщиной более 8 мм.,” признает Джеймс Р., руководитель производства контрактного производителя на Среднем Западе. “Теперь мы сами режем 25 мм с более гладкими краями, чем наш бывший поставщик гидроабразивной резки.. Машина окупила себя 11 месяцев только за счет возмещения затрат на аутсорсинг.”

Такие отзывы подчеркивают, почему волоконные лазеры мощностью 3 кВт — это не просто инструменты, а стратегические активы, меняющие конкурентную среду.. Производители, откладывающие внедрение, рискуют быть опередлены конкурентами, совершающими квантовый скачок в освоении материалов.. По мере улучшения качества луча и углубления интеграции искусственного интеллекта, эти системы будут продолжать раздвигать границы того, что можно разрезать., эффективный, и экономически преобразующий.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина