Новости

4000 Ватт Лазер | Промышленная мощность резки

4000 watt laser systems stand at the forefront of modern industrial manufacturing, blending raw power with precision to redefine what’s possible in metal fabrication, aerospace engineering, and heavy machinery production. Imagine a tool that can slice through 25mm thick steel like a hot knife through butter, yet etch intricate patterns on aluminum with the delicacy of a sculptor’s chisel—this is the duality of the 4000 watt laser, a technology that has moved beyond niche applications to become a cornerstone of high-volume, high-accuracy production lines. In an era where manufacturers demand faster turnaround, более жесткие допуски, and lower operational costs, тот 4000 watt laser emerges not just as a tool, but as a strategic asset that bridges the gap between ambition and execution.

The Evolution of Laser Cutting: Почему 4000 Watts Matters

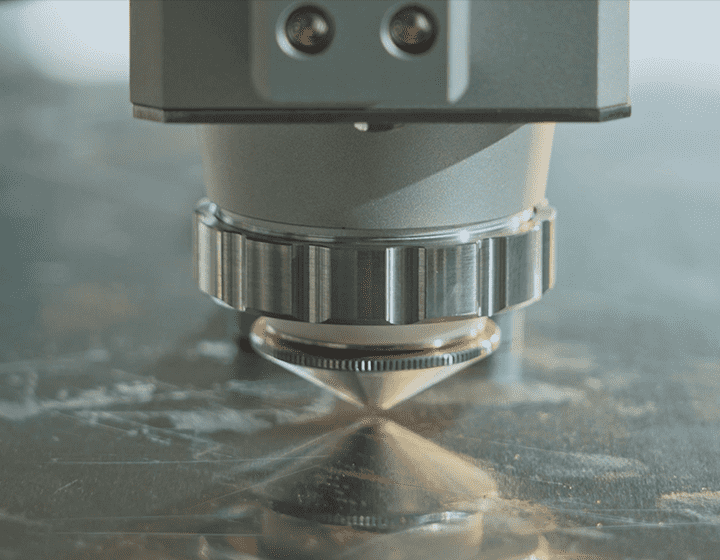

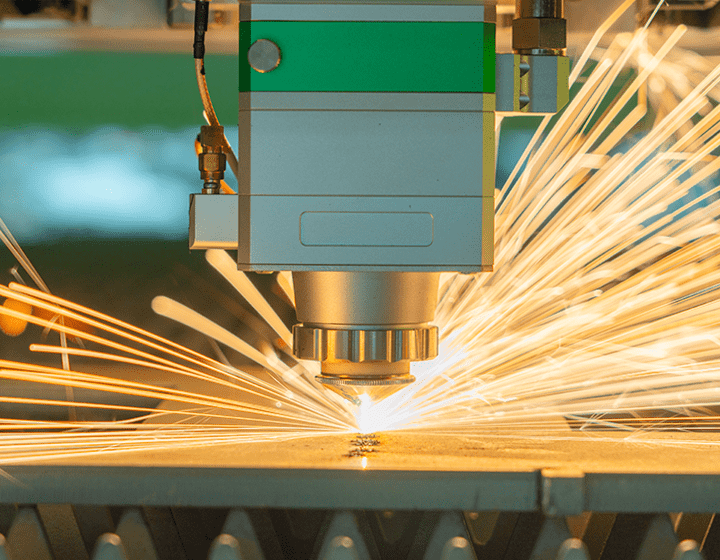

Laser cutting technology has come a long way since its inception in the 1960s, evolving from experimental 100-watt systems to today’s industrial behemoths. The jump to 4000 watts represents a critical threshold in laser power, unlocking capabilities that smaller systems simply cannot match. Unlike 2000 watt lasers, which struggle with thick materials or require multiple passes, а 4000 watt laser delivers concentrated energy—up to 4 kilowatts of coherent light—that can vaporize, melt, or burn through materials in a single pass, drastically reducing cycle times. This power boost is not just about speed, though; it’s about versatility. А 4000 watt laser can handle everything from thin-gauge stainless steel sheets for automotive parts to thick carbon steel plates for construction beams, eliminating the need for multiple machines and streamlining workflows. At the heart of this performance lies the laser source itself. Most 4000 watt systems use fiber laser technology, a choice driven by efficiency and reliability. Fiber lasers convert electrical energy into laser light with up to 30% эффективность, far outperforming CO2 lasers (which typically max out at 10-15%). This efficiency translates to lower energy bills—a critical factor for manufacturers operating 24/7—and less heat generation, reducing wear on components and extending machine lifespan. Кроме того, fiber lasers emit light at a wavelength of 1064nm, which is highly absorbed by metals like steel, алюминий, и медь. This absorption efficiency means more energy is directed into cutting rather than reflecting off the material, resulting in cleaner edges, fewer burrs, and reduced post-processing time.

Приложения: Where 4000 Watt Laser Excel

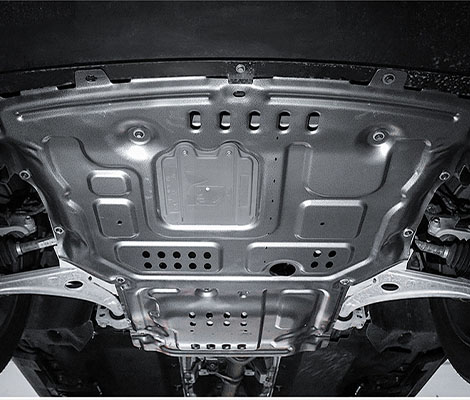

The true value of a 4000 watt laser becomes evident when examining its real-world applications. В автомобильной промышленности, например, these systems are revolutionizing the production of chassis components. Traditional methods like plasma cutting or waterjet machining often leave rough edges or require secondary finishing, but a 4000 watt laser can cut complex geometries in high-strength steel with tolerances as tight as ±0.05mm, ensuring parts fit together seamlessly during assembly. This precision not only reduces waste but also enhances vehicle safety by ensuring structural integrity. Aerospace manufacturers, too, are reaping the benefits. Titanium alloys, which are lightweight yet incredibly strong, are a staple in aircraft construction, but they are notoriously difficult to machine. А 4000 watt laser, однако, can cut through 15mm titanium sheets at speeds of up to 2 meters per minute, a rate that would take hours with conventional tools. This efficiency is why companies in the aerospace sector are increasingly investing in 4000 watt systems to meet the growing demand for fuel-efficient, high-performance aircraft. Heavy machinery and construction are another area where 4000 watt lasers shine. When fabricating bulldozer blades, crane booms, or pipeline components, thickness and durability are non-negotiable. А 4000 watt laser can cut through 30mm carbon steel plates with ease, creating clean, precise edges that require minimal grinding or welding preparation. This not only speeds up production but also reduces the risk of structural failures caused by imprecise cuts.

Efficiency and Cost Savings: The Business Case for 4000 Ватт Лазер

Для производителей, investing in a 4000 watt laser is not just about performance—it’s about the bottom line. Let’s break down the numbers: a typical 4000 watt fiber laser system consumes around 15-20 kWh of electricity per hour, по сравнению с 30-40 kWh for a CO2 laser of similar power. Over a 10-hour shift, that’s a savings of 150-200 kWh, which adds up to thousands of dollars annually. When scaled to a 24/7 операция, the energy savings alone can offset the initial investment within 2-3 годы. Labor costs are another area where 4000 watt lasers deliver. Traditional cutting methods often require operators to monitor machines closely, adjust settings frequently, and perform manual finishing. А 4000 watt laser, equipped with advanced CNC controls and auto-focus technology, can run unattended for hours, requiring minimal operator intervention. This frees up staff to focus on more skilled tasks, reducing the need for additional labor. В некоторых случаях, a single operator can manage multiple laser systems, further lowering overhead. Material waste is also significantly reduced. Laser cutting is a “net-shape” process, meaning the cut parts require little to no trimming. With a 4000 watt laser, the narrow kerf (ширина разреза) minimizes material loss, especially when nesting parts tightly together on a sheet. Например, cutting 1000 steel brackets from a 3m x 1.5m sheet with a 4000 watt laser might result in 5-8% less waste than plasma cutting, saving hundreds of dollars in raw material costs per month.

Key Considerations When Choosing a 4000 Ватт Лазер

While the benefits of 4000 watt lasers are clear, selecting the right system requires careful planning. First, assess your material needs: what thicknesses and types of materials do you typically work with? А 4000 watt laser is ideal for metals up to 30mm thick, but if you frequently cut non-metallic materials like plastics or composites, you may need to consider a different wavelength or power level. Следующий, evaluate your production volume. If you’re cutting hundreds of parts per day, а 4000 watt laser will likely be a worthwhile investment. Однако, if your needs are more sporadic, a lower-power system might be more cost-effective. It’s also important to consider the size of your workspace: 4000 watt lasers are larger than smaller systems, so ensure you have enough floor space for the machine, ventilation, and material handling equipment. Maintenance is another factor. Fiber lasers are generally low-maintenance, with few moving parts and long service intervals (some manufacturers offer 100,000-hour warranties on laser sources). Однако, regular cleaning of lenses and mirrors is essential to maintain cutting quality. Кроме того, ensure your facility has adequate electrical capacity—4000 watt systems require 3-phase power and proper cooling to operate efficiently.

Будущее 4000 Ватт Лазер: Инновации на горизонте

По мере развития технологий, 4000 watt lasers are becoming even more powerful and versatile. One emerging trend is the integration of artificial intelligence (ИИ) and machine learning into laser control systems. AI algorithms can analyze cutting data in real-time, adjusting parameters like power, скорость, and focus to optimize results for different materials or thicknesses. This not only improves precision but also reduces the risk of errors caused by human intervention. Another innovation is the development of multi-head laser systems, which allow a single 4000 watt laser source to power multiple cutting heads. This means manufacturers can cut multiple parts simultaneously, doubling or tripling production output without increasing energy consumption. For high-volume operations, this could be a game-changer, изготовление 4000 watt lasers even more efficient. Кроме того, advancements in beam delivery technology are extending the capabilities of 4000 watt lasers. New fiber optic cables with improved durability and flexibility allow the laser beam to reach more complex workpieces, opening up possibilities in robotics and automated assembly lines. Imagine a robotic arm equipped with a 4000 watt laser, cutting and welding parts in three dimensions—this is no longer science fiction but a reality in some of the world’s most advanced factories.

Почему 4000 Watt Laser Is Here to Stay

In a world where manufacturing is increasingly driven by speed, точность, и устойчивость, 4000 watt lasers have proven themselves to be more than just a passing trend. They are a foundational technology that empowers industries to build better, faster, and more cost-effectively. Whether you’re a small job shop looking to expand your capabilities or a large manufacturer aiming to stay ahead of the competition, а 4000 watt laser offers a level of performance and efficiency that is hard to match. As materials science advances and new alloys and composites enter the market, the demand for higher power, more precise cutting tools will only grow. 4000 watt lasers are already meeting that demand, and with ongoing innovations in AI, beam delivery, и энергоэффективность, their role in industrial manufacturing will only become more central. For those willing to invest, the rewards are clear: increased productivity, lower costs, and a competitive edge in an ever-evolving global market. Так, if you’re ready to take your manufacturing capabilities to the next level, рассмотреть 4000 watt laser. It’s not just a tool—it’s a partner in progress, helping you shape the future of your industry one precise cut at a time.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина