Новости

6 kw laser cutting | Industrial precision guide

The 6 kw laser stands at the intersection of raw power and surgical precision, a technological marvel that has redefined what’s possible in industrial fabrication. Imagine a tool that can slice through 20mm steel like a hot knife through butter, yet etch intricate patterns on aluminum with the delicacy of a calligrapher’s pen. This isn’t science fiction—it’s the reality of the 6 kw laser, a workhorse in modern manufacturing that balances brute force with finesse. In an era where industries demand faster production cycles, tighter tolerances, and cleaner finishes, тот 6 kw laser isn’t just an upgrade; it’s a revolution. But what exactly makes this machine so transformative? How does it differ from lower-wattage lasers, and why has it become the gold standard for metalworking, аэрокосмический, and automotive sectors? This guide dives deep into the world of 6 kw lasers, unpacking their mechanics, Приложения, and the tangible benefits they bring to workshops and factories worldwide. Whether you’re a seasoned fabricator looking to optimize operations or a newcomer curious about the future of manufacturing, understanding the 6 kw laser is key to staying ahead in a competitive market.

The Science Behind 6 kw Laser Power

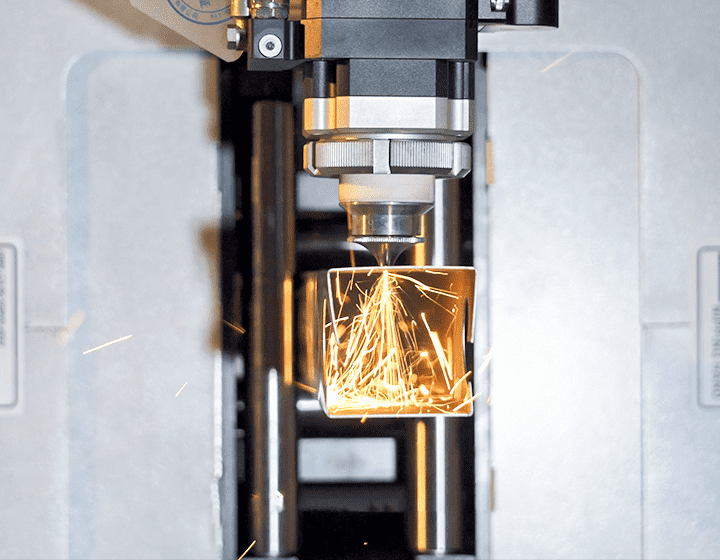

По своей сути, а 6 kw laser is an amplified beam of coherent light, but its power lies in how that energy is harnessed and delivered. Unlike lower-wattage lasers (такой как 1 kw or 3 kw models), тот 6 kw variant generates a beam with six kilowatts of continuous wave (CW) власть, equivalent to the energy output of six standard household space heaters concentrated into a point smaller than a pinhead. This intensity is achieved through a combination of advanced laser diodes, resonant cavities, and fiber optic delivery systems. Волоконные лазеры, the dominant technology in 6 kw systems, use doped optical fibers to amplify light, resulting in a beam with exceptional focus and minimal divergence. This focus is critical: а 6 kw laser’s beam can maintain a spot size of less than 0.1mm over distances of several meters, ensuring that energy is concentrated exactly where it’s needed.

But power alone isn’t enough. The 6 kw laser’s true advantage lies in its ability to balance energy with control. Modern systems integrate real-time sensors and adaptive optics that adjust the beam’s parameters—power, pulse frequency, and focal length—based on the material being processed. Например, when cutting thick steel, the laser might operate in high-power, low-frequency pulses to melt through the material, while switching to high-frequency, lower-power pulses for engraving or fine cutting. This versatility is why the 6 kw laser has displaced older technologies like plasma cutters and waterjets in many applications: it offers the speed of plasma, the precision of waterjet, and the added benefit of a heat-affected zone (ЗТВ) so small it’s often negligible.

Почему 6 кВт? The Sweet Spot in Laser Technology

In industrial laser systems, wattage isn’t just a number—it’s a strategic choice. Пока 10 kw and 12 kw lasers exist, they’re often overkill for most workshops, consuming excessive energy and requiring specialized cooling systems. On the flip side, 3 kw lasers struggle with thick materials, limiting their utility in heavy-duty applications. The 6 kw laser, однако, hits the “sweet spot” for versatility and efficiency. It can handle the majority of industrial tasks, from cutting 25mm carbon steel to welding thin aluminum sheets, without the operational costs of higher-wattage machines.

In industrial laser systems, wattage isn’t just a number—it’s a strategic choice. Пока 10 kw and 12 kw lasers exist, they’re often overkill for most workshops, consuming excessive energy and requiring specialized cooling systems. On the flip side, 3 kw lasers struggle with thick materials, limiting their utility in heavy-duty applications. The 6 kw laser, однако, hits the “sweet spot” for versatility and efficiency. It can handle the majority of industrial tasks, from cutting 25mm carbon steel to welding thin aluminum sheets, without the operational costs of higher-wattage machines.

Приложения: Where the 6 kw Laser Shines

The 6 kw laser’s versatility makes it indispensable across a spectrum of industries. Let’s explore its most impactful applications:

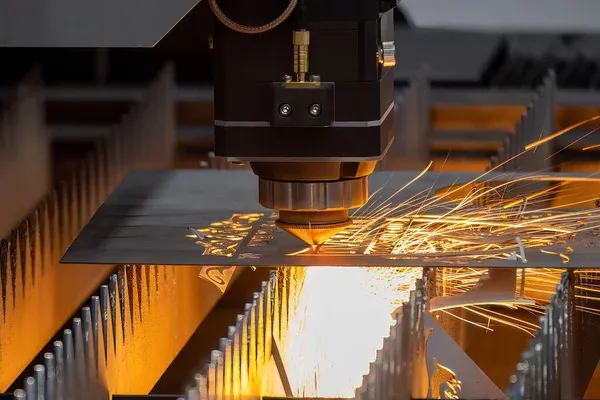

1. Heavy-Duty Metal Cutting

In steel fabrication, time is money, and the 6 kw laser excels at reducing cycle times. Например, cutting a 3m x 1.5m sheet of 16mm mild steel takes a 6 kw laser approximately 2 минуты, по сравнению с 5 minutes with a 3 kw laser and 15 minutes with a plasma cutter. Результат? A workshop can process three times more material daily, boosting revenue while reducing labor costs. What’s more, the laser’s narrow kerf (ширина разреза) minimizes material waste—critical in an era where steel prices fluctuate wildly. А 6 kw laser typically produces a kerf of 0.2mm to 0.3mm, compared to 1mm or more with plasma, meaning less scrap and more usable material per sheet.

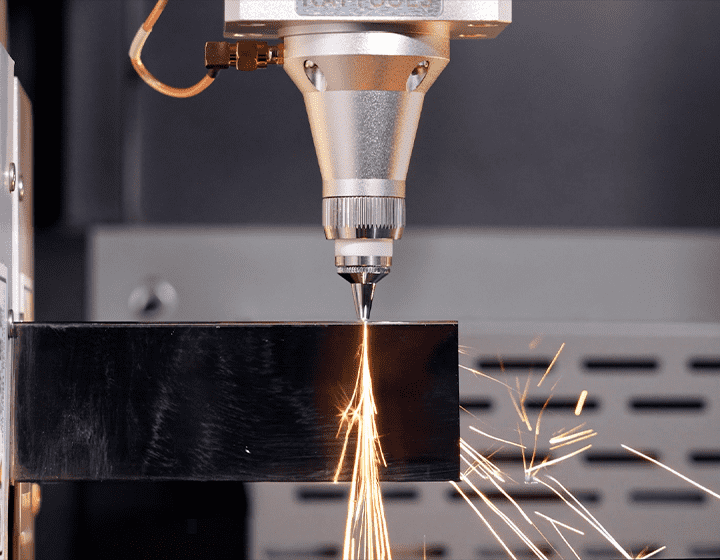

2. Precision Welding and Joining

Beyond cutting, 6 kw lasers are revolutionizing welding. Traditional arc welding struggles with heat distortion, especially in thin or heat-sensitive metals like titanium. The 6 kw laser, однако, delivers energy in short, intense pulses that melt the metal without overheating the surrounding area. This “keyhole welding” technique creates strong, clean joints with minimal HAZ, making it ideal for aerospace components where structural integrity is non-negotiable. В автомобильной промышленности, 6 kw lasers are used to weld battery tabs in electric vehicles, where precision is critical to prevent short circuits. The laser’s speed here is also a game-changer: it can weld 100 tabs per minute, a rate impossible with manual methods.

3. Surface Treatment and Coating Removal

The 6 kw laser isn’t just for cutting and welding—it’s also a master of surface engineering. By adjusting the beam’s power density and scan speed, operators can remove rust, краска, or coatings from metal surfaces without damaging the substrate. This is particularly valuable in shipbuilding, where hulls require frequent maintenance to prevent corrosion. А 6 kw laser can strip paint from a 1m² area in under 5 минуты, compared to hours with sandblasting, and without the environmental mess of abrasive materials. Кроме того, the laser can texture surfaces to improve adhesion for coatings, creating patterns that enhance grip or aesthetics.

4. Additive Manufacturing (3D Printing)

Пока 6 kw lasers are not typically used in desktop 3D printers, they’re powering large-scale metal additive manufacturing. In directed energy deposition (DED) системы, а 6 kw laser melts metal powder or wire as it’s deposited layer by layer, building complex parts like turbine blades or custom tooling. The laser’s high power allows for faster build rates—up to 10 kg of metal per hour—making it feasible to produce industrial-sized components. Unlike traditional subtractive manufacturing, which cuts away material, additive manufacturing with a 6 kw laser reduces waste by up to 70%, a sustainability win for eco-conscious industries.

Key Considerations When Investing in a 6 kw Laser

Purchasing a 6 kw laser is a significant investment, often costing upwards of $200,000. To ensure it delivers ROI, buyers must consider several factors:

1. Совместимость материалов

Пока 6 kw lasers handle most metals (сталь, алюминий, латунь, медь,), their performance varies by material. Медь, например, is highly reflective, requiring specialized optics to prevent beam loss. Workshops processing non-ferrous metals should opt for lasers with polarization control or wavelength adjustment (например, green lasers for copper).

2. Требования к техническому обслуживанию

Fiber lasers are known for their reliability, but 6 kw systems still demand regular upkeep. Key components like laser diodes and optical fibers have lifespans of 10,000–20,000 hours, after which they require replacement at a cost of 10,000–10,000–15,000. Routine cleaning of lenses and mirrors is also critical; dust or debris can scatter the beam, reducing cutting precision and increasing energy consumption.

3. Safety Protocols

А 6 kw laser’s beam is powerful enough to ignite clothing and cause permanent eye damage in milliseconds. Workshops must invest in Class IV laser enclosures, interlock systems, and personal protective equipment (PPE), including laser safety glasses with the correct wavelength rating. OSHA and international standards (например, МЭК 60825) mandate strict safety measures, and non-compliance can result in fines or shutdowns.

4. Программное обеспечение и автоматизация

А 6 kw laser is only as efficient as its control system. Modern machines integrate CAD/CAM software that optimizes cutting paths, minimizes material waste, and syncs with ERP systems for production tracking. Automation features like pallet changers and robotic loaders further boost productivity by enabling lights-out manufacturing—unmanned operation during off-hours.

5. Energy and Cooling Needs

А 6 kw laser consumes approximately 15–20 kWh of electricity per hour, similar to a small household. This requires a dedicated electrical supply (often 3-phase power) and a robust cooling system. Water-cooled chillers are standard, as they dissipate the heat generated by the laser source. Buyers should factor in these ongoing costs when calculating ROI.

The Future of 6 kw Lasers: Innovations on the Horizon

The 6 kw laser is not static; ongoing advancements are pushing its capabilities even further. One promising development is the integration of artificial intelligence (ИИ) and machine learning (ML) into laser control systems. AI algorithms can analyze real-time data from sensors to predict beam degradation, adjust parameters on the fly, and even detect defects in cut edges before they become waste. Например, if the laser starts producing a wider kerf due to a worn lens, the AI can alert operators or automatically compensate by adjusting the cutting speed.

Another trend is the miniaturization of 6 kw laser systems. Traditional laser cutters are large, floor-standing machines, but new compact designs are emerging, making them accessible to smaller workshops. These “benchtop” 6 kw lasers sacrifice some bed size but retain the power and precision of their larger counterparts, opening up new possibilities for job shops and custom manufacturers.

Окончательно, green technology is reshaping the laser industry. Manufacturers are developing 6 kw lasers powered by renewable energy sources, such as solar or wind, reducing their carbon footprint. Кроме того, advances in fiber optic efficiency are making 6 kw lasers more energy-efficient, with some models converting over 30% of electrical input into laser output—up from 15% a decade ago. This not only lowers operating costs but also aligns with global efforts to reduce industrial emissions.

Why the 6 kw Laser Isn’t Just a Tool—It’s a Strategic Asset

In a world where manufacturing is increasingly competitive, тот 6 kw laser isn’t just a piece of equipment; it’s a catalyst for innovation. It allows small and medium-sized enterprises (SMEs) to take on projects once reserved for large corporations, from prototyping aerospace parts to producing custom metal art. For large manufacturers, it streamlines production, reduces waste, and accelerates time-to-market.

Consider a hypothetical scenario: a mid-sized metal fabricator invests in a 6 kw laser to replace its aging plasma cutter. Within six months, it cuts production time by 40%, reduces material waste by 25%, and wins a contract to supply components for a wind turbine manufacturer. The laser pays for itself in under two years, not just through increased revenue but also by attracting new clients impressed by its precision capabilities.

The 6 kw laser also empowers sustainability. By minimizing scrap, reducing energy use, and enabling recycling of metal offcuts, it helps manufacturers meet ESG (Environmental, Social, Governance) goals—a priority for investors and customers alike. In an era where “green manufacturing” is no longer a buzzword but a business imperative, тот 6 kw laser is a tool for both profit and planet.

The 6 kw laser has transcended its role as a mere industrial tool to become the backbone of modern manufacturing. Its blend of power, точность, and versatility makes it indispensable across sectors, from automotive and aerospace to construction and art. По мере развития технологий, we can expect even more innovations—AI-driven automation, greener energy sources, and smaller, more affordable systems—that will expand its reach further. For businesses willing to invest, тот 6 kw laser isn’t just a purchase; it’s a ticket to the future of fabrication. In a world where precision and efficiency reign supreme, тот 6 kw laser doesn’t just keep up—it leads the way.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина