Новости

Революция в отрасли с помощью станка для лазерной резки стальных труб

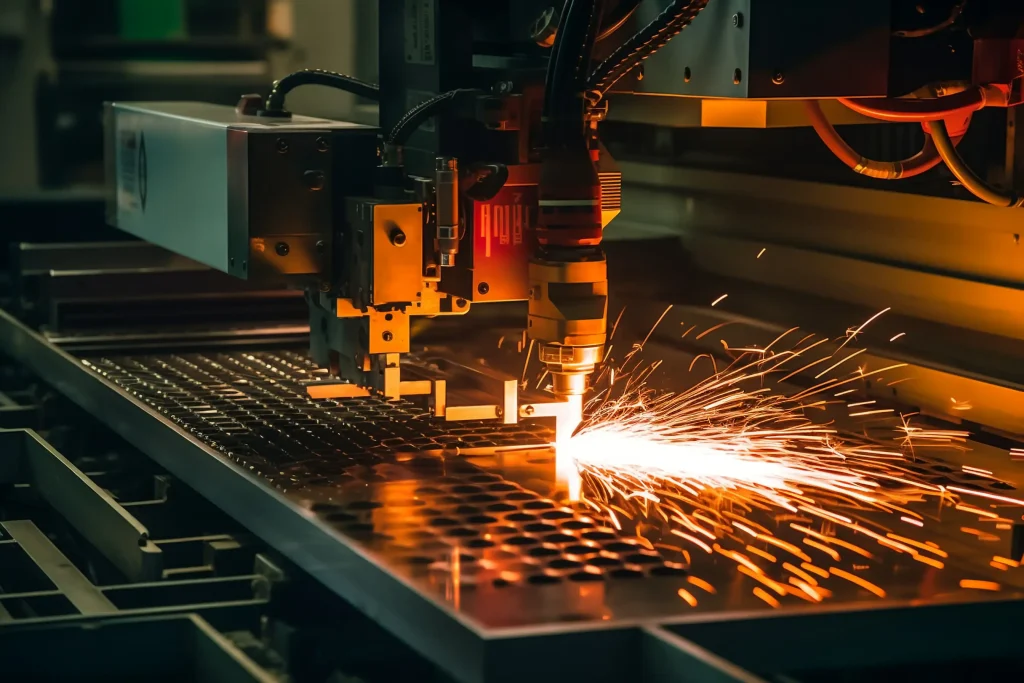

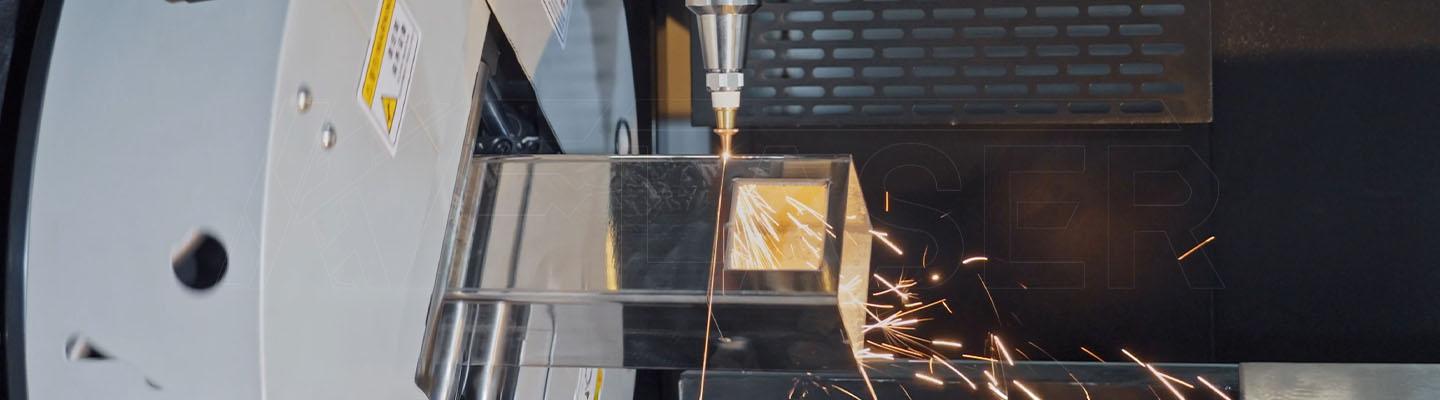

Steel tube laser cutting machine technology is transforming manufacturing landscapes worldwide, offering unprecedented precision and efficiency. Imagine a world where thick steel tubes are sliced with the finesse of a surgeon’s scalpel, reducing waste to near-zero and accelerating production timelines tenfold—this isn’t science fiction; it’s the reality brought to life by modern laser systems. As industries evolve, this cutting-edge equipment stands as a cornerstone for innovation, empowering businesses to tackle complex projects with ease while slashing operational costs.

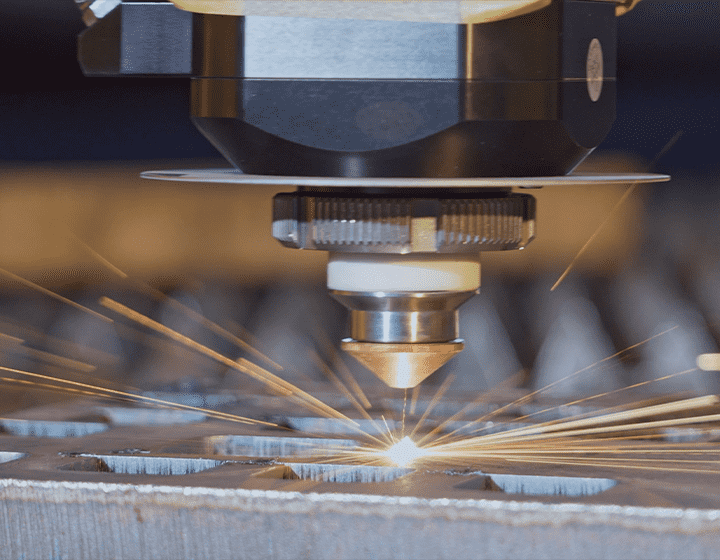

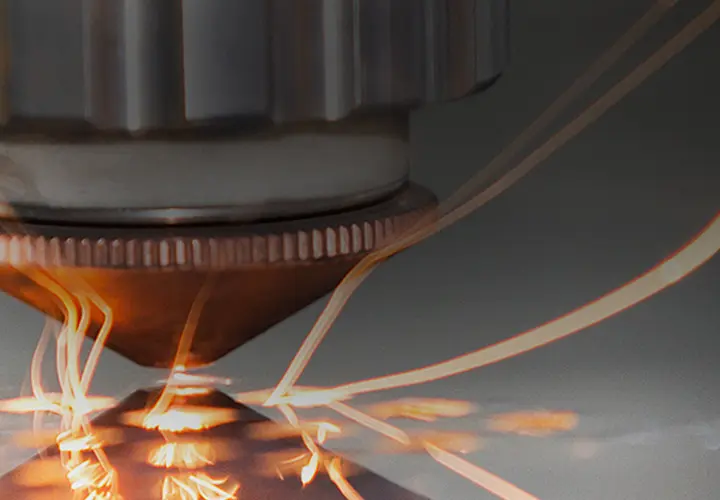

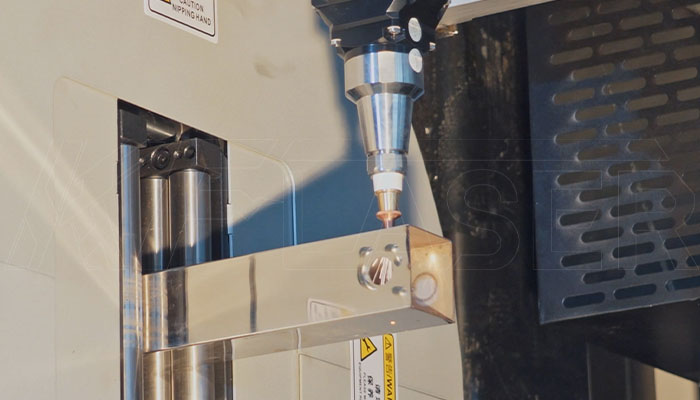

The essence of a steel tube laser cutting machine lies in its ability to harness focused laser beams for high-accuracy material processing. Unlike traditional methods like sawing or plasma cutting, which often result in jagged edges and excessive heat distortion, laser systems utilize coherent light energy to vaporize metal along predefined paths. This process minimizes thermal damage, preserving the structural integrity of steel tubes—a critical factor in applications demanding flawless finishes. Key components include fiber lasers for enhanced power efficiency and CNC controls that automate intricate designs, ensuring repeatability across thousands of cuts. Such advancements stem from decades of research in photonics and materials science, with studies from institutions like the Laser Institute of America confirming that laser-based methods reduce energy consumption by up to 40% compared to conventional techniques.

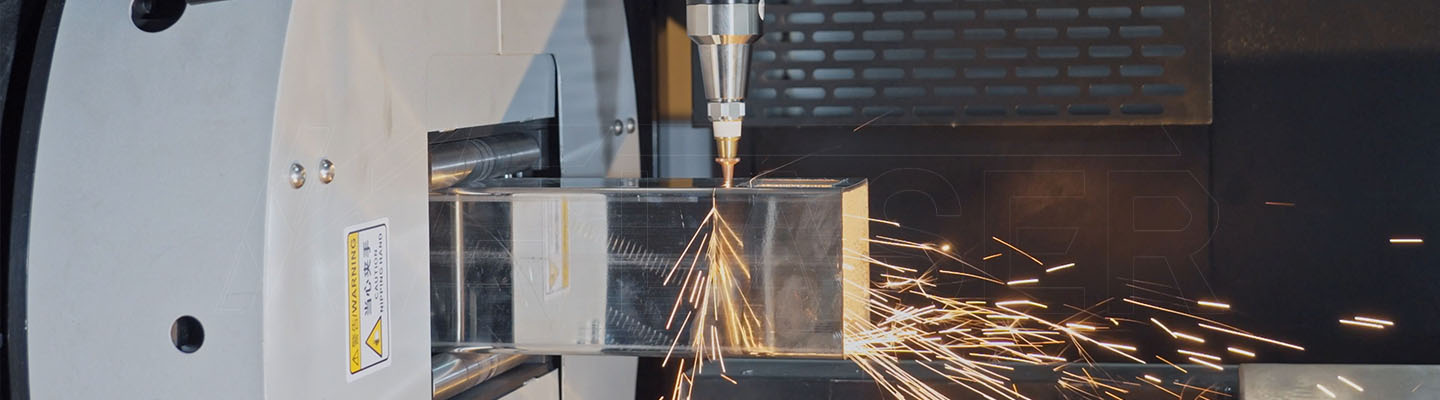

Beyond basic functionality, the advantages of steel tube laser cutting machines extend across multiple dimensions, making them indispensable in today’s competitive markets. First, precision is unparalleled: lasers achieve tolerances within 0.1mm, eliminating the need for secondary finishing and reducing scrap rates by over 90%. This translates to significant cost savings, as manufacturers report ROI periods as short as six months due to lowered material waste and labor expenses. Second, speed and versatility shine through—systems can process tubes of varying diameters (from 10mm to 300mm) at rates exceeding 10 meters per minute, adapting seamlessly to custom geometries like miters or bevels. Например, in the automotive sector, this enables rapid prototyping of exhaust systems, while construction firms leverage it for creating robust structural frameworks without compromising on safety standards. Third, environmental benefits emerge from reduced emissions and noise pollution; laser operations generate minimal fumes and operate quietly, aligning with global sustainability goals.

In practical terms, selecting the right steel tube laser cutting machine requires careful consideration of several factors to maximize value. Power output is paramount—higher wattage (например, 3kW to 6kW) suits heavy-duty applications but increases costs, whereas lower options suffice for thinner materials. Tube handling capabilities, such as automatic loading systems, enhance productivity by minimizing downtime during batch processing. Software integration also plays a pivotal role; advanced CAD/CAM interfaces allow for real-time adjustments and simulation, preventing errors before execution. Кроме того, maintenance aspects shouldn’t be overlooked—opt for models with self-diagnostic features to avoid unexpected breakdowns. Industry surveys indicate that businesses prioritizing these elements see up to 50% gains in throughput, underscoring the importance of tailored investments.

Looking ahead, innovations in steel tube laser cutting machine technology promise even greater leaps. Artificial intelligence is being integrated for predictive maintenance, analyzing data from sensors to foresee issues before they escalate. Hybrid systems combining lasers with other technologies, such as waterjet cutting, are emerging to handle composite materials, expanding applications into aerospace and renewable energy. Более того, advancements in beam quality control aim to push precision boundaries further, potentially enabling nanoscale adjustments for micro-tubing. As global demand for customized manufacturing grows, these machines will continue to evolve, driving efficiencies that ripple through supply chains.

В конечном счете, embracing steel tube laser cutting machine solutions isn’t just about upgrading equipment—it’s about future-proofing operations in an era where agility and quality define success. Companies that adopt these systems position themselves at the forefront of industrial evolution, ready to meet challenges with cutting-edge prowess.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина