Новости

10кВт Лазерная резка | Точность & Власть

how metals, composites, and advanced materials are shaped. In an era where production timelines shrink by the day and material science evolves at a breakneck pace, this equipment stands as a cornerstone of modern fabrication—capable of slicing through 25mm thick steel like butter while etching intricate patterns on 0.1mm aluminum foils with the delicacy of a watchmaker’s tool. But what truly sets the 10kW laser cutting machine apart is not just its brute force; it is the synergy of cutting-edge optics, intelligent software, and energy management systems that make it a game-changer for industries ranging from automotive and aerospace to renewable energy and heavy machinery.

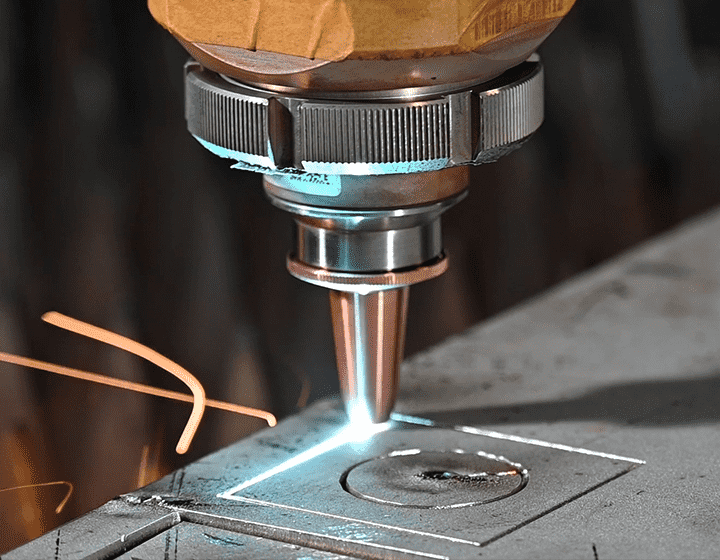

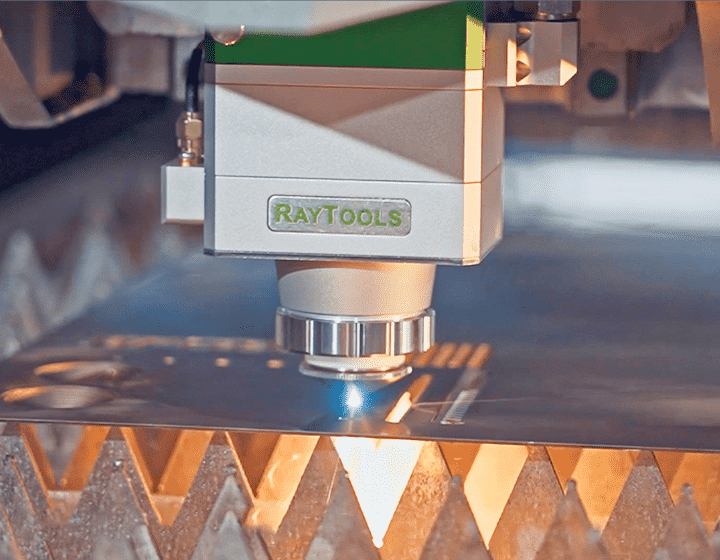

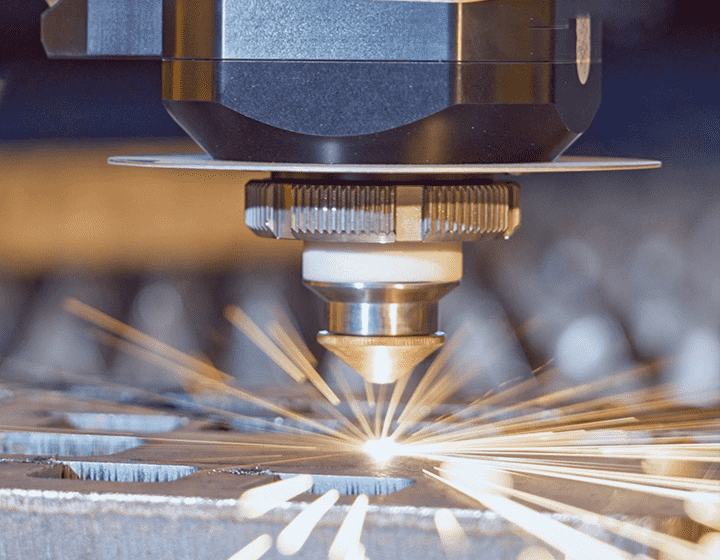

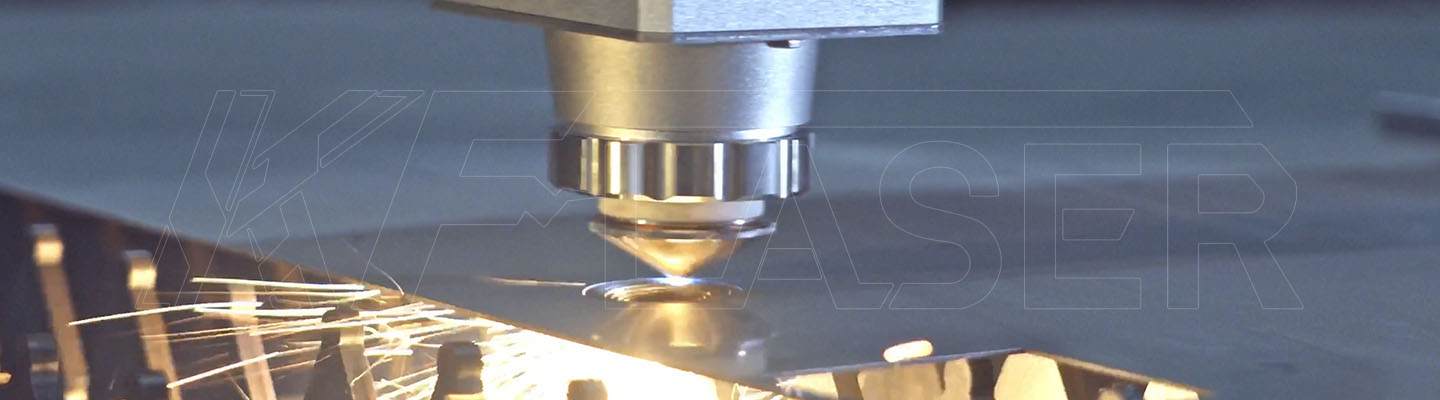

To understand the impact of 10kW laser cutting machines, one must first grasp the physics that fuels their performance. По своей сути, a 10kW fiber laser generates a beam of coherent light with a wavelength of approximately 1064nm, focused through a series of lenses and mirrors to a spot size as small as 0.1mm. This concentration of energy—equivalent to condensing the power of 10,000 household light bulbs into a pinpoint—vaporizes or melts materials at temperatures exceeding 10,000°C, far surpassing the melting points of even the most refractory metals like tungsten. В отличие от лазеров CO2, which rely on gas amplification, fiber lasers use doped optical fibers to amplify light, resulting in higher energy efficiency (up to 30% compared to CO2’s 10%), lower maintenance costs, and a smaller footprint. This efficiency translates to tangible benefits: a 10kW fiber laser can cut carbon steel at speeds up to 5 meters per minute, reducing production time by 40% compared to 6kW models, while consuming 20% less electricity per hour of operation.

But speed and power are only part of the equation. Modern 10kW laser cutting machines are equipped with adaptive cutting technologies that adjust parameters in real time based on material type, толщина, and even surface conditions. Например, when transitioning from cutting 10mm stainless steel to 5mm copper, the machine automatically tunes the beam frequency, gas pressure (using nitrogen for clean cuts or oxygen for faster, oxide-laden edges), and lens focal length to maintain optimal results. This level of automation not only minimizes human error but also unlocks new possibilities for processing exotic materials. В аэрокосмическом секторе, where titanium alloys and Inconel are staples, 10kW lasers ensure burr-free, Затронутые теплом зоны (ЗТВ) as narrow as 0.05mm—critical for parts like turbine blades, where structural integrity is non-negotiable. Similarly, in the renewable energy industry, these machines precision-cut solar panel frames and wind turbine components with tolerances of ±0.01mm, ensuring seamless assembly and maximum energy output.

The economic case for investing in a 10kW laser cutting machine becomes even more compelling when examining long-term operational costs. While the upfront investment—typically ranging from 500,000to500,000to1.2 million—may seem steep, the return on investment (Рентабельность) often materializes within 18–24 months for high-volume manufacturers. This is driven by multiple factors: reduced labor costs due to automation, lower material waste (kerf widths as small as 0.2mm minimize scrap), and the elimination of secondary processes like deburring or post-cut finishing. A study by the Laser Institute of America (LIA) found that manufacturers switching from plasma cutting to 10kW fiber laser cutting reduced their per-part production costs by 35% while increasing output by 50%. For small to medium enterprises (SMEs), this efficiency gain can mean the difference between securing large-scale contracts and being outpriced by competitors.

Another key advantage of 10kW laser cutting machines is their versatility across industries. В автомобильном производстве, they handle everything from body panel trimming and chassis component cutting to the fabrication of lightweight EV battery enclosures. The ability to process high-strength low-alloy (HSLA) steels and aluminum alloys—materials crucial for improving vehicle fuel efficiency—makes them indispensable in the shift toward electric mobility. In the construction sector, these machines cut structural beams and architectural metalwork with intricate designs, replacing traditional sawing and drilling methods that are slower and less precise. Even in niche fields like art and design, 10kW lasers are used to create large-scale metal sculptures, leveraging their power to carve detailed motifs into thick bronze or brass sheets that would be impossible with manual tools.

Еще, for all their capabilities, 10kW laser cutting machines are not without challenges. Energy consumption, though lower than older laser technologies, remains significant: a typical machine draws 15–20 kWh of electricity per hour, which can lead to high utility bills in regions with expensive power. To mitigate this, manufacturers are increasingly integrating energy recovery systems and smart grid connectivity, allowing machines to draw power during off-peak hours or feed excess energy back into the grid. Maintenance is another consideration; while fiber lasers have longer lifespans (up to 100,000 hours of operation) than CO2 lasers, their optical components and cooling systems require regular inspection to prevent degradation. Dust and debris from cutting processes can also accumulate on lenses, reducing beam quality and increasing the risk of thermal damage—a problem addressed by advanced air filtration systems and automated lens cleaning mechanisms in newer models.

Safety is a paramount concern when operating a 10kW laser cutting machine, given the intense heat and potential for combustion. Modern systems comply with strict international standards (such as ISO 11553 and ANSI Z136) and feature multiple safeguards: enclosed cutting chambers with interlock doors, flame detectors that trigger automatic shutdowns, and fume extraction systems to remove toxic byproducts like metal oxides and ozone. Operators must undergo specialized training to handle the equipment, including understanding material-specific cutting parameters and emergency protocols. Кроме того, as laser power increases, so does the risk of reflections—a single errant beam can ignite flammable materials or cause eye damage. For this reason, machine enclosures are lined with anti-reflective coatings, and operators wear laser safety glasses rated for 10kW wavelengths.

Looking to the future, the evolution of 10kW laser cutting machines shows no signs of slowing. Innovations in beam delivery systems, such as adaptive optics that adjust for material warpage in real time, promise even higher precision. Integration with artificial intelligence (ИИ) is another frontier: machine learning algorithms can analyze cutting data to predict tool wear, optimize parameters for new materials, and even self-correct for minor misalignments. The rise of Industry 4.0 has also led to the development of “smart” laser systems that connect to factory IoT networks, allowing remote monitoring, predictive maintenance, and seamless integration with CAD/CAM software. Например, a manufacturer in Germany recently deployed a 10kW laser cutting machine linked to its ERP system, enabling automatic job scheduling based on material availability and delivery deadlines—reducing idle time by 22%.

Material science advancements are further expanding the applications of 10kW lasers. Researchers are exploring their use in cutting advanced composites like carbon fiber-reinforced polymers (CFRPs), which are lightweight and strong but notoriously difficult to machine with traditional tools. Early tests show that 10kW lasers can cut CFRP with minimal delamination, opening doors for use in next-generation aircraft and spacecraft. Similarly, in the medical device industry, these machines are being used to fabricate intricate surgical instruments and implantable components from biocompatible materials like titanium and nitinol, where precision and cleanliness are critical.

For businesses considering investing in a 10kW laser cutting machine, several factors must be weighed. First, assess production volume and material types: high-volume manufacturers processing thick metals will benefit most, while those working with thin sheets or non-metallic materials may find lower-power lasers sufficient. Second, evaluate floor space: 10kW machines require dedicated areas with proper ventilation and cooling, often measuring 5m x 8m or larger. Third, consider long-term scalability—some models allow for power upgrades (например, from 8kW to 10kW) as production needs grow, avoiding the cost of full replacement. Окончательно, partner with reputable suppliers that offer comprehensive training and after-sales support; a reliable service network can minimize downtime and ensure optimal performance over the machine’s lifespan.

В заключение, 10kW laser cutting machines represent more than just a tool—they are a strategic investment in the future of manufacturing. By combining unmatched speed, точность, и универсальность, they empower businesses to take on complex projects, сократить расходы, and stay ahead in a competitive global market. Поскольку технологии продолжают развиваться, these machines will only become more integral to industries pushing the boundaries of what’s possible, proving that in the world of fabrication, power and precision are not mutually exclusive—they are the key to progress. Whether you’re a small workshop looking to scale or a multinational corporation innovating in aerospace, the 10kW laser cutting machine is not just a piece of equipment; it’s a catalyst for transformation.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина