Новости

Откройте для себя лучшая лазерная режущая машина для лучшего волокна для точной резки

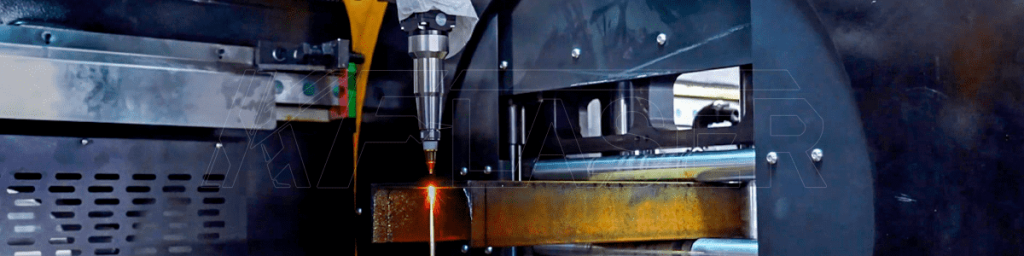

In today’s fast-evolving world of industrial manufacturing, а top fiber laser cutting machine represents the pinnacle of precision, эффективность, и универсальность. These machines have revolutionized the way metal, пластмассы, and other materials are cut, offering exceptional speed and accuracy. Whether you’re in the automotive, аэрокосмический, or electronics industry, the introduction of fiber laser cutting technology has brought about a paradigm shift, setting new benchmarks in material processing.

But what exactly makes the top fiber laser cutting machine stand out in a crowded field of laser technology? The answer lies in the fusion of cutting-edge technology, advanced features, and unparalleled efficiency. If you are seeking to elevate your manufacturing operations or improve your production capabilities, this type of laser cutting machine could be the game-changer you need.

Why Choose a Top Fiber Laser Cutting Machine?

The demand for fiber laser cutting machines has soared in recent years, and for good reason. Their benefits go far beyond traditional laser cutting systems. Let’s take a closer look at what makes a top fiber laser cutting machine an indispensable tool for modern manufacturers.

1. Unmatched Cutting Precision

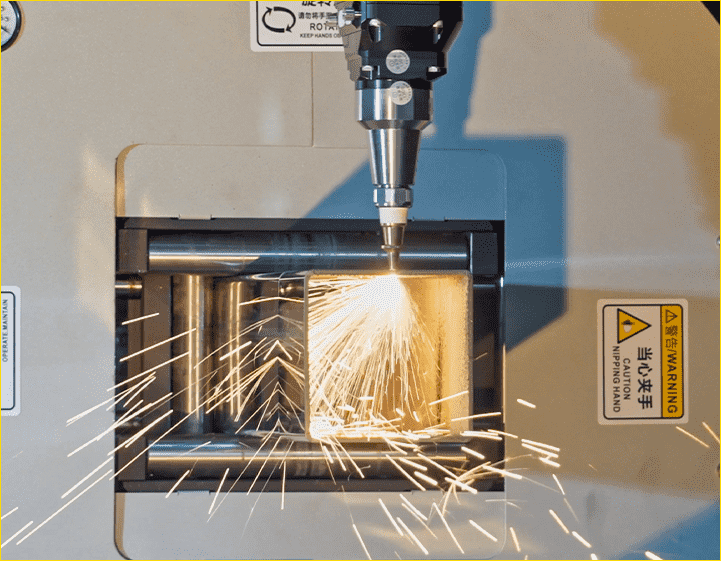

One of the most remarkable features of top fiber laser cutting machines is their extraordinary precision. These machines use high-powered fiber lasers that are able to cut intricate designs with remarkable accuracy. Whether you’re working with thin or thick materials, the fiber laser’s beam remains focused and sharp, delivering highly detailed cuts without the risk of distortion or warping.

2. Increased Cutting Speed

Fiber laser cutting technology allows for faster processing speeds when compared to other conventional methods. This is especially beneficial in industries where production speed is crucial, such as in high-volume manufacturing or when tight deadlines need to be met. By optimizing the cutting process, а top fiber laser cutting machine helps increase throughput, leading to higher productivity levels and lower operational costs.

3. Универсальность материалов

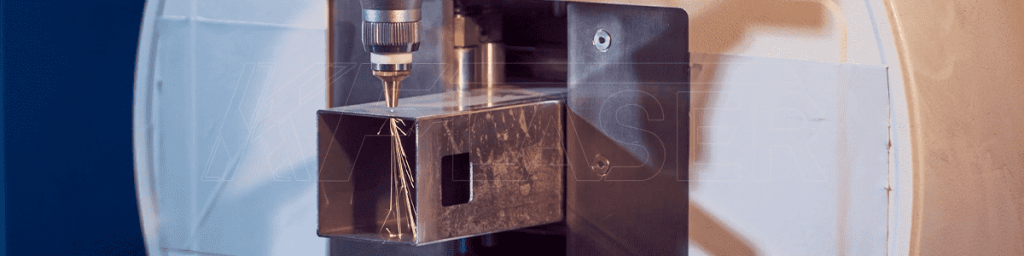

A significant advantage of top fiber laser cutting machine is their ability to cut a wide range of materials, включая нержавеющую сталь, углеродистая сталь, алюминий, латунь, медь, and even non-metals like wood or plastics. This versatility makes them invaluable in a variety of industries, from automotive and electronics to art and design.

4. Энергоэффективность

Compared to CO2 laser systems, fiber lasers are far more energy-efficient, consuming up to 50% less power. This is because fiber lasers generate a higher concentration of energy in a smaller area, leading to less energy waste and lower overall operating costs. The top fiber laser cutting machine is designed to maximize this advantage, allowing businesses to maintain a high production rate while minimizing energy consumption.

5. Снижение затрат на техническое обслуживание

Fiber laser technology requires far less maintenance than traditional laser cutting systems. Because the fiber laser uses a solid-state design with no mirrors or lenses to maintain, the need for frequent maintenance or part replacements is drastically reduced. This results in lower downtime, fewer service calls, and less expensive repair costs—ultimately making the top fiber laser cutting machine a cost-effective solution for manufacturers in the long term.

Key Features to Look for in a Top Fiber Laser Cutting Machine

When selecting the best top fiber laser cutting machine, there are several factors to consider. While every machine may offer a different set of features, certain aspects stand out as essential for optimal performance.

1. Мощность лазера

Laser power is a critical determinant of cutting speed and material thickness. Top fiber laser cutting machine typically offer laser powers ranging from 500W to 12kW, depending on the application. For cutting thicker materials or achieving faster speeds, higher power lasers are generally preferred.

2. Cutting Table Size

The size of the cutting table plays a significant role in determining the types of materials you can work with. Larger tables provide more flexibility in cutting big sheets of metal or other materials, making them ideal for larger-scale operations. Ensure that the cutting table size aligns with your production needs.

3. Возможности автоматизации

Many top fiber laser cutting machine comes equipped with advanced automation features, including automatic nozzle changers, системы обработки материалов, and automatic loading/unloading capabilities. These features increase production efficiency, reduce the need for manual labor, and help maintain consistent quality across all cut pieces.

4. Система управления

An intuitive control system is essential for easy operation and programming of the laser cutter. Some systems offer touch-screen interfaces, while others may have specialized software for advanced CAD designs. Look for a top fiber laser cutting machine with a user-friendly control system that integrates seamlessly with your existing workflow.

5. Cooling Systems

Fiber lasers generate significant amounts of heat during operation, making efficient cooling systems crucial for maintaining optimal performance. Some high-end волоконный лазер для резки feature advanced cooling systems to prevent overheating and ensure consistent, high-quality cutting throughout long production runs.

How the Top Fiber Laser Cutting Machine Enhances Manufacturing Efficiency

One of the primary reasons why manufacturers opt for the top fiber laser cutting machine is its ability to enhance overall production efficiency. This is accomplished through the combination of high precision, скорость, универсальность, и автоматизация. Here’s how:

- Уменьшенные материалы отходы: Fiber laser cutters are known for their ability to cut precisely, which leads to minimal material wastage. This reduces costs and maximizes the use of raw materials.

- Higher Productivity: Thanks to its fast cutting speeds and minimal downtime, а top fiber laser cutting machinecan handle more jobs in less time, increasing output while maintaining quality.

- Улучшенная гибкость дизайна: The high precision of fiber lasers enables the production of complex geometries and intricate designs that would be difficult, if not impossible, to achieve using other cutting methods.

- Less Labor-Intensive: With automation features, тот top fiber laser cutting machinereduces the need for manual intervention, freeing up labor for other critical tasks in the production process.

Industries Benefiting from Top Fiber Laser Cutting Machines

From the aerospace industry to electronics and automotive manufacturing, тот top fiber laser cutting machine has applications in a wide variety of sectors. Here are some industries where these machines provide immense value:

Автомобильная промышленность: Precision cutting of metal components for vehicles, including frames, части тела, and intricate mechanical components.

Аэрокосмическая промышленность: Production of high-precision parts for aircraft and spacecraft, where cutting quality and material integrity are essential.

Электроника: Laser cutting for circuit boards, вложения, and components that require fine details and minimal tolerance.

Ювелирный Дизайн: Laser cutting of intricate jewelry pieces that require sharp edges and delicate designs.

Заключение

Choosing a top fiber laser cutting machine for your manufacturing operations is an investment that can pay off in the form of increased precision, снижение затрат, and higher production speeds. With the ability to cut through a wide range of materials with remarkable accuracy, and the added benefits of energy efficiency and reduced maintenance, this technology represents the future of cutting-edge manufacturing.

By carefully selecting the right top fiber laser cutting machine that fits your specific production requirements, you can significantly enhance your operational efficiency and ensure your company stays ahead in a highly competitive marketplace.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина