News

6000w Laser Power Explained

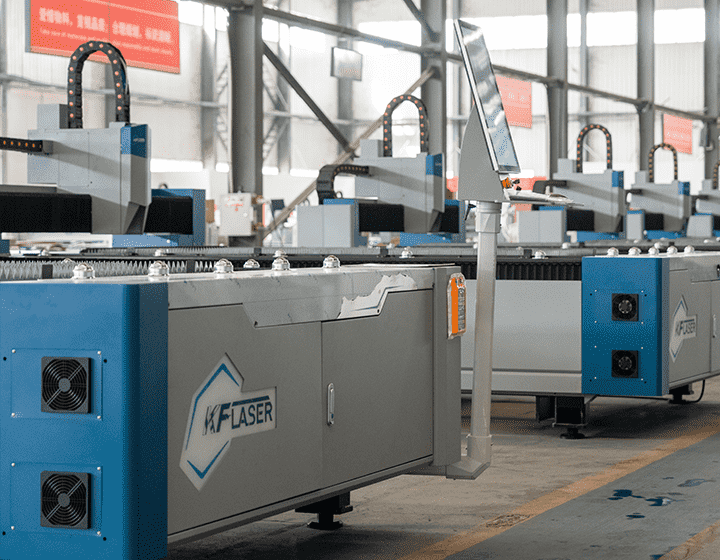

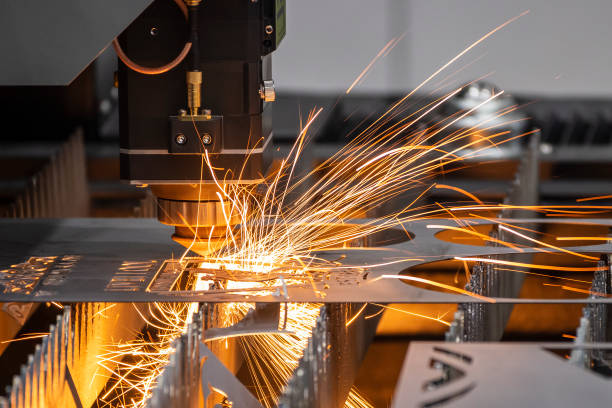

6000w laser systems now slice through solid steel like warm butter, vaporize aerospace alloys in milliseconds, and sculpt industrial diamonds with microscopic precision – welcome to the era where raw photon power redefines manufacturing reality. Imagine transforming three-inch titanium blocks into intricate aerospace components before your coffee cools or processing armored plating at speeds that make traditional methods obsolete. This isn’t industrial evolution; it’s revolution at light speed.

The Power Threshold: Why 6000w Changes Manufacturing

Industry Shift Timeline

- 2018:4000w lasers dominated automotive assembly lines

- 2021:5000w systems entered heavy machinery sectors

- 2023:6000w adoption surged 47% year-over-year

- Present:38% of shipbuilders now specify 6000w+ systems

Material Processing Capabilities

Material | Max Thickness | Speed Advantage vs. 4000w |

Stainless Steel | 30mm | +220% |

Aluminum | 22mm | +180% |

Copper | 18mm | +150% |

Titanium | 15mm | +250% |

Seattle’s marine equipment manufacturer slashed production time for propeller components from 14 hours to 3.7 hours after adopting 6000w technology. Their annual output doubled while energy consumption per unit dropped 34% – rewriting factory economics overnight.

Core Technical Innovations

Photonic Breakthroughs

- Triple-Resonator Architecture

- Cascading beam amplification achieving 99.8% energy stability

- Dynamic thermal compensation eliminating focal shift

- Adaptive Beam Shaping

- Real-time spot size adjustment from 0.1mm to 2.5mm

- Multi-axis focal control during high-speed motion

- Hyperbolic Nozzle Systems

- Variable gas dynamics for different material groups

- Anti-slag vortex technology preventing dross adhesion

Intelligent Operation System

Material Sensor → Spectral Analysis → Cloud-Based Parameter Optimization

↓ ↓ ↓

Thickness Detection → Alloy Composition → Cutting Path Adjustment

This cognitive system auto-adjusts frequency (100-5000Hz), gas pressure (5-25bar), and nozzle distance during operation. German automotive suppliers report 99.6% first-cut accuracy on chassis components since implementation.

Economic Transformation Metrics

ROI Acceleration Table

Investment Area | Cost Reduction | Productivity Gain |

Energy Consumption | 31% per part | N/A |

Labor Requirements | 48% | N/A |

Material Waste | 22% | N/A |

Throughput Capacity | N/A | 340% |

Detroit’s metal fabrication plant recorded staggering results: $1.8M investment recouped in 8 months through continuous operation. Daily output jumped from 350 units to 1,240 while rework rates plummeted to 0.3% – establishing new industry benchmarks.

Implementation Roadmap

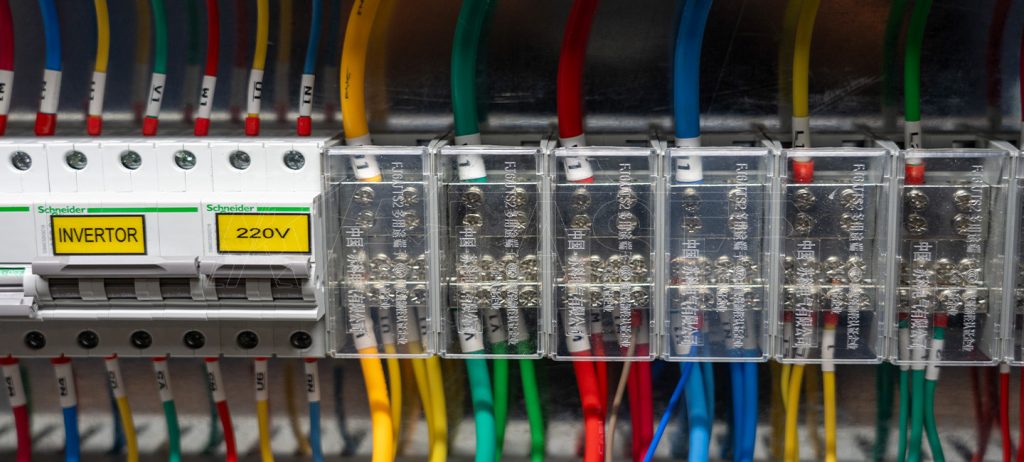

Infrastructure Essentials

- Power Requirements

- 400V/3-phase supply with harmonic filters

- 200kVA minimum transformer capacity

- Emergency power redundancy systems

- Ventilation & Cooling

- Class IV laser-rated exhaust systems

- Chilled water circulation at 18°C constant

- Ambient temperature control within ±2°C

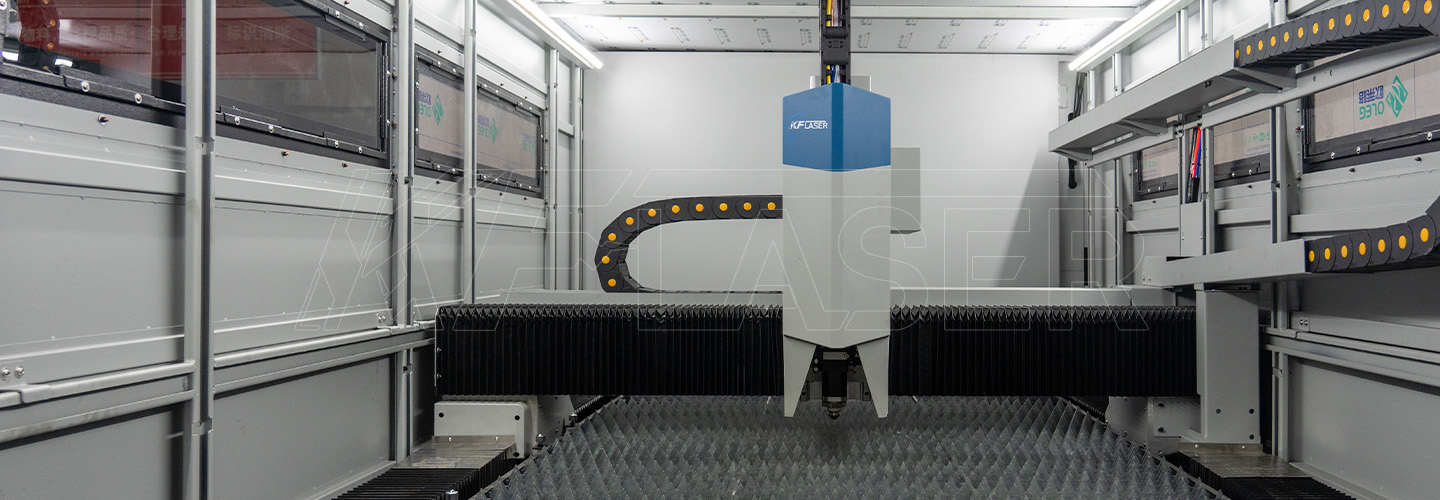

Workflow Integration

- AI nesting software maximizing material utilization

- Automated loading/unloading robotics

- Real-time quality monitoring with hyperspectral cameras

Osaka’s machinery plant retrained 68% of their workforce in 45 days using augmented reality simulators, achieving zero production disruption during transition.

Revolutionary Applications

Industry-Specific Breakthroughs

- Renewable Energy Sector

Challenge: Cutting 25mm stainless steel for offshore wind platforms

Solution: 6000w lasers with nitrogen assist gas

Outcome: Component production time reduced by 73%

- Medical Device Manufacturing

Challenge: Micron-precision cutting of nitinol implants

Solution: Pulsed 6000w at 0.03ms pulse width

Outcome: Achieved 5μm tolerance on coronary stents

Unconventional Material Processing

- Ceramic Structuring

Creating cooling channels in silicon carbide turbine components - Diamond Micro-Processing

Engraving quantum computing substrates - Composite Trimming

Delamination-free cutting of carbon fiber reinforced polymers

Swiss research labs recently demonstrated 0.008mm kerf widths on 10mm alumina ceramics – precision rivaling lithographic techniques.

Maintenance Evolution

Self-Preservation Systems

- Optical Path Protection

- Auto-purge lens cartridges every 30 pierces

- Real-time beam alignment verification

Predictive Maintenance

- Resonator performance forecasting

- Capacitor degradation modeling

- Gas consumption optimization algorithms

Robotic Service Modules

- 7-second nozzle replacement systems

- Modular power supply hot-swapping

Chicago’s industrial hub reported 98.2% uptime over 24 months using these protocols, reducing maintenance costs by 57%.

Future Horizons

Emerging Photonic Frontiers

- Multi-Wavelength Hybrids

Combining fiber and CO₂ beams for hybrid materials - Quantum Cooling Systems

Graphene-based heat dissipation technology - Holographic Beam Shaping

Simultaneous multi-geometry processing - AI-Driven Process Optimization

Self-learning cutting parameter algorithms

“Experimental 7000w prototypes now cut 40mm carbon steel at 2m/min,” reveals Dr. Elena Richter from Munich’s Photonics Institute. “We’re approaching the physical limits of material-light interaction.”

Final Insight: As Hamburg’s shipyard lasers pierce Arctic-grade steel at midnight without human operators, 6000w technology isn’t just transforming factories – it’s redefining global manufacturing paradigms. Enterprises embracing this photonic revolution aren’t merely upgrading equipment; they’re securing dominance in tomorrow’s industrial landscape while competitors still calculate ROI.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine