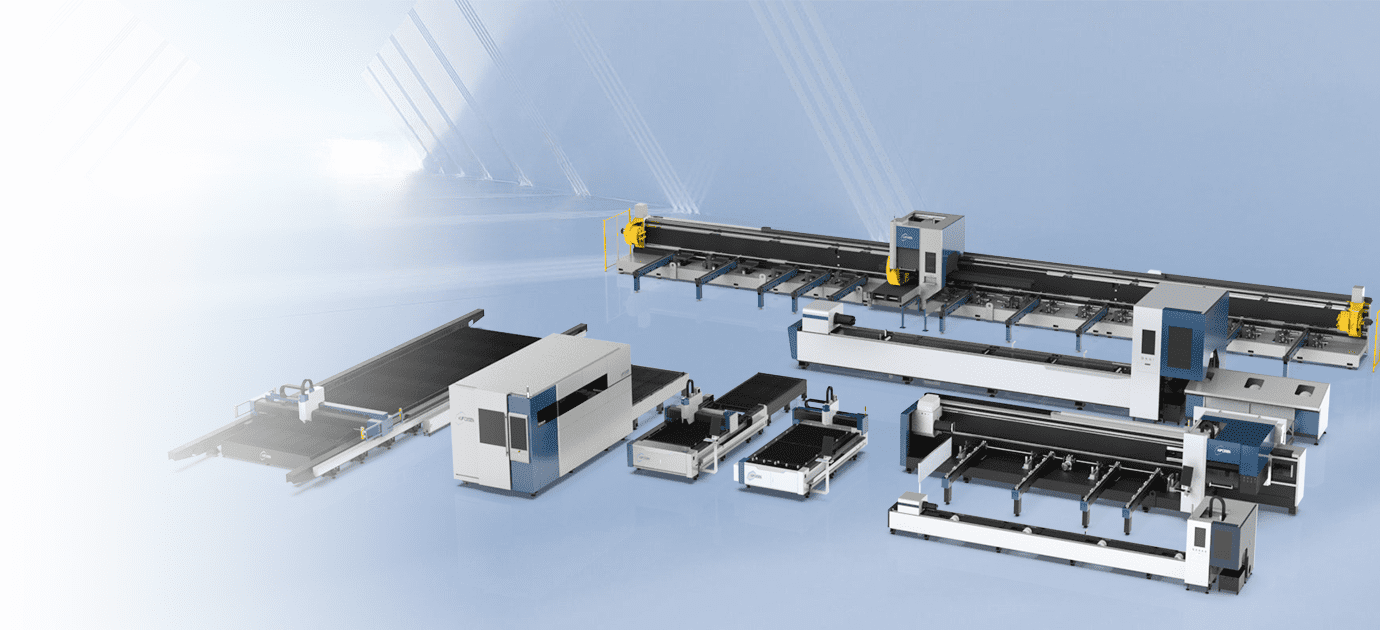

Laser cutting machines have revolutionized manufacturing and design, making it possible to execute intricate cuts and designs with unprecedented precision and speed. Laser cutting machine projects span across various industries, showcasing the versatility and efficiency of these advanced tools.

Laser cutting machine projects leverage the technology of high-powered lasers to cut through materials like metal, wood, plastic, and more. The precision and control offered by laser cutters make them ideal for a wide range of applications, from industrial manufacturing to artistic endeavors. Understanding the capabilities and applications of laser cutting machines can inspire new projects and improve existing processes.

Laser cutting machine projects are integral to the automotive industry. These machines are used to create precise and intricate components for vehicles, enhancing both performance and aesthetics.

– Component Manufacturing: Laser cutting is employed to produce parts such as engine components, brackets, and intricate interior panels. The precision of laser cutting ensures that each part meets exact specifications, reducing waste and improving efficiency.

– Prototyping and Customization: Automotive manufacturers use laser cutting for rapid prototyping and customization of parts. This capability allows for quick iterations and modifications during the design phase, accelerating the development process.

In the aerospace industry, laser cutting machine projects play a crucial role in producing high-precision parts that meet stringent quality standards.

– Aircraft Components: Laser cutting is used to fabricate components like wing structures, fuselage sections, and intricate brackets. The ability to cut with high precision ensures that parts fit perfectly, which is vital for maintaining the structural integrity and safety of aircraft.

– Weight Reduction: Laser cutting allows for the creation of complex, lightweight structures that help reduce the overall weight of the aircraft, leading to improved fuel efficiency and performance.

The medical industry benefits greatly from laser cutting machine projects, particularly in the production of surgical instruments and medical devices.

– Surgical Instruments: Precision is paramount in the production of surgical instruments. Laser cutting provides the accuracy needed to create fine, intricate tools that meet the high standards required for medical procedures.

– Implantable Devices: Laser cutting is used to manufacture components for implantable devices, such as stents and orthopedic implants. The precision of laser cutting ensures that these devices are made to exact specifications, improving patient outcomes.

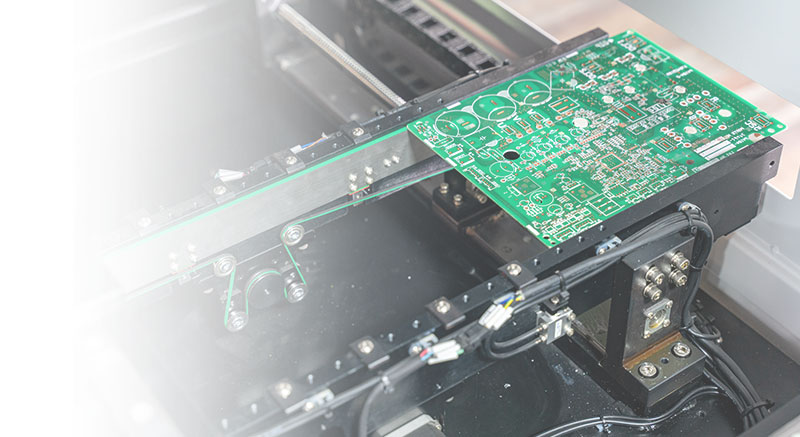

Laser cutting machine projects are also prevalent in the electronics industry, where precision and miniaturization are key.

– PCB Manufacturing: Laser cutting is used to create printed circuit boards (PCBs), ensuring that the intricate pathways and components are accurately placed. This precision is critical for the functionality of electronic devices.

– Component Housing: The casings and housings for electronic components are often cut using laser technology, providing clean and precise cuts that enhance the overall design and functionality of electronic products.

Beyond industrial uses, laser cutting machine projects have opened new possibilities in the world of art and design.

– Custom Artwork: Artists and designers use laser cutting to create detailed and intricate designs on various materials, including wood, acrylic, and metal. This technology allows for the creation of unique and customized art pieces that would be challenging to achieve by hand.

– Jewelry Making: Laser cutting is employed in the jewelry industry to produce intricate designs and patterns. The precision of laser cutting allows for the creation of fine details, enhancing the aesthetic appeal of jewelry pieces.

In architecture, laser cutting machine projects are used to create models, decorative elements, and structural components.

– Architectural Models: Laser cutting is used to produce detailed architectural models that help in visualizing designs and concepts. These models are essential tools for architects and designers in the planning and presentation stages.

– Decorative Elements: Laser cutting enables the creation of intricate decorative elements used in both interior and exterior architectural designs. These elements add a unique touch to buildings and spaces, enhancing their aesthetic appeal.

Laser cutting machine projects are widely used in the signage and advertising industry to create eye-catching and durable signs.

– Custom Signage: Businesses use laser cutting to produce custom signs that stand out. The precision of laser cutting allows for the creation of detailed logos, text, and graphics that attract attention and convey messages effectively.

– Point of Sale Displays: Laser cutting is used to create attractive and functional point of sale displays that help in showcasing products and attracting customers. These displays can be customized to fit specific branding and marketing needs.

In the fashion industry, laser cutting machine projects are utilized to create intricate patterns and designs on fabrics and other materials.

– Pattern Cutting: Laser cutting is used to cut patterns and designs on fabrics with high precision. This technology allows for the creation of complex and detailed patterns that enhance the aesthetic appeal of garments and accessories.

– Customization: Fashion designers use laser cutting to customize clothing and accessories, adding unique touches that set their products apart from the competition.

Understanding the technical aspects of laser cutting machine projects is essential for achieving optimal results.

Different types of lasers are used in cutting machines, including CO2 lasers, fiber lasers, and UV lasers. Each type has its advantages and is suited for specific materials and applications.

The choice of material affects the laser cutting process. Factors such as material thickness, reflectivity, and thermal conductivity must be considered to achieve clean and precise cuts.

Modern laser cutting machines are equipped with advanced software and automation capabilities, allowing for precise control and repeatability. These features enhance efficiency and reduce the likelihood of errors.

The future of laser cutting machine projects looks promising, with ongoing advancements in technology and applications.

Laser cutting machine projects have transformed various industries by providing a versatile, precise, and efficient means of cutting and shaping materials. From automotive and aerospace applications to artistic and creative endeavors, the capabilities of laser cutting machines are vast and continually expanding. As technology advances, the potential for new and innovative laser cutting machine projects will continue to grow, driving further improvements in manufacturing and design.