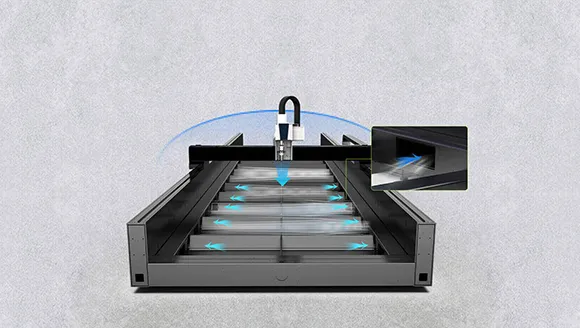

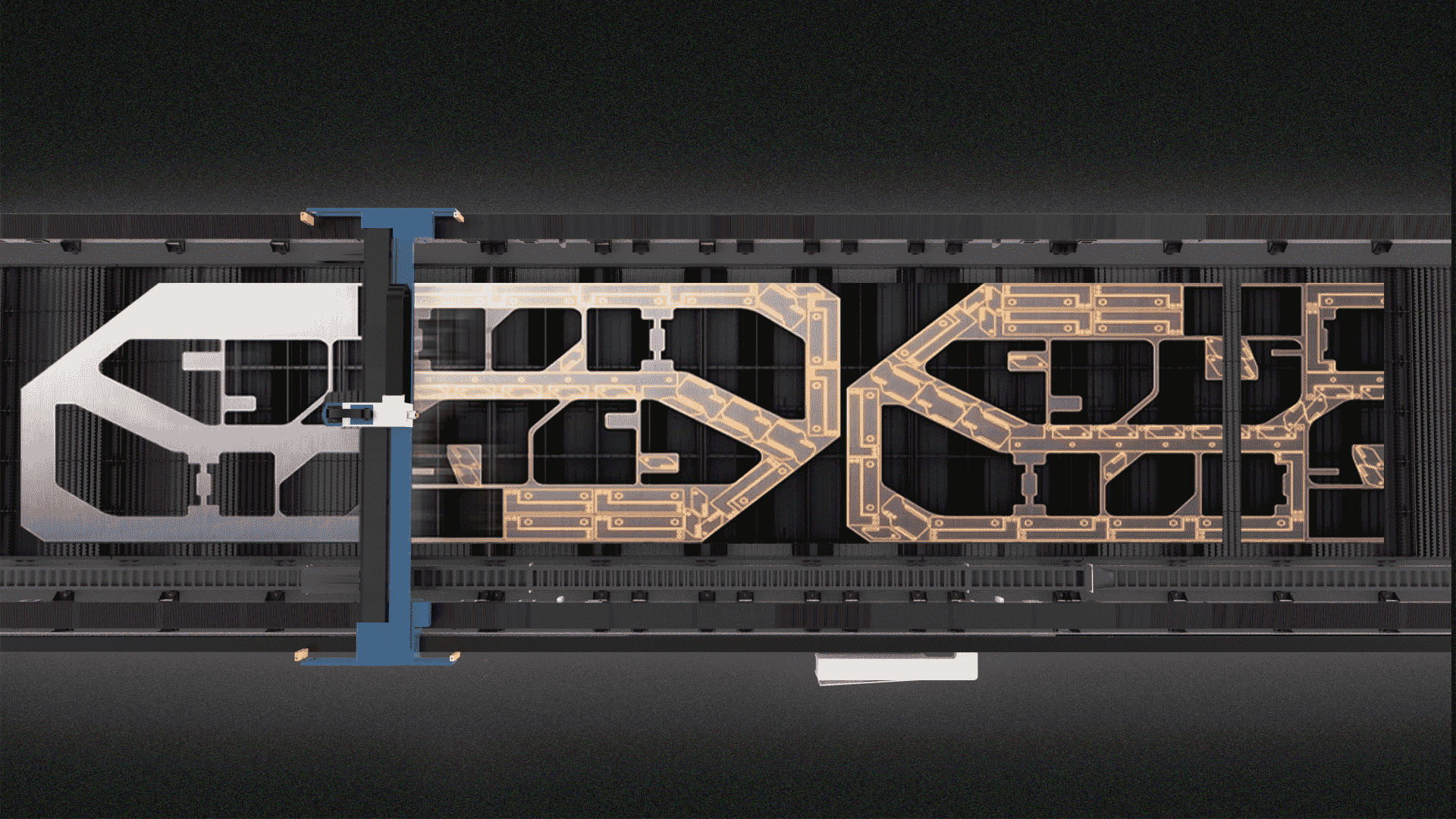

Model B is our single-platform open large-format cutting machine,

with a stable and sturdy bed design,which can meet the processing

needs of large workpieces.

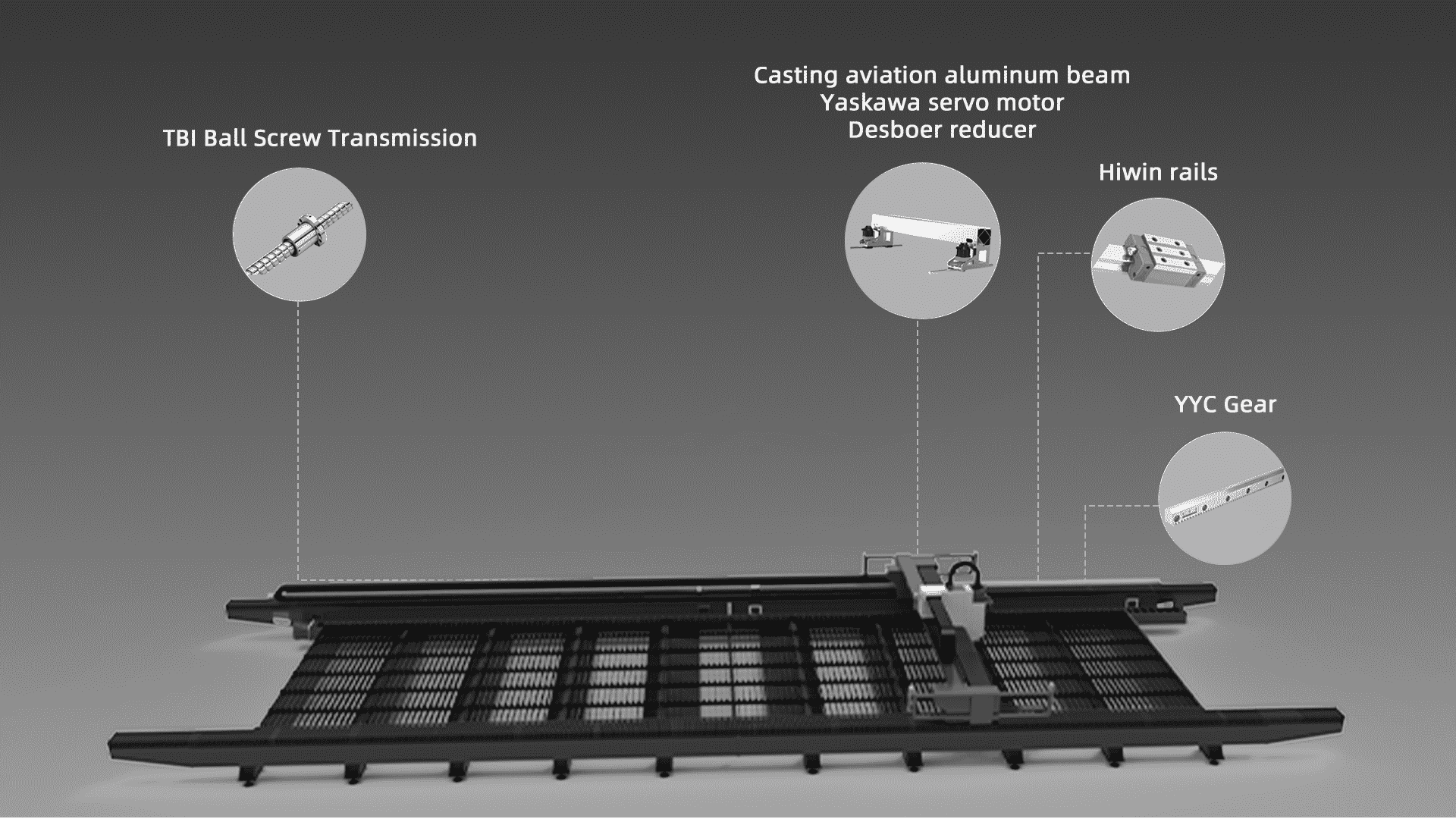

Using Japanese Yaskawa Electric, Japanese Fuji Electric or Inovance Motor, high precision, no step loss, high torque, low noise, using Taiwan yyc/Germany herion gear and Japanese shimpo/French motovario/Germany lead reducer, the machine positioning accuracy reaches 0.02 mm

1 set of B25 can be packaged in 2× 40HQ standard container. We can enable rush delivery and usually charge significantly reduced freights. After arrival, users may assemble all together by using quick insert. No waiting for new installation.

Machine Model | B20 seris | B25 series | B30 serie |

Working Area | 12000*2000mm | 12000*2500mm | 12000*3000mm |

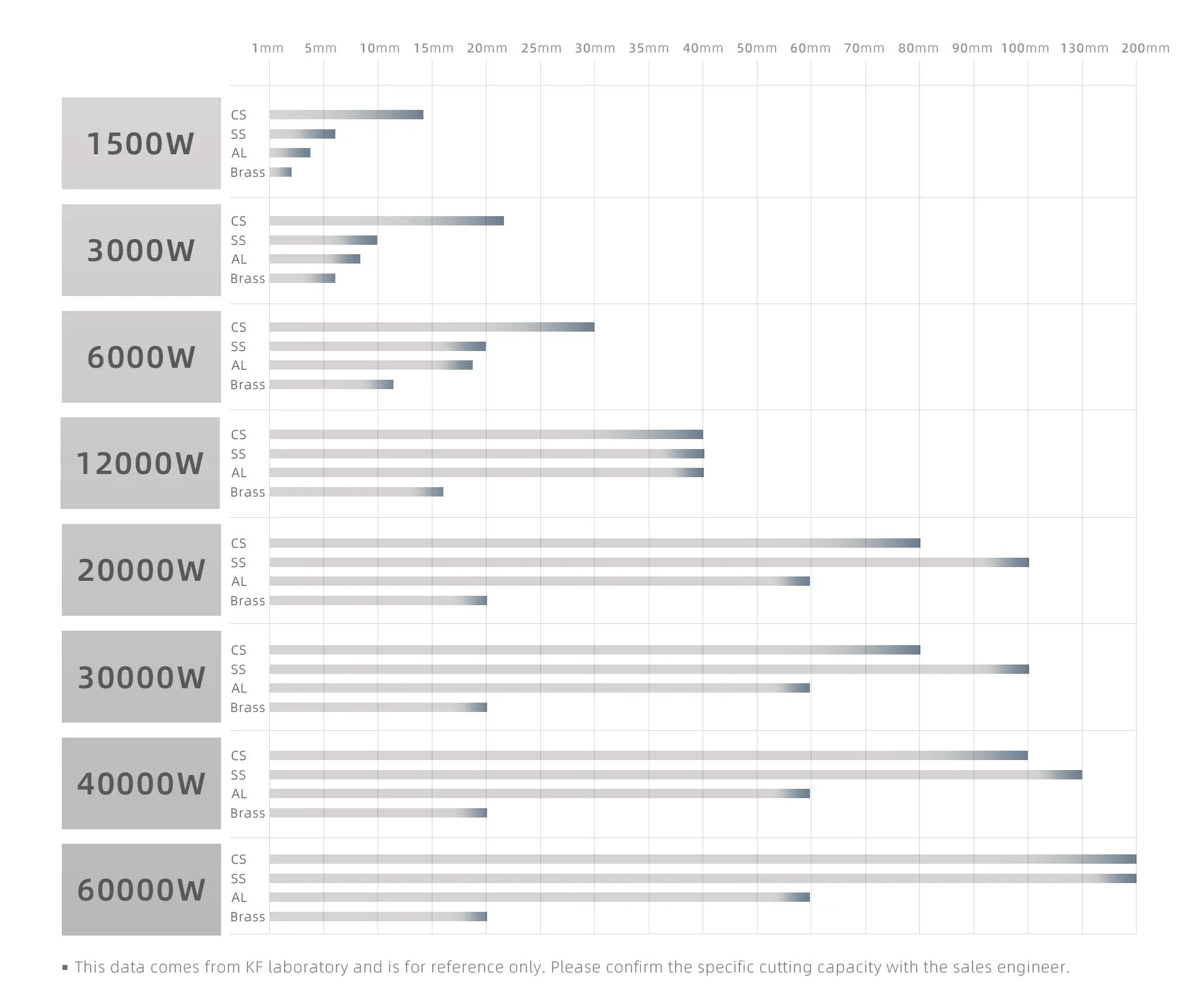

Laser Power | 1-12KW | 1-20KW | 1-20KW |

Dimension | 15500*3350*1975mm | 15500*3850*1975mm | 15500*4350*1975mm |

Weight | 15890KG | 17890KG | 19890KG |

|

|

|

|

Maximum Idle Running Speed(m/min) | 90m/min | ||

Maximum idle acceleration(G) | 1.0G | ||

X/Y axis positioning accuracy/mm | ±0.05mm | ||

Repeat positioning accuracy/mm | ±0.02mm | ||

Cutting accuracy/mm | ≤0.1mm | ||

Working Voltage | 380V,three-phase /50Hz-60Hz | ||

Supported image formats | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

A: In order to recommend you the most suitable machine model, just tell us below information

1)What is your material

2)The size of material

3)The thickness of material

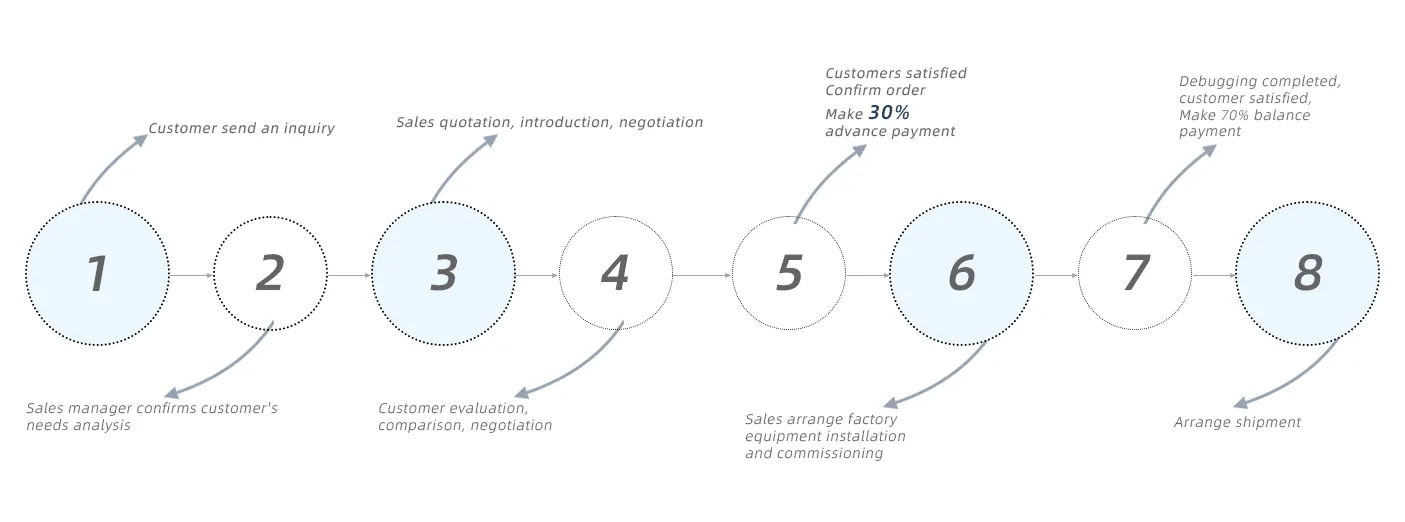

A:1)Alibaba trade assurance/TT/West Union/Payple/LC/Cash and so on.

2)We start making standardized machines after receiving 30% of the payment, inspect the machines after completion, and finally collect the 70% balance before shipping.

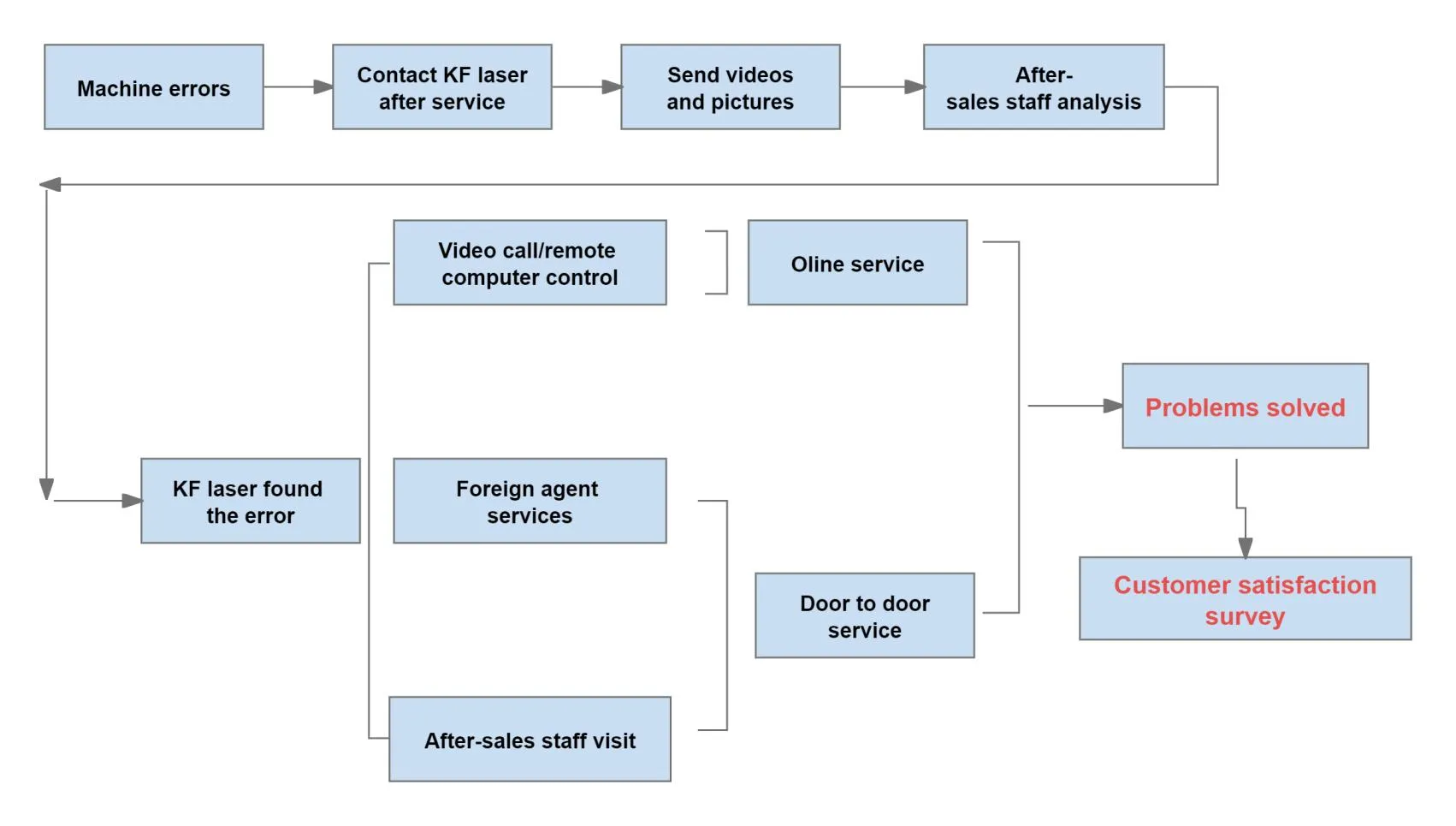

A:1)We provide free training in our factory

2)We provide free online after-sales service

3)We have complete installation instructions and video tutorials

4)Door-to-door service charges are based on region and aircraft model

5)Provide three-year warranty, except for consumable parts, direct replacement for non-human damage

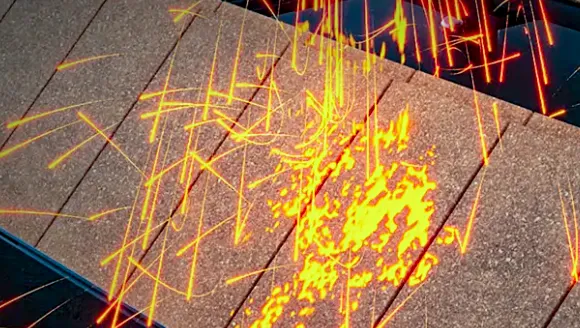

A laser sheet metal cutter is an advanced tool that uses a high-powered laser beam to cut through sheet metal with remarkable precision and speed. The sheet metal laser cutter machine operates by directing the laser beam through an optical path system, focusing it on the surface of the metal to melt or vaporize the material. This technology offers numerous advantages over traditional cutting methods, making it an essential asset in various industries.

Laser cutting for sheet metal involves using a focused laser beam to melt, burn, or vaporize the material. The laser beam is directed onto the metal surface, where it heats and melts the material, creating a precise cut. The process is controlled by computer numerical control (CNC) systems, which ensure high accuracy and repeatability.

Laser sheet metal cutters can handle a variety of metals, including steel, aluminum, brass, and copper. These machines are widely used in manufacturing due to their ability to produce complex shapes and designs with high precision.

Laser sheet metal cutters are used in numerous industries, including:

There are several types of laser cutters used in the industry:

When selecting a sheet metal laser cutter machine, several factors should be taken into account:

There are several techniques used in laser cutting, each suitable for different materials and requirements:

To achieve the best results with a laser sheet metal cutter, consider the following optimization tips:

While laser cutting is generally safe, it involves high-power lasers and potential hazards. Follow these safety guidelines to ensure a safe working environment:

The cost of a sheet metal laser cutter machine depends on several factors, including laser type, power, work table size, and material properties. Understanding these factors can help you choose a machine that fits your budget and cutting needs.

The field of laser sheet metal cutting is continually evolving, with new technologies and advancements improving efficiency, precision, and versatility. Some emerging trends include:

Laser sheet metal cutters offer numerous advantages, including high precision, speed, and versatility. By understanding the different types of lasers, their applications, and the factors to consider when choosing a machine, you can make an informed decision to optimize your cutting processes. Proper optimization and maintenance will ensure consistent high-quality results, making laser cutting an indispensable tool in modern manufacturing.