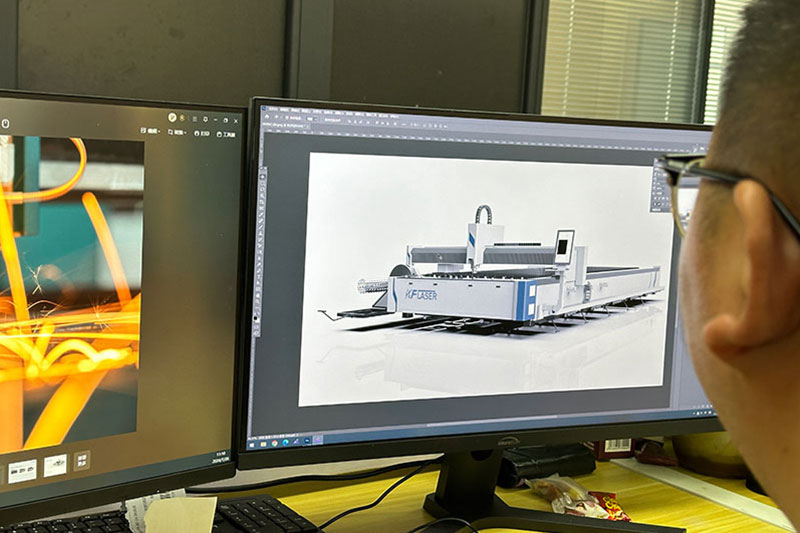

Determine the machine type and specifications, design the machine structure and control system.

manual grinding to reduce roughness.

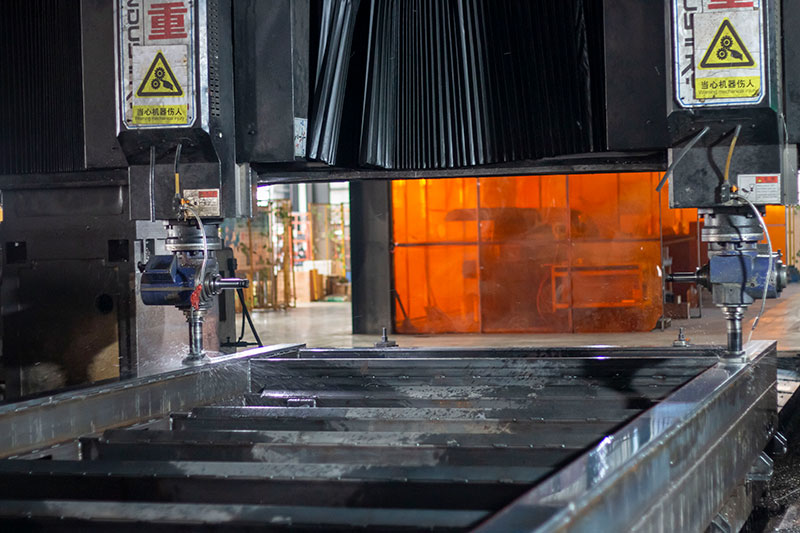

Precision Carbon Dioxide Shielded Welding.

ensuring the machine bed accuracy can reach 0.02mm/3m.

Tempered at 600 degrees Celsius Secondary high temperature tempering treatment.

artificially added anti-rust coating.

The whole bed is sprayed with plastic, which is rust-proof and moisture-proof, and prolongs the service life of the bed. The cost is more than ten times that of painting.

Experienced engineers are responsible for installation and commissioning.

Precision equipment is used for quality inspection to ensure equipment accuracy and operational stability.

Wrapped with waterproof membrane and loaded into container.