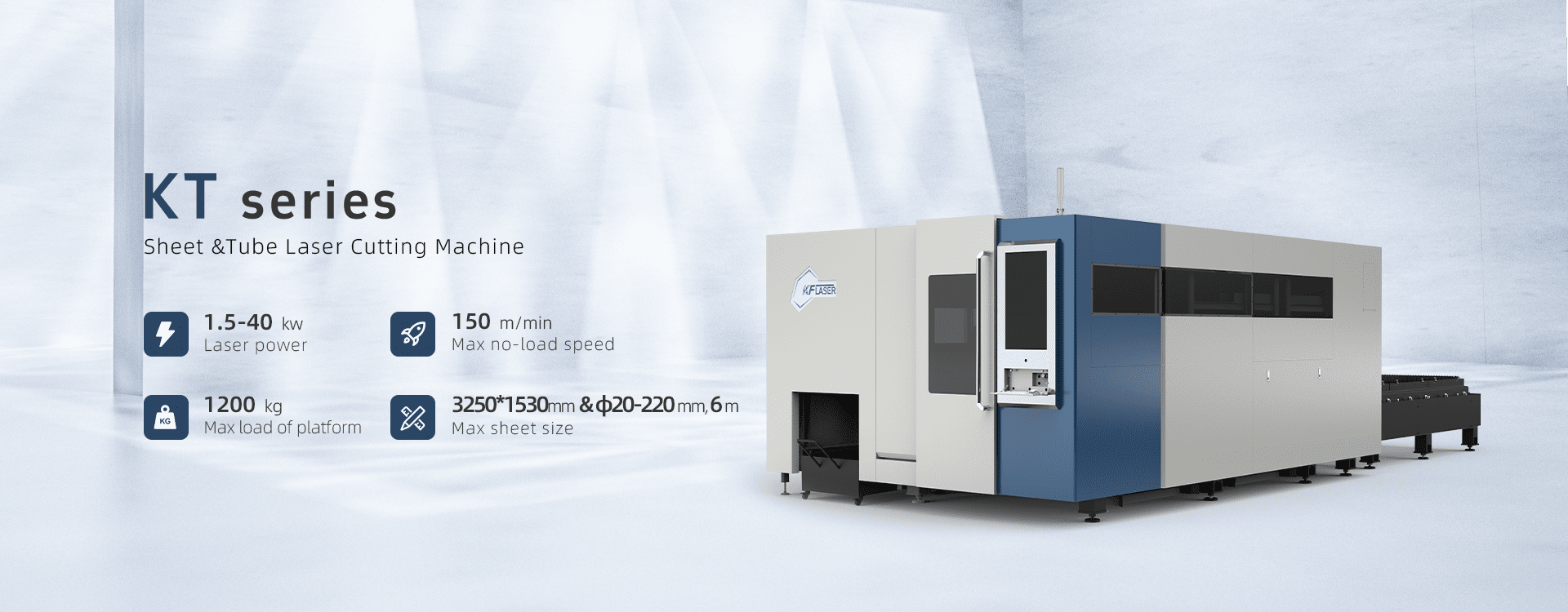

The KT series is a high-eficiency processing equipment that

integrates the plate and tube cutting functions.

It has an enclosed appearance and can achieve zero

pollution cutting with the purifier.

The bed frame is welded using thick square tubes and reinforced internally to enhance structural strength and tensile resistance.It undergoes high-temperature annealing and natural aging treatment to eliminate welding stress, prevent deformation, reduce vibrations, and ensure excellent cutting precision.

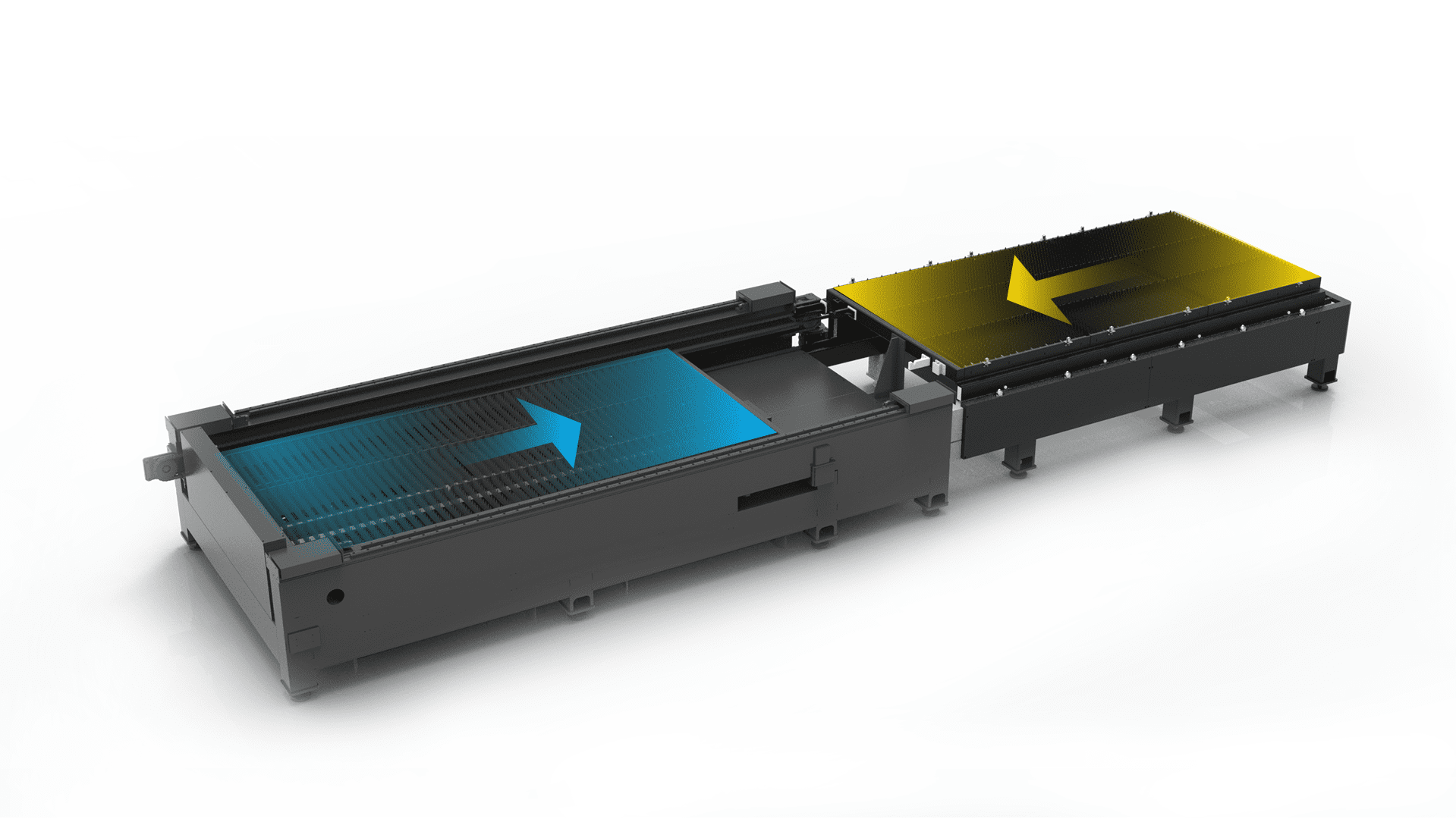

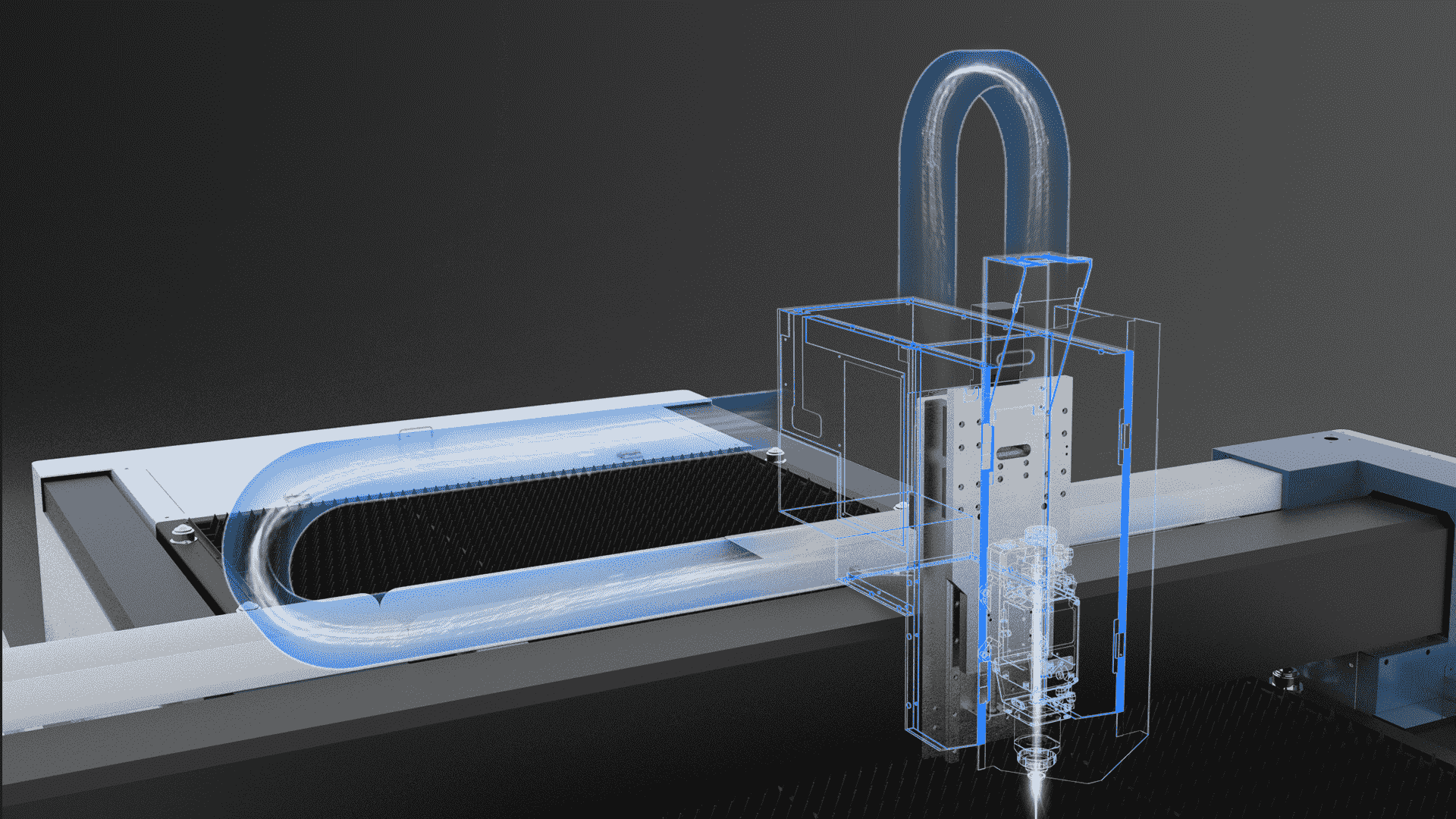

If you attach great importance to environmental protection, this machine is an ideal choice for your business. It has multiple automatic dust removal areas, and the air outlet automatically switches according to the position of the laser head, with precise dust removal, which can seamlessly and efficiently remove dust and smoke generated during the cutting process, meeting your needs for environmentally friendly production.

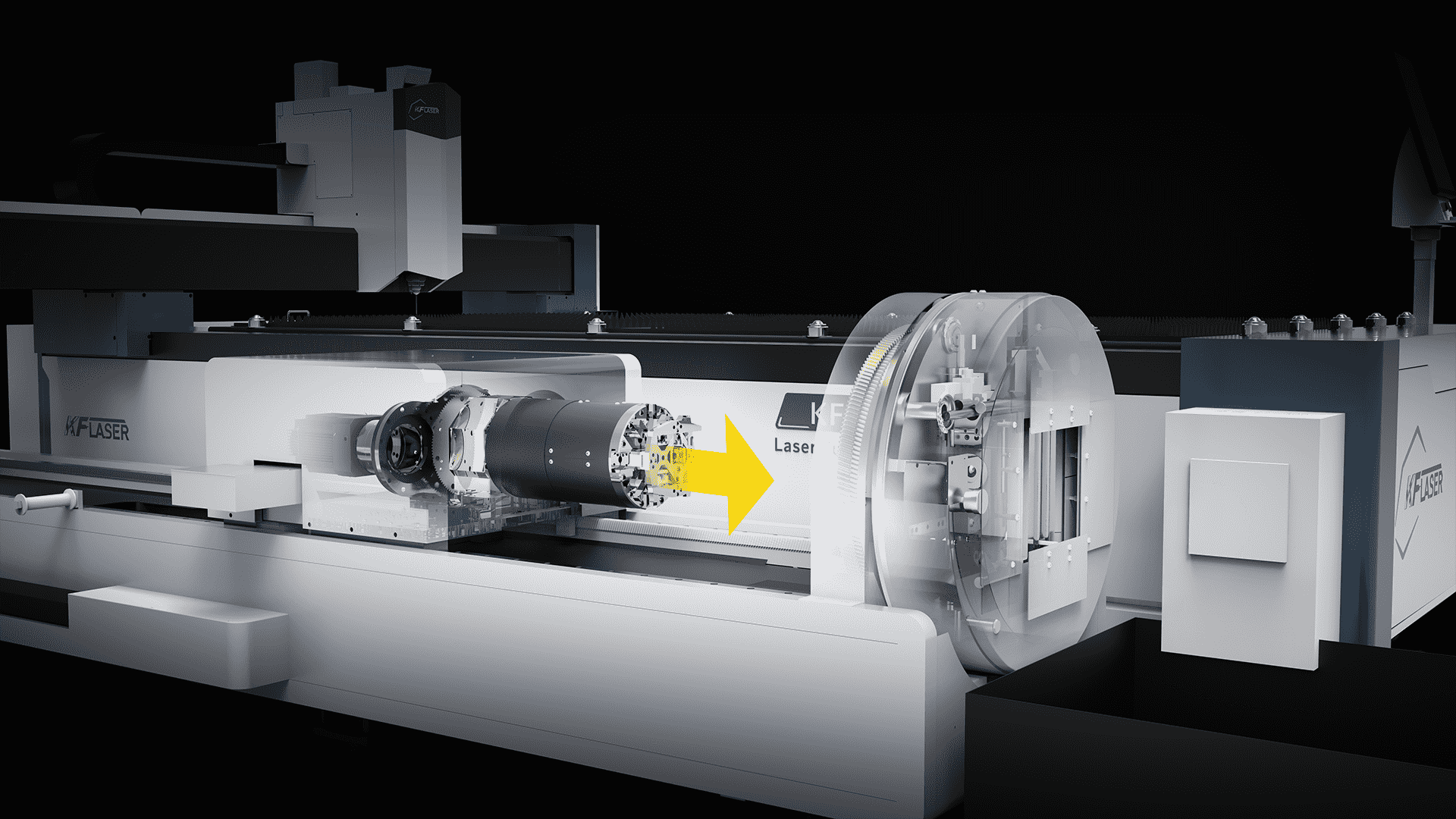

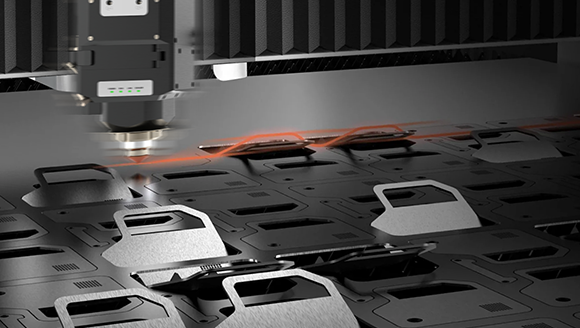

Boci BLT6 series high-power cutting head can achieve precise and stable cutting, meet complex needs and ensure high-quality cutting results. It includes an efficient water cooling system to extend the service life and stable operation. It adopts a multi-functional design with safety enhancement functions such as intelligent obstacle avoidance, collision protection, undervoltage alarm, closed-loop monitoring and intelligent perforation, which can automatically adjust cutting parameters for different materials.

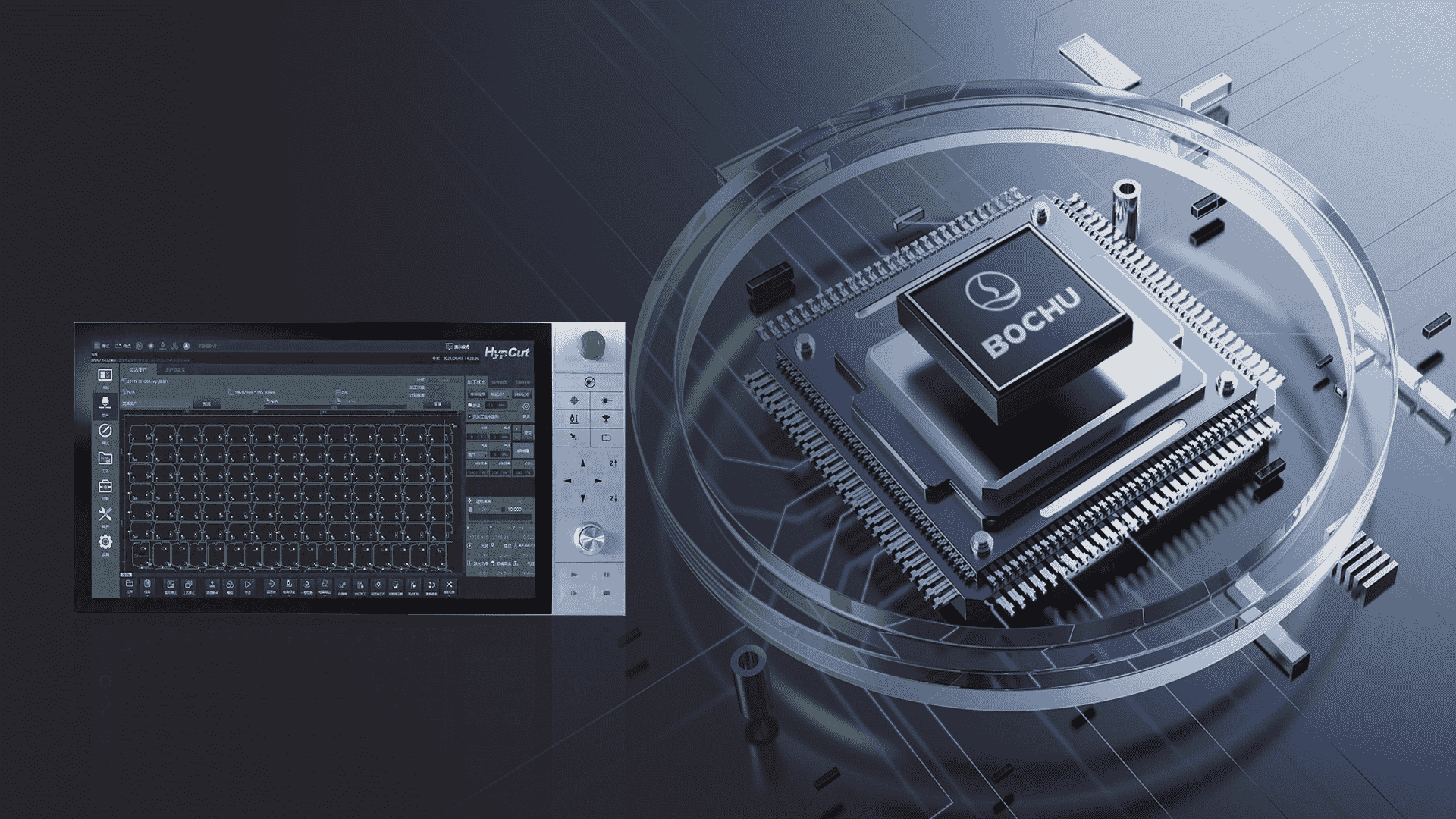

The Bochu advanced control system designed specifically for the plate-tube integrated laser cutting machine has multi-functional cutting support, high-precision motion control, user-friendly interface and real-time monitoring and adjustment capabilities. Its automation function and stability ensure efficient production and cutting quality, and it is suitable for all kinds of metal processing needs, and is an ideal choice for improving production efficiency and cutting accuracy.

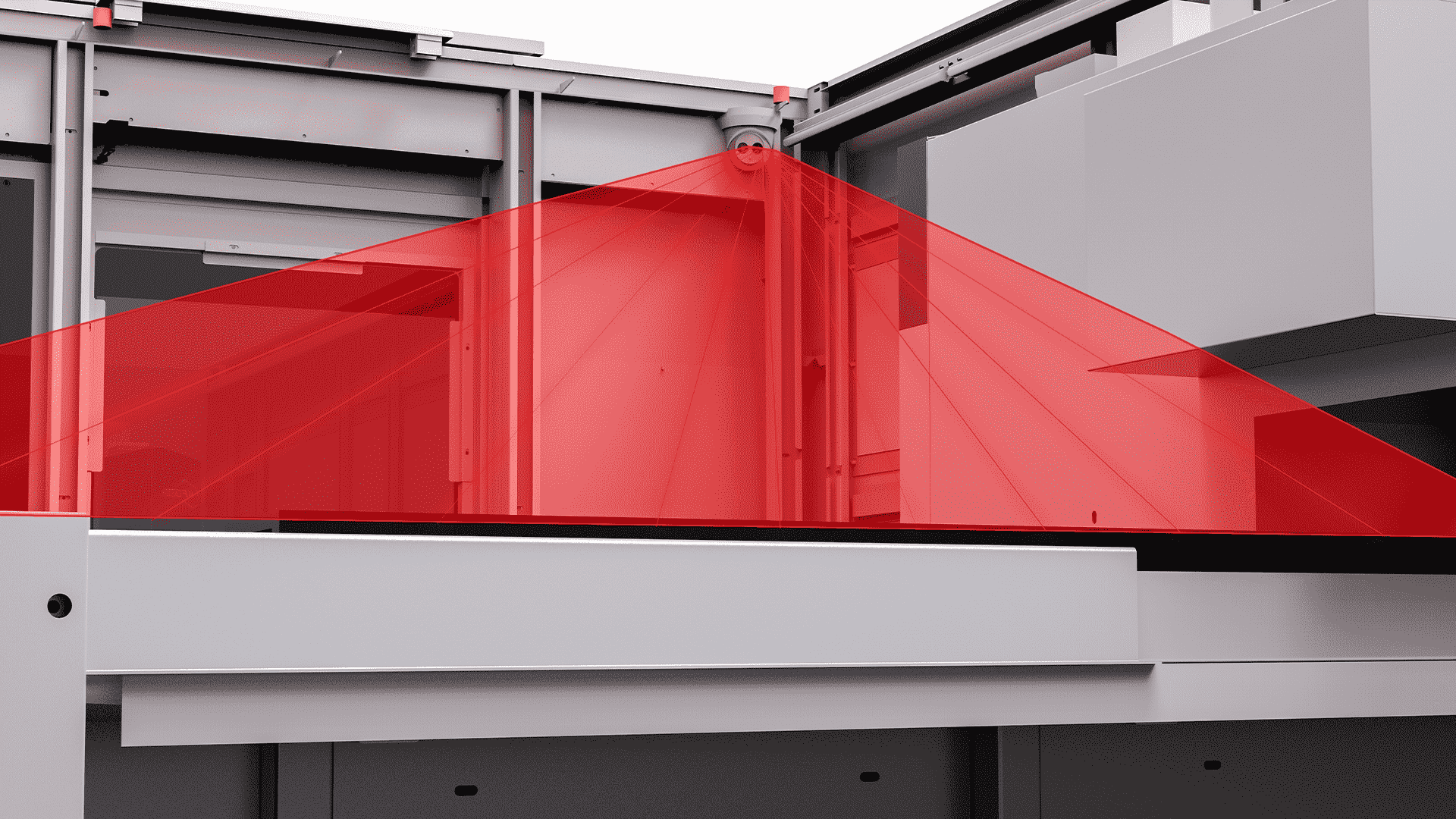

The machine is equipped with internal cameras, enabling real-time observation of its operations via the control panel.

Machine Model | KT3 series | KT4 series | KT6 series |

Working Area | 3050*1530mm | 4100*2050mm | 6100*2550mm |

Laser Power | 1-12KW | 1-20KW | 1-20KW |

Dimension | 8800*4500*2180mm | 10800*5000*2180mm | 14800*5500*2180mm |

Processing pipe size | 6m Φ20-220mm / □20-220 | ||

Weight | 8500KG | 15000KG | 19000KG |

Maximum Idle Running Speed(m/min) | 100m/min-120m/min | ||

Maximum idle acceleration(G) | 1.0G/ 1.2G/ 1.5G | ||

X/Y axis positioning accuracy/mm | ±0.05mm | ||

Repeat positioning accuracy/mm | ±0.03mm | ||

Cutting accuracy/mm | ≤0.1mm | ||

Working Voltage | 380V,three-phase /50Hz-60Hz | ||

Supported image formats | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

A: In order to recommend you the most suitable machine model, just tell us below information

1)What is your material

2)The size of material

3)The thickness of material

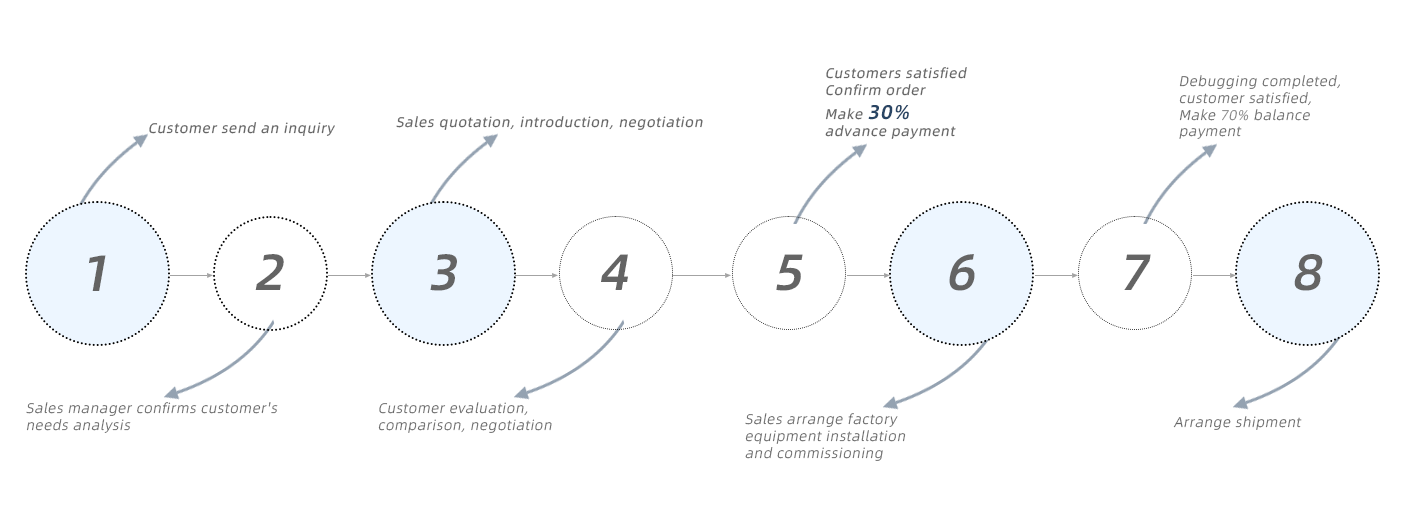

A:1)Alibaba trade assurance/TT/West Union/Payple/LC/Cash and so on.

2)We start making standardized machines after receiving 30% of the payment, inspect the machines after completion, and finally collect the 70% balance before shipping.

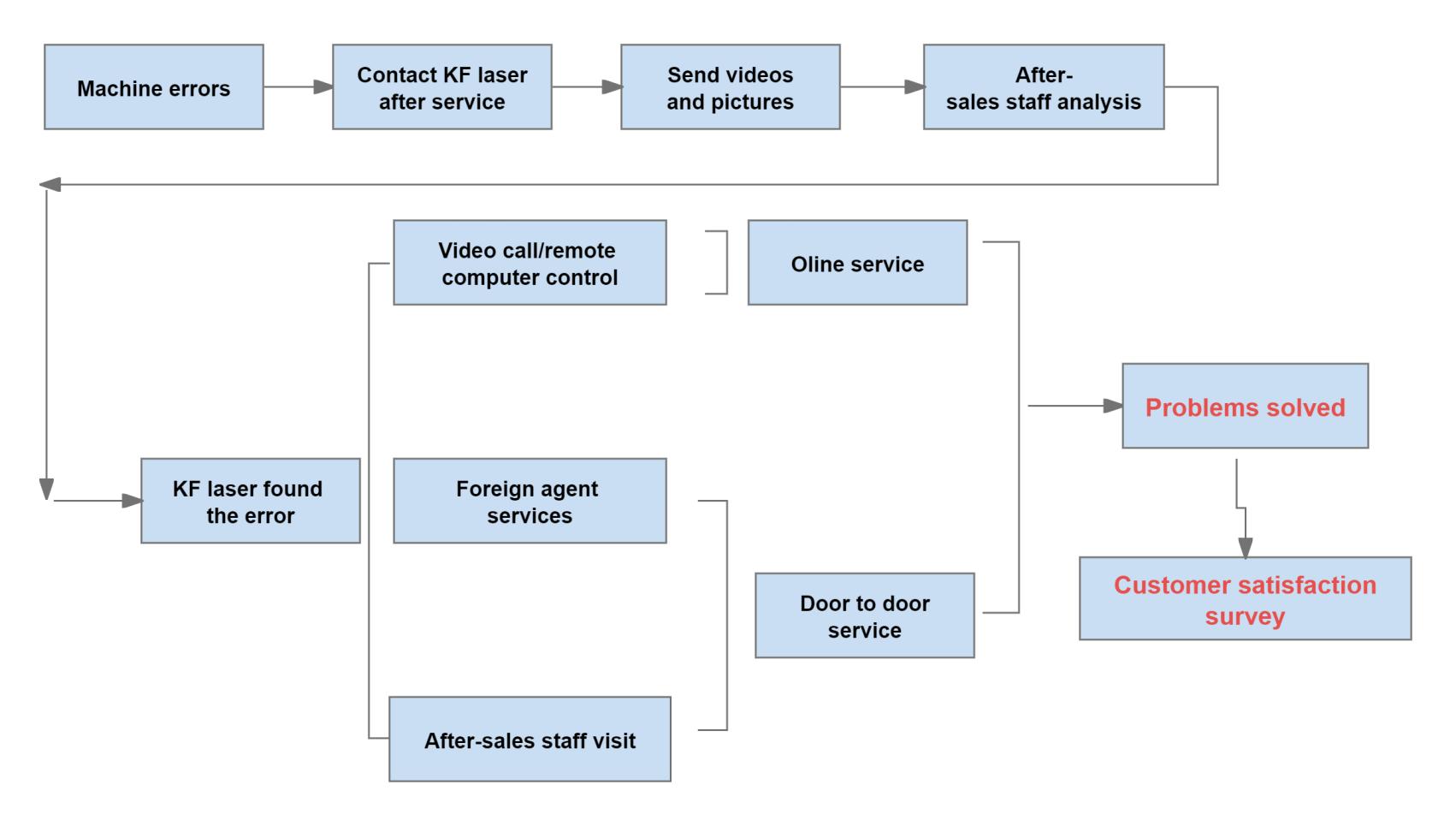

A:1)We provide free training in our factory

2)We provide free online after-sales service

3)We have complete installation instructions and video tutorials

4)Door-to-door service charges are based on region and aircraft model

5)Provide three-year warranty, except for consumable parts, direct replacement for non-human damage

Metal Laser Cutter for Sale: A Comprehensive Guide

When it comes to purchasing a metal laser cutter for sale, there are many factors to consider to ensure you get the best machine for your needs. Whether you are a small business, a large industrial operation, or a hobbyist, understanding the types of laser cutters, their costs, and their benefits can help you make an informed decision.

Laser cutting machines come in several varieties based on the type of laser used. Here are the four major types of lasers commonly found in metal laser cutting machines:

- CO2 (Carbon Dioxide) lasers are the most traditional type and consist of a gas mixture in a glass tube. When electricity flows through the gas mixture, it excites the molecules, producing a laser beam.

- These lasers are suitable for cutting metals and non-metals but struggle with reflective materials like brass and copper.

- Neodymium-doped Yttrium Aluminum Garnet (Nd: YAG) lasers use a crystal as the laser medium. They are less common for industrial cutting but are used in some medical and cosmetic applications.

- Fiber lasers use a fiber optic cable to amplify the laser beam. They are highly efficient and suitable for cutting a wide range of metals, including reflective ones like aluminum and copper.

- Diode lasers are compact and energy-efficient but are generally not powerful enough for cutting thick metals. They are mostly used for engraving and cutting thin materials.

When selecting a metal laser cutter for sale, consider the following factors:

- Ensure the laser cutter can handle the types of materials you need to cut. CO2 lasers are versatile but may struggle with reflective metals, while fiber lasers are more suitable for a variety of metals, including stainless steel and aluminum.

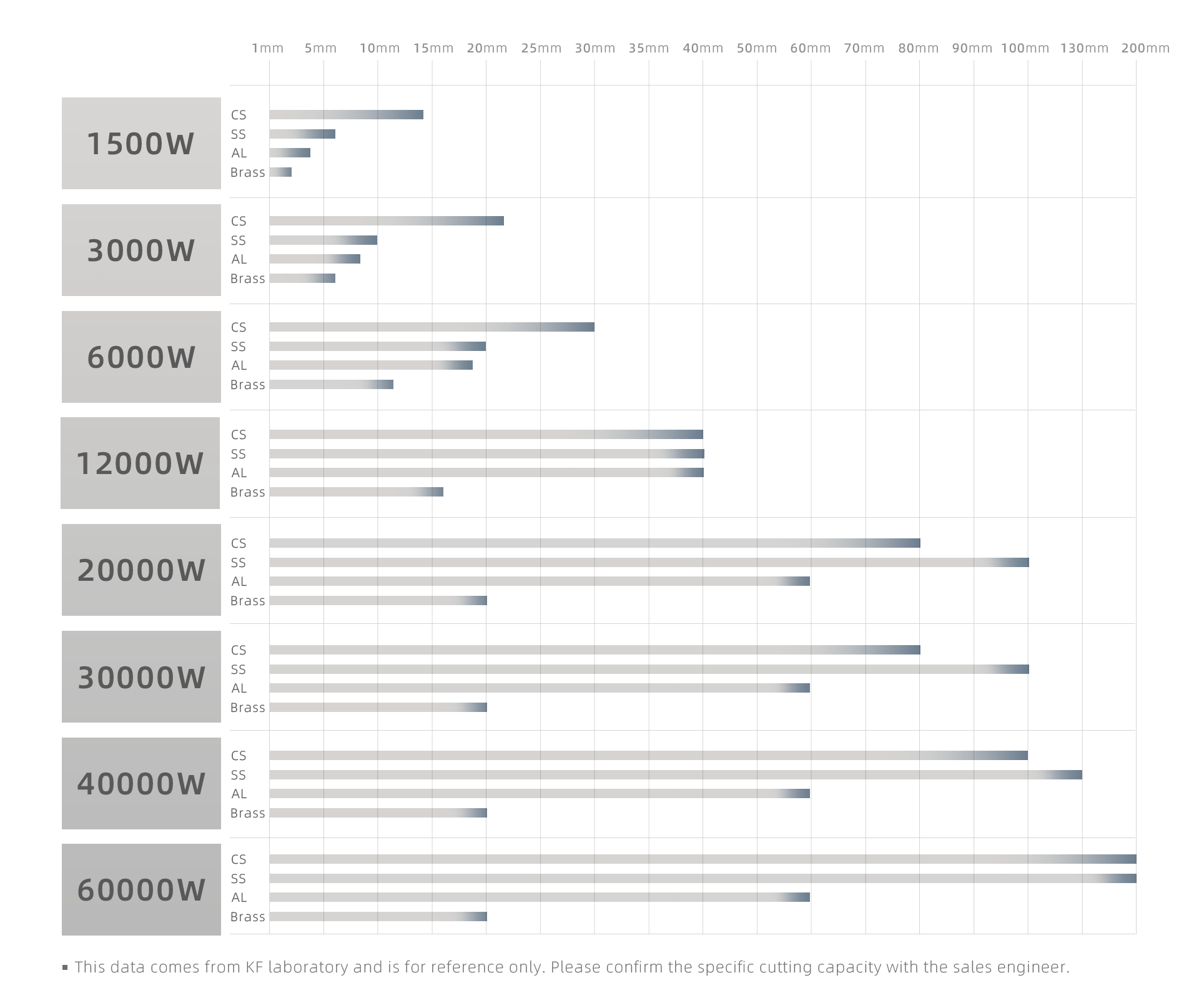

- The power of the laser affects its ability to cut through different thicknesses of metal. Higher power lasers can cut thicker materials but are more expensive.

- Consider the size of the laser cutter and ensure it fits within your workspace. Larger machines can handle bigger sheets of metal but require more space.

- Assess the long-term costs, including power consumption, maintenance, and potential downtime. Fiber lasers are generally more energy-efficient than CO2 lasers.

The cost of a metal laser cutter for sale varies widely depending on the type, power, and features. Here is a general price breakdown:

- Diode laser cutters start at around $500 but are typically not suitable for cutting metals.

- Beginner-friendly CO2 metal laser cutters range from $2,000 to $3,000.

- Entry-level fiber laser cutters start at approximately $15,000. These machines may struggle with thicker metals but are suitable for most small to medium-sized operations.

- Professional CO2 laser cutters range from $30,000 to $100,000.

- High-end fiber laser cutters can cost upwards of $200,000, with specialized models and robotic arm-assisted cutters exceeding this amount.

Purchasing a metal laser cutter for sale offers several advantages:

- Laser cutters provide highly precise cuts, reducing the need for secondary finishing processes.

- Laser cutting is faster than traditional methods, enhancing productivity.

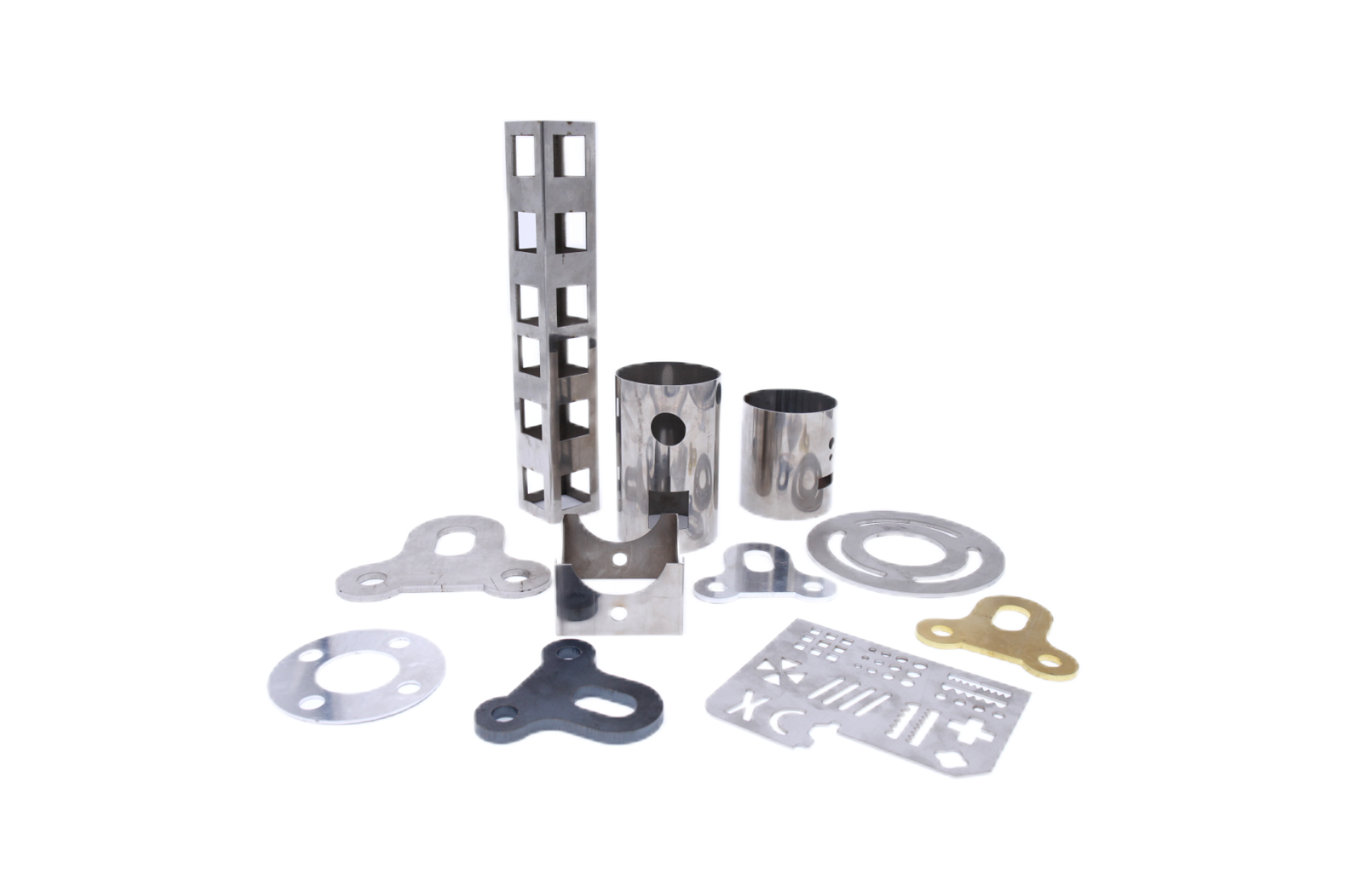

- Laser cutters can handle a wide range of materials and thicknesses, making them suitable for various applications.

- Owning a laser cutter can reduce reliance on external cutting services, lowering production costs over time.

Here are some essential tips to consider when purchasing a metal laser cutter for sale:

- Determine the specific materials and thicknesses you need to cut to choose the right type of laser cutter.

- Account for ongoing operational costs, such as power consumption and maintenance, in your budget.

- Ensure the seller offers reliable customer support, training, and availability of replacement parts.

- Consider the machine's cutting speed and bed size to ensure it meets your production requirements.

The laser cutting industry continues to evolve, with new technologies and advancements improving efficiency and capabilities. Here are some trends to watch:

- Integration with automation systems and robotics will enhance precision and reduce manual labor.

- Advances in software will simplify the optimization of cutting parameters, improving overall efficiency.

- Development of higher power lasers will allow for faster cutting of thicker materials.

- There will be a growing focus on developing environmentally friendly laser cutting technologies to reduce energy consumption and waste.

Investing in a metal laser cutter for sale can significantly benefit your business by providing high precision, efficiency, and versatility in cutting various materials. By understanding the different types of lasers, their costs, and their applications, you can make an informed decision that meets your specific needs and budget. Ensure to evaluate long-term costs and after-sales support to maximize the return on your investment.