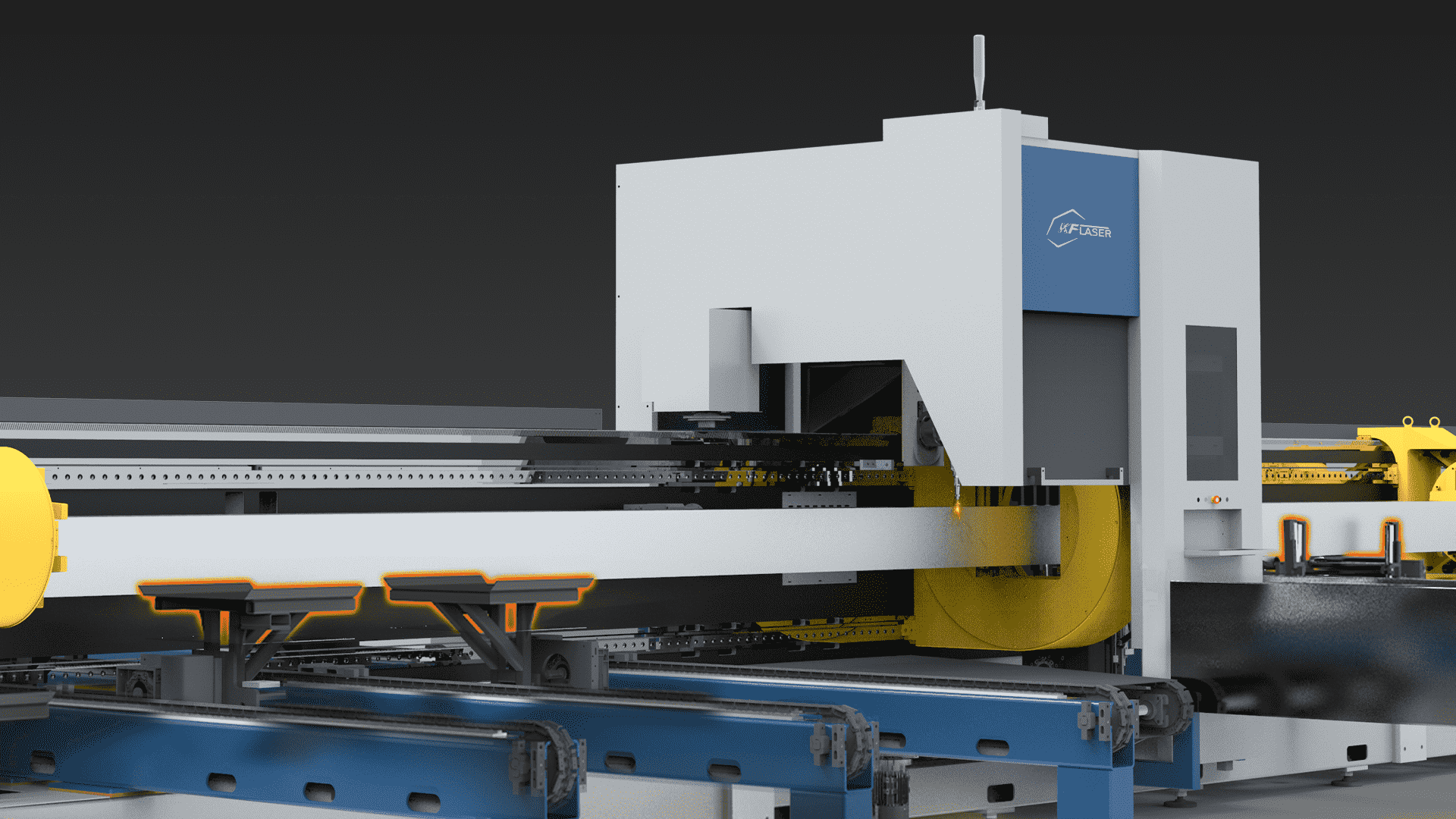

1. Dual-drive high-precision servo motor, gear rack transmission structure

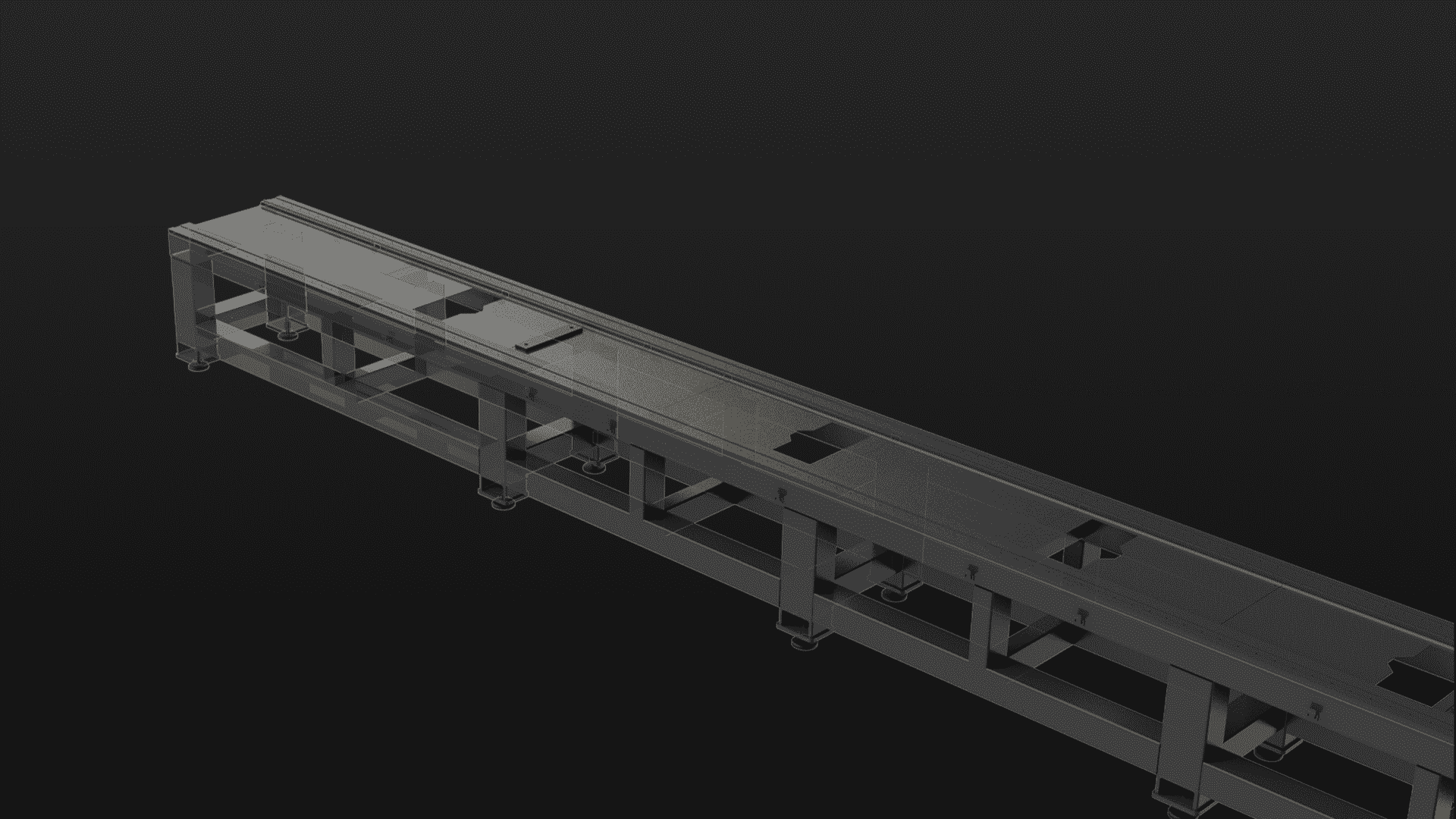

2. Heavy-duty sheet metal welding bed, long-term use accuracy and speed are not affected

3. Aviation aluminum beam, lightweight while ensuring high-speed movement

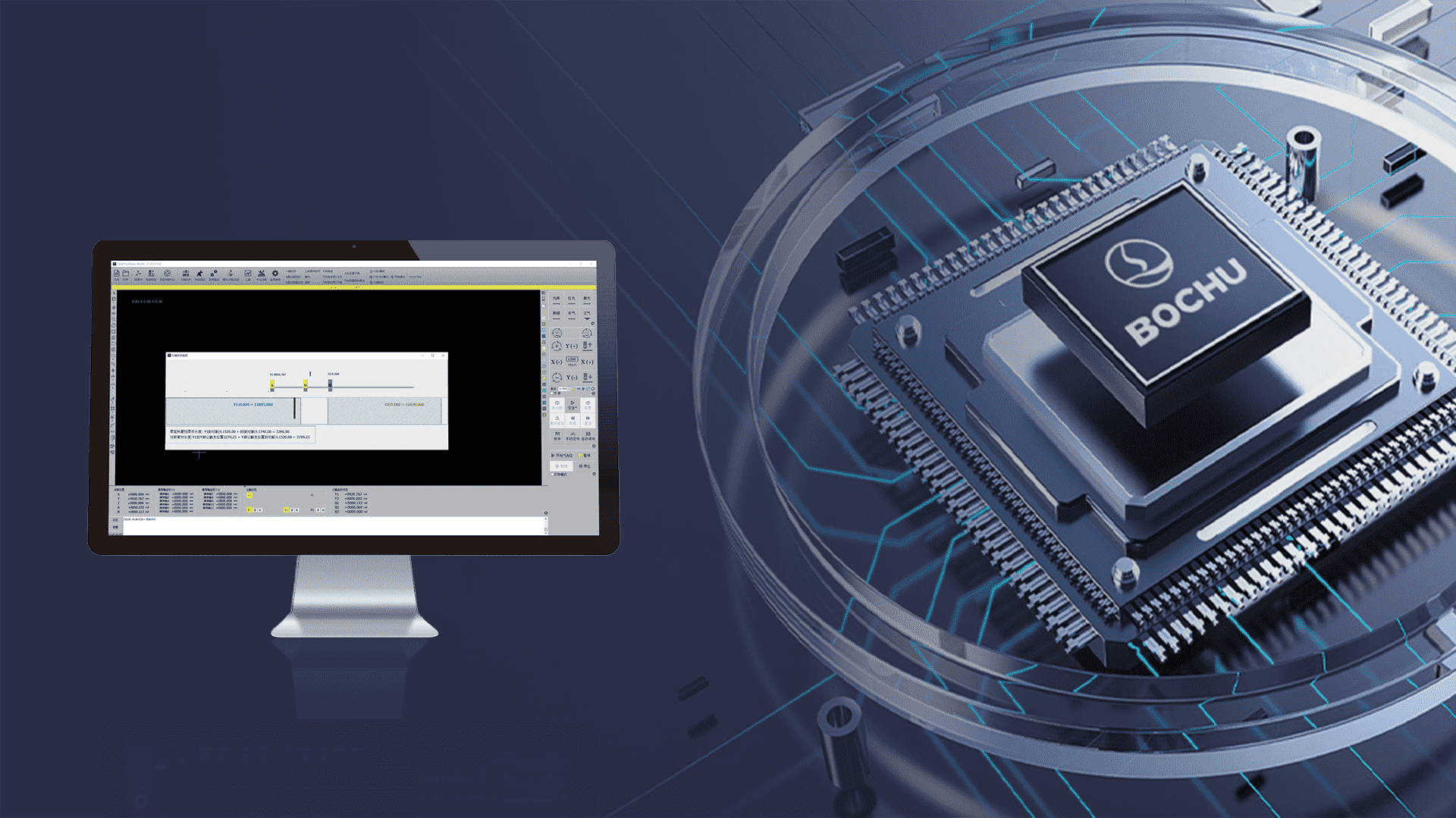

4. Convenient and reliable operating system

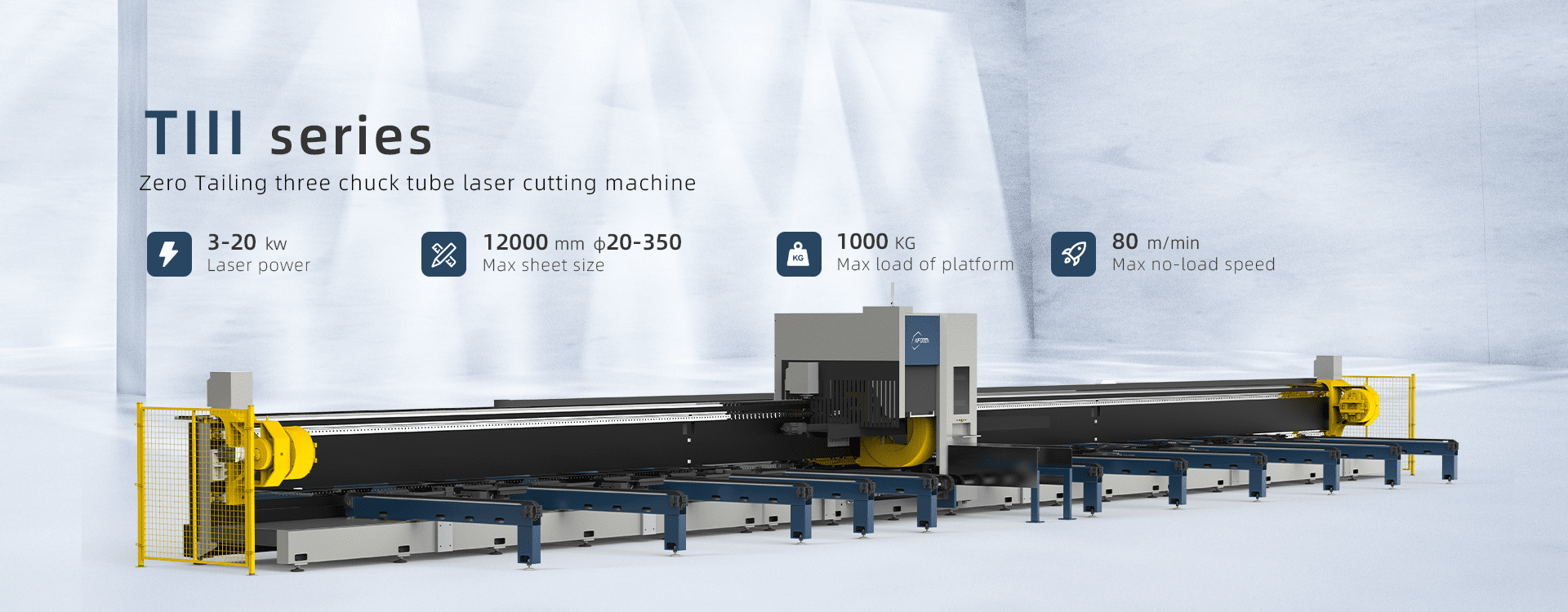

| Model | TIII-3 | TII1-5 |

| Maximum processing length | 6000mm | |

| Unloading length | 3000mm | |

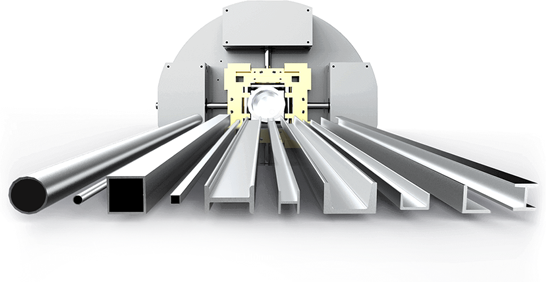

| Power support | φ10-220mm □10-220mm | |

| Processing pipe size | φ20-350mm □20-350mm | φ20-500mm □20-360mm |

| Dimension(L*w*H) | 17500*2800*2800mm | 17500*2800*3300mm |

| Chuck weighing | 1000kg | 1500kg |

| Chuck rotation speed | 100r/min | 60r/min |

| Maximum ldle Running speed | 75m/min | 60r/min |

| Maximum idle acceleration | 0.8G | 0.6G |

| Positioning accuracy | ±0.03mm | ±0.03mm |

| Repeat positioning accuracy | ±0.02mm | ±0.02mm |

| Support device | Follow-up | Follow-up |

| Feeding device (optional) | Semi-automatic | Semi-automatic |

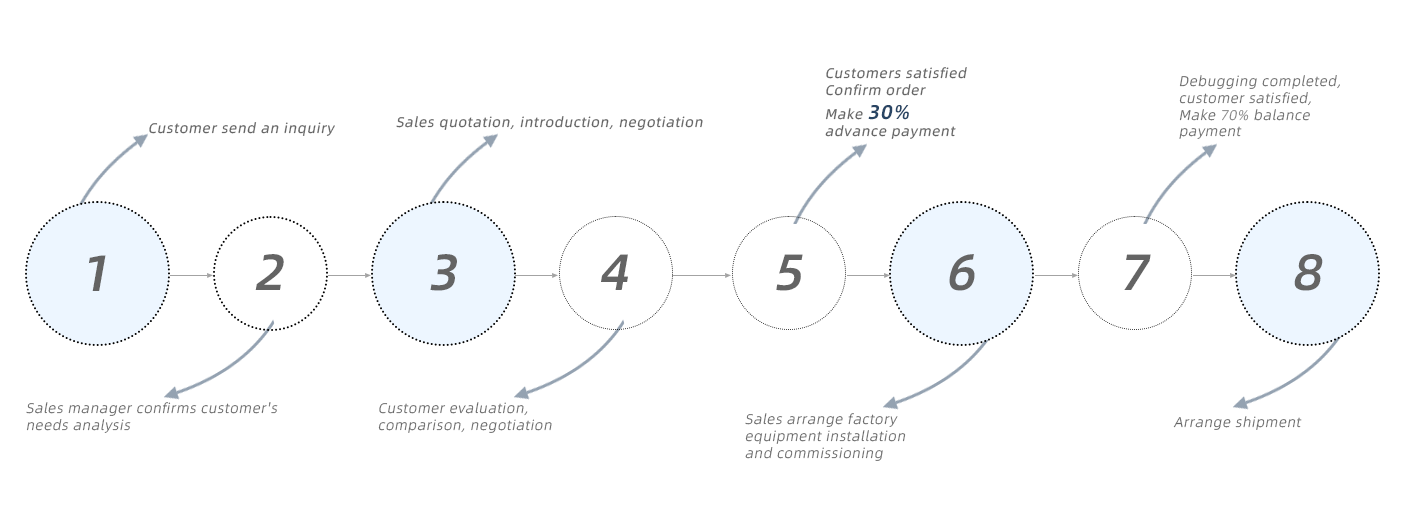

A: In order to recommend you the most suitable machine model, just tell us below information

1)What is your material

2)The size of material

3)The thickness of material

4)Fiber laser cutter for metal(industrial laser cutter)

A:1)Alibaba trade assurance/TT/West Union/Payple/LC/Cash and so on.

2)We start making standardized machines after receiving 30% of the payment, inspect the machines after completion, and finally collect the 70% balance before shipping.(industrial laser cutter)

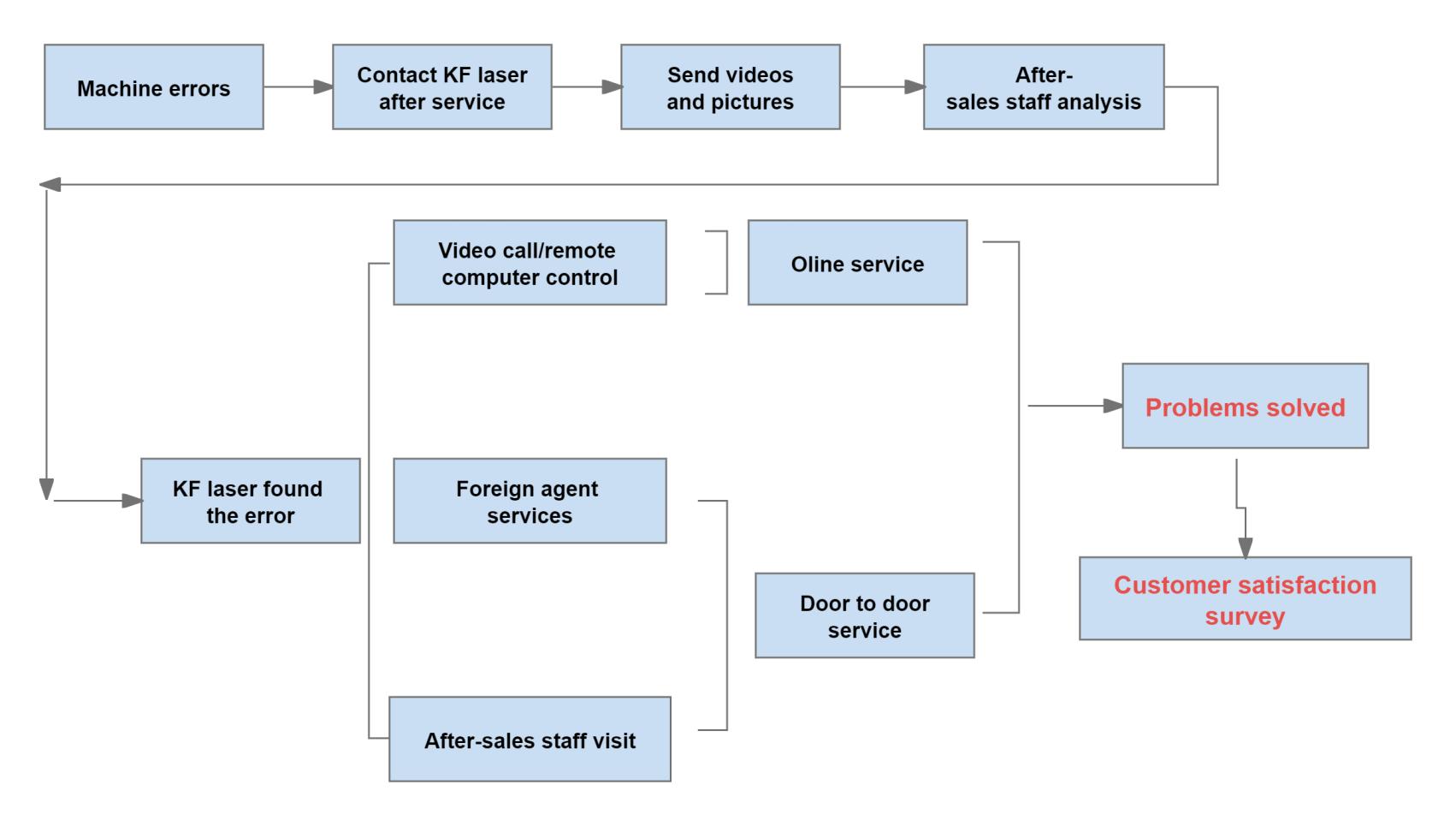

A:1)We provide free training in our factory

2)We provide free online after-sales service

3)We have complete installation instructions and video tutorials

4)Door-to-door service charges are based on region and aircraft model

5)Provide three-year warranty, except for consumable parts, direct replacement for non-human damage(industrial laser cutter)

1):Clean the optical lens: Clean the optical lens regularly to maintain the beam quality.

2):Check the gas supply: Make sure the gas supply system is normal to prevent the cutting quality from being affected.

3):Lubricate the moving parts: Lubricate the guide rails and lead screw regularly to ensure the smooth operation of the moving parts.

4):Replace the chiller’s purified water every month. If it’s below zero in winter, remember to add antifreeze.(industrial laser cutter)

The world of CNC laser cutters has revolutionized metal cutting, offering unmatched precision, efficiency, and versatility. CNC laser cutters are integral in various industries, from automotive to aerospace, and provide precise cuts for complex designs. This guide will delve into the types, applications, benefits, and considerations for choosing the best CNC laser cutter, particularly focusing on CNC laser cutter, CNC laser cutter for metal, and CNC metal laser cutter.

A CNC laser cutter is a computer-controlled machine that uses a laser beam to cut, engrave, or mark materials with high precision. CNC stands for Computer Numerical Control, indicating that the cutting process is automated and programmed through software. This technology allows for intricate designs and detailed cuts, making it ideal for various applications.

- CNC laser cutter for metal applications often use fiber lasers.

- These lasers have a wavelength of 1.06 micrometers, making them highly effective for cutting metals like stainless steel, aluminum, brass, and copper.

- Fiber lasers offer high efficiency, fast cutting speeds, and low maintenance.

- These lasers operate at a wavelength of 10.6 micrometers.

- While versatile and capable of cutting non-metal materials like wood, acrylic, and plastics, they are less efficient for metals compared to fiber lasers.

- CO2 lasers are suitable for thinner metal sheets but require more maintenance.

- These solid-state lasers are effective for both metal and non-metal materials.

- They offer high precision and are often used for detailed engraving and marking.

- Utilized for high-speed cutting of thin metal sheets.

- These lasers are compact, efficient, and offer a robust construction with lower maintenance needs.

The CNC laser cutter for metal is widely used in various industries due to its precision and efficiency. Here are some key applications:

1. Automotive Industry:

- Used for cutting intricate parts and components.

- Ensures high precision in metal sheets and detailed engravings.

2. Aerospace Industry:

- Essential for cutting high-strength materials used in aircraft construction.

- Provides precise cuts needed for complex aerospace components.

3. Electronics Industry:

- Used for producing small, precise components for electronic devices.

- Ideal for cutting circuit boards and engraving detailed patterns.

4. Jewelry Making:

- Enables cutting and engraving of precious metals with high precision.

- Used for creating intricate jewelry designs and custom pieces.

5. Architectural Models:

- Used for cutting detailed models and prototypes.

- Allows for precise cutting of materials like acrylic, wood, and metal.

The CNC metal laser cutter offers numerous advantages that make it an indispensable tool for various applications:

1. High Precision and Accuracy:

- Provides clean and detailed cuts with minimal errors.

- Essential for industries requiring exact measurements and intricate details.

2. Efficiency and Speed:

- Laser cutting is a fast process, reducing production time.

- High-speed cutting leads to quicker turnaround times and higher productivity.

3. Versatility:

- Capable of cutting a wide range of materials, including metals and non-metals.

- Suitable for various applications from industrial manufacturing to creative projects.

4. Minimal Waste:

- High precision ensures minimal material wastage.

- Optimizes material usage, reducing costs and environmental impact.

5. Non-Contact Cutting:

- Laser cutting is a non-contact process, minimizing the risk of damaging materials.

- Ideal for cutting delicate or thin materials without physical contact.

When selecting the best CNC laser cutter for metal, several features should be considered to ensure it meets your specific needs:

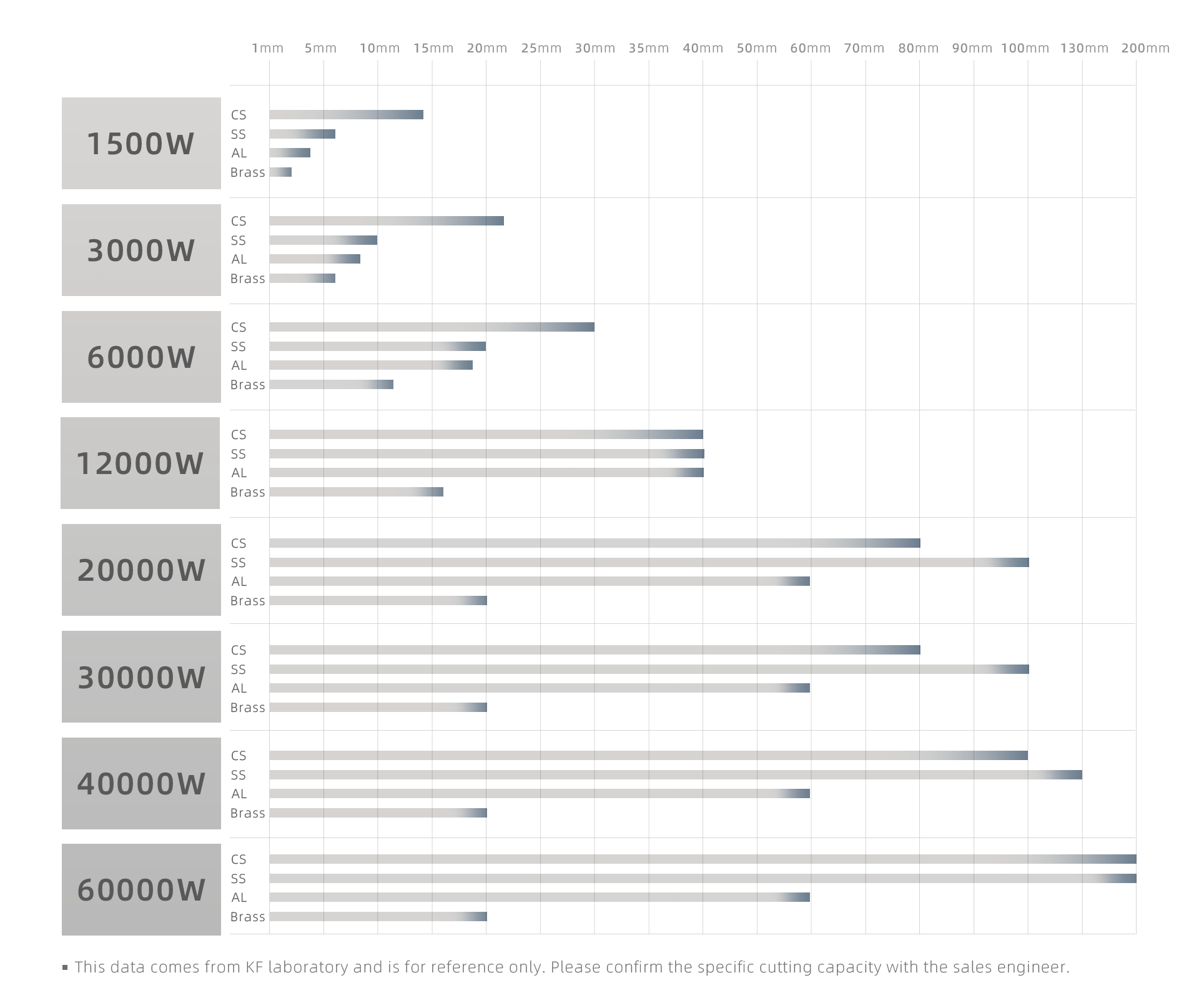

1. Power Requirements:

- Higher wattage lasers are suitable for cutting thicker materials and metals.

- Lower wattage lasers are ideal for engraving and cutting thinner materials.

2. Material Compatibility:

- Determine the primary materials you will work with and choose a laser cutter optimized for those materials.

- Fiber lasers are generally better for metals, while CO2 lasers are versatile for non-metals.

3. Bed Size and Work Area:

- The size of the bed and work area dictates the maximum dimensions of the material you can work with.

- Larger bed sizes are essential for large-scale projects, while smaller bed sizes suffice for detailed engraving work.

4. Software and Control Systems:

- User-friendly software and advanced control systems enhance performance.

- Look for machines with intuitive interfaces and features that simplify the cutting process.

5. Price and Budget Considerations:

- CNC laser cutters vary widely in price; establish a budget that includes initial purchase cost, maintenance, software, and accessories.

- Consider the long-term value of the machine in terms of performance and durability.

Modern CNC metal laser cutters come with advanced features that improve performance and usability:

1. Automatic Focusing:

- Maintains the optimal distance between the laser head and the material, ensuring precise cuts.

- Enhances cutting quality and consistency.

2. Programmable Air Assist:

- Allows for the connection of multiple gas types to the laser system.

- Optimizes cutting performance by selecting the appropriate gas for each material.

3. Pierce Control:

- Controls the laser's piercing parameters, including power, dwell time, and gas pressure.

- Ensures efficient and clean pierces, prolonging the lifespan of the optics.

4. Fine Adjustments:

- Allows for precise control of power and speed during lead-ins and corners.

- Ensures consistent cut quality throughout complex designs.

5. Safety Features:

- Includes protective covers and safety sensors to prevent accidents.

- Ensures safe operation, especially with high-powered lasers.

Proper maintenance and operation of a CNC laser cutter for metal are crucial for ensuring long-term performance and reliability:

1. Regular Cleaning:

- Keep the optics, lenses, and mirrors clean to maintain cutting precision.

- Remove debris and dust from the cutting area regularly.

2. Laser Source Maintenance:

- Follow the manufacturer's guidelines for maintaining the laser source.

- Replace consumables like lenses and mirrors as needed to ensure optimal performance.

3. Software Updates:

- Keep the control software updated to benefit from the latest features and improvements.

- Regularly check for firmware updates from the manufacturer.

4. Proper Ventilation:

- Ensure adequate ventilation to remove fumes and debris during the cutting process.

- Use appropriate exhaust systems to maintain a clean and safe working environment.

5. Training and Safety:

- Provide proper training for operators to ensure safe and efficient use of the laser cutter.

- Follow safety protocols and use protective equipment as recommended by the manufacturer.

The future of CNC laser cutter for metal technology looks promising, with continuous advancements that will enhance capabilities and accessibility:

1. Enhanced Automation:

- Integration of advanced automation features will increase efficiency and reduce labor costs.

- Automation will allow manufacturers to focus on design and innovation.

2. Greater Accessibility:

- As costs continue to decrease, more businesses and individuals will have access to CNC laser cutters.

- Increased accessibility will lead to more innovation and creativity.

3. Advanced Materials:

- Development of new materials and alloys will expand the possibilities for laser cutting.

- Manufacturers will be able to work with materials that offer unique properties and aesthetics.

4. Sustainability:

- Laser cutting technology will play a crucial role in promoting sustainability by reducing material waste.

- Environmentally friendly practices will become more prevalent in the industry.

The CNC laser cutter, especially the CNC laser cutter for metal and CNC metal laser cutter, is a vital tool for various industries, offering unmatched precision, efficiency, and versatility. From automotive and aerospace to jewelry making and architecture, CNC laser cutters have transformed production processes and enabled innovation. By understanding the key features, benefits, and maintenance of CNC laser cutters, and considering your specific needs, you can select the best CNC laser cutter for your projects. As technology continues to advance, the future of CNC laser cutting looks bright, with exciting possibilities for enhanced automation, accessibility, and sustainability.