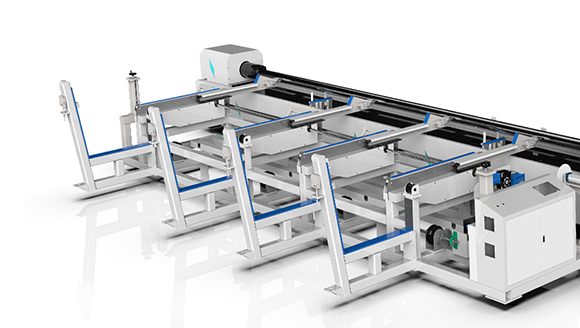

Model | THA62 |

Maximum processing length | 6000mm |

unloading length | 3000mm |

Processing pipe size | Φ10-220mm □10-220mm |

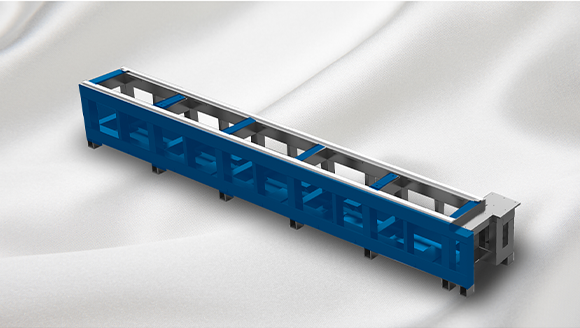

Dimension (L*W*H) | 11230*2030*2140mm |

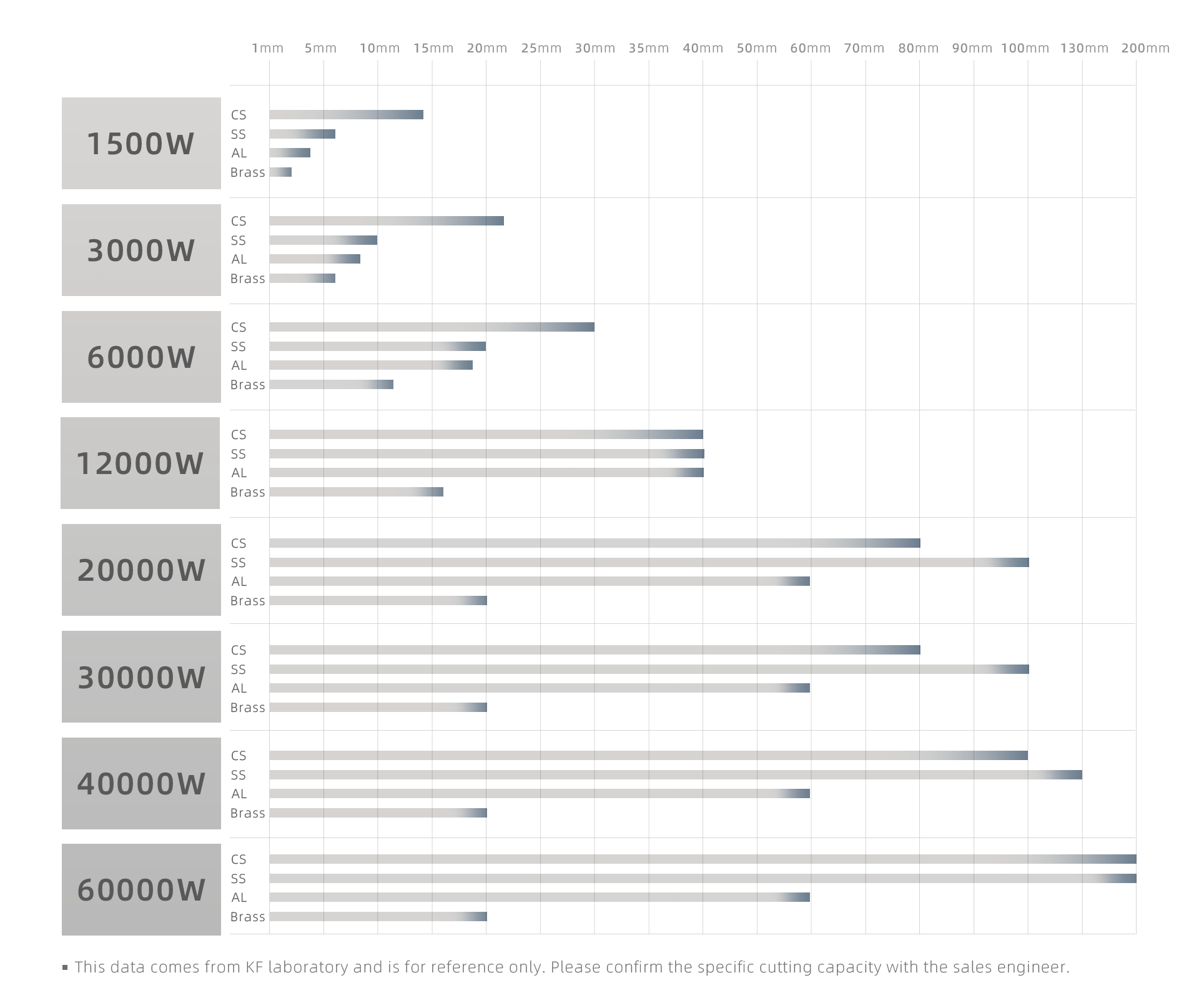

Power support | 1500-6000W |

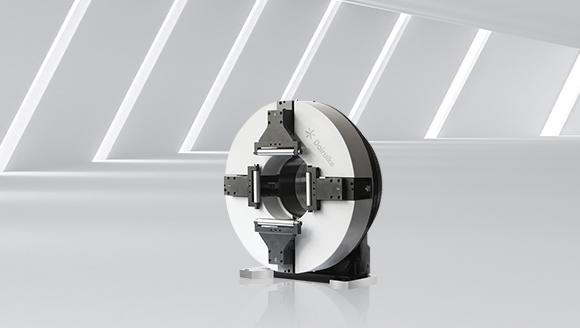

Chuck weighing | 200kg |

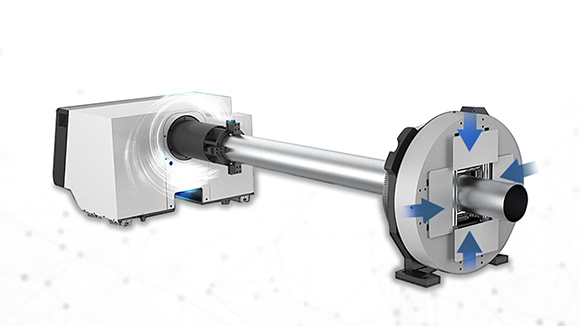

chuck rotation speed | 100r/min |

Maximum Idle Running Speed | 100m/min |

Maximum idle acceleration | 1.0G |

Positioning accuracy | ±0.02mm |

Repeat positioning accuracy | ±0.01mm |

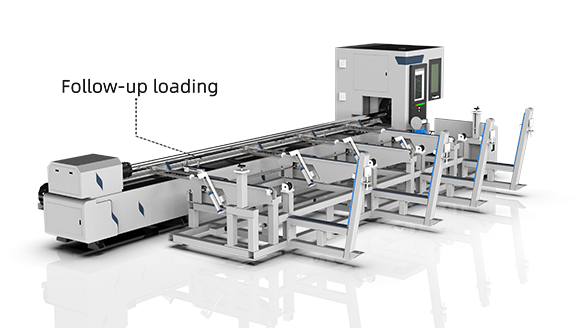

Support device | Follow-up |

Feeding device (optional) | Semi-automatic/Fully automatic feeding |

A: In order to recommend you the most suitable machine model, just tell us below information

1)What is your material

2)The size of material

3)The thickness of material

4)Fiber laser cutter for metal

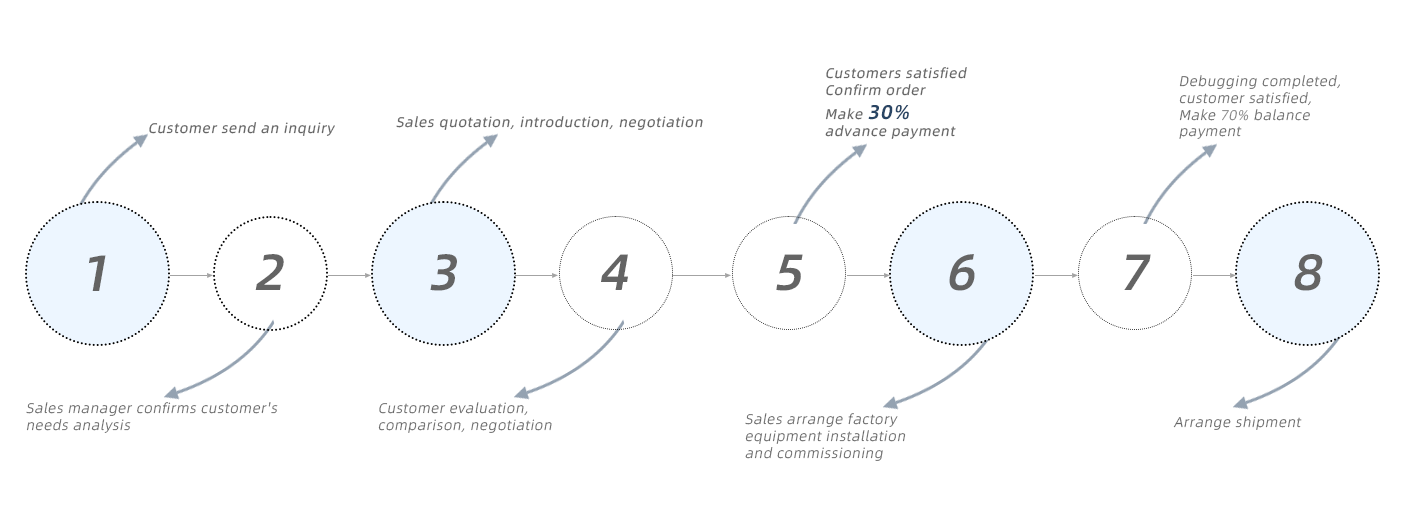

A:1)Alibaba trade assurance/TT/West Union/Payple/LC/Cash and so on.

2)We start making standardized machines after receiving 30% of the payment, inspect the machines after completion, and finally collect the 70% balance before shipping.

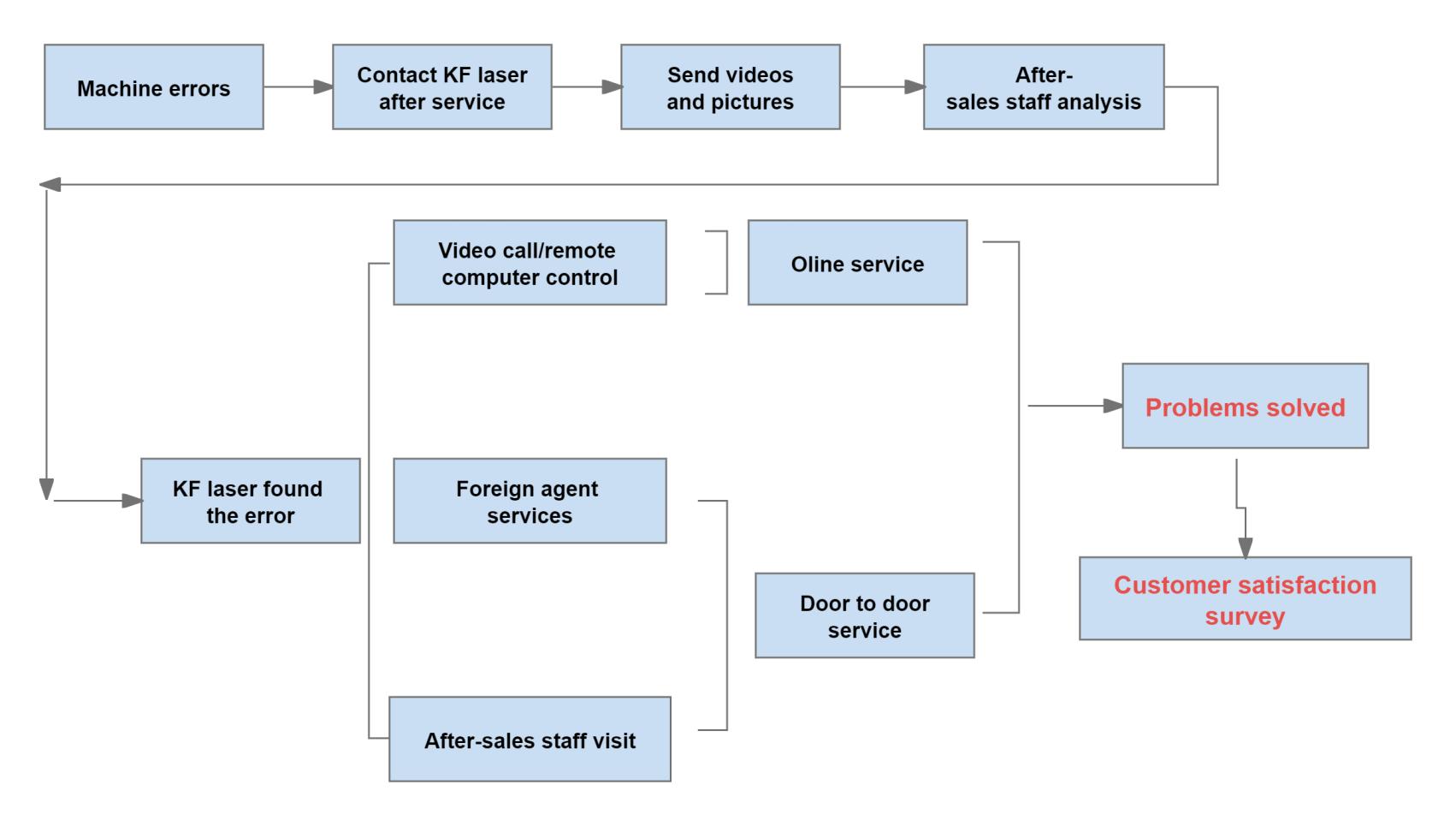

A:1)We provide free training in our factory

2)We provide free online after-sales service

3)We have complete installation instructions and video tutorials

4)Door-to-door service charges are based on region and aircraft model

5)Provide three-year warranty, except for consumable parts, direct replacement for non-human damage

1):Clean the optical lens: Clean the optical lens regularly to maintain the beam quality.

2):Check the gas supply: Make sure the gas supply system is normal to prevent the cutting quality from being affected.

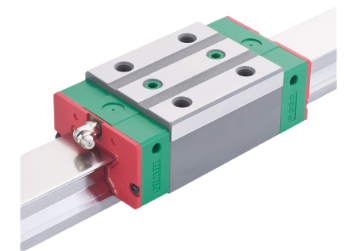

3):Lubricate the moving parts: Lubricate the guide rails and lead screw regularly to ensure the smooth operation of the moving parts.

4):Replace the chiller’s purified water every month. If it’s below zero in winter, remember to add antifreeze.

A laser cutter for aluminum is a powerful and versatile tool used in various industries for precise and efficient cutting of aluminum sheets and plates. This comprehensive guide will cover the key aspects of laser cutting aluminum, including its advantages, challenges, and factors to consider when choosing a laser cutter for aluminum.

A laser cutter for aluminum is a machine that uses a focused laser beam to cut or engrave aluminum. This process involves directing the laser beam onto the surface of the aluminum, which melts or vaporizes the material, creating a clean and precise cut. The laser beam is typically guided by computer numerical control (CNC) systems, allowing for intricate designs and high precision.

Laser cutting aluminum is used across various industries due to its precision and efficiency. Common applications include:

Proper maintenance is crucial for ensuring the longevity and optimal performance of your laser cutter for aluminum. Here are some maintenance tips:

A laser cutter for aluminum offers numerous advantages for metal fabrication, including high precision, speed, and versatility. By considering key features, understanding the applications, and following proper maintenance practices, you can make an informed decision and choose the best laser cutter for aluminum for your needs. Investing in a high-quality laser cutter will enhance your production capabilities, improve efficiency, and ensure consistent, high-quality results in your manufacturing projects.

Send your inquiry / assessment to Us. Anything need us ,please don’t hesitate contact us here! we will keep it secret for you !