News

Laser Stainless Steel Cutting: The Ultimate Solution for Precision and Efficiency in Metal Fabrication

In the world of metal fabrication, laser stainless steel cutting has emerged as one of the most effective and versatile technologies available. Whether for producing complex components or simple shapes, laser cutting offers unparalleled precision, speed, and efficiency, particularly when working with stainless steel. In this article, we explore the technology behind laser cutting, its benefits, and its applications across various industries.

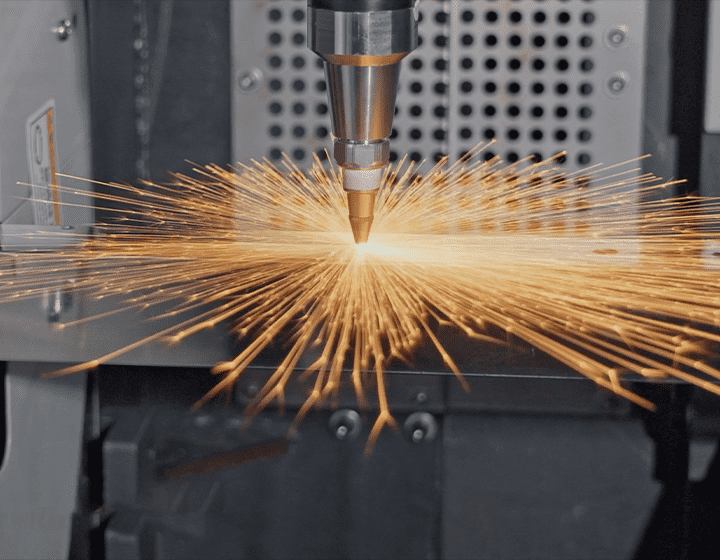

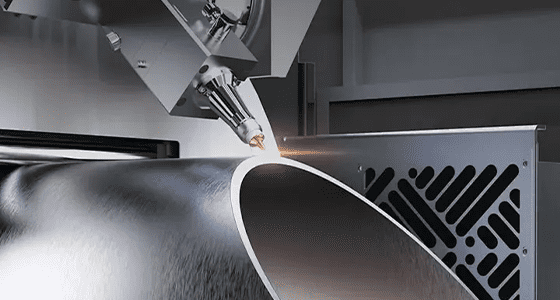

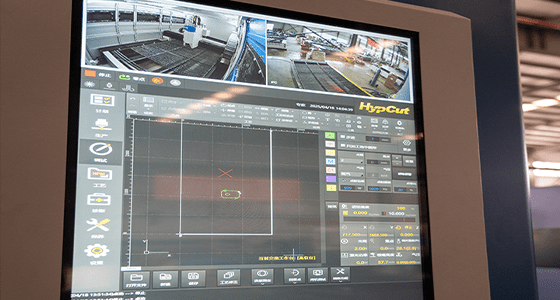

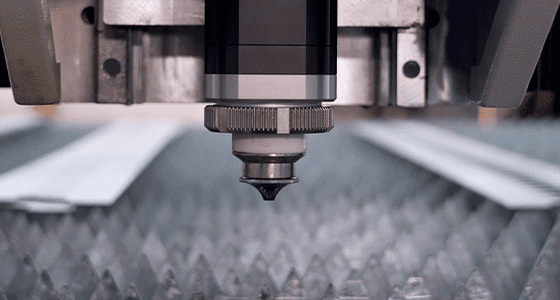

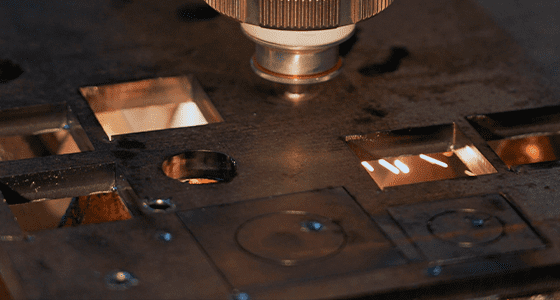

Laser stainless steel cutting refers to the process of using a high-powered laser beam to cut through stainless steel sheets, plates, or tubes. The process is highly efficient and precise, making it ideal for applications that require high-quality cuts and intricate designs. In laser cutting, the focused laser beam melts, vaporizes, or burns through the material along a pre-programmed path, guided by CNC (computer numerical control) technology for maximum accuracy.

The key to laser cutting’s success lies in the laser source, which is usually a fiber laser or CO2 laser, each offering distinct advantages depending on the application. Fiber lasers, in particular, are known for their ability to cut through stainless steel at faster speeds and with superior edge quality.

How Does Laser Stainless Steel Cutting Work?

Laser cutting is a precise and controlled process that follows these basic steps:

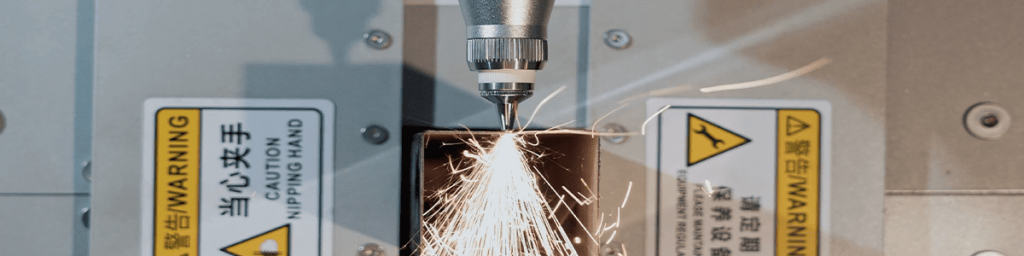

Laser Beam Generation: The laser source produces an intense beam of light that is directed toward the stainless steel surface.

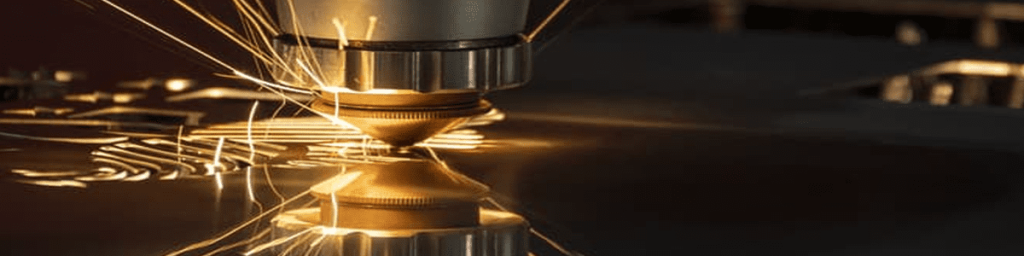

Focusing the Beam: The laser beam is focused into a narrow, concentrated spot by using lenses or mirrors. The focused beam generates temperatures high enough to melt or vaporize the stainless steel.

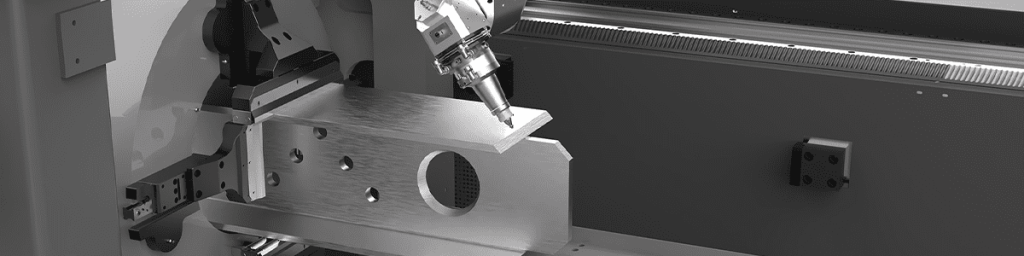

Cutting Path: Using CNC technology, the machine guides the laser head along the pre-programmed cutting path. The precision of CNC allows for accurate and intricate designs to be cut with minimal deviation.

Assist Gas: Often, an assist gas like nitrogen or oxygen is used during the cutting process. The gas helps to blow away molten material from the cut, resulting in cleaner cuts and faster processing times.

Benefits of Laser Stainless Steel Cutting

1. High Precision and Accuracy

One of the primary reasons laser stainless steel cutting is preferred in the industry is its exceptional precision. The laser beam can make extremely fine cuts with tight tolerances, making it ideal for producing detailed and complex shapes that traditional cutting methods cannot achieve with the same level of accuracy.

2. Speed and Efficiency

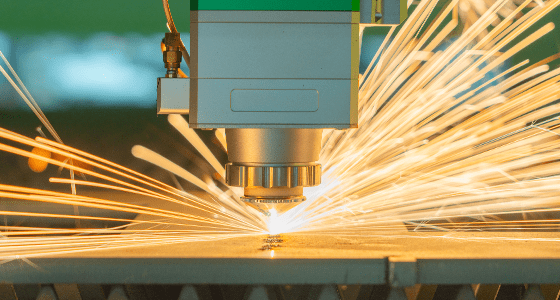

Laser cutting offers rapid cutting speeds, reducing production times significantly compared to mechanical cutting methods. The high-speed cutting capabilities make it possible to process large volumes of stainless steel in less time, improving overall productivity. Additionally, laser stainless steel cutting minimizes the need for post-cutting processes like grinding or finishing, as it produces cleaner edges.

3. Minimal Heat-Affected Zone (HAZ)

The laser cutting process generates less heat compared to other methods like plasma cutting. As a result, laser stainless steel cutting produces a minimal heat-affected zone (HAZ), which reduces the likelihood of warping, discoloration, or distortion of the material. This is especially important for stainless steel, which can be sensitive to heat, affecting its structural integrity.

4. Versatility in Thickness

Laser cutting is incredibly versatile, allowing you to cut stainless steel sheets of varying thicknesses, ranging from thin gauge sheets to thicker plates. With the right settings and equipment, lasers can handle everything from delicate, intricate designs on thin stainless steel to cutting through thick, heavy plates without compromising the quality of the cut.

5. High-Quality Edge Finish

Laser stainless steel cutting produces a clean, smooth edge with minimal burrs and roughness. This eliminates the need for secondary finishing processes, such as deburring or polishing, saving both time and labor costs.

6. Minimal Material Waste

Because of the precision and narrow kerf (cut width) of the laser beam, laser stainless steel cutting results in minimal material waste. This makes it a cost-effective solution, especially for industries where material efficiency is crucial.

7. Automation and Precision Control

The integration of CNC technology allows for fully automated laser cutting with precise control over the cutting path and speed. The precision offered by CNC-driven lasers makes it easier to replicate the same cuts repeatedly with high consistency, making it ideal for large-scale production runs.

Applications of Laser Stainless Steel Cutting

Laser cutting has widespread applications across various industries, particularly when it comes to working with stainless steel, due to the material’s strength, durability, and corrosion resistance. Below are some common uses:

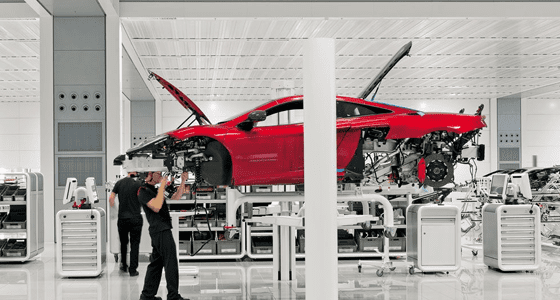

1. Automotive Industry

In the automotive industry, laser stainless steel cutting is used to produce a wide variety of components, such as exhaust systems, chassis parts, body panels, and brackets. The ability to cut intricate designs and complex geometries makes it an ideal choice for automotive manufacturers looking to optimize production efficiency.

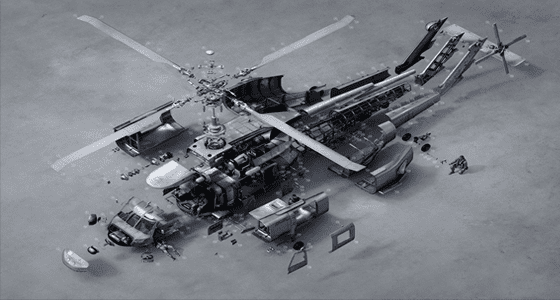

2. Aerospace Industry

The aerospace industry requires high-precision components, and laser stainless steel cutting provides the ideal solution. It is used to create critical parts for aircraft, such as structural components, brackets, and engine components, where strength, durability, and precision are paramount.

3. Architectural and Decorative Elements

Laser stainless steel cutting is widely used in architecture for creating decorative panels, custom signage, and building facades. The ability to achieve precise cuts and intricate designs makes it a popular choice for architects looking to integrate metal features into their designs.

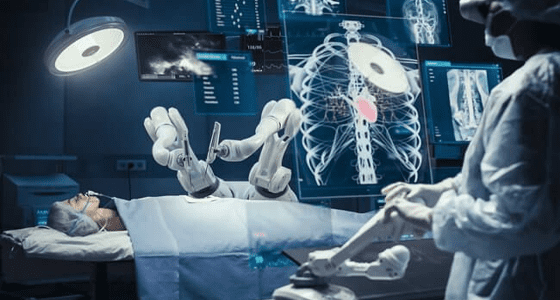

4. Medical Devices

In the medical device industry, laser stainless steel cutting is used to produce precise parts for medical instruments and equipment, such as surgical tools, implants, and diagnostic devices. The high precision and minimal heat distortion ensure that the parts meet stringent quality standards.

5. Food and Beverage Industry

Stainless steel is commonly used in food processing equipment due to its resistance to corrosion and ease of cleaning. Laser stainless steel cutting is employed to create specialized components like food processing machines, conveyors, and storage containers, ensuring the parts meet food safety standards.

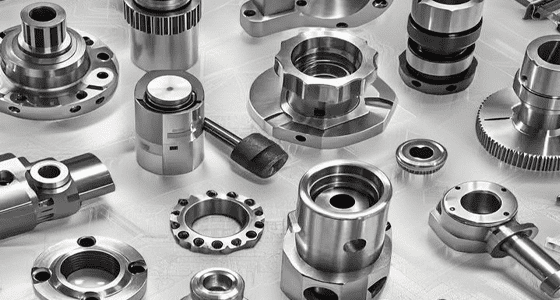

6. Metal Fabrication and Custom Parts

Many custom fabrication shops use laser stainless steel cutting for creating bespoke metal parts. From one-off designs to low-volume production runs, laser cutting allows manufacturers to produce custom pieces with complex geometries without the need for expensive tooling.

Challenges of Laser Stainless Steel Cutting

While laser stainless steel cutting offers many advantages, it is not without its challenges:

Cost of Equipment: The initial investment for a high-quality laser cutting machine can be expensive. However, the return on investment (ROI) in terms of increased productivity and reduced waste often justifies the cost over time.

Thickness Limitations: While laser cutting is versatile, extremely thick stainless steel plates may require slower cutting speeds or additional techniques (such as using a higher-powered laser or slower cutting speeds) to ensure clean cuts.

Material Type and Reflectivity: Some grades of stainless steel, particularly those with high reflectivity, may present challenges for laser cutting, requiring adjustments in laser power and assist gas pressure.

Conclusion

Laser stainless steel cutting has revolutionized the way manufacturers work with stainless steel, offering unmatched precision, speed, and efficiency. From the automotive and aerospace industries to custom metal fabrication, laser cutting provides an efficient and cost-effective solution for producing high-quality stainless steel parts.

With advancements in laser technology, the applications for laser stainless steel cutting continue to grow, making it an essential tool for modern manufacturing. Whether you’re cutting thin sheets or thick plates, the precision and versatility offered by laser cutting make it the ideal choice for a wide range of industries. Investing in a laser stainless steel cutting system can help companies improve their production efficiency, reduce waste, and deliver high-quality products to their customers.

This guide outlines the key benefits and applications of laser stainless steel cutting, showcasing how this technology is shaping the future of metal fabrication across industries.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine