When it comes to cutting stainless steel, laser cutting SS stands out as one of the most advanced and efficient methods available. Whether you’re in manufacturing, design, or engineering, understanding how laser cutting works and why it’s particularly well-suited for stainless steel (SS) is crucial to optimizing your projects. From its precision to speed, laser cutting has revolutionized industries by providing accurate, cost-effective, and scalable cutting solutions.

In this article, we’ll explore the process of laser cutting SS, its benefits, techniques, and why it’s the go-to choice for many industrial applications.

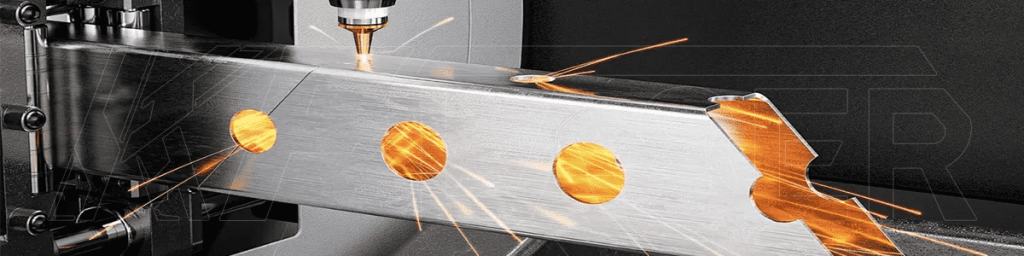

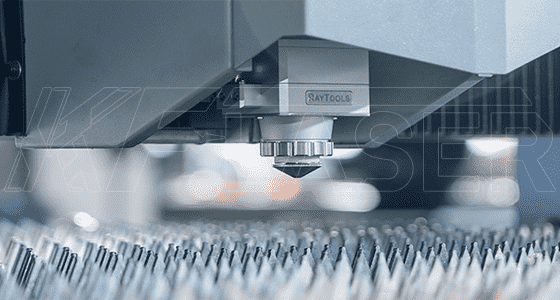

Laser cutting SS refers to the process of using a high-powered laser beam to cut through stainless steel. A laser cutter directs focused light beams to melt, burn, or vaporize the material along the cutting line. This method ensures incredibly precise, smooth, and clean cuts on stainless steel sheets, tubes, and plates. It is ideal for materials that require a high degree of accuracy and minimal thermal distortion.

One of the most significant advantages of laser cutting stainless steel is the ability to cut through a wide range of thicknesses, from thin sheets to thicker plates, while maintaining high levels of precision. It can handle complex geometries, intricate designs, and fine details that other traditional methods like saws or plasma cutters might struggle with.

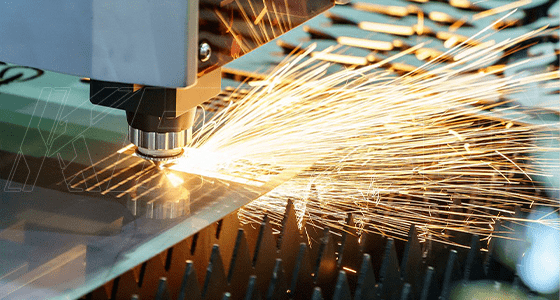

Laser cutting is unmatched in terms of precision. The focused laser beam allows for incredibly fine, intricate cuts, with tolerances as tight as +/- 0.1mm, making it ideal for high-precision applications like aerospace, medical device manufacturing, and automotive production. The clean edges and smooth surfaces minimize the need for post-processing, which is a significant time saver.

One of the primary advantages of laser cutting SS is the minimal material wastage it produces. Unlike mechanical cutting methods that can produce significant offcuts, laser cutting is a non-contact process. This reduces the risk of deformation or warping, and the precision of the cuts means less material is wasted, leading to better material utilization and lower production costs.

Laser cutting machines are incredibly fast, which makes them perfect for high-volume production. The machine can cut at speeds of up to 20 meters per minute, depending on the material thickness and laser power. This makes laser cutting SS a highly efficient choice for businesses that need to produce large quantities of parts quickly while maintaining a high level of quality.

The heat affected zone (HAZ) is minimal when using a laser cutter compared to other cutting methods. This means that the stainless steel around the cut remains largely unaffected by heat, reducing the risk of warping, discoloration, or distortion. This is especially important when working with materials like stainless steel, which can be prone to heat-related changes in structure and appearance.

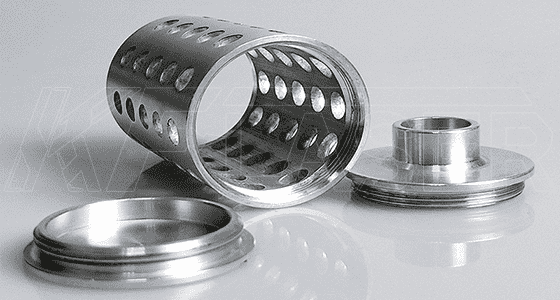

Laser cutters can easily follow intricate patterns and complex geometries, including sharp corners, curves, and even holes within a cut. This capability makes laser cutting SS the preferred choice for custom designs and parts with detailed features, such as perforations, slots, and non-linear shapes.

Laser cutting works by focusing a high-intensity laser beam onto the surface of the stainless steel. Here’s a simple breakdown of the process:

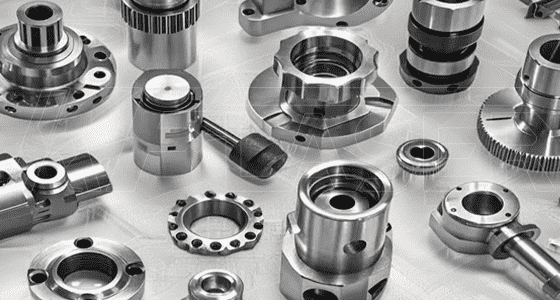

The versatility of laser cutting SS allows it to be used in various industries and applications. Below are some common sectors that benefit from this advanced technology:

To achieve the best results when using a laser cutting machine for SS, it’s essential to follow certain best practices:

Laser cutting SS has proven to be an indispensable technology in various industries requiring high precision and minimal waste. From automotive and aerospace to architecture and medical devices, the ability to achieve intricate designs with accuracy and speed makes laser cutting an optimal choice for stainless steel applications. By understanding how the process works and following best practices, you can achieve superior results, optimize production times, and reduce material waste, all while maintaining the quality and integrity of the final product.

If you’re considering investing in laser cutting technology for stainless steel, understanding these benefits and techniques will help you make an informed decision and maximize the potential of your projects.