News

Fiber Laser Cutting Steel Guide

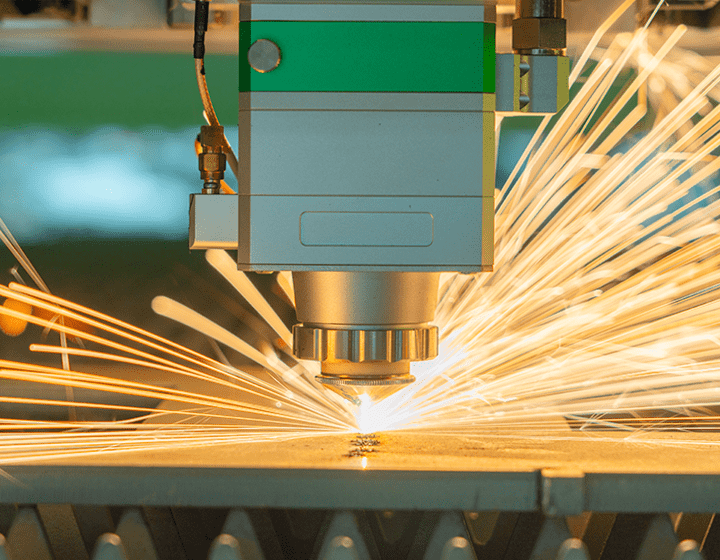

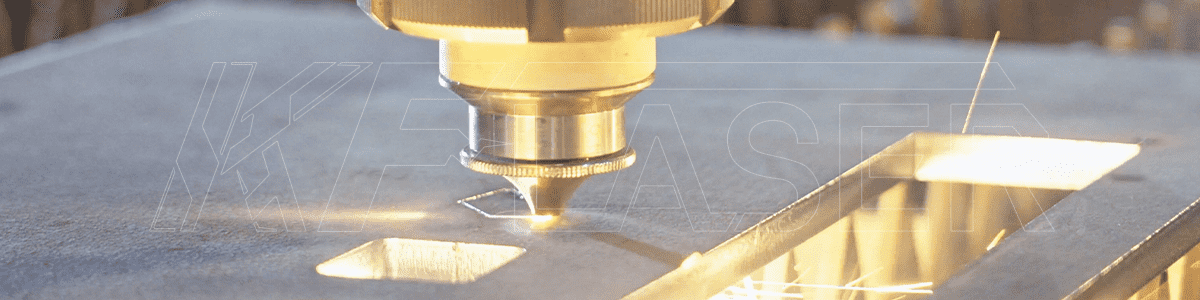

Fiber laser cutting steel transforms brute metal into precision art where sparks become obsolete, jagged edges turn mirror-smooth, and industrial alchemy occurs at light speed. Imagine slicing through armored plating like parchment while maintaining tolerances finer than human hair – this photonic revolution redefines metal fabrication across continents. Modern manufacturing demands more than just severed steel; it requires surgical precision, energy efficiency, and flawless repeatability that only optimized fiber laser systems deliver.

The Steel Transformation Matrix

Not all steel sings to the same laser wavelength. Cutting performance hinges on understanding four critical dimensions:

- Metallurgical Composition

- Carbon Steels: 1070nm wavelength penetrates best at 1-3kW power

- Stainless Series: Nitrogen assist prevents chromium depletion at edges

- Tool Steels: Pre-heating protocols prevent micro-fracturing

- Galvanized Coatings: Burst-mode pulsing avoids zinc vapor explosions

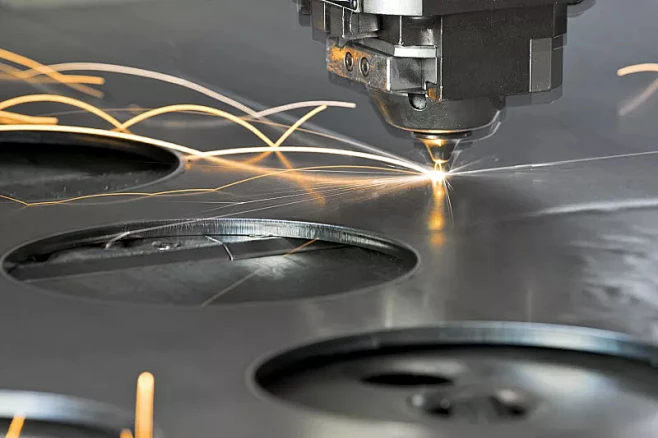

- Thickness Thresholds

Steel Grade | Optimal Thickness | Speed (m/min) | Assist Gas |

Mild (1.0038) | 0.5-20mm | 15-40 | O₂ |

Stainless (1.4301) | 0.8-25mm | 8-25 | N₂ |

AR400 Armor | 2-12mm | 3-8 | Compressed Air |

Data from European Laser Institute trials (2024)

- Surface Science Secrets

- Oil-coated sheets require 17% higher threshold energy

- Rust layers scatter beams – abrasive cleaning boosts efficiency 31%

- Reflective finishes demand anti-backreflection sensors

- Thermal Management Breakthroughs

Next-gen systems now incorporate:- Dynamic focal shift compensation during piercing

- Real-time molten pool viscosity monitoring

- Predictive kerf width algorithms

Cutting-Edge Applications Redefined

Aerospace Frame Fabrication

- Titanium-stainless hybrids cut at 0.02mm tolerance

- Zero-thermal-distortion techniques for load-bearing parts

- Micro-ventilation slots <0.1mm width

Electric Vehicle Battery Trays

- Burr-free cutting of copper-clad steel

- Flawless welding seam preparation

- 3D contour cutting at 45° angles

Architectural Marvels

- 40mm corten steel sculpting with artistic bevels

- Perforated facade patterns with 500+ holes/m²

- Interlocking components with zero gap tolerance

The Photonic Advantage Chart

Traditional methods vs. fiber laser cutting steel:

Parameter | Plasma Cutting | Waterjet | Fiber Laser |

Precision | ±0.5mm | ±0.1mm | ±0.05mm |

Heat Affected Zone | 2.1-3.8mm | None | 0.15-0.4mm |

Energy Cost | $17.30/hr | $23.80/hr | $8.20/hr |

Maintenance Downtime | 18% | 12% | 4% |

Minimum Feature Size | 3× thickness | 1.2× thickness | 0.6× thickness |

Based on Fraunhofer IPT productivity study (2025)

Operator Mastery Toolkit

Parameter Optimization Secrets

- Piercing Protocols: Ramp power 30-100% in 0.8ms for explosion-free starts

- Corner Strategies: Adaptive deceleration prevents overcuts

- Nozzle Science: Standoff distance = (nozzle diameter) × 1.3

Material Handling Innovations

- Ferromagnetic lifting systems prevent surface scratches

- Vacuum clamping for oil-coated sheets

- AI-based nesting software achieving 94% material utilization

Troubleshooting Matrix

Issue | Root Cause | Solution |

Bottom Dross | Gas pressure too low | Increase 0.2-0.3 bar |

Top Spatter | Focus too high | Lower 0.3-0.5mm |

Irregular Kerf | Wobble head misalignment | Recalibrate harmonic drives |

Edge Oxidation | Nitrogen purity <99.95% | Install molecular sieve filters |

Future-Forward Technologies

- Hyperspectral Monitoring

Real-time spectral analysis of molten pools detects:- Carbon content variations >0.03%

- Alloy composition deviations

- Impurity concentrations

- Self-Learning Systems

- Neural networks optimizing cut paths during operation

- Predictive lens contamination alerts

- Automatic gas mixture adjustment

- Hybrid Additive Manufacturing

- Direct metal deposition after cutting

- In-situ quality verification

- Closed-loop defect correction

- Sustainable Revolution

- 92% energy recovery during beam modulation

- Metal vapor recapture systems

- Photovoltaic integration

Implementation Blueprint

Facility Integration Checklist

☑️ Power Stability: ±1% voltage fluctuation tolerance

☑️ Floor Load: 7.5 ton/m² minimum

☑️ Air Preparation: Class 1 ISO 8573-1 air quality

☑️ Fume Extraction: 3500m³/hr capacity

☑️ Data Infrastructure: 10Gbps fiber optic backbone

ROI Calculation Model

- Typical ROI timeframe: 14-22 months

- Hidden savings:

» 68% less secondary processing

» 42% reduction in consumables

» 83% faster job changeovers

Industry 4.0 Integration

- OPC UA communication protocols

- MTConnect monitoring dashboards

- Digital twin synchronization

Global manufacturing now pivots on photonic precision. As the International Journal of Advanced Manufacturing Technology recently noted: “Fiber laser cutting steel represents not merely improved technology, but a fundamental reimagining of material transformation physics.”

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine