A capacidade de cortar alumínio com precisão é um aspecto vital da fabricação moderna. Corte a laser de alumínio é uma técnica avançada que utiliza um laser de alta potência para cortar ou gravar material de alumínio com precisão excepcional. Este método combina velocidade, precisão, e desperdício mínimo de material, tornando-o um processo essencial em vários setores.

Como o alumínio continua a ser uma escolha popular para aplicações em indústrias como a automotiva, aeroespacial, e construção, a demanda por métodos de corte eficientes e confiáveis aumentou. Neste artigo, vamos nos aprofundar no que é o corte a laser de alumínio, suas vantagens, e como é aplicado em diferentes setores.

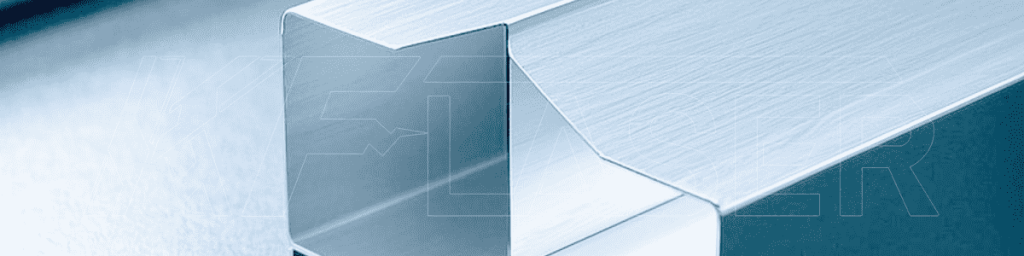

Corte a laser de alumínio refere-se ao processo de utilização de um feixe de laser focado para cortar ou gravar folhas ou peças de alumínio. A alta densidade de energia do laser permite cortar facilmente o alumínio, um metal que normalmente é leve, mas também pode ser difícil de cortar usando métodos mecânicos tradicionais devido à sua natureza reflexiva e espessura variável.

Existem dois tipos principais de lasers usados para cortar alumínio: Lasers de CO2 e lasers de fibra. Cada um tem seus pontos fortes e é escolhido com base nos requisitos específicos do projeto. O feixe de laser derrete ou vaporiza o material no ponto de corte, e um gás auxiliar como nitrogênio ou oxigênio ajuda a limpar o metal fundido da área de corte, melhorando a qualidade do corte.

Um dos principais benefícios corte a laser de alumínio é a sua precisão incomparável. O feixe focado do laser permite cortes complexos e detalhados com tolerâncias restritas, até 0,1 mm em alguns casos. Isto é particularmente importante em indústrias onde a precisão é crucial, como fabricação aeroespacial e de dispositivos médicos.

O corte a laser produz resultados limpos, bordas suaves sem a necessidade de pós-processamento adicional. O feixe de laser essencialmente derrete o alumínio no ponto de corte, o que resulta em um corte limpo com o mínimo de rebarbas e sem necessidade de acabamento. Isso leva a custos de mão de obra reduzidos e tempos de produção mais rápidos.

O corte a laser de alumínio é um processo altamente eficiente que minimiza o desperdício. Porque o laser pode ser controlado com precisão, corta o material exatamente de acordo com as especificações, com pouco ou nenhum excesso. Isso reduz a quantidade de material de sucata, tornando-o mais ecológico e econômico.

O corte a laser permite a criação de formas complexas, padrões, e projetos que seriam impossíveis ou demorados de serem alcançados com métodos de corte tradicionais. Quer se trate de padrões geométricos intrincados, logotipos, ou designs de peças exclusivos, o corte a laser de alumínio oferece versatilidade incomparável em termos de design.

Em comparação com métodos de corte tradicionais, como jato de água ou corte mecânico, corte a laser é muito mais rápido. A velocidade e a precisão com que o laser pode cortar peças de alumínio levam a taxas de produção mais altas, tornando-o ideal para indústrias com necessidades de fabricação de alto volume.

O alumínio pode ser cortado usando diferentes métodos dependendo do tipo de laser, espessura do material, e o resultado desejado. Os dois principais tipos de lasers usados para corte a laser de alumínio são:

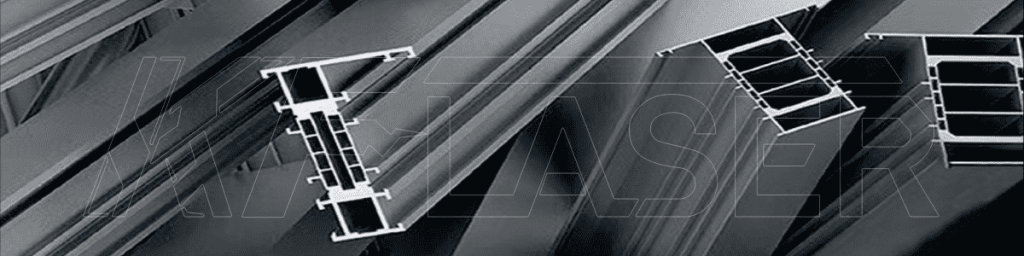

Os lasers de CO2 são ideais para cortar chapas de alumínio mais espessas. Esses lasers produzem um feixe de luz infravermelha de alta intensidade que derrete e vaporiza o alumínio.. Os lasers de CO2 são amplamente utilizados para cortar folhas e placas de alumínio com até vários milímetros de espessura. Eles são eficazes para criar cortes complexos e também podem ser usados para gravar ou marcar.

Os lasers de fibra usam um feixe de laser gerado por um cabo de fibra óptica. Esses lasers são especialmente eficazes para cortar alumínio de espessura fina a média. Eles oferecem maior eficiência e velocidades de corte mais rápidas em comparação com os lasers de CO2, tornando-os adequados para operações de alto volume. Os lasers de fibra também são mais eficientes em termos energéticos e requerem menos manutenção do que os lasers de CO2, tornando-os uma escolha popular para aplicações de corte modernas.

Além de cortar, gravação a laser é outra técnica usada para marcar ou gravar desenhos em superfícies de alumínio. Este processo usa um laser menos potente para queimar a camada superficial, criando detalhes finos ou logotipos. A gravação a laser em alumínio é comumente usada para marcação de marca ou número de série em componentes.

Corte a laser de alumínio tem uma ampla gama de aplicações em diversos setores devido à sua precisão, velocidade, e versatilidade. Abaixo estão alguns setores-chave que se beneficiam desta tecnologia de corte:

A indústria aeroespacial exige peças e componentes que atendam a rigorosos padrões de qualidade e ao mesmo tempo permaneçam leves. Corte a laser é comumente usado para fabricar peças de aeronaves, como estruturas de asas, fuselagens, e componentes do motor. As propriedades leves e resistentes do alumínio fazem dele um material perfeito para o setor aeroespacial, e o corte a laser garante que essas peças sejam fabricadas de acordo com as especificações exatas.

Na fabricação automotiva, alumínio cortado a laser é usado para criar componentes como painéis de carroceria, quadros, e suportes estruturais. O baixo peso do alumínio contribui para a eficiência de combustível, tornando-o um material preferido para veículos modernos. Os cortes precisos feitos pela tecnologia laser ajudam a agilizar o processo de fabricação e garantem os mais altos padrões de qualidade em termos de segurança e desempenho..

O alumínio é frequentemente utilizado na produção de gabinetes para dispositivos eletrônicos, placas de circuito, e painéis elétricos. O corte a laser permite que os fabricantes obtenham cortes precisos para projetos complexos, garantindo que os componentes se encaixem perfeitamente e funcionem com eficiência. A excelente condutividade térmica do alumínio também o torna ideal para dissipadores de calor e outros componentes de gerenciamento térmico.

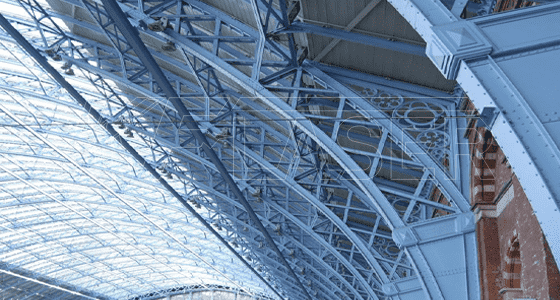

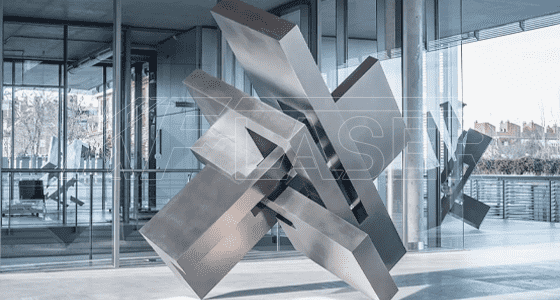

O corte a laser de alumínio também é amplamente utilizado nos setores de construção e arquitetura, especialmente para criar fachadas decorativas, grades, e outros trabalhos em metal. A versatilidade do corte a laser permite designs complexos que agregam valor estético, mantendo a resistência e durabilidade.

O alumínio cortado a laser é frequentemente usado na criação de sinalização, peças de arte, e esculturas. A capacidade de cortar desenhos detalhados e formas complexas torna-o um favorito entre designers e artistas. O acabamento de alta qualidade obtido através do corte a laser significa que as peças muitas vezes requerem pouco trabalho adicional de acabamento, economizando tempo e custos de mão de obra.

Se você está pensando em terceirizar suas necessidades de corte de alumínio ou comprar uma máquina de corte a laser, há vários fatores que você deve considerar:

O corte a laser de alumínio continua a ser uma pedra angular da fabricação moderna, proporcionando às indústrias a capacidade de criar produtos de alta qualidade, peças precisas com rapidez e eficiência. Aproveitando o poder da tecnologia laser, os fabricantes podem atender às demandas por peso leve, durável, e componentes complexos que atendem aos mais altos padrões de design e funcionalidade. Esteja você no setor aeroespacial, Automotivo, ou qualquer outro setor, investindo em corte a laser de alumínio pode agilizar seu processo de produção e elevar seus produtos para o próximo nível.