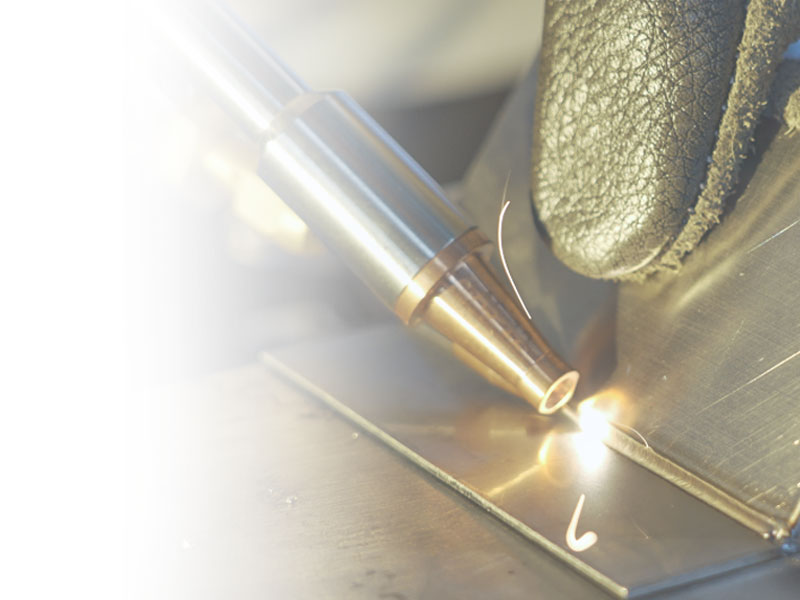

O soldador a laser mantido à mão é uma tecnologia inovadora que revolucionou a indústria de soldagem. Esta ferramenta avançada fornece precisão, velocidade, e versatilidade, tornando -o uma escolha ideal para várias aplicações industriais. Ao contrário dos métodos de soldagem tradicionais, Os soldadores a laser de manutenção oferecem inúmeras vantagens que aumentam significativamente a produtividade e a eficiência. Neste artigo, Vamos explorar os principais recursos, benefícios, formulários, e aspectos técnicos de soldas a laser com manuseio.

Um soldador a laser com manutenção à mão é um dispositivo portátil que usa um feixe de laser concentrado para se juntar aos materiais de metal. Este dispositivo combina a flexibilidade da operação manual com a precisão da tecnologia a laser. O soldador consiste em uma fonte de laser, um sistema de entrega de cabos de fibra óptica, uma cabeça de solda, um sistema de controle, um suprimento de gás de blindagem, e um sistema de refrigeração. Esses componentes trabalham juntos para produzir uma fonte de calor finamente focada, permitindo soldas de alta qualidade com distorção mínima.

Portabilidade e flexibilidade: O design mantido à mão permite fácil manobrabilidade, tornando-o adequado para projetos de soldagem no local e fora do local. A natureza leve e compacta desses soldadores garante que eles possam ser usados em espaços apertados e ambientes desafiadores.

Alta precisão e velocidade: Os soldadores a laser de manutenção oferecem precisão superior em comparação com os métodos de soldagem tradicionais. O feixe de laser focado permite controle preciso sobre o processo de soldagem, resultando em soldas mais limpas e mais fortes. Adicionalmente, A soldagem a laser é significativamente mais rápida, reduzindo os tempos de produção.

Entrada mínima de calor: O feixe a laser aquece apenas um pequeno, Área localizada do material, minimizar a distorção do calor e reduzir a zona afetada pelo calor (HAZ). Isso é particularmente benéfico para soldagem de materiais finos ou delicados.

Versatilidade: Esses soldadores são compatíveis com uma ampla gama de metais, incluindo aço inoxidável, aço carbono, alumínio, cobre, titânio, e mais. Eles também podem ser usados para soldagem de materiais diferentes.

Baixa manutenção: Os soldadores a laser com manuseio exigem manutenção mínima em comparação com o equipamento de soldagem tradicional. O processo sem contato reduz o desgaste, prolongando a vida útil da máquina.

Custo-benefício: Apesar do maior investimento inicial, Os soldadores a laser de manutenção oferecem economia de custos significativos a longo prazo. Os custos de mão -de -obra reduzidos, tempos de produção mais rápidos, e o uso mínimo de uso consumível contribui para economias gerais.

Requisito de habilidade reduzida: Os métodos tradicionais de soldagem geralmente requerem operadores altamente qualificados. No entanto, Os soldadores a laser de manutenção são projetados para serem amigáveis, Permitir que operadores com menos experiência obtenham soldas de qualidade profissional. Isso ajuda a abordar a escassez de soldadores qualificados na indústria.

Segurança aprimorada: A soldagem a laser elimina muitos dos perigos associados à soldagem tradicional, como respingos, fumaça, e radiação ultravioleta. Adicionalmente, O processo sem contato reduz o risco de queimaduras e outras lesões.

Ecológico: A soldagem a laser é uma tecnologia verde que não depende de consumíveis ou produtos químicos. Isso reduz o desperdício e o impacto ambiental, Alinhando -se com práticas de fabricação sustentáveis.

Os soldadores a laser de manutenção são usados em uma variedade de indústrias devido à sua versatilidade e eficiência. Algumas aplicações comuns incluem:

Indústria automobilística: Usado para soldar componentes do corpo do carro, chassis, e sistemas de exaustão, garantindo articulações fortes e duráveis.

Indústria aeroespacial: Ideal para soldagem de materiais leves e de alta resistência usados em estruturas e componentes de aeronaves.

Fabricação de dispositivos médicos: Usado para criar soldas precisas e limpas em instrumentos e dispositivos médicos, garantir higiene e confiabilidade.

Indústria de eletrônicos: Adequado para soldar componentes eletrônicos delicados, fornecendo controle preciso para evitar danos a peças sensíveis.

Jóias e relojoaria: Permite a criação de soldas finas e complexas necessárias nas jóias e na manufatura.

Construção e infraestrutura: Usado para soldagem componentes estruturais, grades, e estruturas de metal, garantir durabilidade e força.

Fonte a laser: A fonte do laser é o componente central do soldador, Determinando o poder e a eficiência do processo de soldagem. Fontes comuns incluem lasers de fibra e lasers de estado sólido, ambos conhecidos por sua alta potência e estabilidade.

Cavidade óptica: A cavidade óptica contém espelhos reflexivos que amplificam o feixe de laser, garantindo uma saída focada e poderosa. A refletividade dos espelhos é crucial para otimizar o desempenho do laser.

Sistema de resfriamento: O resfriamento eficaz é essencial para manter a estabilidade e a eficiência do laser. Sistemas de resfriamento, normalmente líquido ou baseado em ar, dissipar o calor gerado durante o processo de soldagem, prevenir superaquecimento e dano.

Sistema de controle: Os sistemas de controle avançado permitem que os operadores ajustem os parâmetros como a energia, velocidade, e frequência de pulso. Isso garante desempenho e precisão ideais para várias aplicações de soldagem.

Blindagem de suprimento de gás: Gases de proteção como argônio e hélio protegem a área de solda da contaminação atmosférica, impedir a oxidação e garantir soldas limpas. O sistema de fornecimento de gás é parte integrante da manutenção da qualidade da solda.

Cabeça de solda: A cabeça de soldagem concentra o feixe de laser no material. Inclui uma lente de foco, bico de proteção, e portas de suprimento de gás. O design da cabeça de soldagem afeta a precisão e a consistência das soldas.

O futuro da tecnologia de soldagem a laser mantida à mão parece promissora, com avanços contínuos destinados a aumentar a eficiência, precisão, e versatilidade.

Automação e Integração: Os soldadores a laser futuros mantidos na mão provavelmente apresentarão maiores níveis de automação, Integração perfeitamente com sistemas robóticos para processos de soldagem totalmente automatizados.

Precisão aprimorada: Pesquisa e desenvolvimento em andamento melhorarão a precisão da soldagem a laser, permitindo soldas ainda mais precisas e consistentes, particularmente para partes complexas e delicadas.

Aumento da eficiência energética: Os avanços na tecnologia a laser continuarão a melhorar a eficiência energética, Reduzir o consumo geral de energia e tornar a soldagem a laser mais sustentável.

Compatibilidade de material expandido: Desenvolvimentos futuros expandirão a gama de materiais que podem ser efetivamente soldados usando a tecnologia a laser, Abrindo novas aplicações em vários setores.

Os soldadores a laser de manutenção representam um avanço significativo na tecnologia de soldagem, oferecendo inúmeros benefícios sobre os métodos tradicionais. Sua precisão, velocidade, versatilidade, E o custo-efetividade os torna uma ferramenta inestimável para uma ampla gama de aplicações industriais. À medida que a tecnologia continua a evoluir, Os soldadores a laser de manutenção se tornarão ainda mais essenciais aos processos de fabricação, dirigindo inovação e eficiência na indústria de soldagem.