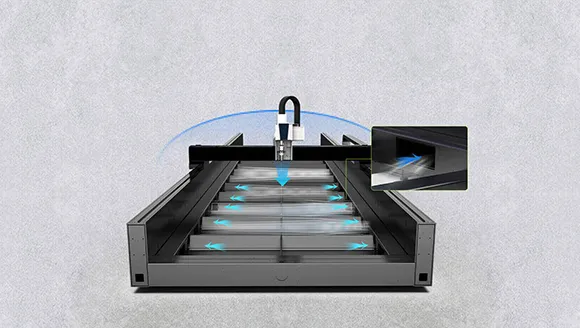

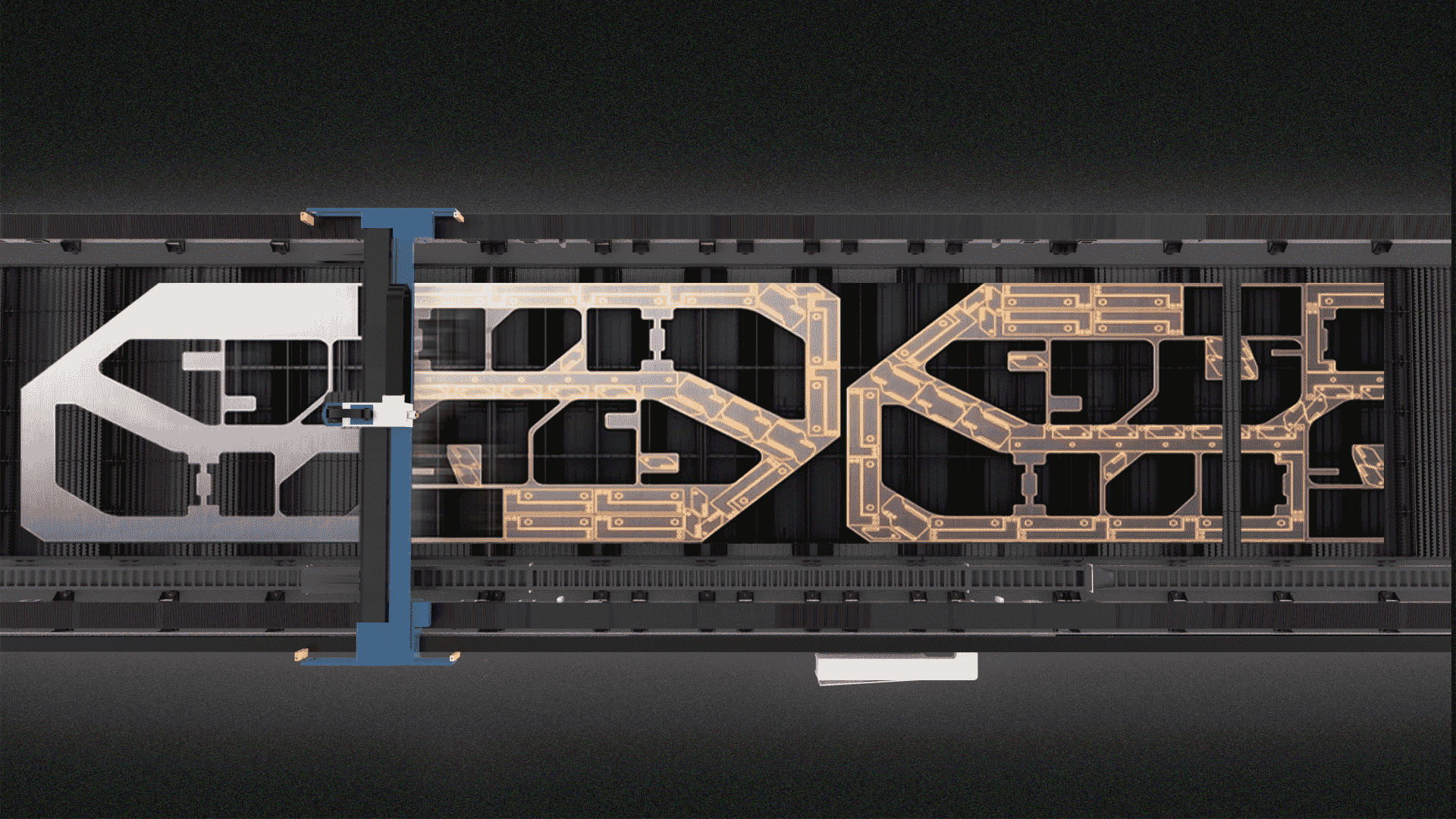

O Modelo B é a nossa máquina de corte aberta de plataforma única para grandes formatos,

com um design de cama estável e robusto,que pode atender ao processamento

necessidades de grandes peças de trabalho.

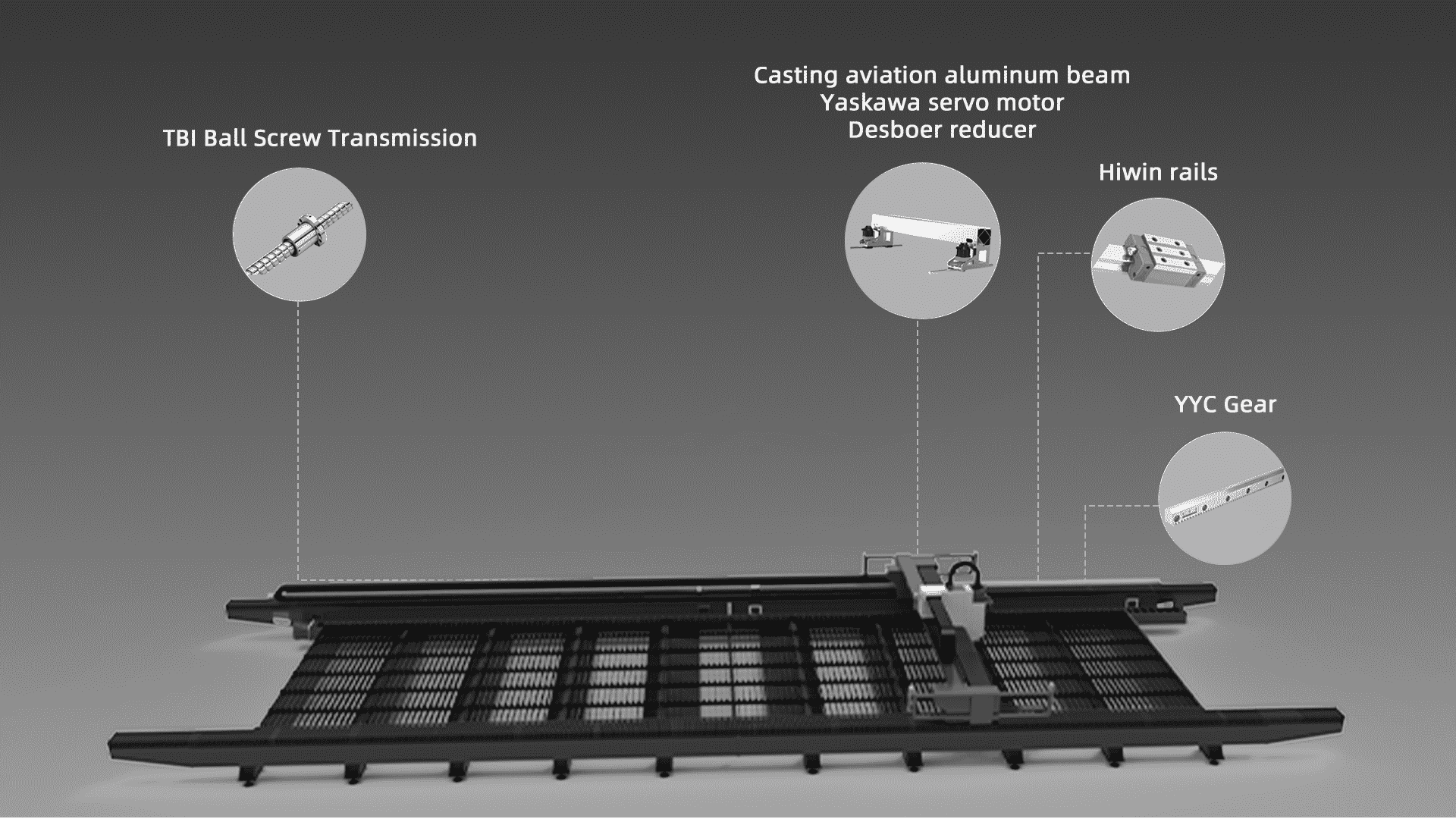

Usando o japonês Yaskawa Electric, MOTOR ELÉTRICO DE FUJI JAPONES, alta precisão, sem perda de etapa, alto torque, baixo ruído, Usando Taiwan YYC/Alemanha Herion Gear e Shimpo Japonês/Redutor de Cíder de Motovario/Alemanha, A precisão do posicionamento da máquina atinge 0.02 milímetros

1 conjunto de B25 pode ser embalado em contêiner padrão 2 × 40HQ. Podemos permitir a entrega apressada e geralmente cobrar frete reduzido significativamente. Após a chegada, Os usuários podem se reunir tudo usando inserção rápida. Sem esperar pela nova instalação.

Modelo de máquina | Série B20 | Série B25 | Série B30 |

Área de Trabalho | 12000*2000milímetros | 12000*2500milímetros | 12000*3000milímetros |

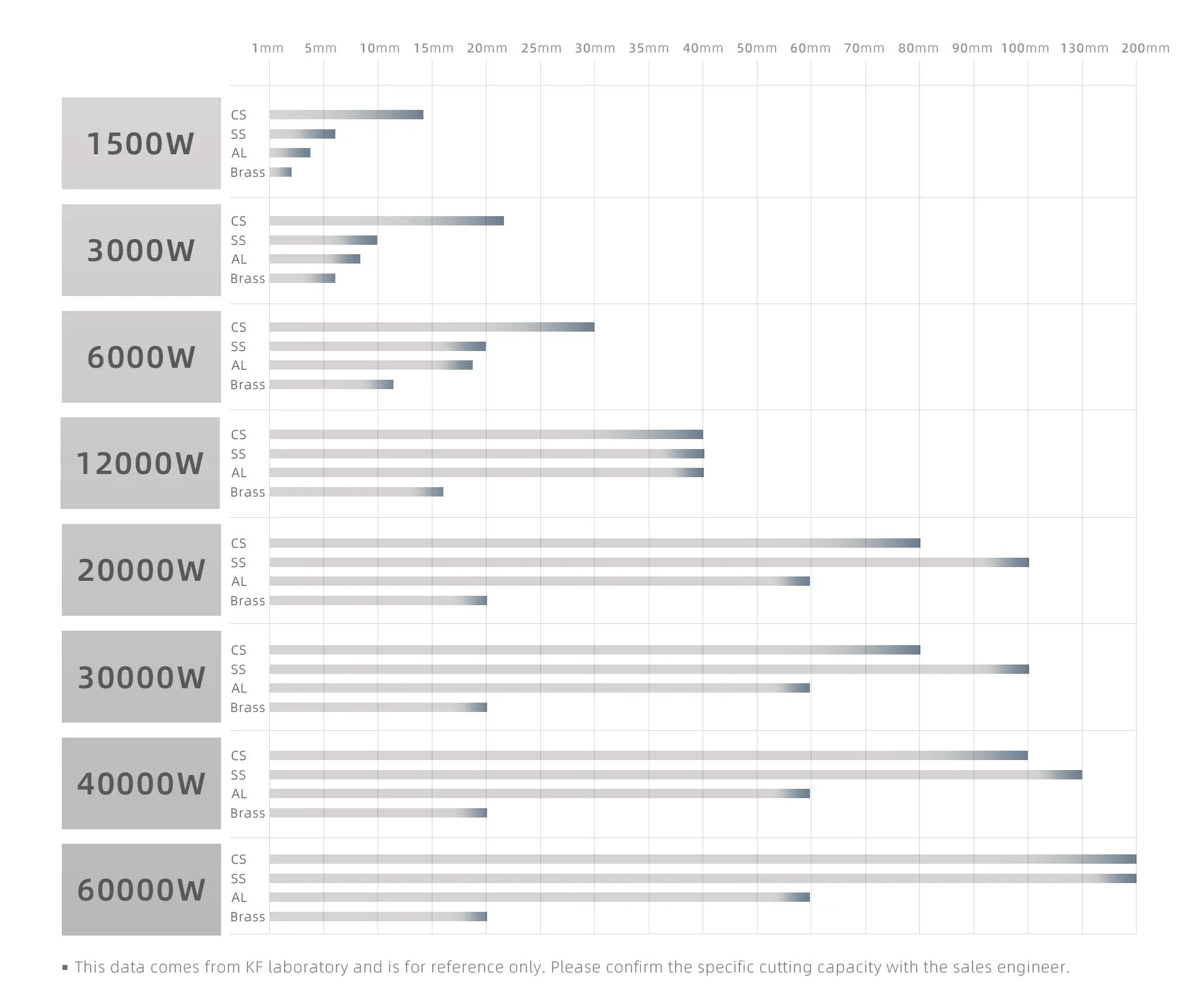

Potência Laser | 1-12KW | 1-20KW | 1-20KW |

Dimensão | 15500*3350*1975milímetros | 15500*3850*1975milímetros | 15500*4350*1975milímetros |

Peso | 15890KG | 17890KG | 19890KG |

|

|

|

|

Velocidade máxima de marcha lenta(m/min) | 90m/min | ||

Aceleração máxima em marcha lenta(G) | 1.0G | ||

Precisão de posicionamento do eixo X/Y/mm | ±0,05 mm | ||

Precisão de posicionamento repetido/mm | ±0,02mm | ||

Precisão de corte/mm | ≤0,1 mm | ||

Tensão de trabalho | 380V,trifásico /50Hz-60Hz | ||

Formatos de imagem suportados | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

UM: Para lhe recomendar o modelo de máquina mais adequado, basta nos dizer as informações abaixo

1)Qual é o seu material

2)O tamanho do material

3)A espessura do material

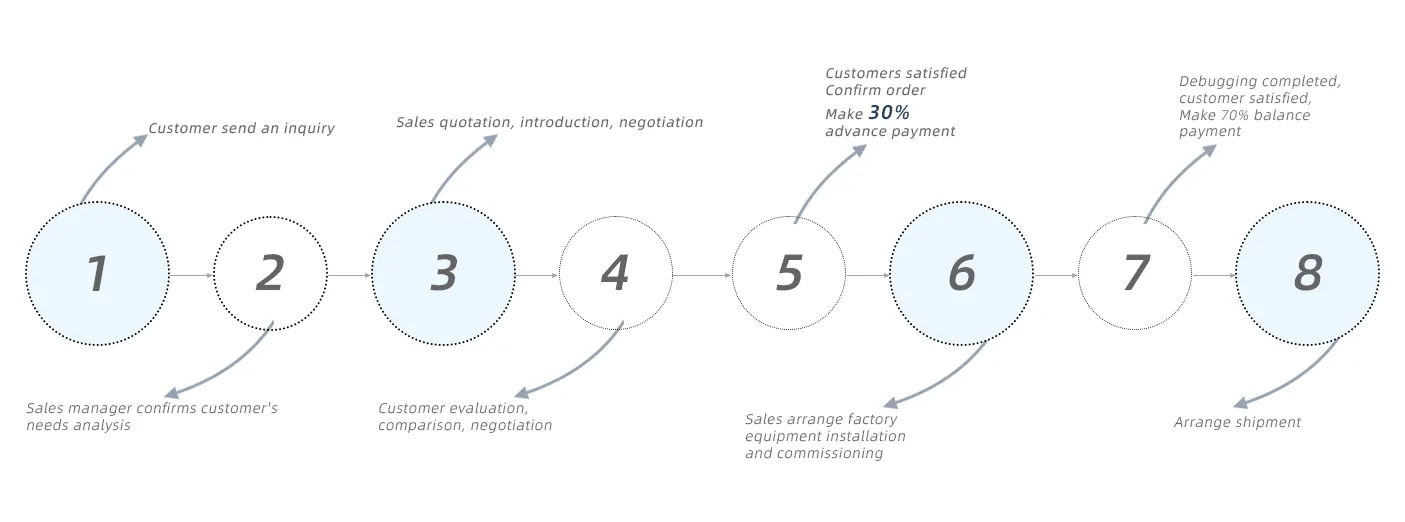

UM:1)Garantia comercial Alibaba/TT/West Union/Payple/LC/Cash e assim por diante.

2)Começamos a fabricar máquinas padronizadas após recebermos 30% do pagamento, inspecionar as máquinas após a conclusão, e finalmente coletar o 70% saldo antes do envio.

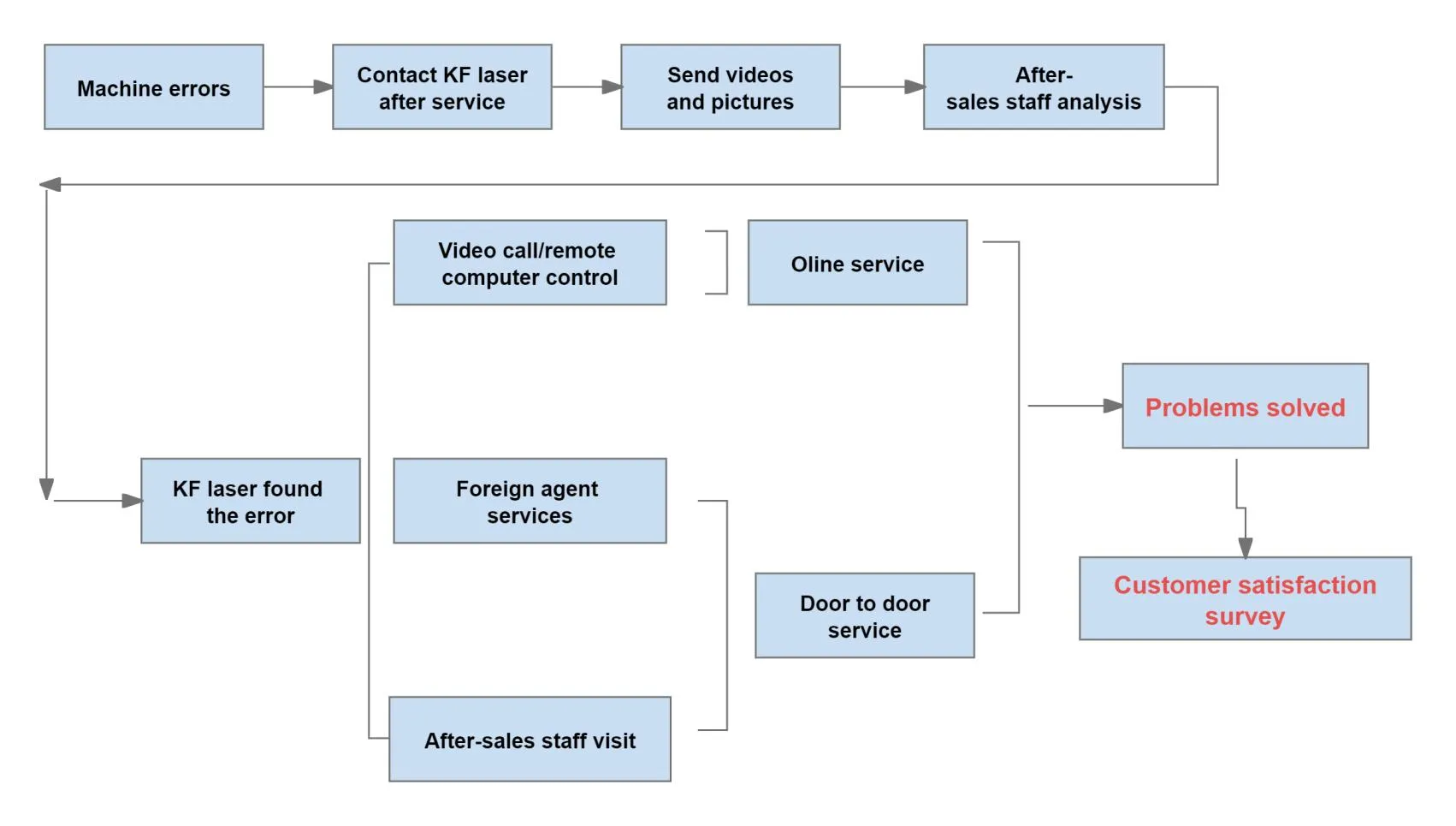

UM:1)Oferecemos treinamento gratuito em nossa fábrica

2)Oferecemos serviço pós-venda on-line gratuito

3)Temos instruções completas de instalação e tutoriais em vídeo

4)As taxas de serviço porta a porta são baseadas na região e no modelo da aeronave

5)Fornece garantia de três anos, exceto peças consumíveis, substituição direta por danos não humanos

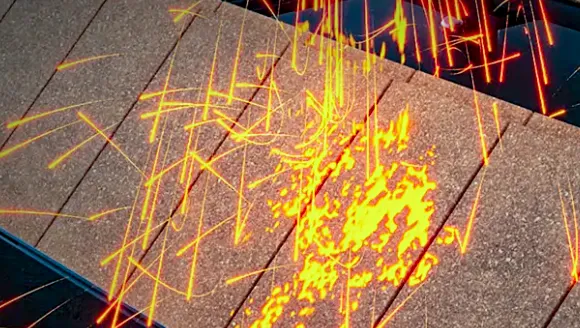

Um cortador de chapa a laser é uma ferramenta avançada que usa um feixe de laser de alta potência para cortar chapas com notável precisão e velocidade.. A máquina de corte a laser para chapas metálicas opera direcionando o feixe de laser através de um sistema de caminho óptico, focando-o na superfície do metal para derreter ou vaporizar o material. Esta tecnologia oferece inúmeras vantagens sobre os métodos de corte tradicionais, tornando-o um ativo essencial em vários setores.

O corte a laser para chapas metálicas envolve o uso de um feixe de laser focado para derreter, queimar, ou vaporizar o material. O feixe de laser é direcionado para a superfície do metal, onde aquece e derrete o material, criando um corte preciso. O processo é controlado por controle numérico de computador (CNC) sistemas, que garantem alta precisão e repetibilidade.

Os cortadores de chapa a laser podem lidar com uma variedade de metais, incluindo aço, alumínio, latão, e cobre. Essas máquinas são amplamente utilizadas na fabricação devido à sua capacidade de produzir formas e designs complexos com alta precisão..

Os cortadores de chapa a laser são usados em vários setores, Incluindo:

Existem vários tipos de cortadores a laser usados na indústria:

Ao selecionar uma máquina de corte a laser para chapas metálicas, vários fatores devem ser levados em conta:

Existem diversas técnicas utilizadas no corte a laser, cada um adequado para diferentes materiais e requisitos:

Para obter os melhores resultados com um cortador de chapa a laser, considere as seguintes dicas de otimização:

Embora o corte a laser seja geralmente seguro, envolve lasers de alta potência e perigos potenciais. Siga estas diretrizes de segurança para garantir um ambiente de trabalho seguro:

O custo de uma máquina de corte a laser para chapas metálicas depende de vários fatores, incluindo tipo de laser, poder, tamanho da mesa de trabalho, e propriedades dos materiais. Compreender esses fatores pode ajudá-lo a escolher uma máquina que atenda ao seu orçamento e necessidades de corte.

O campo do corte a laser de chapas metálicas está em constante evolução, com novas tecnologias e avanços melhorando a eficiência, precisão, e versatilidade. Algumas tendências emergentes incluem:

Os cortadores de chapa a laser oferecem inúmeras vantagens, incluindo alta precisão, velocidade, e versatilidade. Ao entender os diferentes tipos de lasers, suas aplicações, e os fatores a serem considerados ao escolher uma máquina, você pode tomar uma decisão informada para otimizar seus processos de corte. A otimização e manutenção adequadas garantirão resultados consistentes de alta qualidade, tornando o corte a laser uma ferramenta indispensável na fabricação moderna.