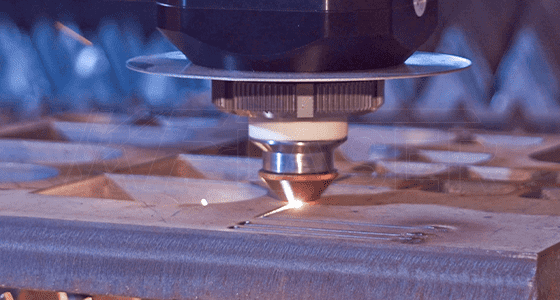

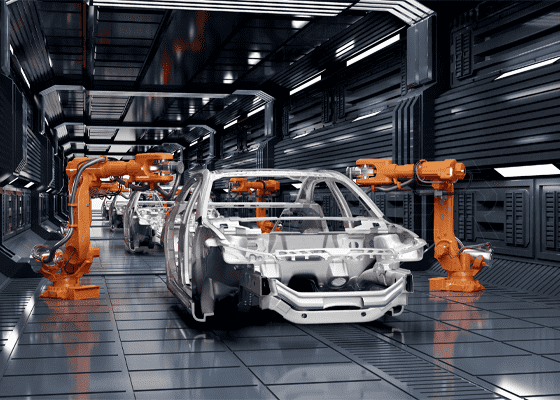

Laser cutting has become an indispensable tool in modern manufacturing, offering precision, velocidade, and versatility across various industries. Among the many types of lasers used for cutting, fiber optic laser cutting machines are rapidly gaining prominence due to their efficiency and capability to handle different materials with exceptional precision. These machines are transforming industries, De automotivo ao aeroespacial, by providing enhanced performance in cutting metals and other materials.

Neste artigo, we will explore the mechanics of fiber optic laser cutting machines, their unique benefits, typical applications, and key factors to consider when adopting this cutting-edge technology.

UM fiber optic laser cutting machine utilizes a fiber laser as its cutting source. Fiber lasers are powered by optical fibers doped with rare earth elements like ytterbium, which allows the generation of high-power laser beams. The laser beam is directed onto the material to be cut, onde derrete, queimaduras, or vaporizes the material along a precisely controlled path.

Ao contrário dos lasers de CO2 tradicionais, fiber lasers are more energy-efficient and can cut through materials faster with greater precision. The fiber optic technology ensures that the laser is focused to a fine point, allowing it to cut through metals, plásticos, and other materials with minimal heat-affected zones.

O fiber optic laser cutting machine offers numerous advantages over conventional laser cutting technologies, such as CO2 lasers or mechanical cutting methods. These benefits make it a preferred option for manufacturers looking to improve precision, velocidade, and overall production efficiency.

Fiber optic laser cutting machines operate at higher speeds than traditional CO2 laser cutters. The fiber laser’s beam quality is superior, allowing for faster cutting speeds and reduced operating costs. With more power concentrated on the cutting area, fiber lasers enable faster processing of materials, increasing productivity and reducing lead times.

One of the most significant advantages of fiber lasers over CO2 lasers is their energy efficiency. Fiber optic lasers require significantly less power to operate, which reduces energy consumption and overall operational costs. The energy-efficient design also leads to reduced heat generation, which improves the lifespan of the machine and minimizes maintenance costs.

Fiber optic laser cutting machines are known for their precision and the clean edges they produce. The focused beam allows for intricate and accurate cuts, with minimal heat distortion or burrs. This makes fiber laser cutting ideal for applications that require high tolerances and clean edges, reducing the need for post-processing or finishing.

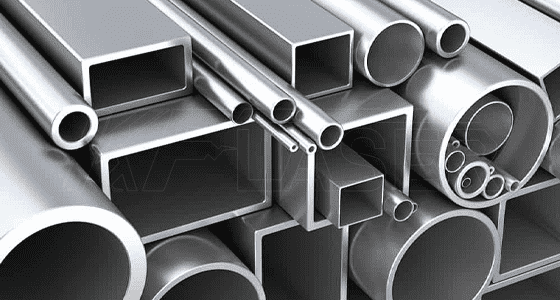

Fiber optic lasers can cut a wide range of materials, Incluindo aço inoxidável, alumínio, aço carbono, titânio, and various non-metals. This versatility makes them suitable for a diverse array of industries, from automotive manufacturing to electronics and even jewelry production. Whether cutting thin sheets or thicker plates, fiber lasers offer flexibility in material handling.

Fiber lasers are designed with fewer moving parts compared to traditional CO2 laser machines. This reduces the wear and tear on the system, making fiber optic cutting machines more durable and requiring less frequent maintenance. Their long lifespan and reduced need for regular servicing contribute to a lower total cost of ownership.

A versatilidade e eficiência do fiber optic laser cutting machines make them applicable across numerous sectors, each benefiting from their precision and speed. Here are some of the key industries and applications:

Fiber optic laser cutters are widely used in sheet metal fabrication, where their ability to cut through a variety of metals with high precision is highly valued. These machines allow manufacturers to produce components with complex geometries, such as panels, colchetes, and chassis, with minimal material waste.

Examples: Automotive body parts, electrical enclosures, and metal frames.

In the aerospace and defense sectors, fiber optic laser cutting machines are crucial for producing lightweight, high-precision components that meet stringent safety standards. These machines allow for the creation of intricate parts from materials like titanium and aluminum, which are essential in aircraft manufacturing.

Examples: Aircraft components, satellite parts, and military-grade equipment.

Fiber optic lasers are increasingly being used in the production of medical devices, where high precision is essential. The ability to cut small, complex shapes without compromising the integrity of the material makes fiber lasers ideal for manufacturing delicate components such as surgical instruments and medical implants.

Examples: Surgical instruments, medical prosthetics, e equipamento de diagnóstico.

The electronics industry also benefits from fiber optic laser cutting, particularly for creating micro-sized components used in semiconductor devices. The ability to precisely cut thin metals and create tiny, intricate designs is vital for the production of circuit boards and other electronics.

Examples: Circuit boards, conectores, and sensors.

Artists and jewelry designers are also adopting fiber laser cutting technology for creating intricate and detailed designs. The high precision and ability to cut through materials like stainless steel and precious metals make fiber lasers ideal for these applications.

Examples: Custom jewelry, esculturas, e itens decorativos.

When considering the adoption of a fiber optic laser cutting machine, several factors should be taken into account to ensure that it fits the specific needs of your production process. These factors include:

Espessura do material: Fiber lasers are ideal for cutting thin to medium thickness metals, but their performance can vary with thicker materials. It’s important to choose a machine with the right power and specifications based on the thickness of the material you plan to cut.

Machine Power and Specifications: The power of the fiber laser determines its cutting speed and ability to handle different materials. Machines with higher power are capable of cutting through thicker materials faster. Ensure the machine’s power is suitable for your specific cutting needs.

Maintenance Requirements: While fiber optic lasers require less maintenance than CO2 lasers, it’s still essential to keep the machine in good working condition. Regular inspections and proper handling can extend the lifespan of the laser and ensure continued efficiency.

Cutting Speed and Production Volume: The cutting speed of a fiber optic laser cutting machine will depend on factors like material type, grossura, and design complexity. Ensure that the machine meets the production speed requirements for your business.

Cost vs. ROI: The initial cost of purchasing a fiber optic laser cutting machine may be higher than traditional cutting methods, but the long-term benefits—such as lower operational costs, resíduos reduzidos, and increased production speed—offer a significant return on investment. It’s essential to weigh the initial cost against the potential savings and benefits.

The rise of fiber optic laser cutting machines marks a significant shift in the manufacturing landscape. With faster cutting speeds, eficiência energética, and unmatched precision, these machines are providing industries with the tools they need to stay competitive in a fast-paced world. Whether you’re cutting sheet metal, aerospace components, or medical devices, fiber optic laser cutting offers a versatile, confiável, and cost-effective solution that can enhance your production capabilities and reduce overall costs.