In the world of industrial manufacturing and design, Precisão é fundamental, especially when working with materials like steel. Laser cut steel panels have become an essential component in industries ranging from architecture to automotive manufacturing due to their durability, precisão, e versatilidade. This technology offers a high level of accuracy and the ability to create intricate designs that would otherwise be difficult or impossible with traditional cutting methods.

But what exactly makes laser cutting so effective for steel, and how can it be applied to various fields? Neste artigo, we’ll dive deep into the process, benefícios, and common uses of laser cut steel panels, as well as key considerations when choosing this technology for your project.

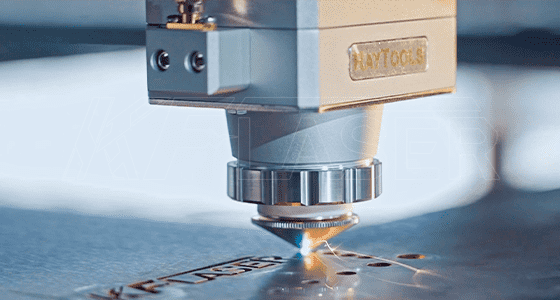

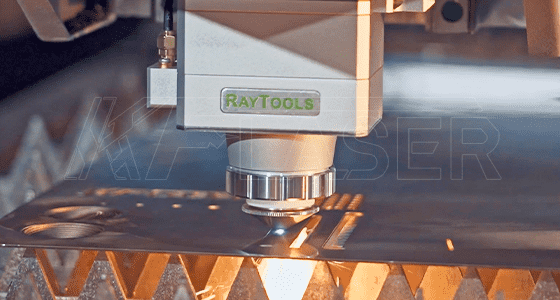

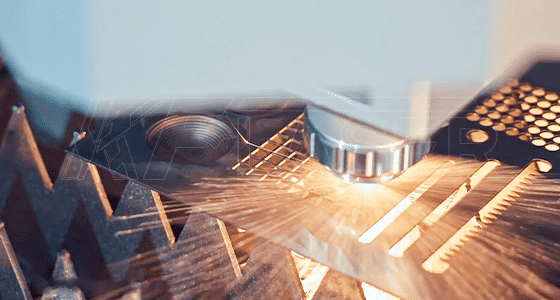

Laser cutting is a non-contact process that uses a high-powered laser beam to cut through steel panels. The process involves focusing the laser on the steel surface, melting or vaporizing the material along the cutting path. The precision of laser cutting allows for sharp, clean edges and complex geometries, making it the go-to method for cutting steel into panels for a wide variety of applications.

There are several types of lasers used for steel cutting, Incluindo lasers de fibra e Lasers de CO2, each with unique benefits depending on the steel thickness and cutting requirements. Fiber lasers are the preferred choice for cutting steel, as they offer faster cutting speeds, maior eficiência energética, and the ability to cut through thicker materials.

The growing popularity of laser cut steel panels can be attributed to several significant advantages over traditional methods like shearing or mechanical cutting. These benefits make laser cutting an attractive option for many industries.

One of the standout benefits of laser cutting is its unmatched precision. The laser beam can create intricate and detailed patterns with tight tolerances, ensuring that each panel meets exact specifications. This is particularly valuable in industries like architecture and automotive manufacturing, where the precision of components can significantly impact the final product.

Laser cutting can handle a wide range of steel thicknesses, from thin sheets to thick plates. This versatility makes it suitable for a variety of applications, including custom designs, prototyping, and large-scale production. Whether you’re cutting aço inoxidável, Aço suave, ou aço carbono, laser cutting offers flexibility in terms of both material types and design complexity.

Laser cutting is a highly efficient process. Because the laser beam is so precise, it generates minimal material waste, reduzindo custos e impacto ambiental. The precision also means there is less need for post-processing, further saving time and resources. This makes laser cutting a cost-effective option for companies looking to maximize the value of their raw materials.

Another advantage of laser cut steel panels is the quality of the cut. Unlike mechanical cutting, which can create rough edges or burrs that require additional finishing, laser cutting produces smooth, clean edges that often require little to no post-processing. This is especially important in applications where aesthetics and smooth finishes are essential, such as in interior design or modern architecture.

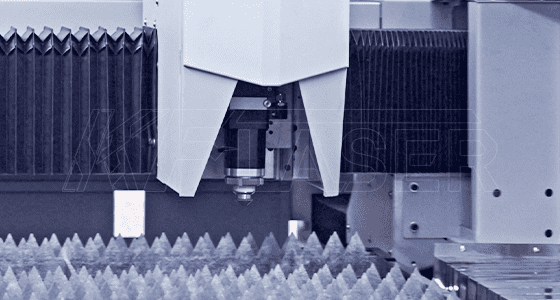

Laser cutting machines are capable of operating at high speeds, which increases production efficiency and reduces turnaround times. This is ideal for industries that require fast, high-volume production, such as the automotive sector or sheet metal fabrication.

Laser cut steel panels are used across a wide variety of industries due to their precision, durabilidade, and aesthetic appeal. Aqui estão algumas das aplicações mais comuns:

In modern architecture, laser cut steel panels are frequently used for decorative features in buildings, including façades, screens, and partitions. The ability to cut intricate patterns and designs into steel allows architects to create visually striking elements that enhance the aesthetic appeal of a building. Whether for exterior cladding or interior wall treatments, laser-cut steel provides both beauty and durability.

Examples: Laser-cut steel panels can be used for exterior cladding, room dividers, privacy screens, and perforated walls, adding texture and depth to the space.

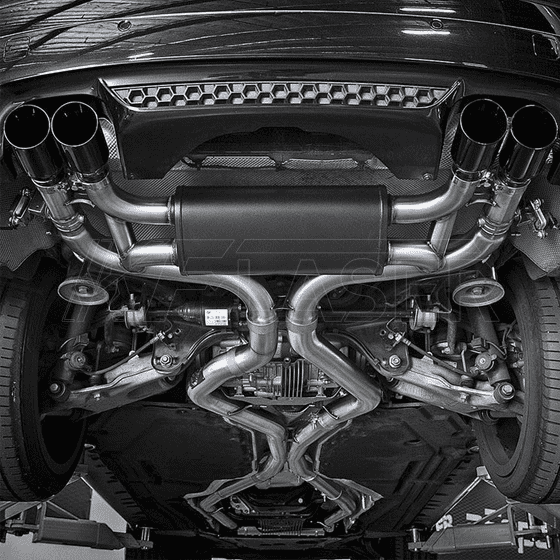

Na indústria automotiva, laser-cut steel panels are essential for producing parts like body panels, quadros, e componentes estruturais. The precision of laser cutting ensures that each piece fits perfectly, contributing to the overall quality and safety of the vehicle. Adicionalmente, the ability to handle various steel alloys makes it a versatile choice for different automotive applications.

Examples: Car body parts, sistemas de escape, and brackets are often laser cut from steel for their strength and reliability.

Laser cut steel panels are becoming increasingly popular in the furniture industry, especially for creating modern, industrial-style furniture. The clean lines and intricate designs achievable with laser cutting make it an ideal solution for producing unique tables, chairs, shelving units, and decorative pieces.

Examples: Laser-cut steel panels can be used in tables, lamps, and decorative furniture elements, adding a modern edge to home and office spaces.

Laser cut steel is frequently used in the creation of business signage and branding materials. The precision of the cuts ensures that the text and logos are sharp and clear, and the durability of the material means that these signs can withstand harsh weather conditions. Steel signs are often used for both outdoor and indoor applications.

Examples: Street signs, company logos, and commercial signage often use laser-cut steel for a professional, polished look.

Steel panels are essential components in the construction and engineering sectors. Laser cutting allows for the accurate fabrication of structural components such as beams, colunas, and reinforcements, which are crucial for the integrity of a building. Laser cut steel is used not only for structural purposes but also for aesthetic enhancements like decorative elements or patterned cladding.

Examples: Steel panels in bridges, buildings, and industrial structures are often laser cut for both function and design.

When selecting laser cut steel panels for a project, several factors should be taken into account to ensure optimal results:

Tipo de material e espessura: The type of steel and its thickness will affect the cutting process. Thicker materials may require higher-powered lasers, while thinner sheets can be cut faster and with lower power.

Design Complexity: Laser cutting excels at creating intricate patterns, but the complexity of the design may impact production time. Ensure that the design is optimized for laser cutting to avoid unnecessary delays or costs.

Finish and Quality: Dependendo do aplicativo, you may require specific finishes. Some laser-cut panels may need additional processing to achieve a particular surface finish or coating, such as powder coating or galvanization, to enhance corrosion resistance.

Volume de produção: Consider the volume of panels required for your project. Laser cutting machines are ideal for both small and large runs, but the lead time for large volumes may vary depending on machine capacity and material handling.

Eficiência de custos: While laser cutting is highly precise and efficient, the cost can vary depending on factors like material type, grossura, and design complexity. It’s important to balance the quality and speed of production with your budget constraints.

The growing popularity of laser cutting technology continues to reshape industries that rely on precision and efficiency. By offering cleaner cuts, minimal waste, and versatile applications, laser cut steel panels provide an ideal solution for modern manufacturing and design needs. Whether you’re building a new structure, creating custom furniture, or designing an innovative vehicle, laser cutting offers the precision and flexibility needed to bring your vision to life.