News

Laser Cutting Aluminum Tube: Precision and Efficiency in Manufacturing

Laser cutting aluminum tube has rapidly become the industry standard for achieving unparalleled precision and quality. With the increasing demand for more intricate designs in aerospace, automotive, and construction, the ability to cut aluminum tubes accurately and efficiently has never been more critical. Laser cutting technology, known for its precision, speed, and cost-effectiveness, is used to create parts that require high dimensional accuracy, clean edges, and minimal waste.

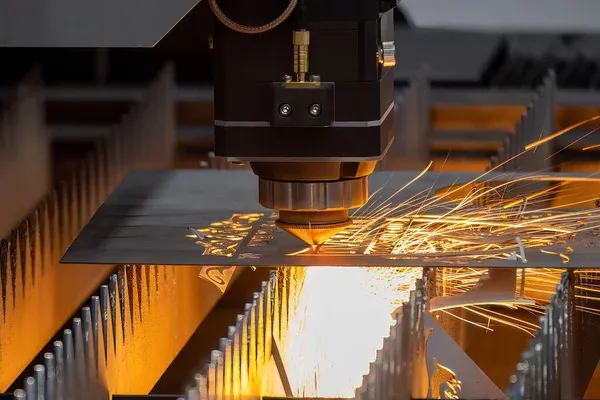

Laser cutting uses a focused laser beam to melt, burn, or vaporize material along a predefined cutting path. The process is fully automated and controlled by CNC (Computer Numerical Control) systems, ensuring that even the most complex geometries can be produced with ease. When it comes to cutting aluminum, this technology allows manufacturers to achieve the sharpest cuts with minimal post-processing.

The Technology Behind Laser Cutting Aluminum Tube

Laser cutting involves the use of a laser beam that is focused on the surface of the aluminum tube. The heat from the laser beam melts or vaporizes the material in a controlled manner, following a precise path determined by the CAD design. The process involves high-energy beams, typically emitted from a CO2 or fiber laser, to cut through the aluminum material.

There are two primary types of lasers used for aluminum tube cutting:

CO2 Lasers:

These lasers are best suited for cutting materials like aluminum that are reflective and conductive. The CO2 laser uses a gas mixture to produce a high-energy laser beam that is capable of cutting thicker materials.

Fiber Lasers:

Fiber lasers offer higher efficiency and faster cutting speeds, particularly for thinner materials. Their precision and power make them an excellent choice for cutting delicate designs in aluminum tubes.

Why Laser Cutting Aluminum Tube Is the Preferred Method

Laser cutting offers numerous advantages over traditional cutting methods, such as saw cutting or punching. Some of the key benefits include:

Unmatched Precision and Accuracy:

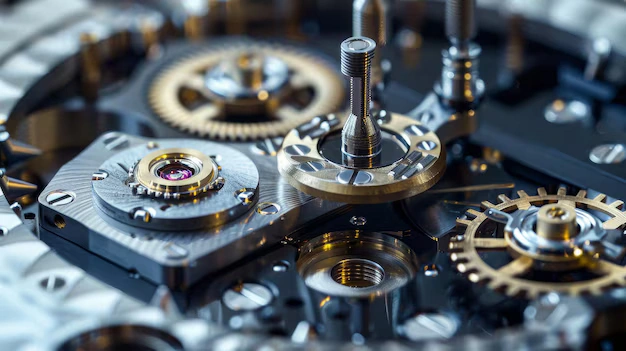

Laser cutting provides exceptional precision, with cutting tolerances as low as ±0.1mm. This level of accuracy is critical when working with aluminum tubes for high-performance applications, such as aerospace or medical devices.

Minimal Waste:

Laser cutting uses a very narrow kerf width, meaning less material is lost during the cutting process. This is particularly beneficial when working with expensive materials like aluminum, as it reduces both scrap material and costs.

Complex Geometries:

Unlike traditional methods that may require specialized tooling or die setups, laser cutting allows manufacturers to create complex shapes and intricate designs with ease. This flexibility is especially valuable in industries where design innovation is key, such as automotive or architecture.

Faster Production Times:

Laser cutting is a faster process compared to traditional methods. Because it requires minimal setup time and operates with high cutting speeds, laser cutting significantly reduces lead times, which helps businesses meet tight production schedules.

Reduced Need for Post-Processing:

The clean edges produced by laser cutting typically require little to no further finishing. This reduces the need for secondary operations like deburring or polishing, saving both time and cost.

Applications of Laser Cutting Aluminum Tube

Laser cutting of aluminum tubes is used across several industries due to its unique capabilities and precision. Here are some of the major applications:

Aerospace Industry:

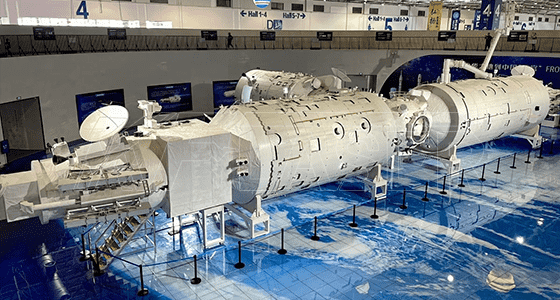

The aerospace sector relies heavily on aluminum for structural components, and laser cutting ensures that parts are both lightweight and strong. Components such as brackets, frames, and other structural elements are made with the precision needed to meet the demanding specifications of the industry.

Automotive Manufacturing:

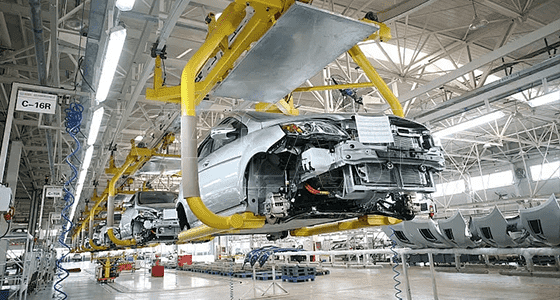

In automotive manufacturing, laser cutting aluminum tubes is commonly used to create parts such as exhaust systems, roll cages, and vehicle frames. The precision and ability to handle complex shapes make it ideal for these applications.

Medical Equipment:

The medical industry often uses laser-cut aluminum tubes for surgical instruments, medical device enclosures, and other precision components. The ability to cut thin walls and intricate shapes ensures high-quality standards are met.

Architectural and Structural Applications:

Laser cutting is also utilized in creating architectural elements such as railings, window frames, and columns. The precision cuts ensure that aluminum tubes fit perfectly into structural designs, providing both strength and aesthetic appeal.

Electronics:

For the electronics industry, aluminum tubes are often used in creating enclosures for devices like heat exchangers or cooling systems. Laser cutting helps create seamless designs with high precision.

Choosing the Right Laser Cutting Service for Aluminum Tube

When selecting a laser cutting service provider for aluminum tubes, several factors should be considered:

Laser Technology and Equipment:

The type of laser used (CO2 vs. fiber) and the cutting capabilities of the equipment are crucial to achieving the desired results. Ensure that the service provider has the appropriate technology for cutting aluminum tubes.

Experience and Expertise:

Experience matters when it comes to laser cutting aluminum tubes. A provider with extensive experience in cutting aluminum tubes will understand the material’s unique properties and be able to deliver the highest-quality results.

Customization and Design Flexibility:

Check if the provider offers customization options for unique shapes and designs. Laser cutting is ideal for creating complex geometries, so working with a provider who understands how to translate your designs into precise cuts is essential.

Turnaround Time and Cost:

While laser cutting is typically faster than traditional methods, it’s essential to ensure that the provider can meet your deadlines without compromising on quality. Comparing cost structures among different providers will help you make an informed decision.

The Future of Laser Cutting Aluminum Tube

The future of laser cutting aluminum tubes looks bright with technological advancements continually improving the efficiency, speed, and precision of the process. Innovations such as automation and AI-driven design software are making it even easier to create complex designs with minimal human intervention. Additionally, as environmental concerns increase, the efficiency of laser cutting will continue to reduce waste and energy consumption, contributing to more sustainable manufacturing practices.

By adopting laser cutting technology, industries that rely on aluminum tubes can achieve the highest standards in terms of precision, speed, and cost-efficiency. As the technology evolves, it will unlock even greater possibilities for manufacturers, ensuring that laser cutting remains the go-to solution for aluminum tube processing for years to come.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine