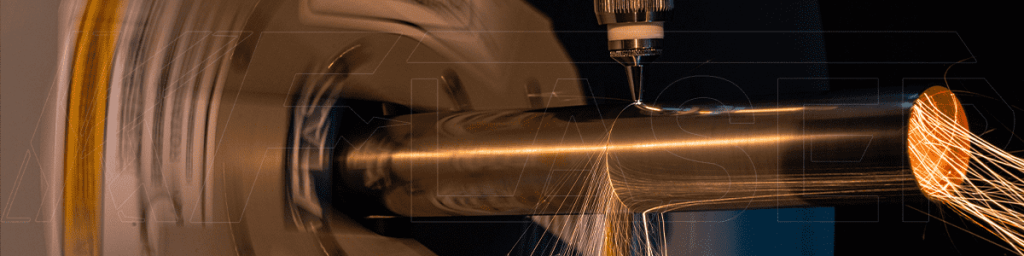

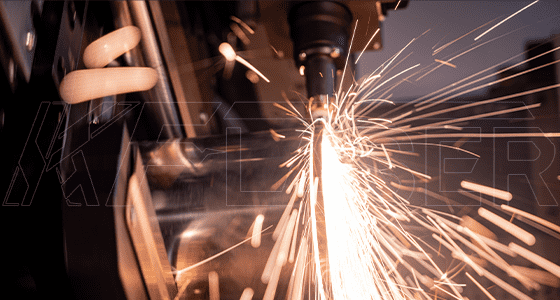

O laser cutting machine tube has become an essential tool in various industries, oferecendo precisão incomparável, velocidade, and versatility when cutting metal tubes. Whether you’re involved in automotive manufacturing, structural engineering, or custom fabrication, understanding how these machines work and their numerous benefits can elevate your projects to a new level.

Neste guia, we’ll explore the capabilities, vantagens, and different applications of laser cutting machines specifically designed for tubes.

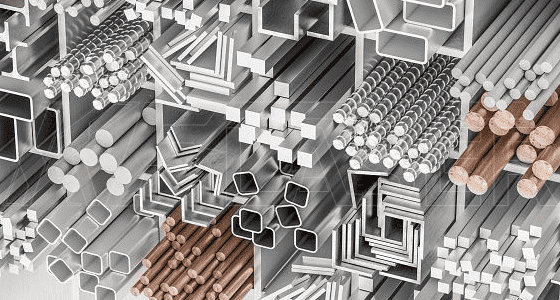

UM laser cutting machine tube is a specialized cutting system designed to precisely cut metal tubes using laser technology. These machines use a high-powered laser beam to melt or vaporize the material along a specific cut line, resulting in clean, accurate cuts with minimal waste. They are commonly used for cutting metals such as steel, aço inoxidável, alumínio, e latão, and are particularly useful for creating complex shapes and designs in tubular materials.

Unlike traditional cutting methods such as sawing or punching, laser cutting provides cleaner edges, higher precision, and the ability to cut intricate designs without the need for additional tools or mechanical components.

O laser cutting machine tube works by focusing a high-powered laser beam onto the surface of the metal tube. Here’s a breakdown of the process:

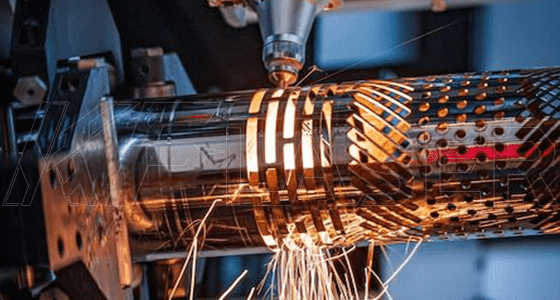

Geração a laser: A laser cutting machine uses a laser generator, typically a CO2 or fiber laser, to produce a concentrated beam of light. This light is then directed through a series of mirrors and lenses to focus it onto the surface of the tube.

Focusing the Laser: The laser beam is precisely focused on the material at a high intensity. The focused light causes the metal to either melt or vaporize, depending on the material and thickness.

Movement and Cutting: As the laser beam moves along the pre-programmed path, it continuously cuts through the tube material. The machine’s computer controls the movement of the laser and the positioning of the tube, ensuring accuracy and consistency.

Cooling and Cleanup: After the cut is made, the heat from the laser is dissipated, and any molten material or debris is removed from the cutting area, typically with a gas blow or vacuum system, leaving behind a clean edge.

O laser cutting machine tube offers several benefits over traditional cutting methods. Some of the most significant advantages include:

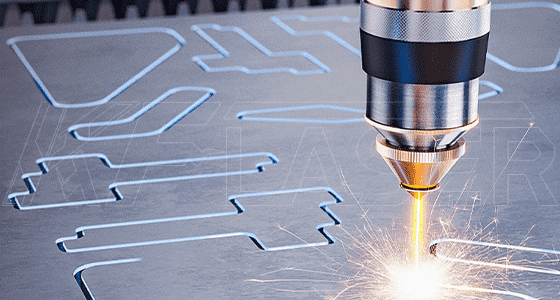

Laser cutting machines are known for their incredible precision. When it comes to cutting metal tubes, even complex designs can be produced with tight tolerances and sharp, Bordas limpas. This makes it ideal for applications where accuracy is critical.

Laser cutting machines can handle a wide variety of shapes, including intricate curves, slots, buracos, and patterns. Whether you need simple straight cuts or highly detailed custom designs, a laser cutting machine can easily meet your requirements.

Ao contrário dos métodos tradicionais, laser cutting is a non-contact process, meaning there is no physical contact with the material being cut. This helps minimize material waste, as the cuts are incredibly precise and accurate. Adicionalmente, laser cutting can handle very thin and thick tubes, making it an efficient choice for different tube sizes.

Laser cutting machines are incredibly fast compared to manual or mechanical cutting methods. With the ability to cut at high speeds, laser cutters are well-suited for high-volume production runs. The setup time is also minimal, making it an ideal solution for custom or low-volume work.

Laser cutting often eliminates the need for additional finishing processes like deburring or sanding. The smoothness and precision of the cut edges reduce post-production time, making the entire process more cost-effective.

Laser cutting machines can handle a wide range of materials, including various metals like carbon steel, aço inoxidável, alumínio, e cobre. This versatility makes them ideal for industries that work with different types of metal tubes.

Laser cutting machine tube technology is used in a wide range of industries, with applications spanning from simple components to complex, custom parts. Algumas das aplicações mais comuns incluem:

No setor automotivo, laser cutting machine tube technology is used to manufacture components such as exhaust systems, structural frames, and suspension parts. The ability to cut tubes with precision is essential for ensuring the integrity and safety of vehicle components.

Laser cutting is widely used in aerospace for creating lightweight and high-strength parts, such as fuselages, wing components, and engine brackets. The precision of laser cutting is crucial for meeting the stringent safety and performance standards of the aviation industry.

Laser cutting machines are used to produce decorative metal tubing for furniture, including chair frames, tables, e elementos decorativos. Custom laser-cut metal tubes can add a unique, modern aesthetic to interior design, making them a popular choice for bespoke furniture pieces.

Laser cutting machines are employed in the manufacturing of industrial equipment, including pipelines, conveyor systems, e suportes estruturais. The precision and speed of laser cutting ensure that parts fit together correctly and function effectively.

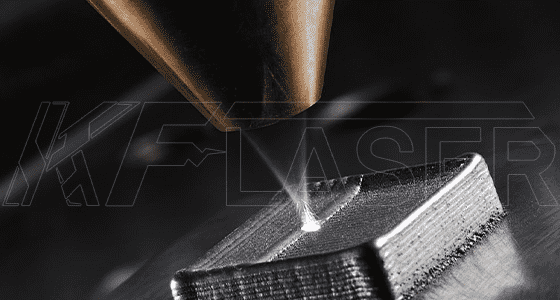

Na indústria médica, laser cutting is used for manufacturing medical tubes and components, such as those found in surgical instruments, stents, e implantes. The precision and ability to handle intricate designs make laser cutting ideal for these delicate and highly regulated products.

Custom fabrication is one of the primary uses of laser cutting machine tube tecnologia. Whether it’s for creating art installations, custom metal railings, or unique industrial designs, laser cutting allows for high levels of creativity and customization.

Laser cutting machines are often used to produce custom signs and advertising materials. Metal tubes can be cut into intricate shapes and designs for use in illuminated signs, suportes estruturais, or stand-alone displays.

When selecting a laser cutting machine tube, there are several factors to consider to ensure it meets your needs:

UM laser cutting machine tube is an indispensable tool for industries requiring precision cutting of metal tubes. With its ability to deliver high-quality cuts, minimal waste, and the flexibility to handle a variety of materials, laser cutting is a superior alternative to traditional methods. Whether you’re involved in automotive manufacturing, custom furniture design, or industrial equipment fabrication, understanding the benefits and applications of laser cutting technology can help optimize your production processes and achieve better results.

By investing in a laser cutting machine designed specifically for tube cutting, you can unlock new possibilities in design, eficiência, and customization, giving your projects a competitive edge in today’s fast-paced industrial landscape.