Notícias

Aço inoxidável de corte a laser com oxigênio: Revolucionando o processo de corte

Laser cutting has become one of the most precise and efficient methods for processing materials, especialmente metais. Laser cutting stainless steel with oxygen is gaining significant attention in industries like automotive, aeroespacial, e fabricação. Por que? Because this technique dramatically enhances the cutting process by increasing speed, reducing costs, and providing excellent quality. But what exactly makes laser cutting stainless steel with oxygen such a game-changer? Let’s dive into the science and practical applications of this process.

The Science Behind Laser Cutting with Oxygen

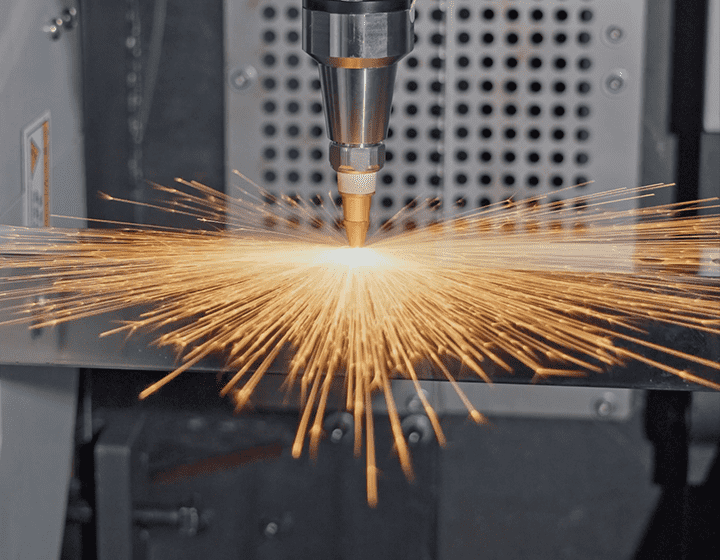

Na sua essência, laser cutting involves focusing a high-powered laser beam on the material to melt or vaporize the material, which is then removed by a stream of gas. Tipicamente, laser cutting processes utilize nitrogen or compressed air, but oxygen has specific advantages when it comes to cutting stainless steel.

When oxygen is introduced into the laser cutting process, it reacts with the steel to produce an exothermic reaction. This accelerates the melting process and increases the cutting speed. The result? A faster, more cost-effective method for cutting through stainless steel with incredible precision.

Advantages of Using Oxygen in Laser Cutting

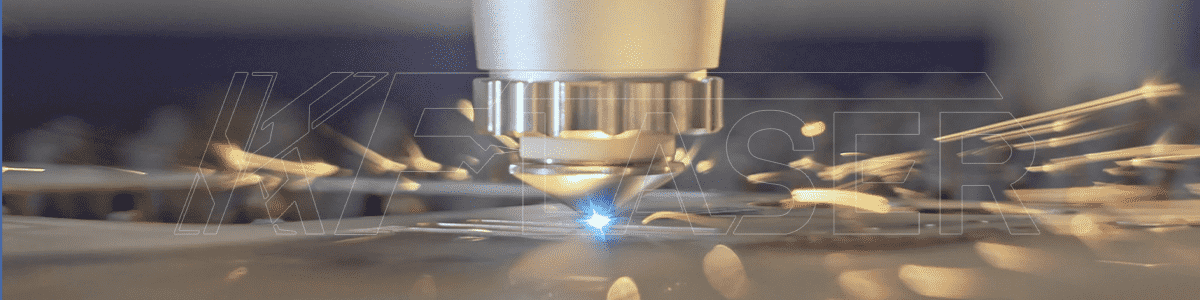

Increased Cutting Speed

Oxygen acts as a fuel for the laser cutting process, increasing the speed at which stainless steel can be cut. The exothermic reaction helps the laser cut through the metal more efficiently, allowing for quicker production times.

Eficiência de custos

Using oxygen instead of nitrogen or air reduces operational costs, as oxygen is typically more affordable and readily available. This makes laser cutting with oxygen a highly cost-effective solution, especialmente para produção de alto volume.

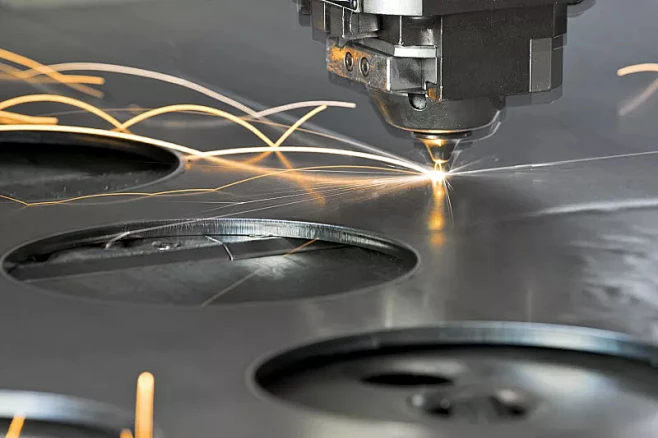

Improved Edge Quality

Laser cutting with oxygen can result in cleaner, smoother edges. While nitrogen can produce oxidation-free edges, oxygen cutting offers excellent edge quality with minimal burrs or irregularities. This is especially important in industries where part quality is a critical factor.

Enhanced Precision and Cleanliness

The precision of the laser beam, combined with the oxygen-assisted reaction, ensures that cuts are not only quick but also accurate. The clean cut edges improve the overall look and quality of the finished product, reducing the need for secondary processing like deburring or polishing.

How Laser Cutting with Oxygen Works

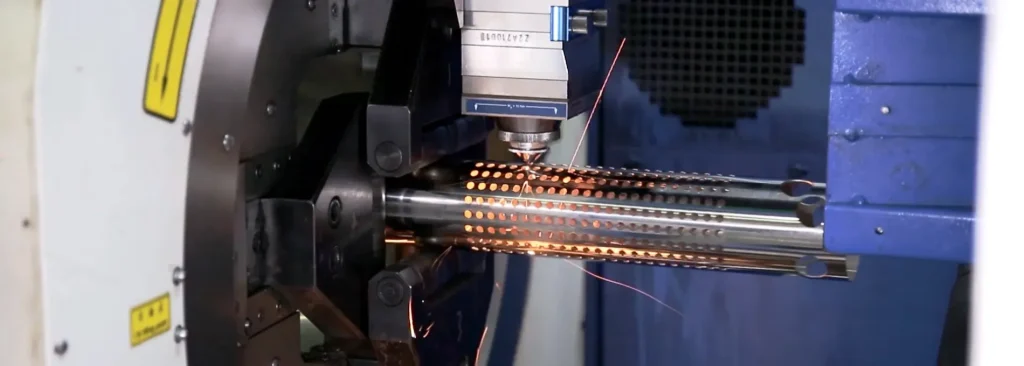

In the process, oxygen is introduced through the nozzle of the laser cutter and is directed onto the workpiece. As the laser beam heats the stainless steel to its melting point, the oxygen reacts with the material, oxidizing it and making the cut process faster. The oxygen also assists in blowing away the molten metal, ensuring a clean, precise cut without excess material buildup.

This is particularly effective for cutting thicker sheets of stainless steel, as the reaction generates additional heat, which speeds up the cutting process. This means that businesses can process large volumes of stainless steel more quickly than with traditional cutting methods.

Key Applications of Laser Cutting Stainless Steel with Oxygen

The applications of laser cutting stainless steel with oxygen are vast and diverse. Some of the most common industries leveraging this technique include:

Fabricação Automotiva: Laser cutting stainless steel with oxygen allows for rapid prototyping and production of car parts like chassis and exhaust systems.

Aeroespacial: Aerospace companies require precise, clean cuts in stainless steel for structural components. The speed and efficiency of laser cutting with oxygen provide significant benefits for these applications.

Eletrônica: In the electronics sector, manufacturers use laser cutting to create intricate designs on stainless steel components like housings and frames.

Comparing Oxygen-Assisted Laser Cutting with Other Methods

When compared to traditional methods of cutting stainless steel, such as mechanical cutting or waterjet cutting, laser cutting with oxygen stands out in terms of speed, precisão, and cost-effectiveness.

Mechanical Cutting: Mechanical cutting, such as using saws or shears, can be slower, menos preciso, and may result in more material waste. Laser cutting with oxygen, por outro lado, offers precise control, reducing waste and increasing efficiency.

Waterjet Cutting: While waterjet cutting can produce highly precise results, it is often slower and more costly. Laser cutting with oxygen allows for faster processing times and lower energy consumption, making it a better choice for high-volume production.

Challenges and Considerations When Using Oxygen for Laser Cutting

While the benefits are clear, there are a few things to keep in mind when opting for laser cutting stainless steel with oxygen:

Espessura do material

Oxygen-assisted laser cutting is typically most effective on thinner materials (up to 12mm thick). For thicker materials, using nitrogen or compressed air may yield better results.

Oxidation Effects

Although oxygen cutting creates clean cuts, the oxidation may slightly discolor the edges of the stainless steel. This may not be suitable for some high-end applications, where aesthetic quality is important.

Environmental Concerns

The increased speed and energy consumption of the oxygen-assisted process may lead to higher environmental impacts if not properly managed. No entanto, this can often be mitigated through energy-efficient laser systems.

The Future of Laser Cutting with Oxygen

À medida que a tecnologia continua a avançar, the efficiency and capabilities of laser cutting with oxygen will only improve. With ongoing innovations in laser technology and material science, we can expect even faster, more precise cutting methods. Laser cutting will continue to shape the manufacturing landscape, driving cost reductions and improvements in product quality.

With its speed, precisão, and cost-effectiveness, laser cutting stainless steel with oxygen offers immense benefits to industries that require high-quality metal cuts. As the demand for faster, more efficient manufacturing methods grows, this technique will likely become a standard practice in many industries. Embracing this technology not only saves time and money but also ensures high-quality results that meet the demands of the modern manufacturing world.

Let’s not forget that mastering the laser cutting process, especially with oxygen, is a game-changer for any business looking to remain competitive in the fast-paced world of metal processing.

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa