Notícias

Máquinas de corte de tubos a laser: Transformando o futuro da fabricação de metais

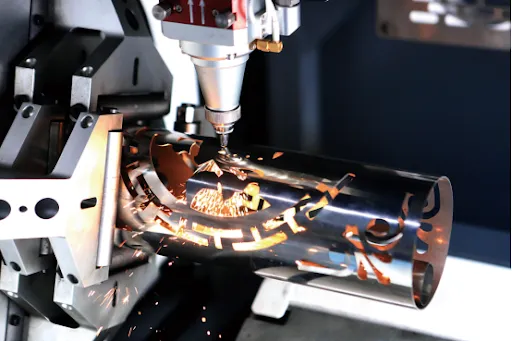

The world of metal fabrication has evolved at an unprecedented rate, and at the forefront of this revolution are laser tube cutting machines. These machines have not only advanced the speed and precision of cutting metal tubes but also opened up new possibilities for industries worldwide. From aerospace to automotive manufacturing, and from energy production to architectural designs, laser tube cutting is helping companies produce parts with unparalleled accuracy and efficiency.

1. Understanding Máquinas de corte de tubos a laser

A laser tube cutting machine uses a focused beam of light to cut through metal tubes, ensuring sharp edges, desperdício mínimo de material, e designs intrincados. Unlike traditional cutting methods such as sawing or punching, laser tube cutting uses high-powered lasers that melt or vaporize the metal, leaving behind smooth, cortes precisos. The versatility of these machines makes them indispensable for industries that require both precision and flexibility in cutting a variety of materials, incluindo aço inoxidável, alumínio, cobre, e outros metais.

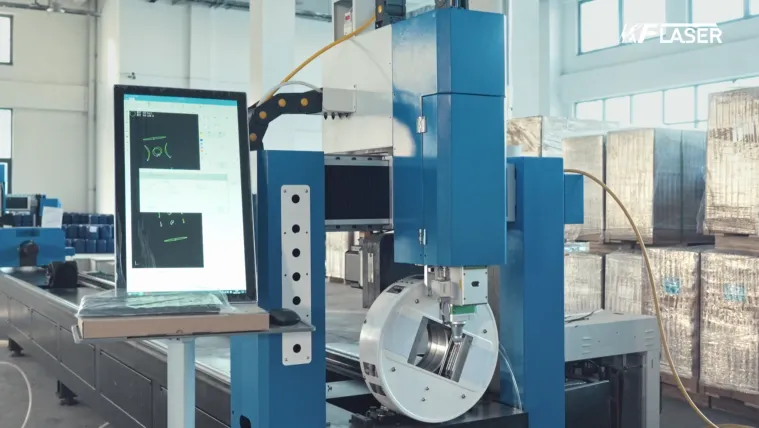

The technology relies on the principles of CNC (controle numérico de computador), which allows the machine to follow highly detailed design files. This ensures that each part is cut with consistent accuracy, reducing the likelihood of human error and enabling rapid production cycles.

2. How Do Laser Tube Cutting Machines Work?

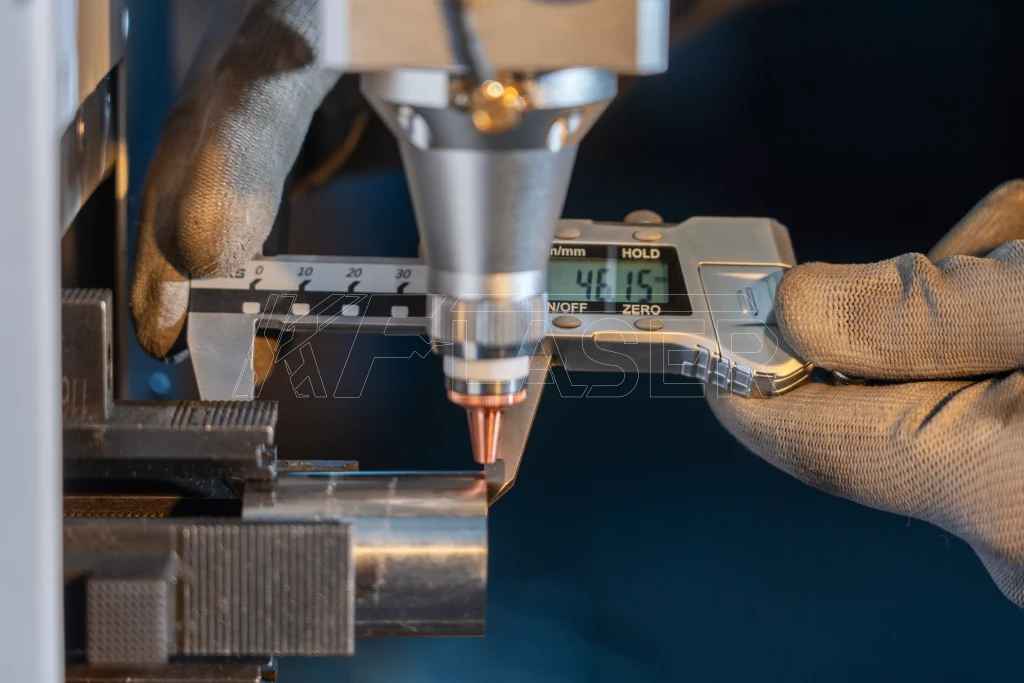

▶The Laser Technology

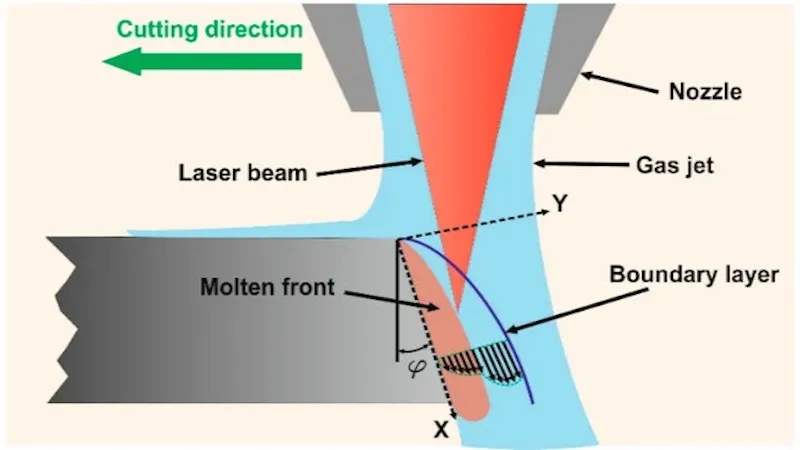

At the heart of a laser tube cutting machine lies a fiber laser, which generates a powerful, concentrated beam of light. This laser is directed at the metal tube, where it focuses on the material’s surface, heating it to the point of melting or vaporization. In some cases, gases like nitrogen, oxigênio, or air assist in the cutting process by blowing away the molten metal and providing a cleaner cut.

▶ Controle do CNC

A CNC system controls the movement of the laser cutting head along the material. The operator programs the machine to follow a specific cutting path based on a digital design file, often generated using CAD software. This automation enables the machine to cut tubes with precision and efficiency, reducing the need for manual labor and significantly cutting down on production time.

▶The Material Interaction

As the laser beam strikes the material, it melts or burns the metal, creating a narrow kerf or cut path. The heat affected zone (HAZ) is minimal, meaning there is less thermal distortion of the surrounding material. This feature ensures that the structural integrity of the part is maintained, making laser tube cutting ideal for precision applications in industries such as aerospace, Automotivo, and medical device manufacturing.

3. Key Benefits of Laser Tube Cutting Machines

● Alta Precisão e Exatidão

Laser tube cutting machines provide some of the most precise cuts in the industry. The ability to maintain tight tolerances means that manufacturers can produce parts that fit perfectly within complex assemblies. For industries like aerospace, where even the slightest error can lead to catastrophic results, the accuracy provided by laser cutting technology is indispensable.

● Versatility in Materials and Shapes

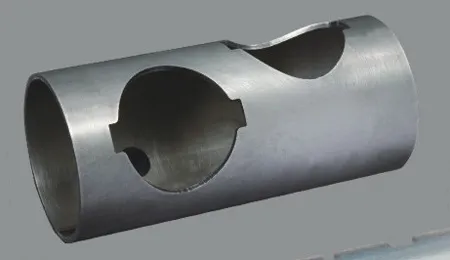

One of the primary advantages of laser tube cutting is its ability to handle a wide variety of materials. De aço inoxidável ao alumínio, the machine can cut tubes with different thicknesses, providing versatility in applications. Adicionalmente, the machine can accommodate various tube shapes, incluindo redondo, square, retangular, and even custom profiles, making it ideal for industries with diverse production needs.

● Increased Efficiency and Productivity

Laser tube cutting machines are much faster than traditional cutting methods. These machines can process multiple tubes simultaneously, or automatically feed tubes into the machine for continuous cutting. The automated system reduces downtime, and since the cutting process requires little to no manual intervention, overall production efficiency is dramatically increased.

● Desperdício de material mínimo

Traditional cutting methods, such as sawing or punching, tend to produce a large amount of material waste. No entanto, laser tube cutting is incredibly precise, allowing manufacturers to maximize the yield from raw material. The narrow kerf produced by the laser means that less material is lost during the cutting process, leading to both cost savings and a more sustainable manufacturing process.

4. Applications of Laser Tube Cutting Machines

● Automotive Industry

The automotive industry relies heavily on precision metal components for vehicles. Laser tube cutting machines are widely used to cut exhaust pipes, structural frames, roll cages, e outros componentes. The ability to cut complex shapes, such as intricate patterns and holes, allows automotive manufacturers to meet both functional and aesthetic demands.

● Indústria aeroespacial

Em aeroespacial, components must meet strict regulatory and safety standards. Laser tube cutting machines are ideal for producing parts like airframes, fuel lines, and support brackets, all of which require precise cuts for optimal fit and performance. The ability to handle different types of materials, including alloys, makes these machines invaluable to the aerospace industry.

● Construção e Arquitetura

Laser cutting machines also play a significant role in the construction and architectural industries. These industries require both strength and design flexibility, and laser tube cutting allows for the creation of everything from structural elements to decorative features. Metal frames, handrails, and custom-designed ornamental pieces can all be produced with ease, enhancing the aesthetic appeal of architectural projects.

● Medical Device Manufacturing

The medical device industry often requires parts that are not only precise but also free from imperfections that could affect the quality and safety of the devices. Laser tube cutting is used to manufacture medical tubes, implantes, and surgical instruments with high precision, ensuring that the parts meet the exact specifications required for use in critical applications.

5. Choosing the Right Laser Tube Cutting Machine

When selecting a laser tube cutting machine, several factors need to be considered to ensure the right fit for your needs:

▶ Laser Power

Laser power affects the thickness of the material the machine can cut. Higher-powered lasers are ideal for cutting thicker materials, while lower-powered lasers are suited for thinner materials. Be sure to choose a machine with the right power level for the types of materials you plan to work with.

▶ Cutting Speed

The cutting speed of the machine determines how quickly parts can be produced. Machines that offer faster cutting speeds can improve overall productivity, especially for high-volume applications. No entanto, it’s important to strike the right balance between speed and precision to meet your production requirements.

▶ Automation and Features

Many modern laser tube cutting machines come with automation features such as automatic loading and unloading, part nesting, and material handling systems. These features reduce labor costs and ensure that production is as efficient as possible.

▶ Manutenção e Suporte

As with any industrial machine, regular maintenance is crucial to ensure optimal performance. When choosing a laser tube cutting machine, consider the manufacturer’s reputation for after-sales support, availability of spare parts, and the ease of maintenance.

Manutenção e Suporte

By investing in a laser tube cutting machine, manufacturers can significantly improve their cutting capabilities, reduzir os tempos de produção, and produce high-quality parts with minimal waste. Whether you’re involved in the automotive, aeroespacial, or construction industry, the precision, velocidade, and versatility of laser tube cutting machines can provide a competitive edge, helping you stay ahead in an increasingly demanding market.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa