No mundo da manufatura, máquinas de corte a laser de metal estão transformando as indústrias, fornecendo soluções mais rápidas, métodos de corte mais precisos do que ferramentas tradicionais. Esteja você no setor automotivo, aeroespacial, ou fabricação de metal, o corte a laser tornou-se uma tecnologia indispensável. Com sua capacidade de lidar com designs complexos e cortes de alta precisão, essas máquinas são essenciais para linhas de produção modernas.

Se você está pensando em investir em um máquina de corte a laser de metal, este guia irá orientá-lo nos principais aspectos desses sistemas, desde sua funcionalidade até os fatores que você precisa considerar ao comprar um.

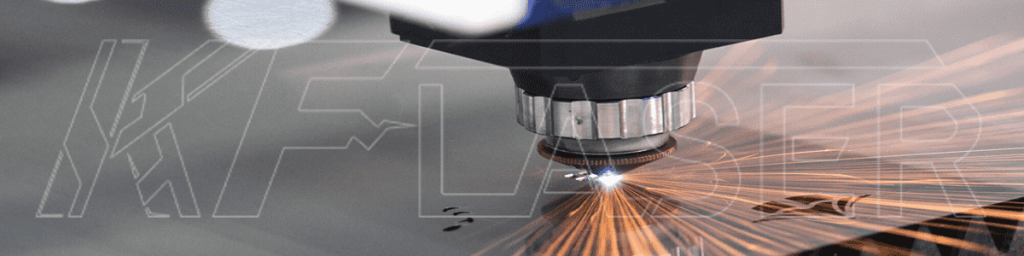

UM máquina de corte a laser de metal usa um feixe de laser focado para derreter, queimar, ou vaporizar material, criando cortes precisos ao longo do caminho desejado. Tipicamente, essas máquinas são usadas para cortar metais como aço inoxidável, alumínio, latão, e aço carbono. O processo de corte a laser é favorecido por sua alta precisão, velocidade, e distorção térmica mínima.

Existem vários tipos de máquinas de corte a laser, cada um oferecendo vantagens distintas dependendo do material e da espessura com que você está trabalhando. Essas máquinas se tornaram uma parte vital das indústrias que exigem componentes metálicos de alta precisão, como fabricação automotiva, fabricação de aço estrutural, e eletrônica.

O corte a laser é baseado em um princípio relativamente simples: energia luminosa focada. Veja como o processo normalmente funciona:

Geração a laser: A máquina gera um feixe concentrado de luz usando uma fonte de laser (CO2 ou fibra). O feixe é altamente focado e direcionado para o material.

Interação material: O feixe de laser interage com o metal, e dependendo da potência e intensidade do laser, ou derrete, vaporiza, ou queima o material.

Assistência a gás: Para auxiliar no processo de corte, gás (como oxigênio, azoto, ou ar comprimido) é frequentemente usado para soprar o metal fundido, ajudando o processo de corte a permanecer limpo e livre de contaminação.

Seguindo o caminho: O feixe de laser é guiado ao longo do material através de um sistema controlado por computador, seguindo o caminho de design preciso criado por um CAD (Design Assistido por Computador) modelo.

A eficiência da máquina garante que cortes intrincados e formas complexas possam ser alcançados com alta precisão e desperdício mínimo.

Compreender os diferentes tipos de máquinas de corte a laser de metal irá ajudá-lo a selecionar o caminho certo para suas necessidades. Aqui estão os tipos principais:

Os lasers de CO2 são um dos tipos de laser mais comuns e amplamente utilizados para corte de metais. Eles operam usando uma mistura de gases (principalmente CO2) para gerar o feixe de laser.

Prós:

Adequado para cortar materiais espessos como aço inoxidável e aço carbono.

Econômico para materiais de espessura média.

Bom para aplicações metálicas e não metálicas.

Contras:

Normalmente mais lento que os lasers de fibra para corte de metal fino.

Menor eficiência em termos de consumo de energia.

Os lasers de CO2 continuam populares para empresas que buscam um equilíbrio entre custo e desempenho, especialmente para trabalhos de corte pesados.

Os lasers de fibra usam uma fonte de laser de estado sólido (normalmente feito de fibras de vidro dopadas com elementos de terras raras) para produzir o feixe de laser. Essas máquinas estão ganhando popularidade por sua velocidade e eficiência.

Prós:

Maior eficiência energética em comparação com lasers de CO2.

Velocidades de corte mais rápidas, especialmente para materiais mais finos.

Grande precisão e cortes de qualidade, tornando-os ideais para designs complexos.

Requer menos manutenção devido a menos peças móveis.

Contras:

Geralmente mais caro antecipadamente.

Pode exigir resfriamento adicional para máquinas de maior potência.

Os lasers de fibra são frequentemente preferidos para aplicações que exigem corte de alta velocidade e maior precisão, particularmente em indústrias como fabricação de eletrônicos e dispositivos médicos.

Yag (Granada de ítrio e alumínio) cortadores a laser são outro tipo de laser de estado sólido. Essas máquinas são capazes de cortar materiais com alta precisão e são frequentemente usadas para metais mais finos.

Prós:

Alta precisão no corte de detalhes finos.

Mais adequado para materiais específicos e operações de pequeno e médio porte.

Contras:

Velocidade de corte inferior à dos lasers de CO2 e de fibra para materiais mais espessos.

Requer manutenção e calibração específicas.

Os lasers YAG são menos comuns em operações em escala industrial, mas são valorizados por sua capacidade de fornecer cortes precisos em componentes delicados ou pequenos.

Existem inúmeras vantagens em usar um máquina de corte a laser de metal, Incluindo:

A tecnologia de corte a laser proporciona uma precisão notável, permitindo designs complexos e cortes limpos. O corte estreito (largura de corte) minimiza o desperdício de material, garantindo que cada peça seja cortada de acordo com as especificações exigidas.

Porque o feixe de laser está focado em uma área muito pequena, há menos calor envolvido, o que reduz as chances de distorção térmica ou empenamento no metal. Isto resulta em bordas limpas que muitas vezes não requerem mais trabalho de acabamento.

Máquinas de corte a laser, particularmente lasers de fibra, pode cortar metais em velocidades muito mais rápidas do que os métodos de corte tradicionais, como corte por jato de água ou corte mecânico. Isso pode aumentar significativamente a eficiência da produção e reduzir os custos trabalhistas.

Máquinas de corte a laser podem ser usadas para cortar vários materiais, incluindo aço inoxidável, alumínio, latão, e até mesmo não-metais como plásticos e madeira. Essa versatilidade os torna adequados para uma ampla gama de indústrias, incluindo aeroespacial, Automotivo, e eletrônica.

Devido à precisão do laser, o corte é altamente preciso, e há desperdício mínimo. O corte a laser permite um agrupamento otimizado, o que maximiza o uso de material e reduz a quantidade de sucata produzida.

A capacidade de cortar com alta precisão e desperdício mínimo torna máquinas de corte a laser de metal indispensável em vários setores. Aqui estão algumas das principais aplicações:

Na indústria automotiva, máquinas de corte a laser são usadas para cortar chapas metálicas para painéis de carrocerias de automóveis, componentes estruturais, e sistemas de exaustão. Sua velocidade e precisão os tornam ideais para a produção em massa de peças automotivas.

A indústria aeroespacial depende fortemente do corte a laser de metais para a produção de componentes críticos, como pás de turbina, peças do motor, e elementos estruturais, onde a precisão e a resistência do material são essenciais.

O corte a laser é usado para fabricar pequenos componentes para dispositivos elétricos, como placas de circuito, conectores, e caixas metálicas. A precisão fina garante que peças pequenas sejam cortadas de acordo com as especificações exatas necessárias para componentes eletrônicos de alto desempenho.

Oficinas de fabricação de metal usam corte a laser para criar uma ampla variedade de produtos, de placas metálicas a suportes estruturais. A capacidade das máquinas de cortar formas e contornos complexos as torna ideais para trabalhos em metal personalizados.

Ao comprar a máquina de corte a laser de metal, é essencial manter os seguintes fatores em mente para garantir que você selecione a melhor máquina para suas necessidades:

Máquinas de corte a laser de metal são um investimento essencial para as empresas da indústria transformadora, engenharia, e fabricação. A versatilidade, velocidade, e a precisão dessas máquinas podem melhorar enormemente a produtividade e a qualidade das peças. Ao compreender os diferentes tipos de máquinas, suas capacidades, e suas necessidades específicas, você pode tomar uma decisão bem informada que se alinhe com seus requisitos técnicos e orçamentários.

Escolher a máquina certa vai além do custo inicial: trata-se de garantir que a tecnologia na qual você investe seja eficiente, confiável, e escalável para atender às demandas do seu processo de produção. Se você precisa de uma máquina para pequenas, trabalho detalhado ou para operações industriais em grande escala, o corte a laser continua sendo uma das melhores tecnologias disponíveis para fabricação de metal.