Integrated Automation Remote Monitoring Diagnosis

Precise Positioning High Repeatability

Easy Programming Mold Replacement

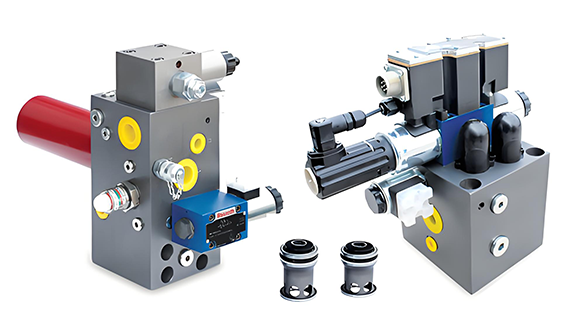

Strong Structure Stable Hydraulic System

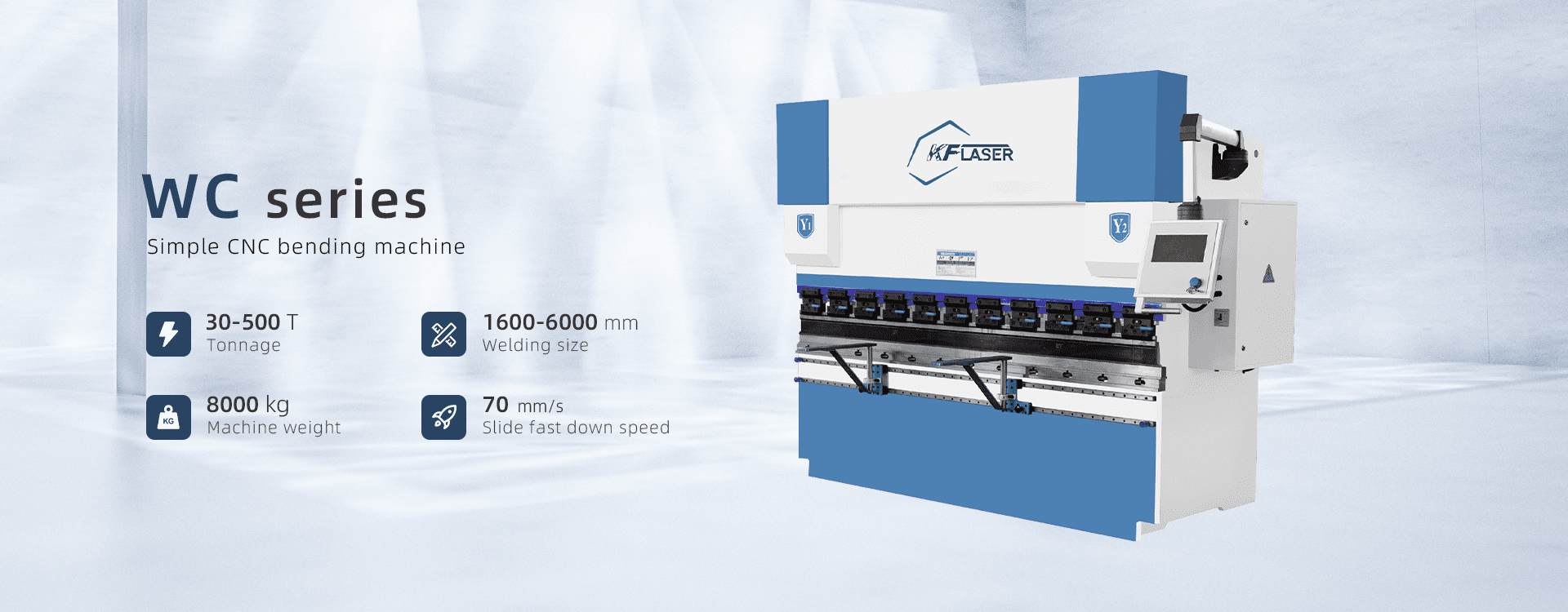

Model | WE67K-160T/3200 | WG67-160T/3200 | WC67-160T/3200 |

Dimension (L*W*H) | 3300*1850*2700mm | 3200*1750*2600MM | 3200*1650*2600MM |

Distance between columns | 2560mm | 2500mm | 2600mm |

Throat Depth & Open Height | 320mm | 340mm | 340mm |

Slide fast down speed | 180mm/s | 100mm/s | 70mm/s |

Slide return speed | 110mm/s | 85mm/s | 65mm/s |

CNC system | KT15 | TP10S | E21 |

Nominal pressure | 1600KN | ||

Bending length | 3200mm | ||

Slide Moving journey/stroke | 200mm | ||

Slide working speed | 10mm/s | ||

Main motor power | 11 KW | ||

Voltage | 220/380/420/660 V | ||

Customizable width | 1600-12000mm | ||

Customizable tonnage | 30-2000T | ||

A: In order to recommend you the most suitable machine model, just tell us below information

1)What is your material

2)Maximum width and thickness of the material to be bent

3)We will simulate the bending process based on your final workpiece drawing to determine the mold that is suitable for you, or customize the mold for you.

A :1)Check the hydraulic oil regularly for impurities.

2)The mold may have reduced accuracy after one year of use. You can purchase additional molds based on actual conditions.

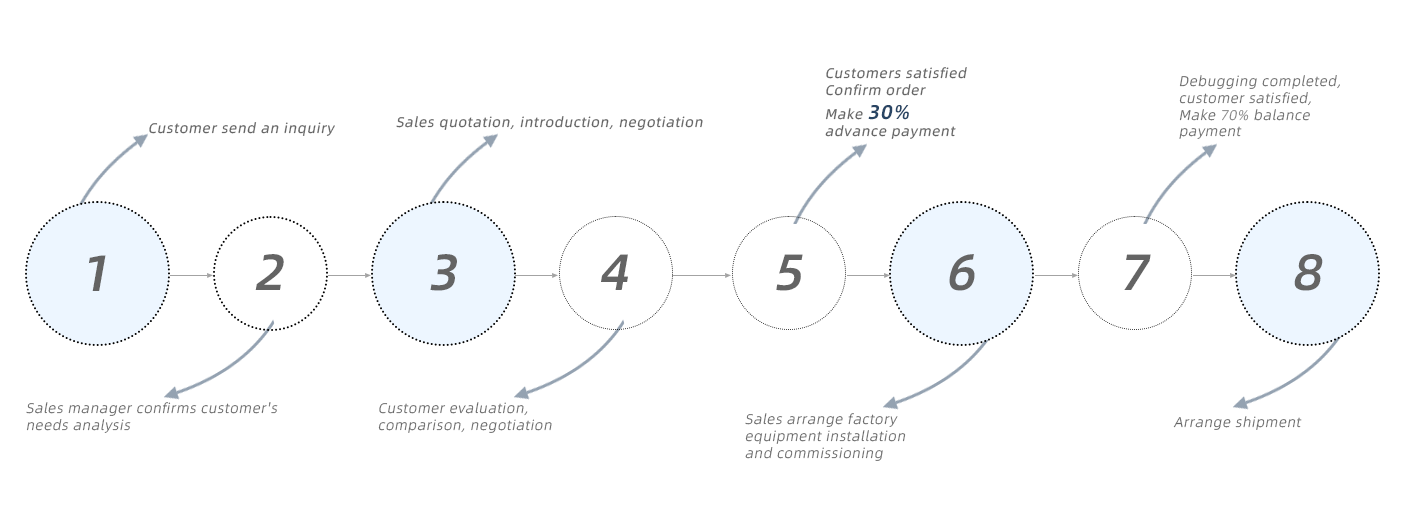

A:1)Alibaba trade assurance/TT/West Union/Payple/LC/Cash and so on.

2)We start making standardized machines after receiving 30% of the payment, inspect the machines after completion, and finally collect the 70% balance before shipping.

A:1)We provide free training in our factory

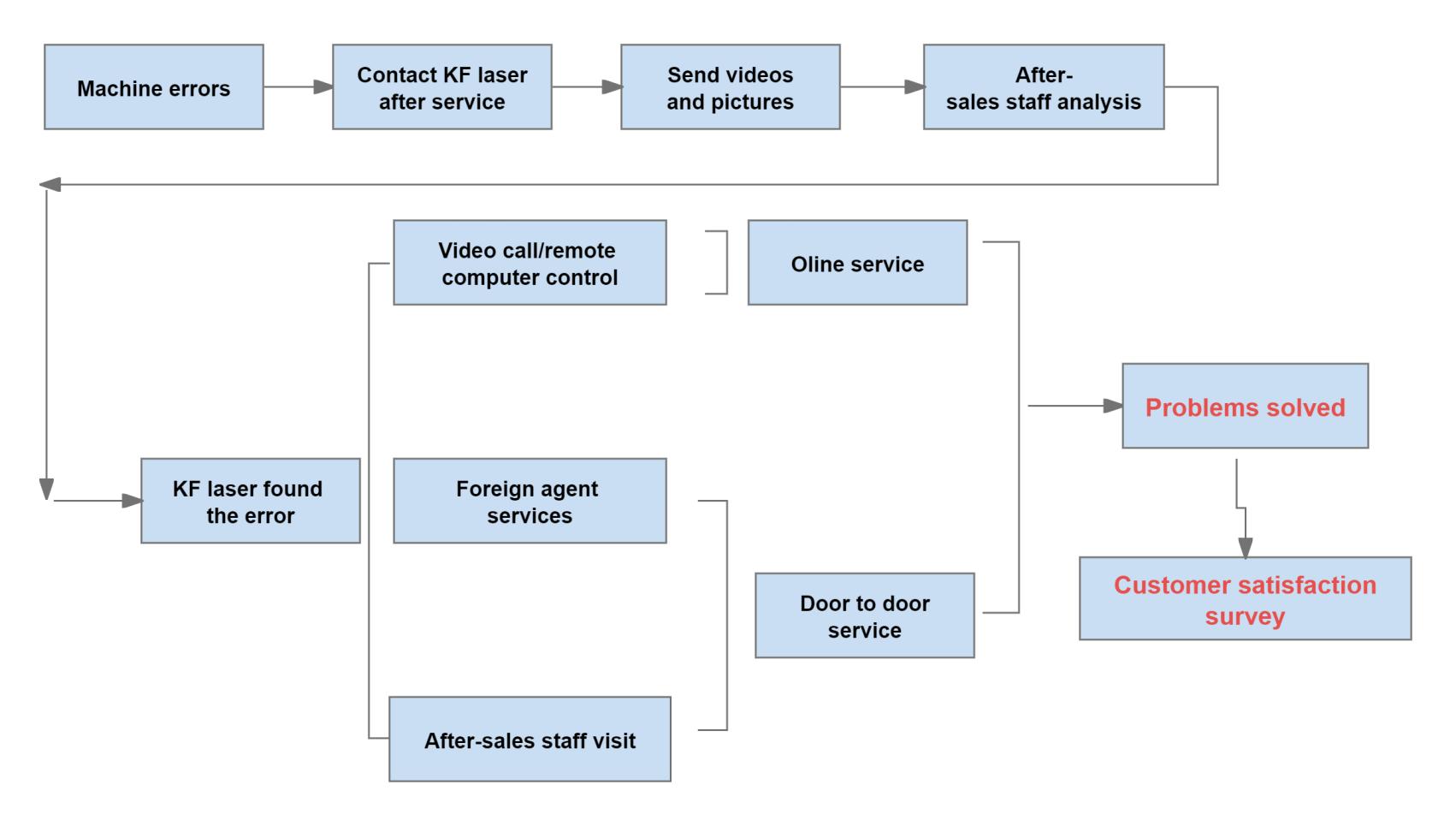

2)We provide free online after-sales service

3)We have complete installation instructions and video tutorials

4)Door-to-door service charges are based on region and aircraft model

5)Provide three-year warranty, except for consumable parts, direct replacement for non-human damage