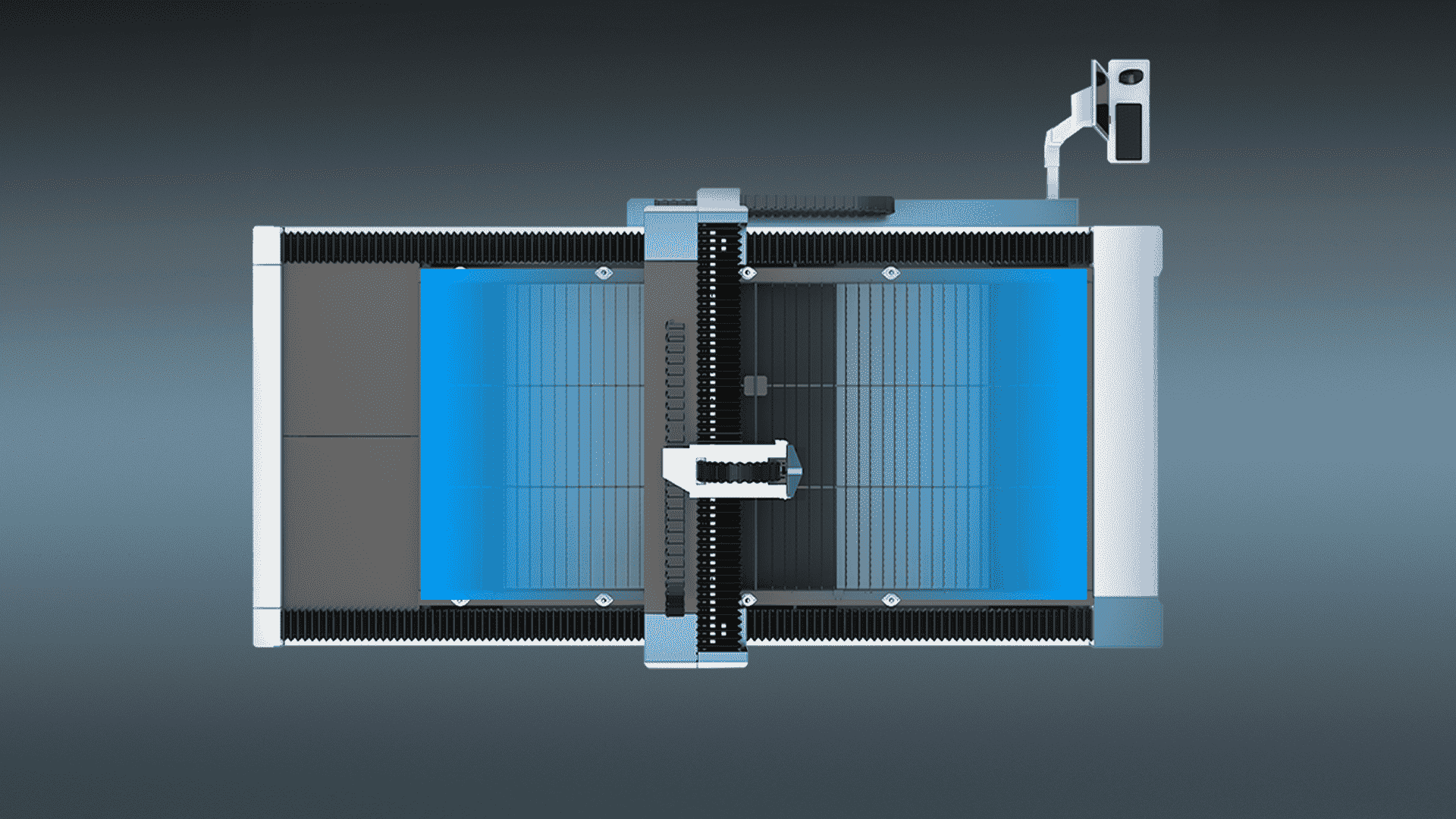

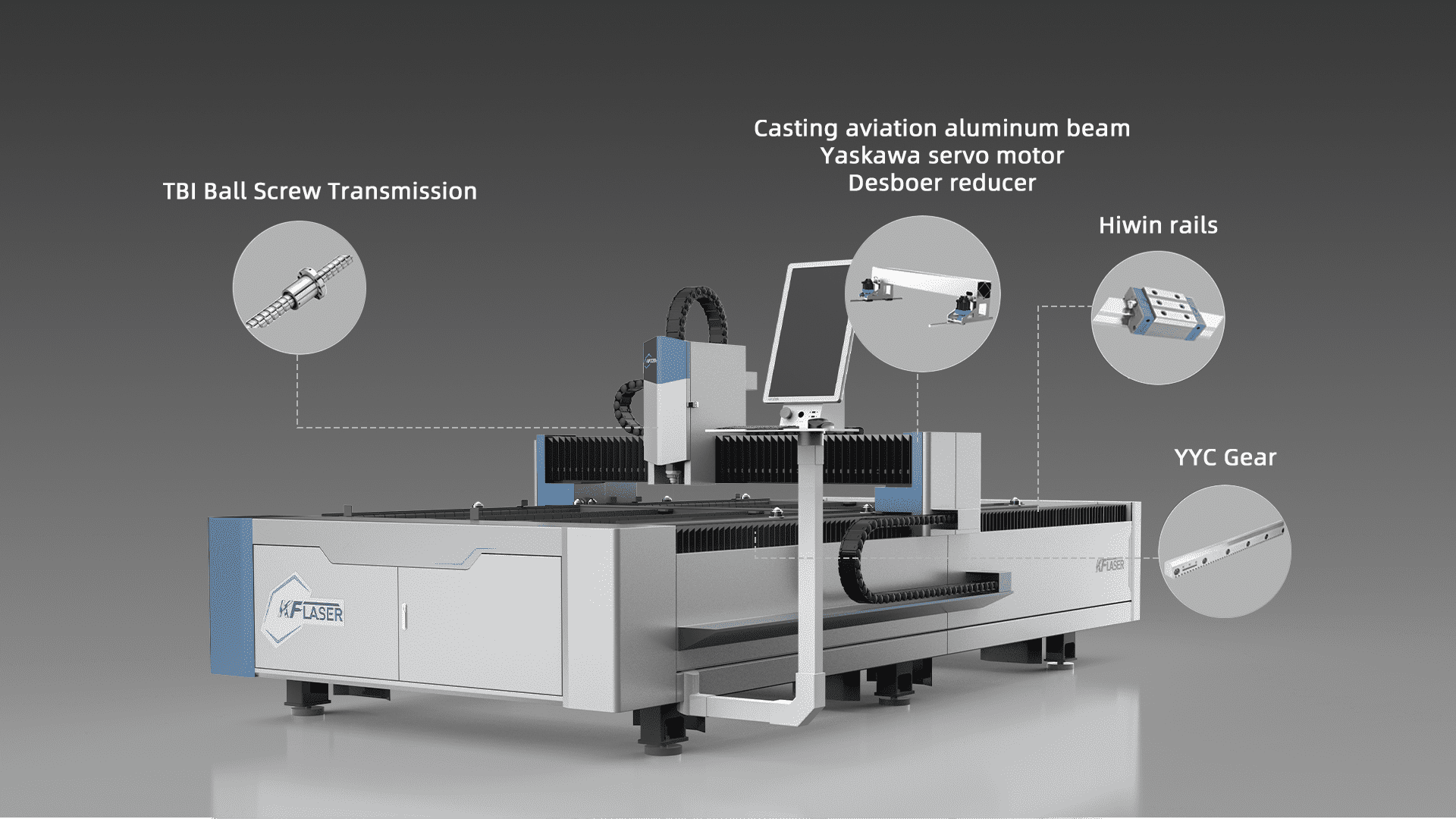

1. Motor de servo de alta precisão de direção dupla, Estrutura de transmissão de rack de engrenagem

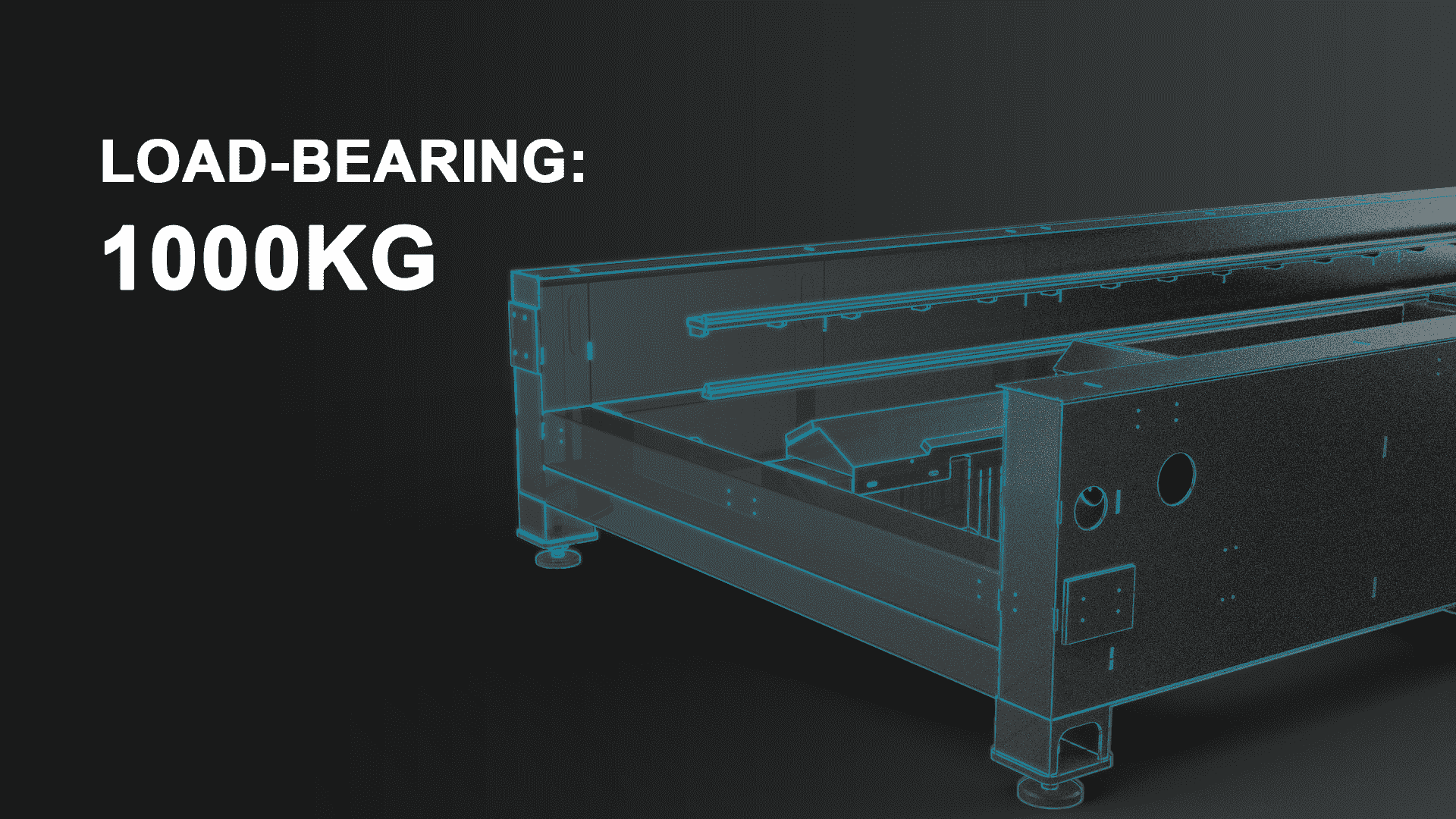

2. Cama de solda de chapas de chapas pesadas, A precisão e velocidade do uso a longo prazo não são afetadas

3. Feixe de alumínio da aviação, leve e garantindo movimento de alta velocidade

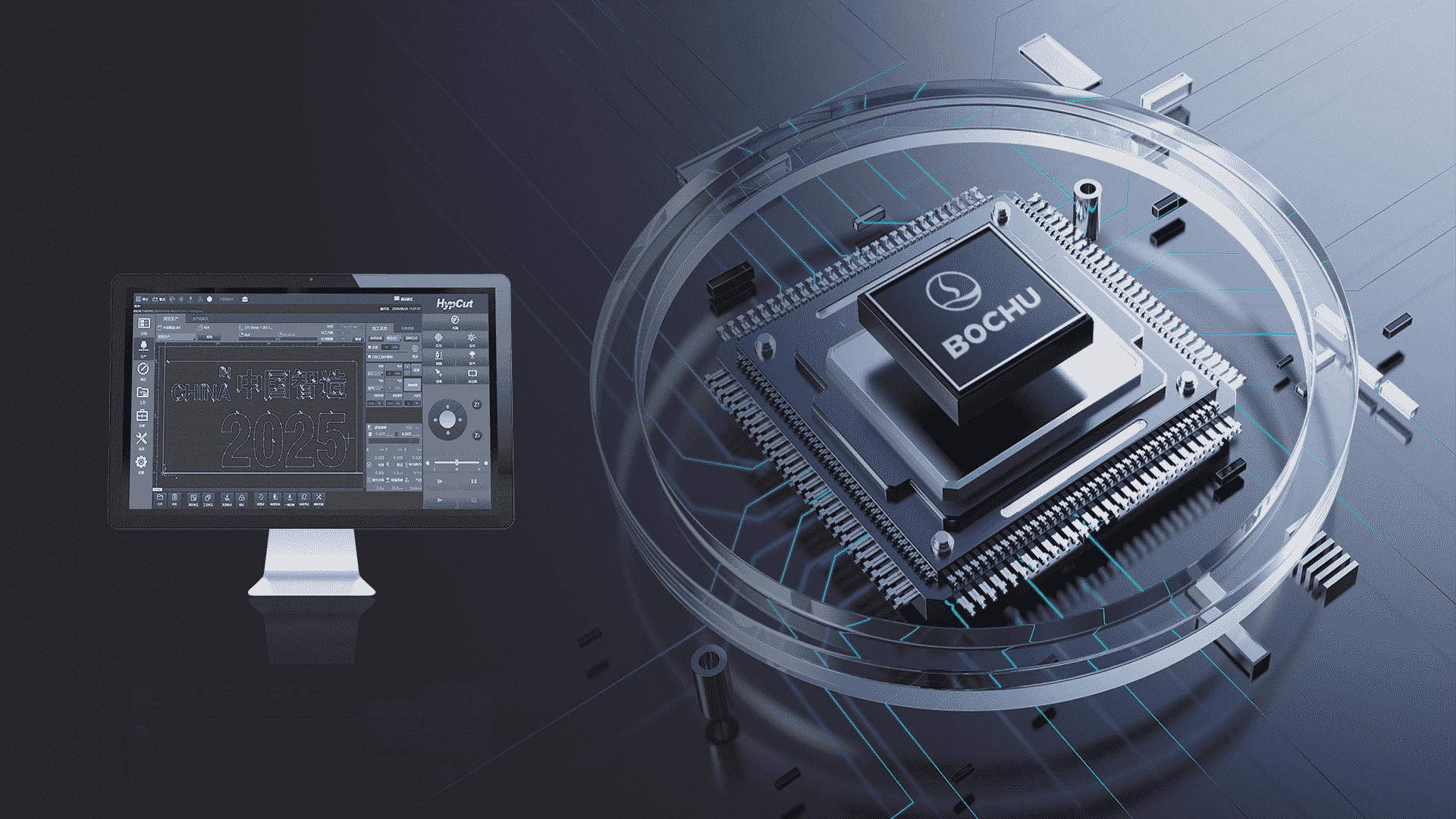

4. Sistema operacional conveniente e confiável

2024 novo design, com um formato maior do que as máquinas de corte comuns, e uma área de trabalho de 3250*1550mm. Modelo de máquina de corte de plataforma única econômica, Power de suporte até 6kW, Máquina padrão entrega rápida dentro de 7 dias.

A estrutura da cama é soldada usando tubos quadrados grossos e reforçado internamente para melhorar a força estrutural e a resistência à tração., impedir a deformação, reduzir vibrações, e garantir uma excelente precisão de corte.

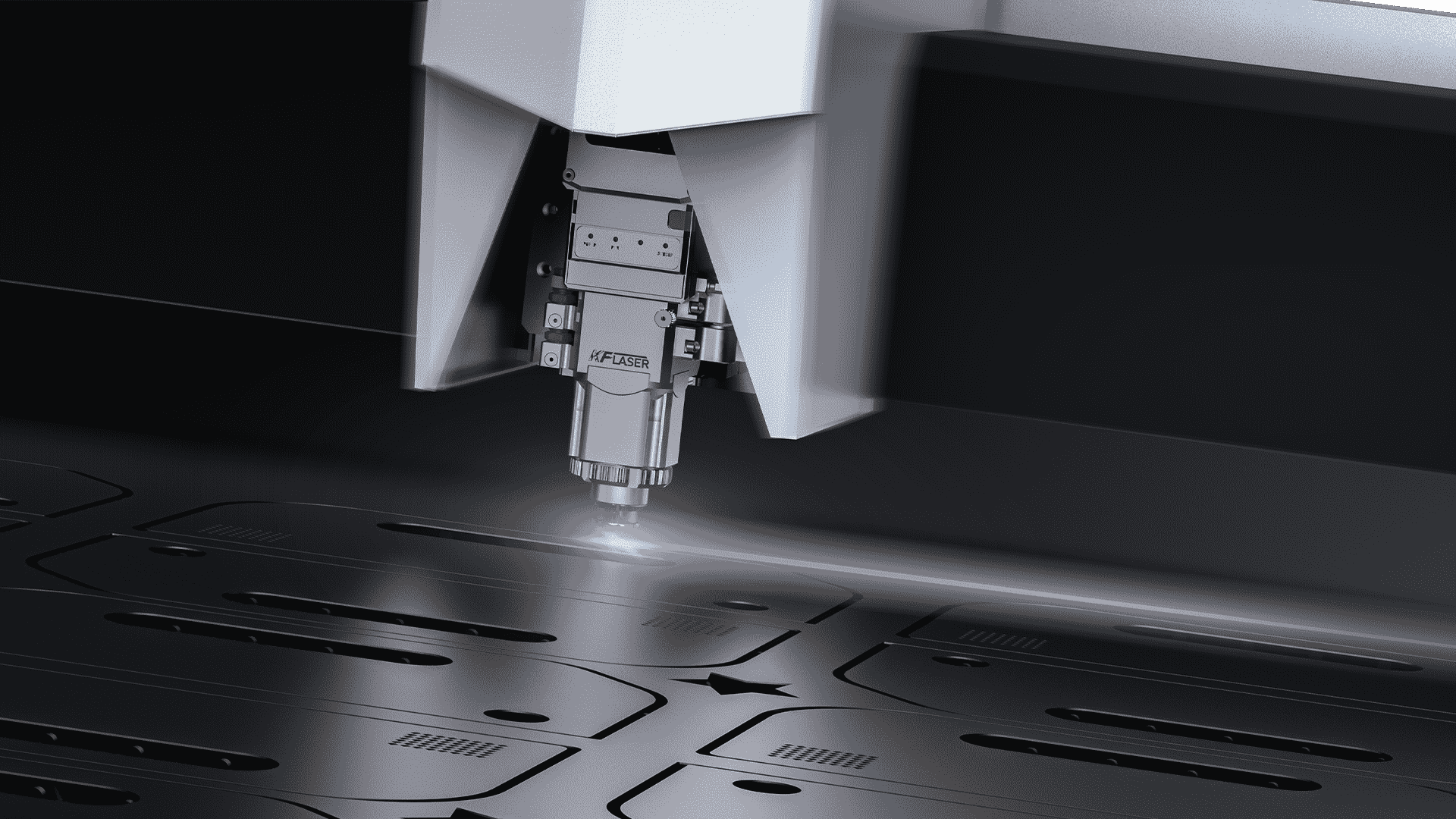

O eixo z usa transmissão de parafuso de bola TBI, Os dois lados do corpo da máquina estão equipados com racks YYC e Taiwan Hiwin Guide Rails, e o feixe está lançando alumínio da aviação. Está equipado com motores elétricos japoneses Yaskawa e redutores desboer, alto torque, baixo ruído, e a precisão do posicionamento da máquina -ferramenta pode atingir 0,02 mm.

8 Conjuntos de séries S3 podem ser embaladas em 1 40Contêiner padrão HQ. Podemos permitir a entrega apressada e geralmente cobrar frete reduzido significativamente. Após a chegada, Os usuários podem se reunir tudo usando inserção rápida. Sem esperar pela nova instalação.

Modelo de máquina | S3 sered | Série S4 | S6 Serie |

Área de Trabalho | 3050*1530milímetros | 4100*2050milímetros | 6100*2550milímetros |

Potência Laser | 1.5KW-12KW | ||

Dimensão | 4500*2800*1825milímetros | 5500*3275*1855milímetros | 7400*3700*1855milímetros |

Peso | 2500KG | 4000Kg/6200kg | 7500Kg/8900kg |

Velocidade máxima de marcha lenta(m/min) | 100m/min-120m/min | ||

Aceleração máxima em marcha lenta(G) | 1.0G/1,2G/1,5G | ||

Precisão de posicionamento do eixo X/Y/mm | ±0,05 mm | ||

Precisão de posicionamento repetido/mm | ±0,03mm | ||

Precisão de corte/mm | ≤0,1 mm | ||

Tensão de trabalho | 380V,trifásico /50Hz-60Hz | ||

Formatos de imagem suportados | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

UM: Para lhe recomendar o modelo de máquina mais adequado, basta nos dizer as informações abaixo

1)Qual é o seu material

2)O tamanho do material

3)A espessura do material

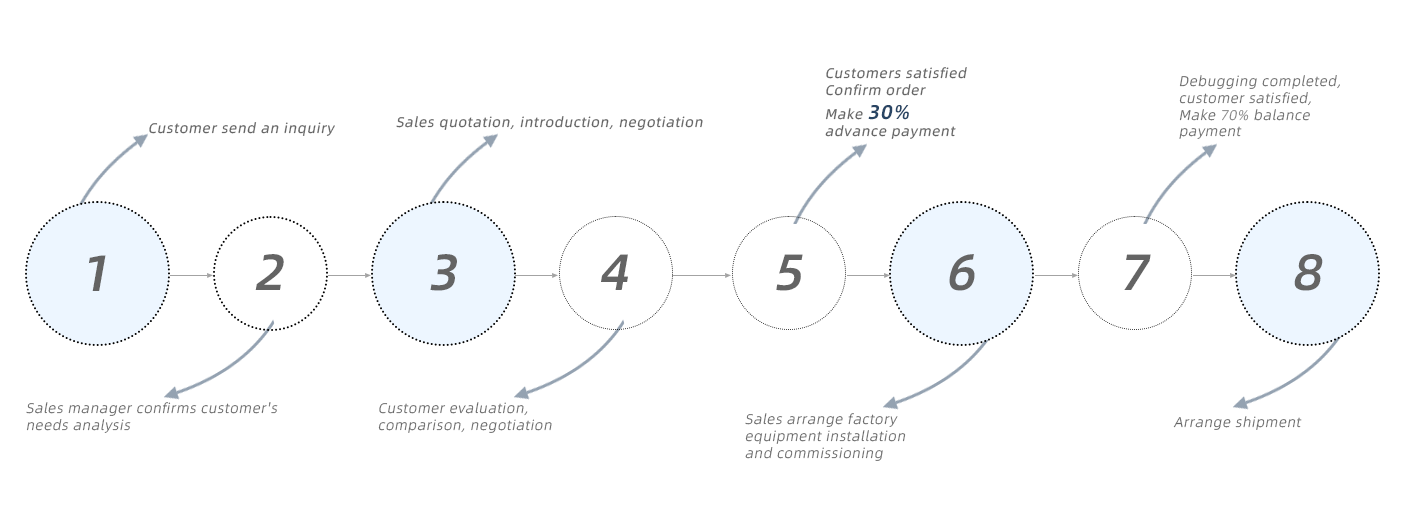

UM:1)Garantia comercial Alibaba/TT/West Union/Payple/LC/Cash e assim por diante.

2)Começamos a fabricar máquinas padronizadas após recebermos 30% do pagamento, inspecionar as máquinas após a conclusão, e finalmente coletar o 70% saldo antes do envio.

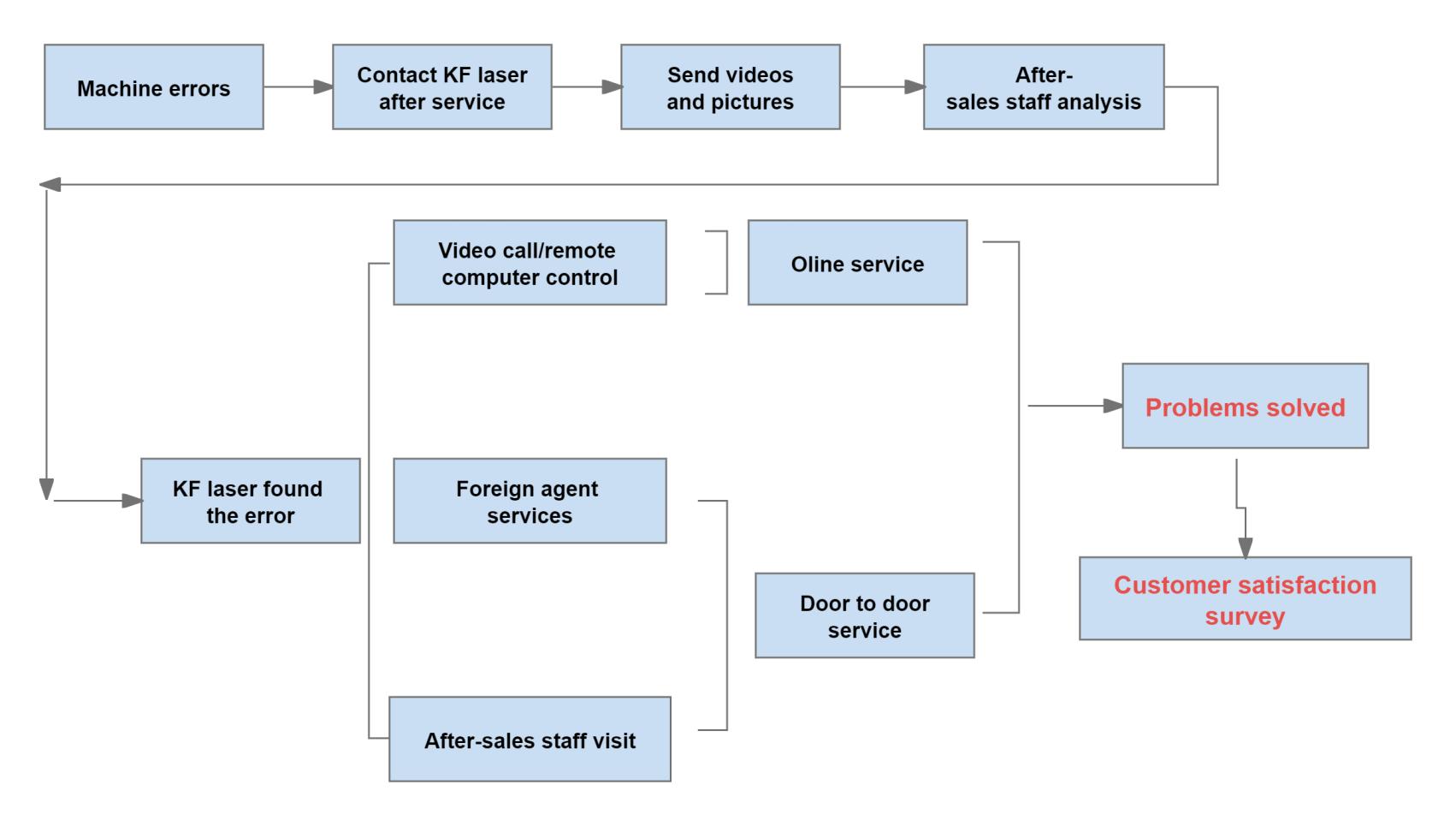

UM:1)Oferecemos treinamento gratuito em nossa fábrica

2)Oferecemos serviço pós-venda on-line gratuito

3)Temos instruções completas de instalação e tutoriais em vídeo

4)As taxas de serviço porta a porta são baseadas na região e no modelo da aeronave

5)Fornece garantia de três anos, exceto peças consumíveis, substituição direta por danos não humanos

O mundo dos cortadores de laser CNC revolucionou o corte de metal, oferecendo precisão incomparável, eficiência, e versatilidade. Os cortadores de laser CNC são essenciais em vários setores, De automotivo ao aeroespacial, e fornecer cortes precisos para designs complexos. Este guia se aprofundará nos tipos, formulários, benefícios, e considerações para escolher o melhor cortador de laser CNC, particularmente focado no cortador de laser CNC, Cortador de laser CNC para metal, e cortador de laser de metal CNC.

Um cortador de laser CNC é uma máquina controlada por computador que usa um feixe de laser para cortar, gravar, ou marcar materiais com alta precisão. CNC significa Controle numérico de computador, indicando que o processo de corte é automatizado e programado através do software. Esta tecnologia permite desenhos complexos e cortes detalhados, tornando -o ideal para várias aplicações.

- Cutter a laser CNC para aplicações de metal geralmente usam lasers de fibra.

- Esses lasers têm um comprimento de onda de 1.06 micrômetros, tornando -os altamente eficazes para cortar metais como aço inoxidável, alumínio, latão, e cobre.

- Os lasers de fibra oferecem alta eficiência, Velocidade de corte rápido, e baixa manutenção.

- Esses lasers operam em um comprimento de onda de 10.6 micrômetros.

- Enquanto versátil e capaz de cortar materiais não metal como madeira, acrílico, e plásticos, Eles são menos eficientes para metais em comparação com lasers de fibra.

- Os lasers de CO2 são adequados para folhas de metal mais finas, mas exigem mais manutenção.

- Esses lasers de estado sólido são eficazes para materiais metal e não-metal.

- Eles oferecem alta precisão e são frequentemente usados para gravação e marcação detalhadas.

- Utilizado para corte de alta velocidade de folhas de metal finas.

- Esses lasers são compactos, eficiente, e oferecer uma construção robusta com menores necessidades de manutenção.

O cortador de laser CNC para metal é amplamente utilizado em várias indústrias devido à sua precisão e eficiência. Aqui estão alguns aplicativos -chave:

1. Indústria automobilística:

- Usado para cortar peças e componentes complexos.

- Garante alta precisão em folhas de metal e gravuras detalhadas.

2. Indústria aeroespacial:

- Essencial para cortar materiais de alta resistência usados na construção de aeronaves.

- Fornece cortes precisos necessários para componentes aeroespaciais complexos.

3. Indústria de eletrônicos:

- Usado para produzir pequeno, componentes precisos para dispositivos eletrônicos.

- Ideal para cortar placas de circuito e gravação padrões detalhados.

4. Fabricação de joias:

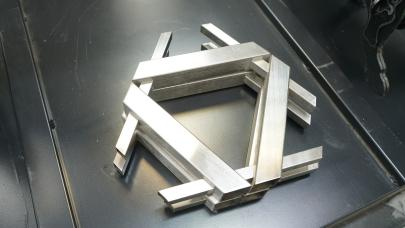

- Permite o corte e a gravação de metais preciosos com alta precisão.

- Usado para criar desenhos de jóias intrincados e peças personalizadas.

5. Modelos Arquitetônicos:

- Usado para cortar modelos e protótipos detalhados.

- Permite corte preciso de materiais como acrílico, madeira, e metal.

O cortador de laser de metal CNC oferece inúmeras vantagens que o tornam uma ferramenta indispensável para várias aplicações:

1. Alta Precisão e Exatidão:

- Fornece cortes limpos e detalhados com erros mínimos.

- Essencial para as indústrias que exigem medições exatas e detalhes complexos.

2. Eficiência e Velocidade:

- O corte a laser é um processo rápido, reduzindo o tempo de produção.

- O corte de alta velocidade leva a tempos de resposta mais rápidos e maior produtividade.

3. Versatilidade:

- Capaz de cortar uma ampla gama de materiais, incluindo metais e não metais.

- Adequado para várias aplicações, desde a fabricação industrial até projetos criativos.

4. Desperdício mínimo:

- Alta precisão garante desperdício mínimo de material.

- Otimiza o uso do material, reduzindo custos e impacto ambiental.

5. Corte sem contato:

- O corte a laser é um processo sem contato, minimizando o risco de materiais prejudiciais.

- Ideal para cortar materiais delicados ou finos sem contato físico.

Ao selecionar o melhor cortador de laser CNC para metal, Vários recursos devem ser considerados para garantir que atenda às suas necessidades específicas:

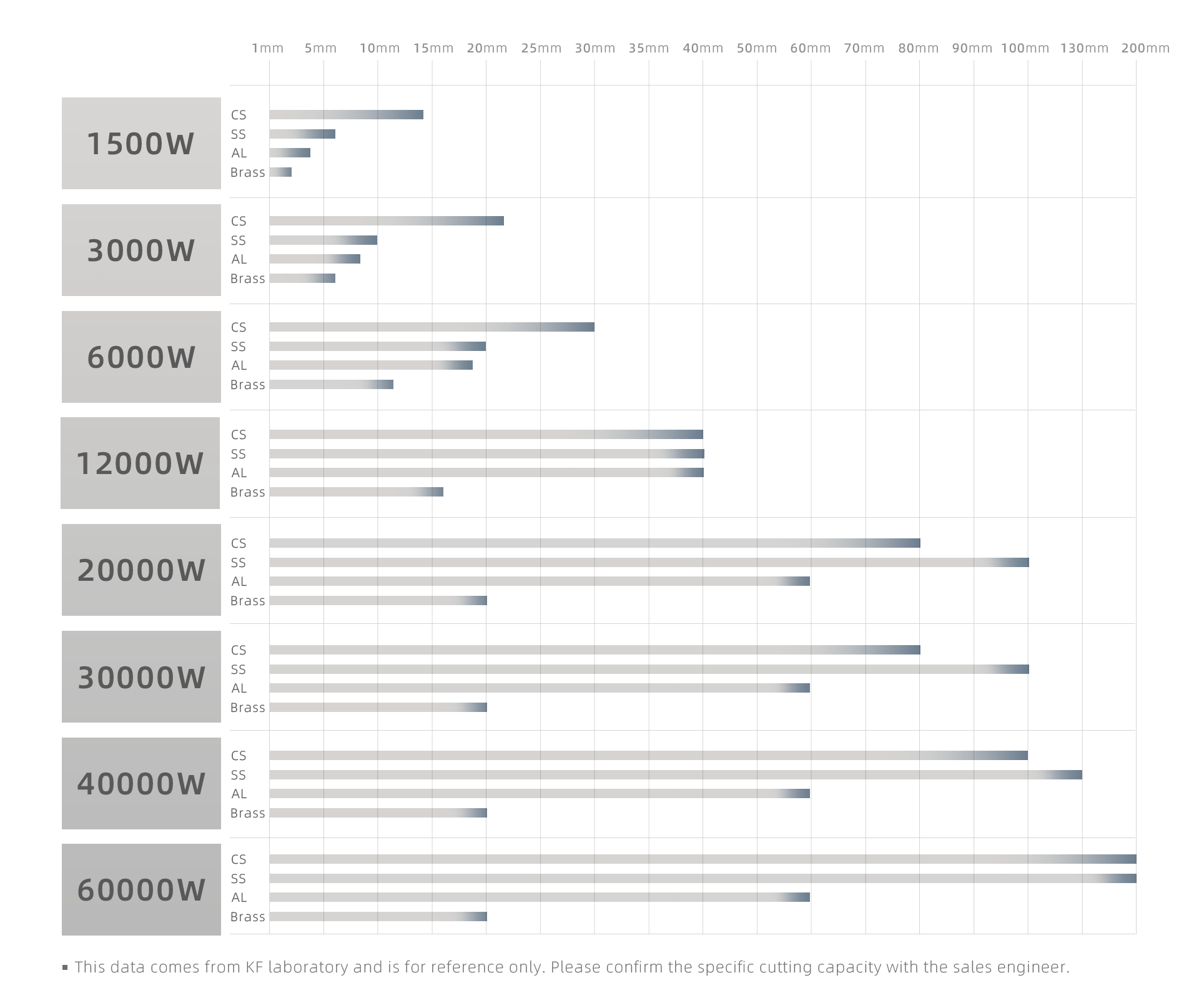

1. Requisitos de energia:

- Os lasers de potência mais altos são adequados para cortar materiais e metais mais espessos.

- Os lasers de potência inferior são ideais para gravar e cortar materiais mais finos.

2. Compatibilidade de materiais:

- Determine os materiais principais com os quais você trabalhará e escolha um cortador a laser otimizado para esses materiais.

- Os lasers de fibra geralmente são melhores para metais, Enquanto os lasers de CO2 são versáteis para não metais.

3. Tamanho da cama e área de trabalho:

- O tamanho da cama e da área de trabalho determina as dimensões máximas do material com o qual você pode trabalhar.

- Tamanhos de cama maiores são essenciais para projetos em larga escala, enquanto tamanhos de cama menores são suficientes para um trabalho detalhado de gravação.

4. Sistemas de software e controle:

- Software amigável e sistemas de controle avançado aprimoram o desempenho.

- Procure máquinas com interfaces e recursos intuitivos que simplificam o processo de corte.

5. Considerações de preço e orçamento:

- Os cortadores de laser CNC variam amplamente de preço; estabelecer um orçamento que inclua o custo inicial de compra, manutenção, software, e acessórios.

- Considere o valor a longo prazo da máquina em termos de desempenho e durabilidade.

Os modernos cortadores de laser de metal CNC vêm com recursos avançados que melhoram o desempenho e a usabilidade:

1. Foco automático:

- Mantém a distância ideal entre a cabeça do laser e o material, garantir cortes precisos.

- Aprimora a qualidade e a consistência do corte.

2. Assistência aérea programável:

- Permite a conexão de vários tipos de gás ao sistema a laser.

- Otimiza o desempenho de corte selecionando o gás apropriado para cada material.

3. Controle de pierce:

- Controla os parâmetros de piercing do laser, incluindo poder, Horário de permanência, e pressão do gás.

- Garante piores eficientes e limpos, prolongando a vida útil da óptica.

4. Ajustes finos:

- Permite controle preciso de energia e velocidade durante os leads e cantos.

- Garante qualidade de corte consistente em projetos complexos.

5. Recursos de segurança:

- Inclui capas de proteção e sensores de segurança para evitar acidentes.

- Garante operação segura, especialmente com lasers de alta potência.

A manutenção e operação adequadas de um cortador de laser CNC para metal são cruciais para garantir o desempenho e a confiabilidade de longo prazo:

1. Limpeza regular:

- Mantenha a óptica, lentes, e espelhos limpos para manter a precisão de corte.

- Remova detritos e poeira da área de corte regularmente.

2. Manutenção da fonte a laser:

- Siga as diretrizes do fabricante para manter a fonte do laser.

- Substitua consumíveis como lentes e espelhos conforme necessário para garantir o desempenho ideal.

3. Atualizações de software:

- Mantenha o software de controle atualizado para se beneficiar dos recursos e melhorias mais recentes.

- Verifique regularmente as atualizações de firmware do fabricante.

4. Ventilação adequada:

- Garanta a ventilação adequada para remover a fumaça e os detritos durante o processo de corte.

- Use sistemas de escape adequados para manter um ambiente de trabalho limpo e seguro.

5. Treinamento e segurança:

- Forneça treinamento adequado para os operadores para garantir um uso seguro e eficiente do cortador de laser.

- Siga os protocolos de segurança e use o equipamento de proteção, conforme recomendado pelo fabricante.

O futuro do cortador de laser CNC para a tecnologia de metal parece promissor, com avanços contínuos que aprimorarão as capacidades e acessibilidade:

1. Automação aprimorada:

- A integração de recursos avançados de automação aumentará a eficiência e reduzirá os custos de mão -de -obra.

- A automação permitirá que os fabricantes se concentrem no design e inovação.

2. Maior acessibilidade:

- À medida que os custos continuam a diminuir, Mais empresas e indivíduos terão acesso a cortadores de laser CNC.

- O aumento da acessibilidade levará a mais inovação e criatividade.

3. Materiais avançados:

- Desenvolvimento de novos materiais e ligas expandirá as possibilidades de corte a laser.

- Os fabricantes poderão trabalhar com materiais que oferecem propriedades e estética exclusivas.

4. Sustentabilidade:

- A tecnologia de corte a laser desempenhará um papel crucial na promoção da sustentabilidade, reduzindo o desperdício de material.

- Práticas ambientalmente amigáveis se tornarão mais prevalentes na indústria.

O cortador de laser CNC, Especialmente o cortador de laser CNC para cortador de laser de metal e metal CNC, é uma ferramenta vital para várias indústrias, oferecendo precisão incomparável, eficiência, e versatilidade. De automotivo e aeroespacial à fabricação e arquitetura de jóias, Os cortadores de laser CNC transformaram processos de produção e habilitaram a inovação. Ao entender os principais recursos, benefícios, e manutenção de cortadores de laser CNC, e considerando suas necessidades específicas, Você pode selecionar o melhor cortador de laser CNC para seus projetos. À medida que a tecnologia continua a avançar, O futuro do corte a laser CNC parece brilhante, com possibilidades emocionantes de automação aprimorada, acessibilidade, e sustentabilidade.