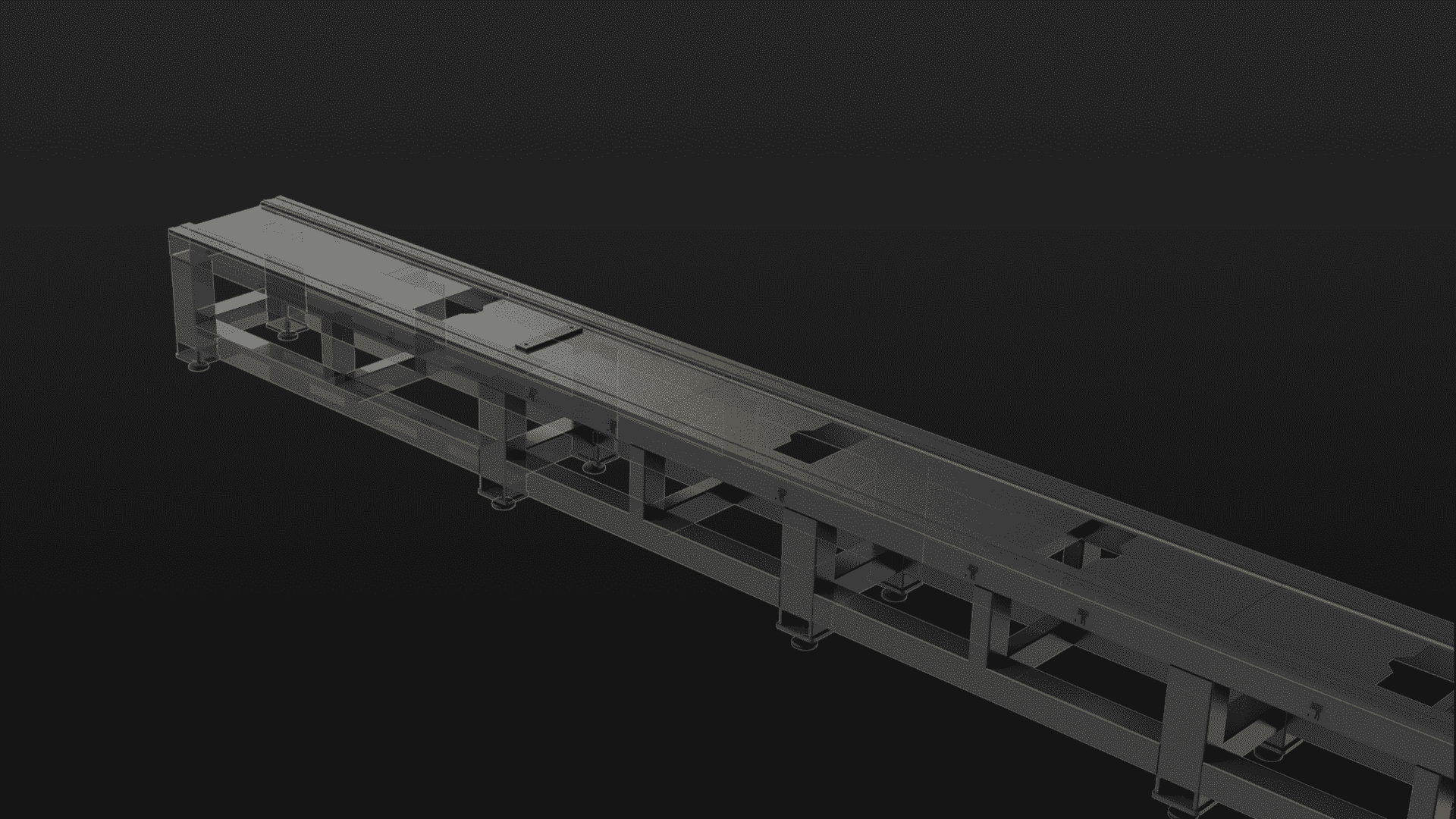

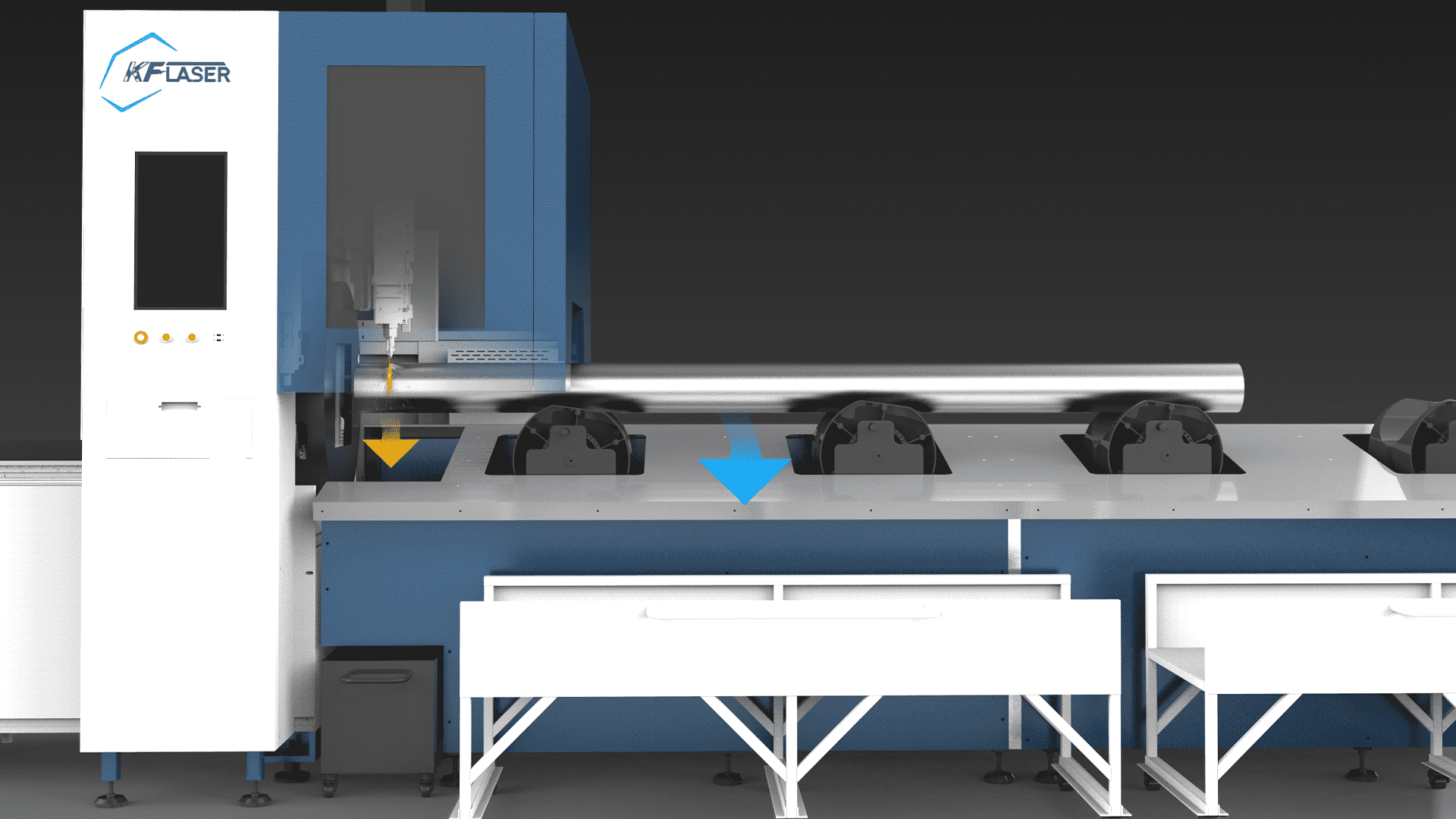

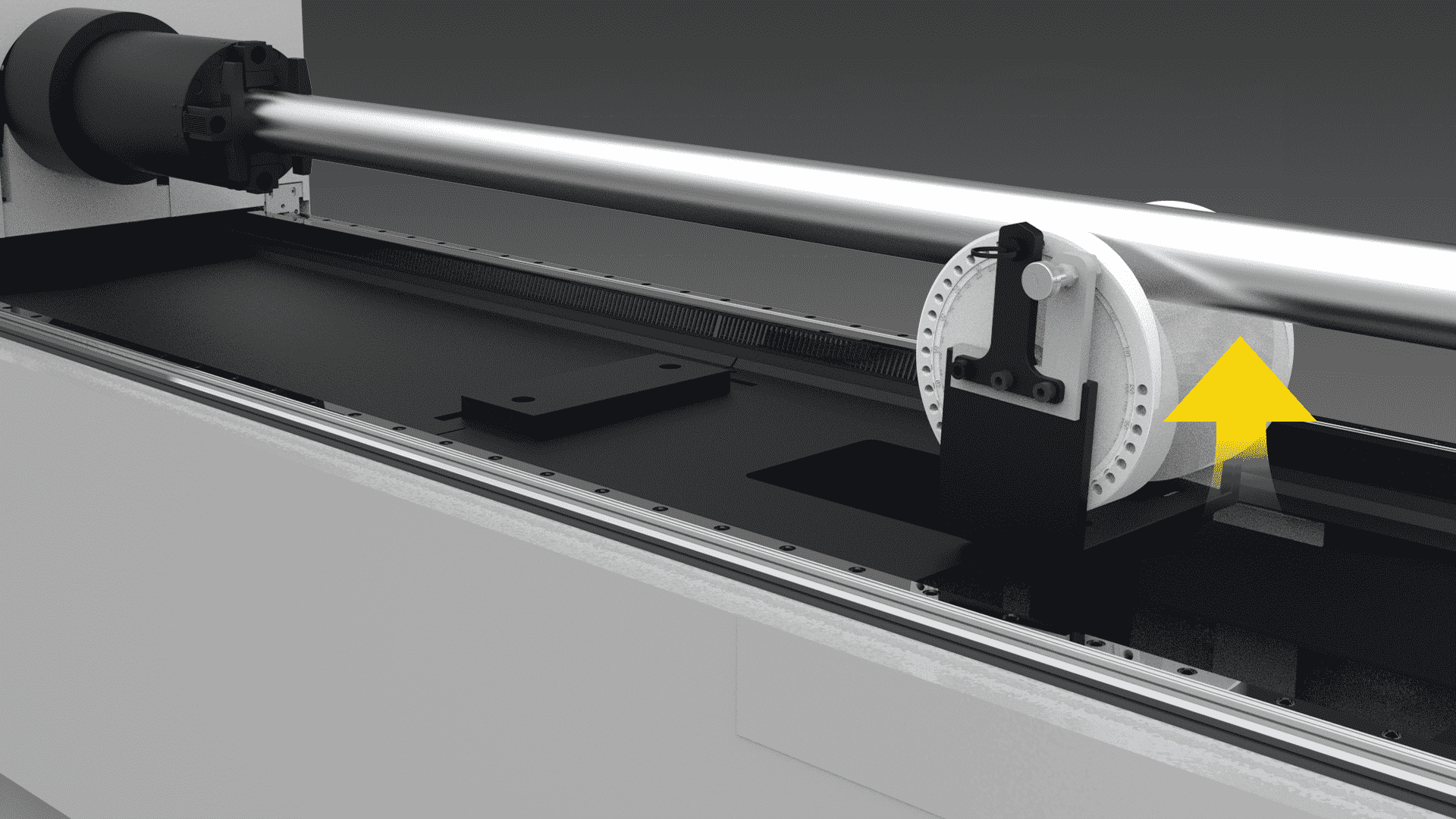

The TS series can be equipped with fully automatic loading and has high-speed cutting capabilities for all types of pipes.

Machine Model | TS62 seris | TS72 series | TS82 serie |

Working Area | 6000mm&20-220mm | 7000mm&20-220mm | 8000mm&20-220mm |

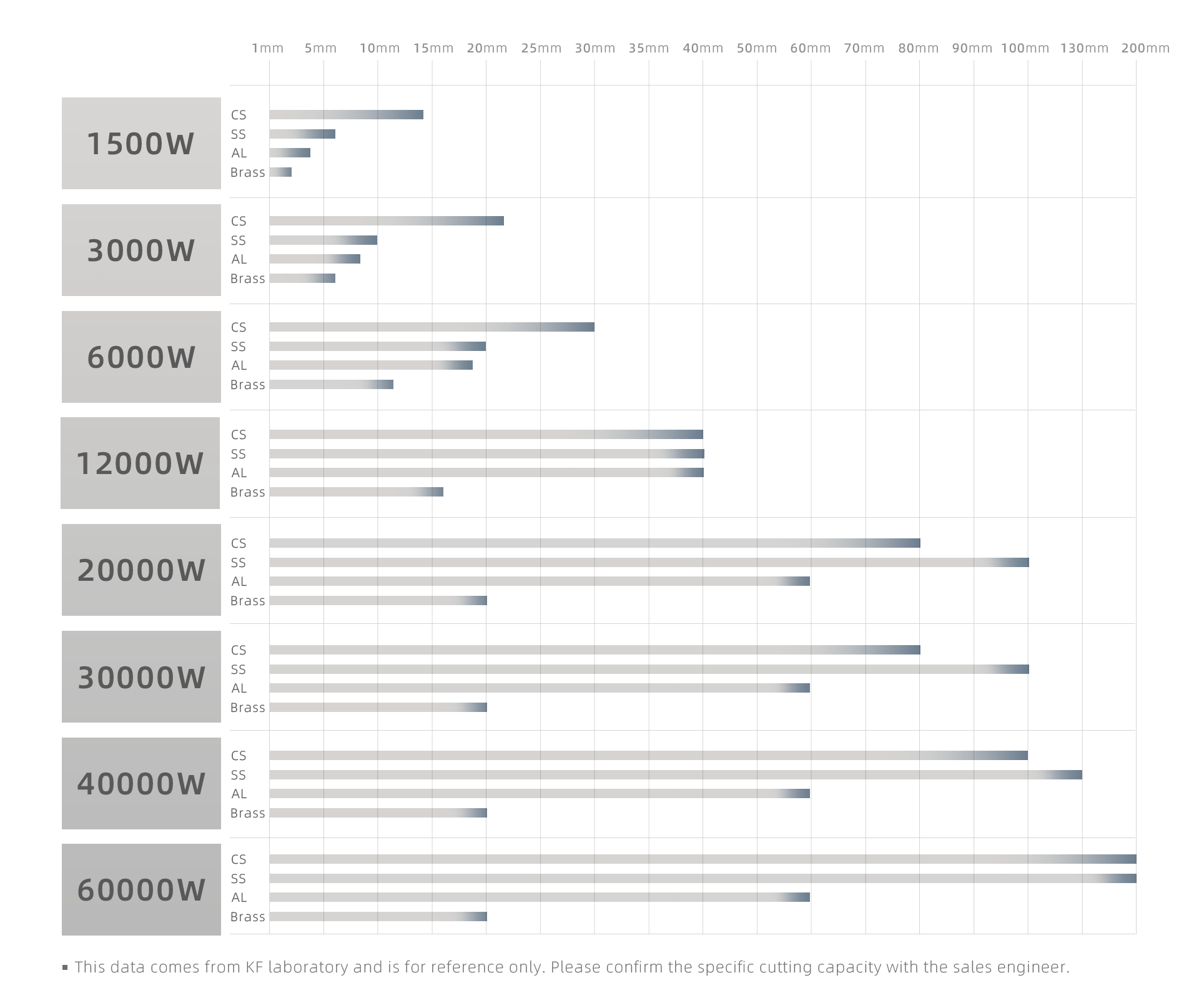

Laser Power | 1-6KW | 1-6KW | 1-6KW |

Dimension | 11230*2021*2133mm | 12000*2021*2136mm | 13000*2021*2139mm |

Weight | 2500KG | 4000KG | 7500KG |

Maximum Idle Running Speed(m/min) | 100m/min-120m/min | ||

Maximum idle acceleration(G) | 1.0G | ||

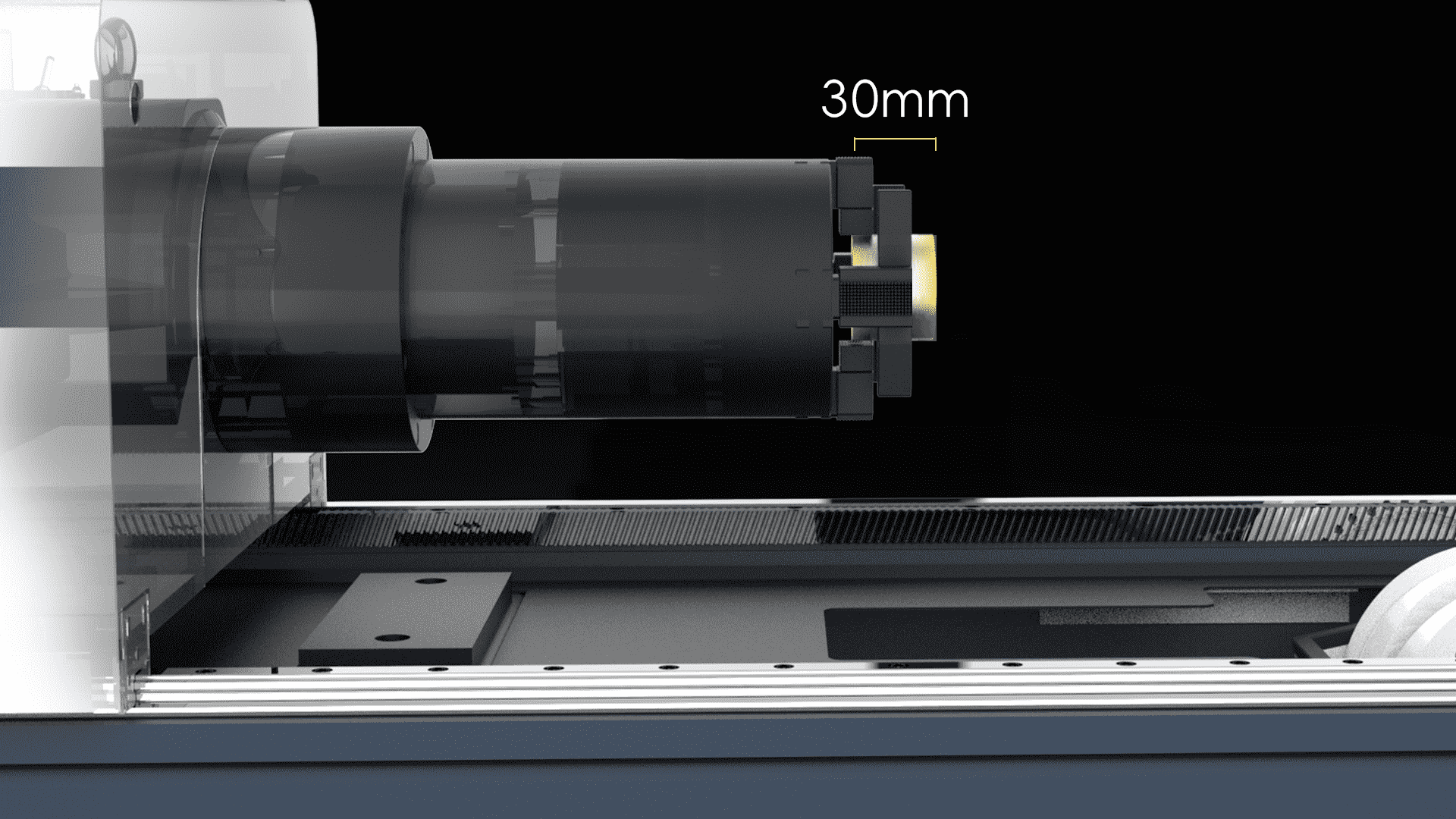

X/Y axis positioning accuracy/mm | ±0.05mm | ||

Repeat positioning accuracy/mm | ±0.03mm | ||

Cutting accuracy/mm | ≤0.1mm | ||

Working Voltage | 380V,three-phase /50Hz-60Hz | ||

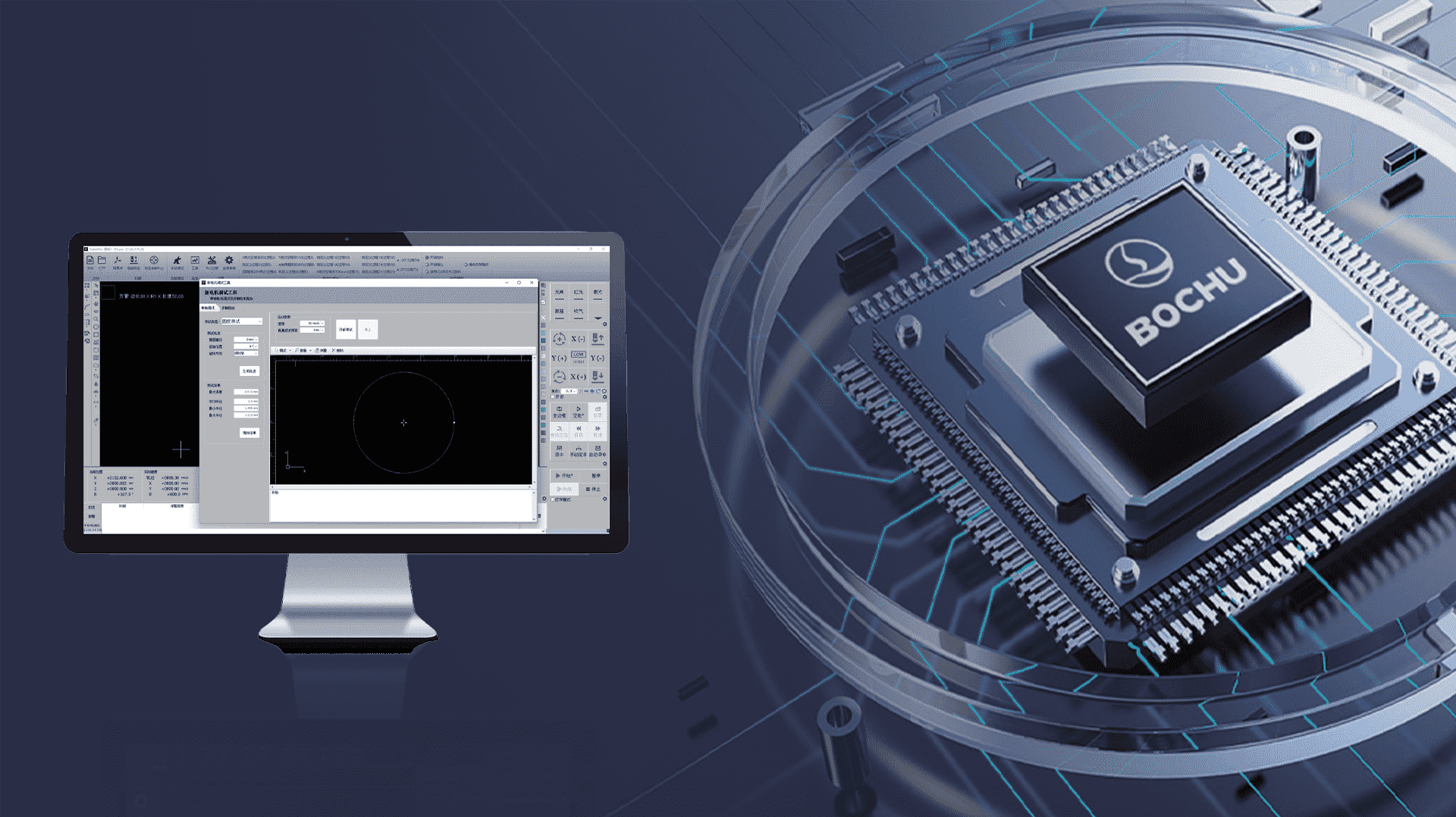

Supported image formats | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

A: In order to recommend you the most suitable machine model, just tell us below information

1)What is your material

2)The size of material

3)The thickness of material

4)Fiber laser cutter for metal

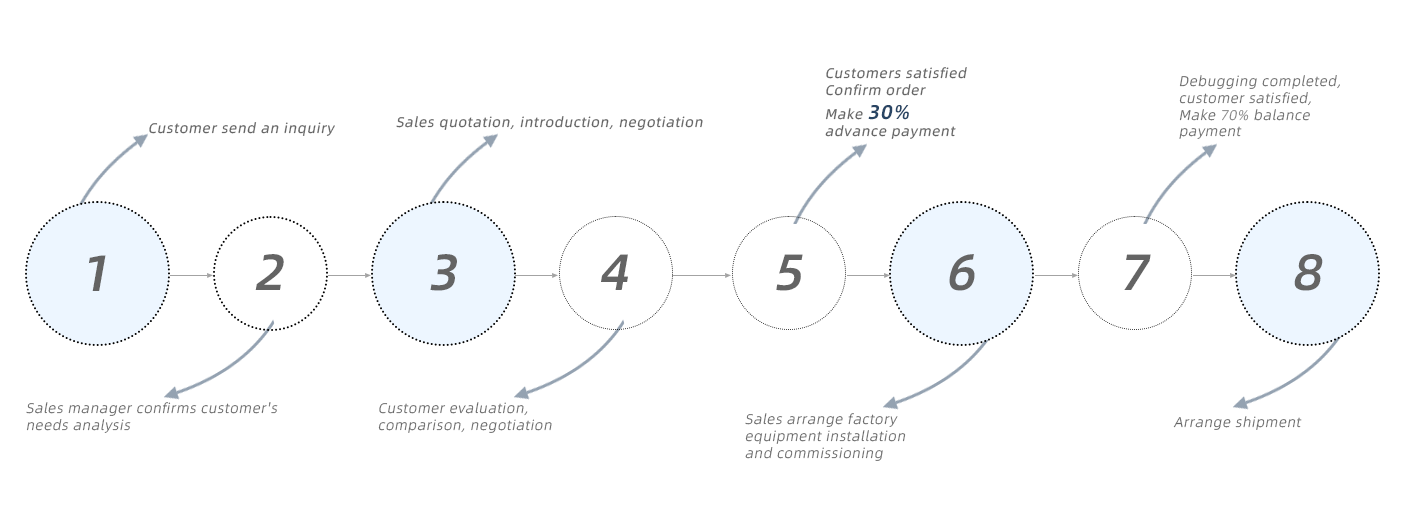

A:1)Alibaba trade assurance/TT/West Union/Payple/LC/Cash and so on.

2)We start making standardized machines after receiving 30% of the payment, inspect the machines after completion, and finally collect the 70% balance before shipping.

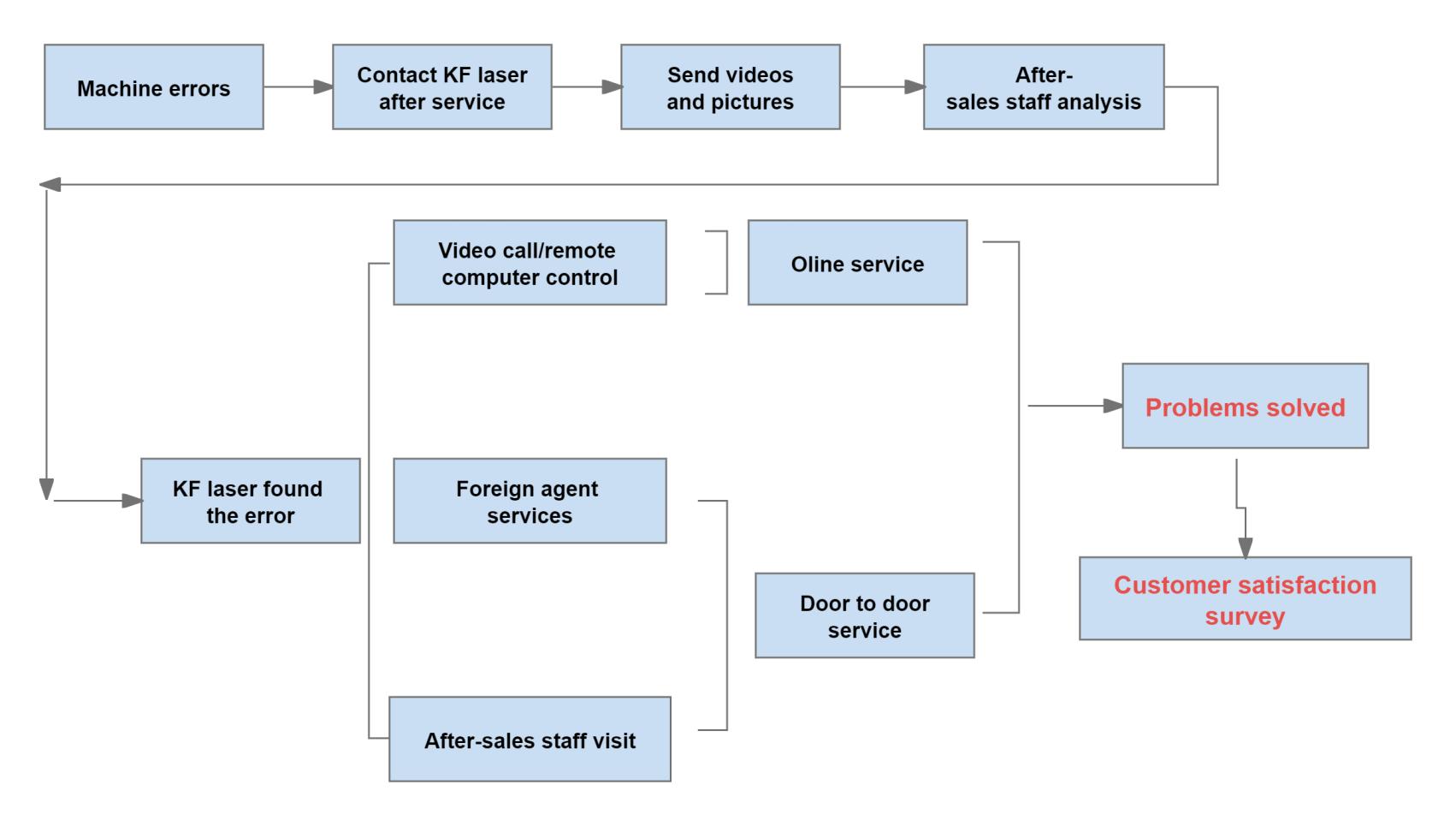

A:1)We provide free training in our factory

2)We provide free online after-sales service

3)We have complete installation instructions and video tutorials

4)Door-to-door service charges are based on region and aircraft model

5)Provide three-year warranty, except for consumable parts, direct replacement for non-human damage

1):Clean the optical lens: Clean the optical lens regularly to maintain the beam quality.

2):Check the gas supply: Make sure the gas supply system is normal to prevent the cutting quality from being affected.

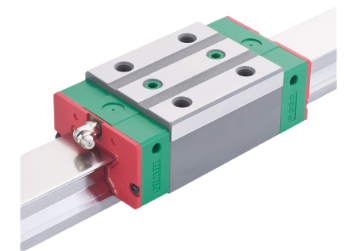

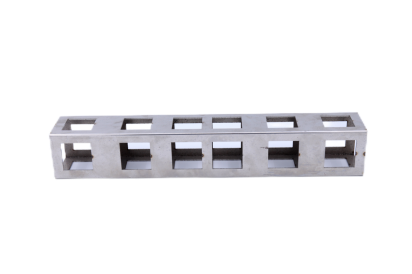

3):Lubricate the moving parts: Lubricate the guide rails and lead screw regularly to ensure the smooth operation of the moving parts.

4):Replace the chiller’s purified water every month. If it’s below zero in winter, remember to add antifreeze.

Fiber Laser Cutter for Metal: The Ultimate Tool for Precision and Efficiency

A fiber laser cutter for metal is a revolutionary tool in the manufacturing and fabrication industries. It leverages advanced laser technology to deliver high precision, speed, and efficiency, transforming how metal cutting is performed. This comprehensive guide will explore the workings, applications, and advantages of fiber laser cutters for metal, ensuring you understand why they are indispensable in modern manufacturing.(Fiber laser cutter for metal)

A fiber laser cutter for metal utilizes a highly focused laser beam to melt and cut through metal materials. This process is facilitated by the use of optical fibers as the gain medium, which amplifies the light and directs it to the cutting head. The concentrated laser beam is then used to cut through various metals with incredible precision and speed.

The operation of a fiber laser cutter for metal begins with a laser diode emitting light, which is then sent through a fiber optic cable to be amplified. This amplified laser beam, with its high intensity, strikes the metal surface, where it is absorbed and converted into heat. This heat melts the metal, and a high-speed airflow blows away the molten material, creating a precise cut.

Fiber laser cutters for metal are used in various industries due to their precision and efficiency. Some key applications include:

When choosing the best fiber laser cutter for metal, several features should be considered to ensure it meets your specific needs:

Fiber laser cutters for metal come in various configurations, each suited to specific applications:

Proper maintenance and operation are crucial for ensuring the long-term performance of fiber laser cutters for metal:

The future of fiber laser cutters for metal is bright, with ongoing advancements promising even greater capabilities:

Fiber laser cutters for metal are indispensable tools in modern manufacturing, offering unparalleled precision, speed, and versatility. From automotive and aerospace to electronics and jewelry making, these machines are revolutionizing how metal cutting is performed. By understanding the key features, applications, and maintenance tips, you can select the best fiber laser cutter for your needs and stay ahead in the competitive world of metal fabrication. As technology continues to advance, the potential of fiber laser cutting will only grow, making it an essential investment for any business involved in metalworking.