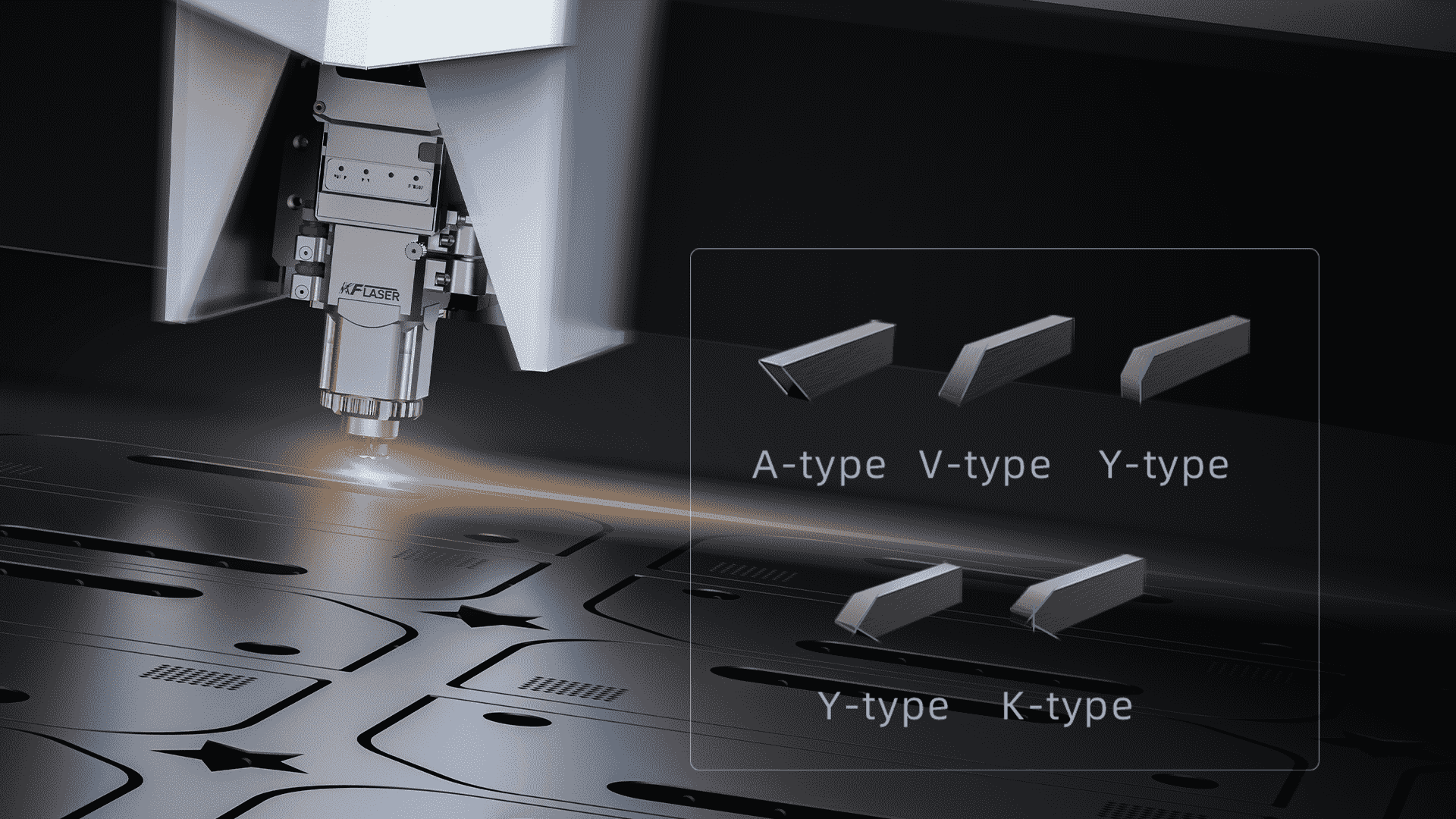

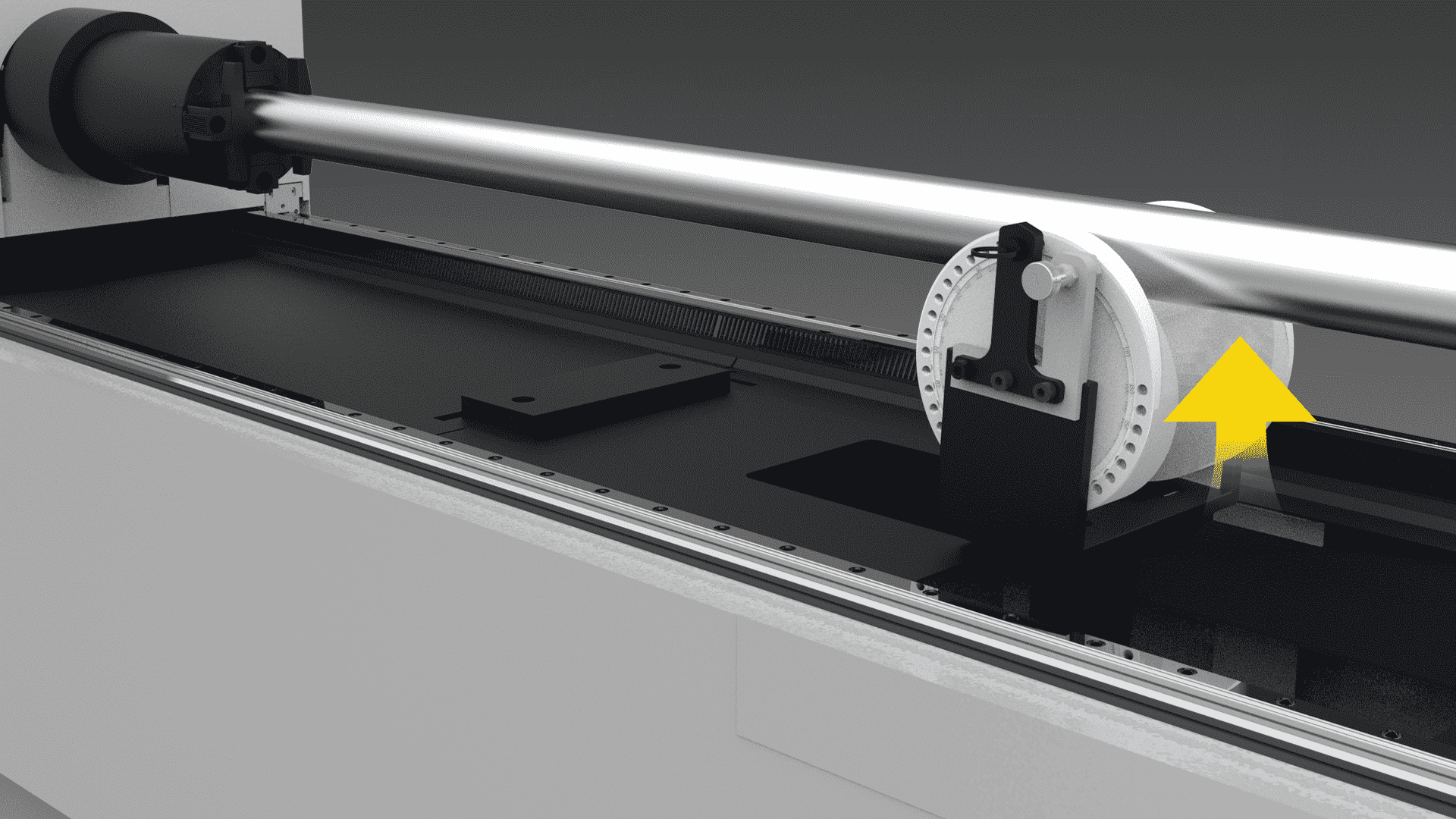

The K-type laser cutting machine has a replaceable worktable and a

closed design that meets high-speed and environmental protection

requirements.It has an overweight bed and supports bevel cutting.

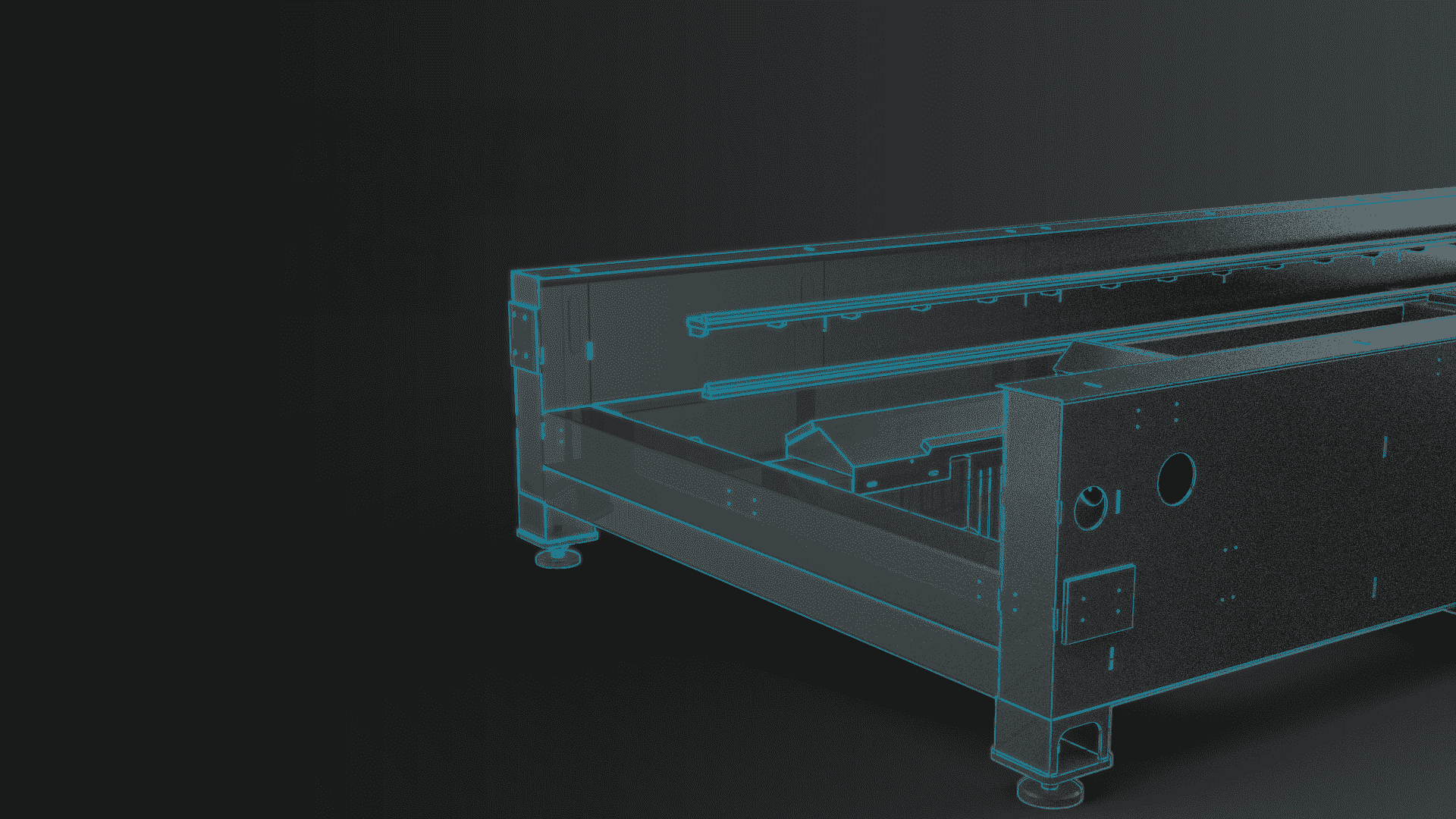

A cama O quadro é soldado usando tubos quadrados grossos e reforçado internamente para melhorar a força estrutural e a resistência à tração., impedir a deformação, reduzir vibrações, e garantir uma excelente precisão de corte

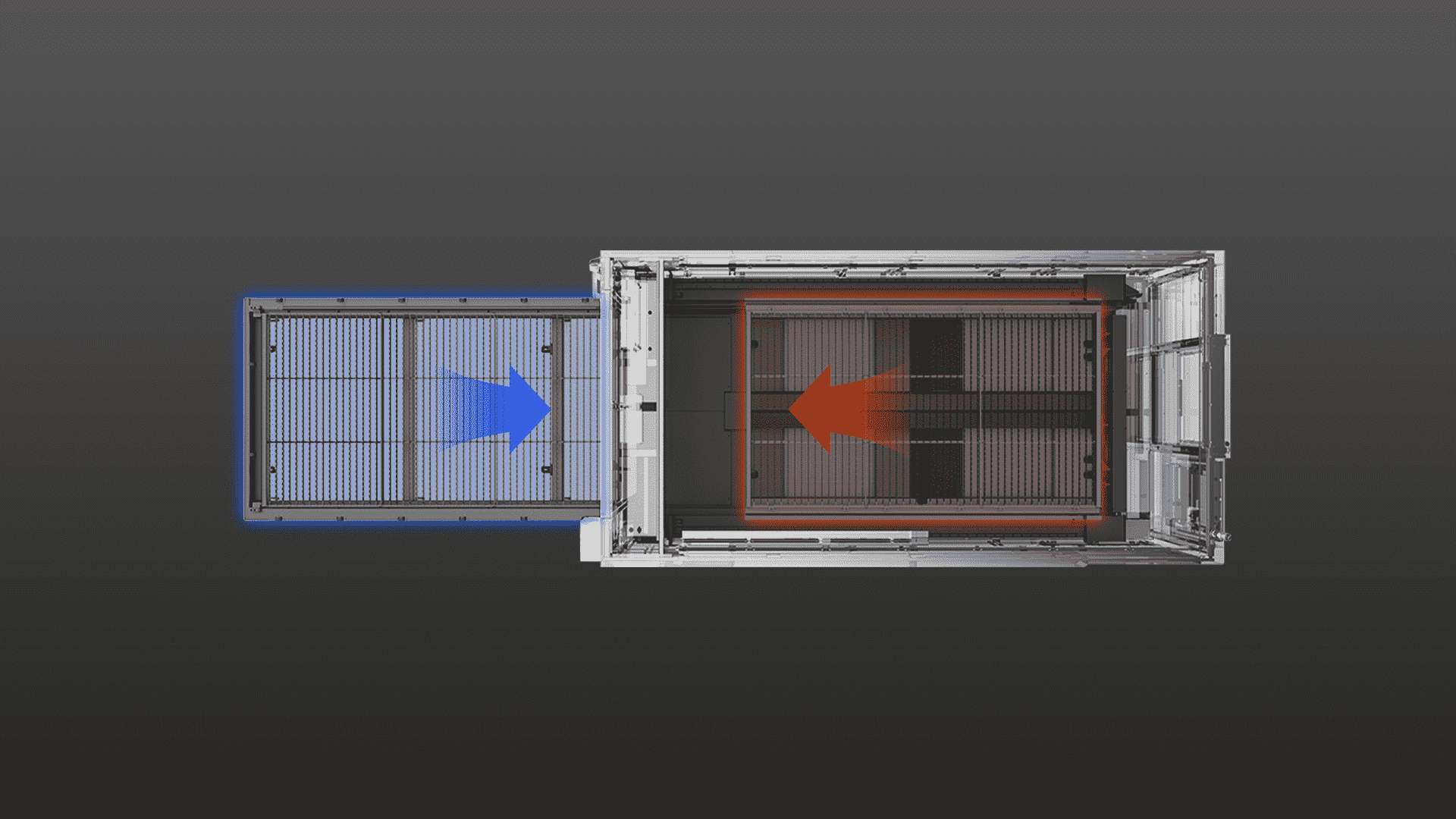

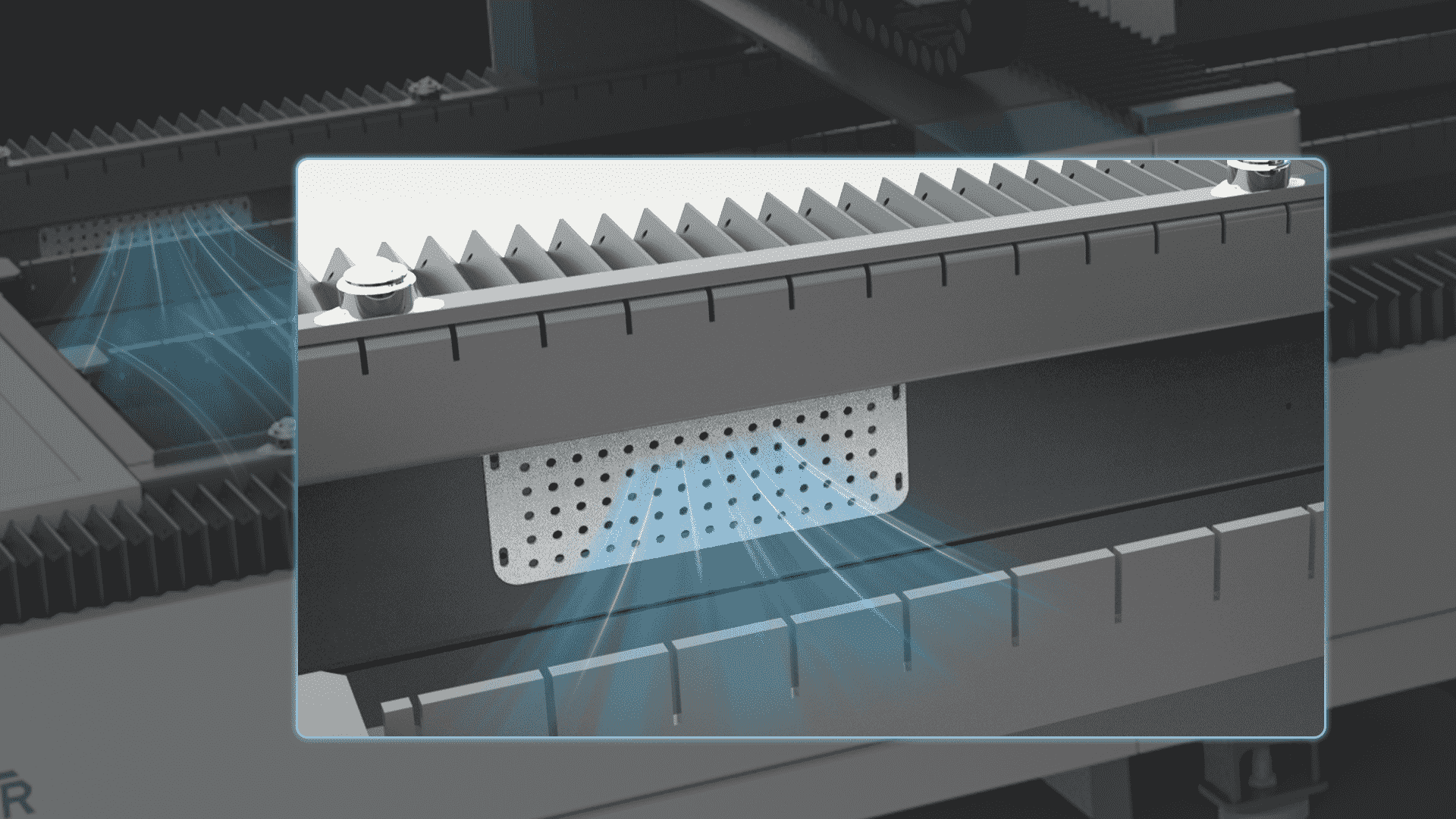

Se você atribuir grande importância à proteção ambiental, Esta máquina é uma escolha ideal para o seu negócio. Possui várias áreas automáticas de remoção de poeira, e a saída de ar muda automaticamente de acordo com a posição da cabeça do laser, com remoção precisa de poeira, que pode remover de maneira perfeita e eficientemente a poeira e a fumaça geradas durante o processo de corte, atendendo às suas necessidades de produção ecologicamente correta.(Máquina de corte a laser de chapa metálica série K – Detalhes da imagem (laser cutter sheet metal)

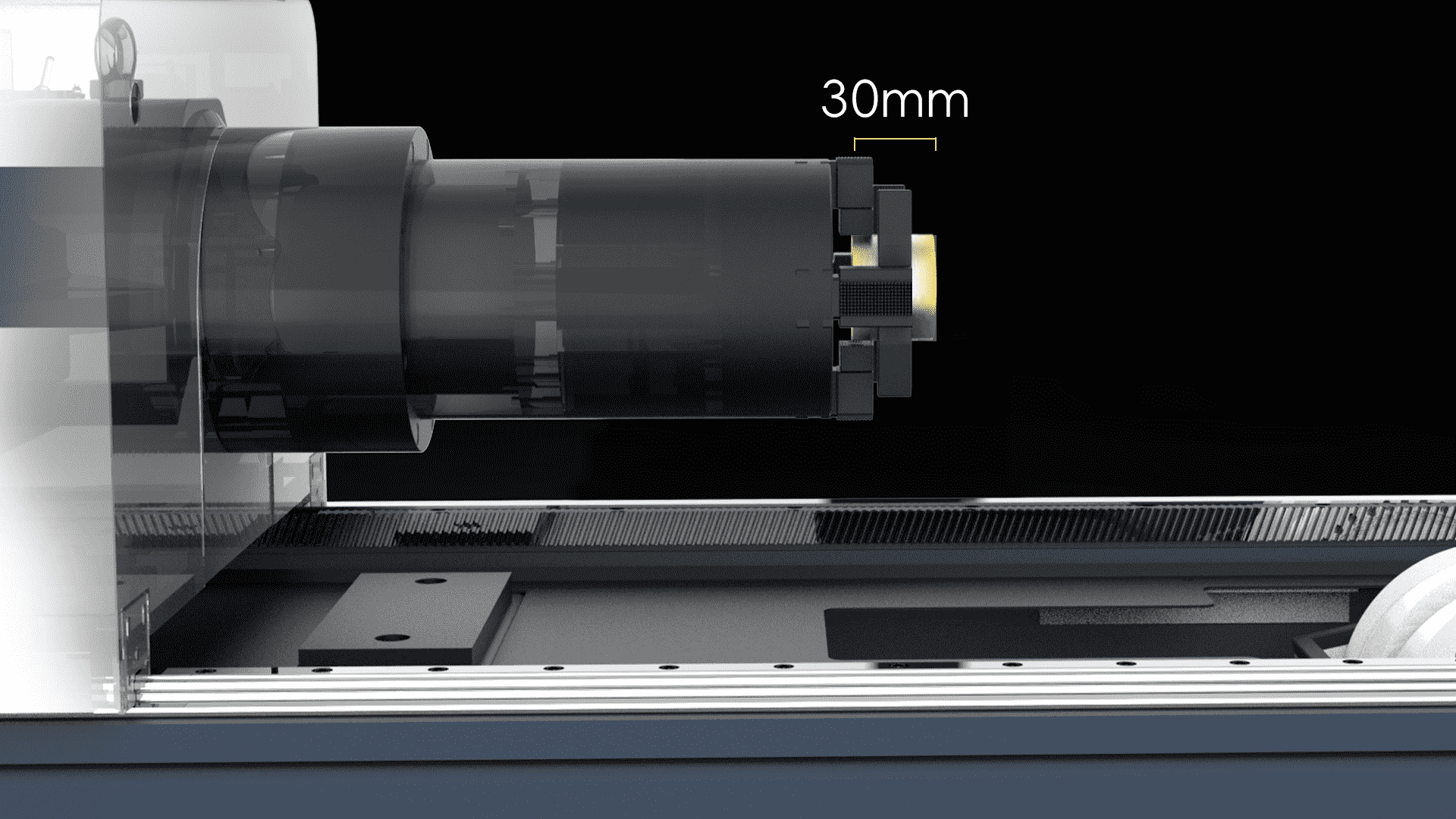

A cabeça de corte de alta potência da série Boci BLT6 pode obter corte preciso e estável, atender necessidades complexas e garantir resultados de corte de alta qualidade. Inclui um sistema eficiente de resfriamento de água para prolongar a vida útil e operação estável. Adota um design multifuncional com funções de aprimoramento de segurança, como prevenção inteligente de obstáculos, proteção contra colisão, alarme de subtensão, monitoramento de circuito fechado e perfuração inteligente, que pode ajustar automaticamente os parâmetros de corte para diferentes materiais.

A máquina está equipada com câmeras internas, permitindo a observação em tempo real de suas operações através do painel de controle.

Modelo de máquina | K3 series | K4 series | K6 series |

Área de Trabalho | 3050*1530milímetros | 4100*2050milímetros | 6100*2550milímetros |

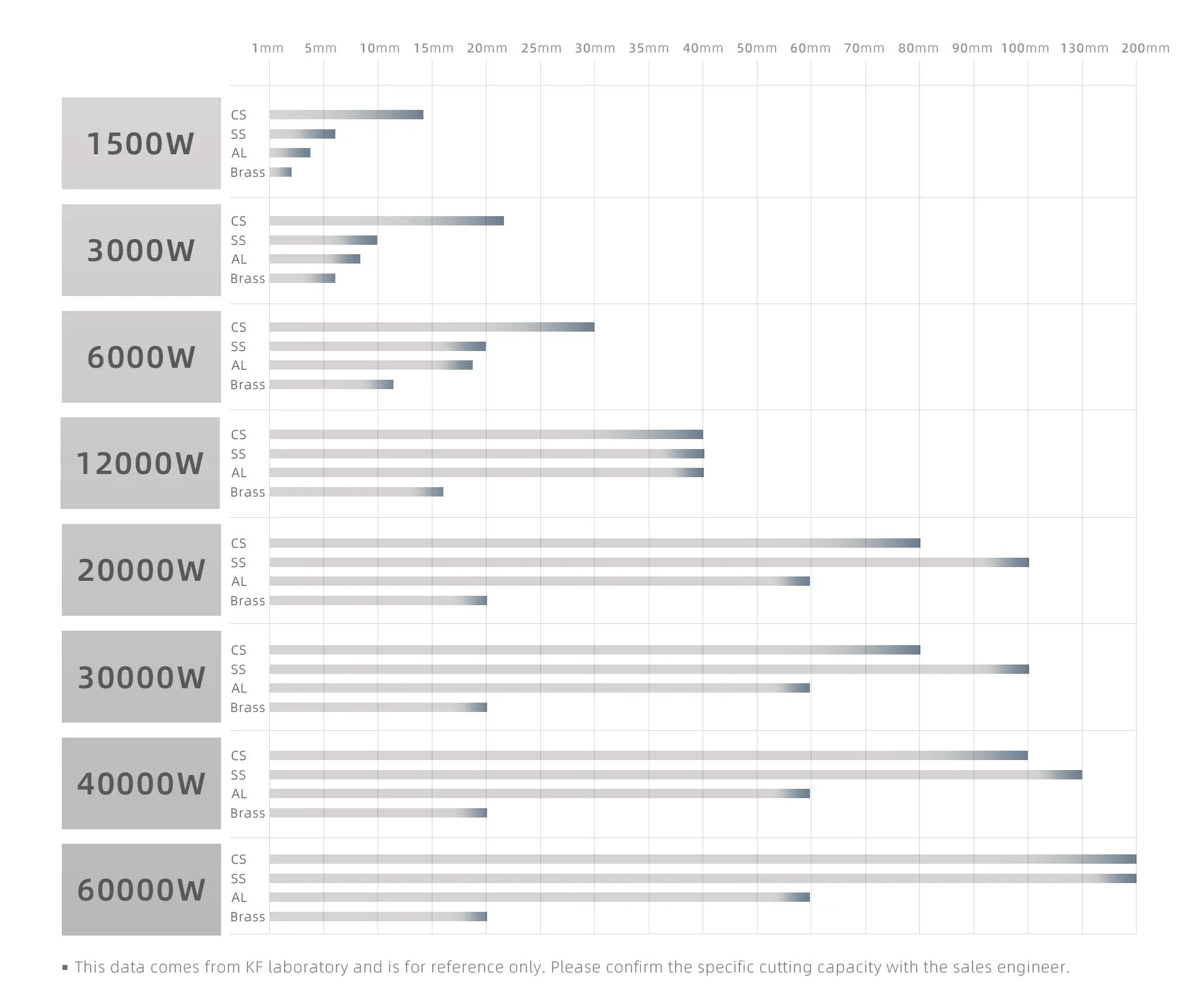

Potência Laser | 1500-20000C | 1500-40000C | 1500-40000C |

Dimensão | 8300*3100*2400milímetros | 10300*3600*2400milímetros | 14300*4100*2400milímetros |

Peso | 6750KG | 13500KG | 17500KG |

Velocidade máxima de marcha lenta(m/min) | 100m/min-120m/min | ||

Aceleração máxima em marcha lenta(G) | 1.0G/1,2G/1,5G | ||

Precisão de posicionamento do eixo X/Y/mm | ±0,05 mm | ||

Precisão de posicionamento repetido/mm | ±0,02mm | ||

Precisão de corte/mm | ≤0,1 mm | ||

Tensão de trabalho | 380V,trifásico /50Hz-60Hz | ||

Formatos de imagem suportados | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

UM: Para lhe recomendar o modelo de máquina mais adequado, basta nos dizer as informações abaixo

1)Qual é o seu material

2)O tamanho do material

3)A espessura do material

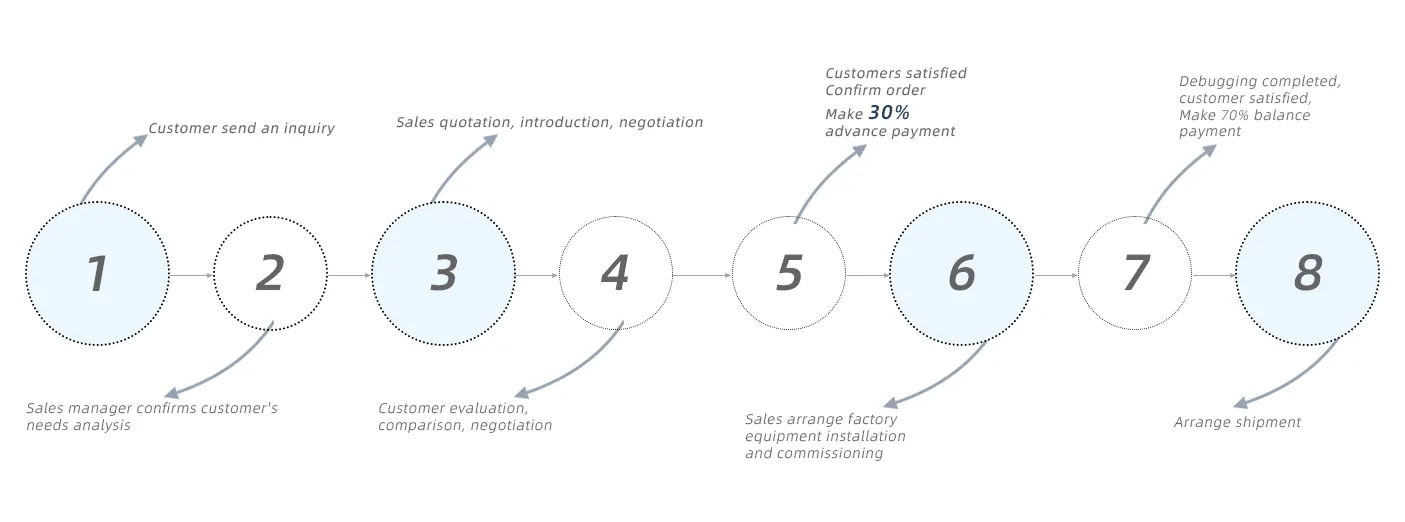

UM:1)Garantia comercial Alibaba/TT/West Union/Payple/LC/Cash e assim por diante.

2)Começamos a fabricar máquinas padronizadas após recebermos 30% do pagamento, inspecionar as máquinas após a conclusão, e finalmente coletar o 70% saldo antes do envio.

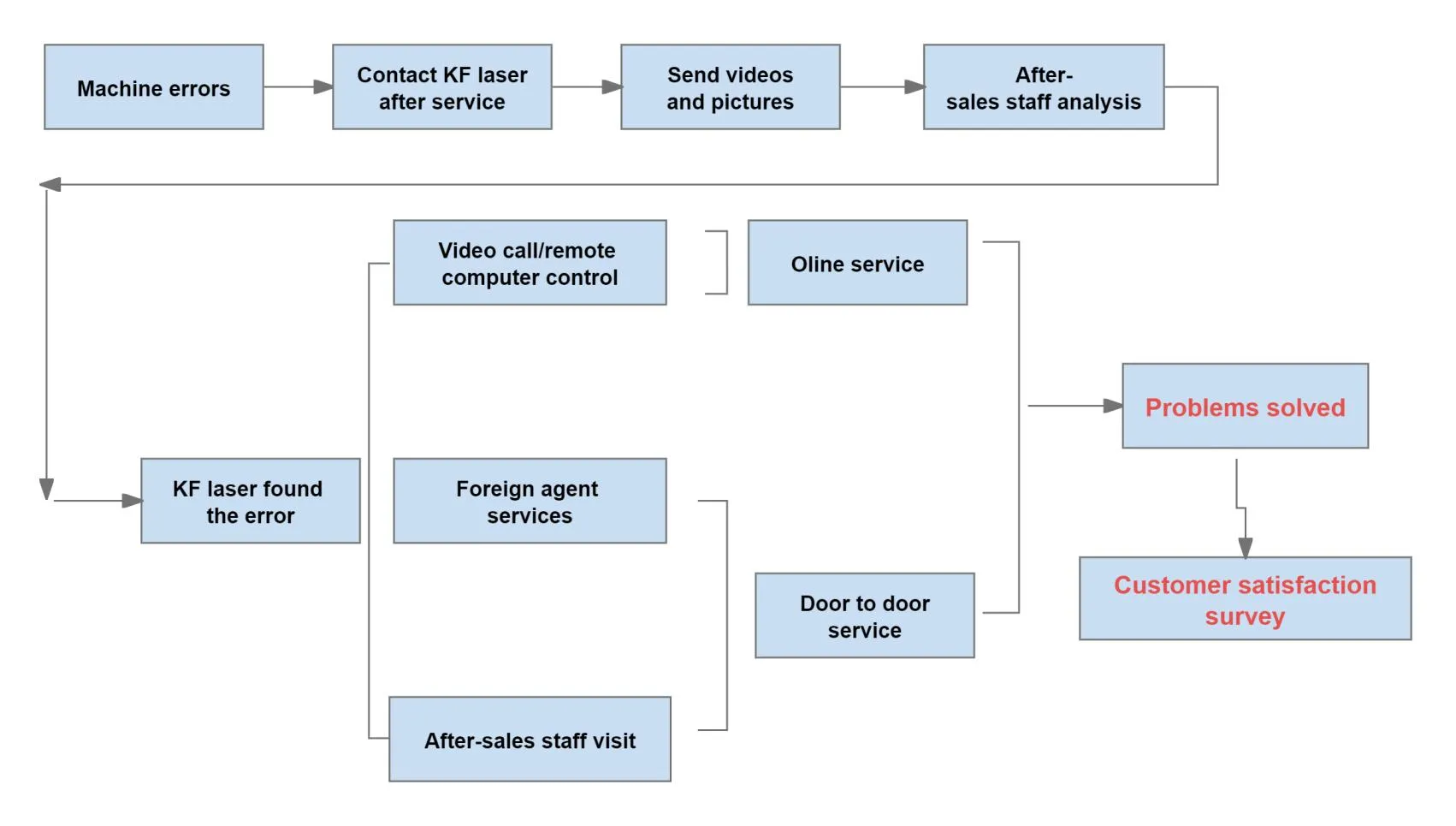

UM:1)Oferecemos treinamento gratuito em nossa fábrica

2)Oferecemos serviço pós-venda on-line gratuito

3)Temos instruções completas de instalação e tutoriais em vídeo

4)As taxas de serviço porta a porta são baseadas na região e no modelo da aeronave

5)Fornece garantia de três anos, exceto peças consumíveis, substituição direta por danos não humanos

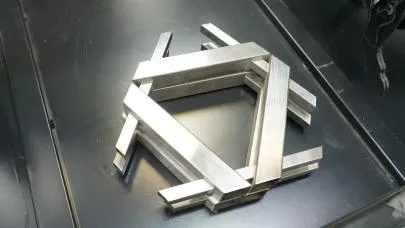

A laser cutter sheet metal machine is a versatile and efficient tool for cutting a variety of sheet metal materials. This guide will provide an in-depth understanding of the technology, suas aplicações, vantagens, and considerations when selecting a laser cutter for sheet metal. The aim is to help you make an informed decision and optimize your cutting processes.

A laser cutter for sheet metal uses a focused laser beam to cut or engrave sheet metal materials. O raio laser, controlado por um CNC (Controle numérico do computador) sistema, is directed at the material, melting, burning, or vaporizing it to produce a precise cut. This technology is widely used in various industries due to its precision, velocidade, e versatilidade.

Laser cutting sheet metal is used across many industries due to its versatility and efficiency. Aplicações comuns incluem:

There are several types of laser cutters used for sheet metal, cada um com suas vantagens específicas e aplicações adequadas:

When selecting a laser cutter for sheet metal, considere os seguintes fatores para garantir que você escolha a melhor máquina para suas necessidades:

Different techniques can be employed when laser cutting sheet metal, cada um adequado para materiais específicos e resultados desejados:

To achieve the best results when using a laser cutter for sheet metal, considere as seguintes dicas de otimização:

Embora o corte a laser seja geralmente seguro, envolve lasers de alta potência e materiais potencialmente perigosos. Siga estas diretrizes de segurança para garantir um ambiente de trabalho seguro:

A laser cutter for sheet metal offers numerous advantages, incluindo alta precisão, velocidade, e versatilidade. Ao entender os diferentes tipos de lasers, suas aplicações, e os fatores a serem considerados ao escolher uma máquina, você pode tomar uma decisão informada para aprimorar seus processos de corte. A otimização e manutenção adequadas garantirão, resultados de alta qualidade, tornando o corte a laser uma ferramenta inestimável na fabricação moderna.