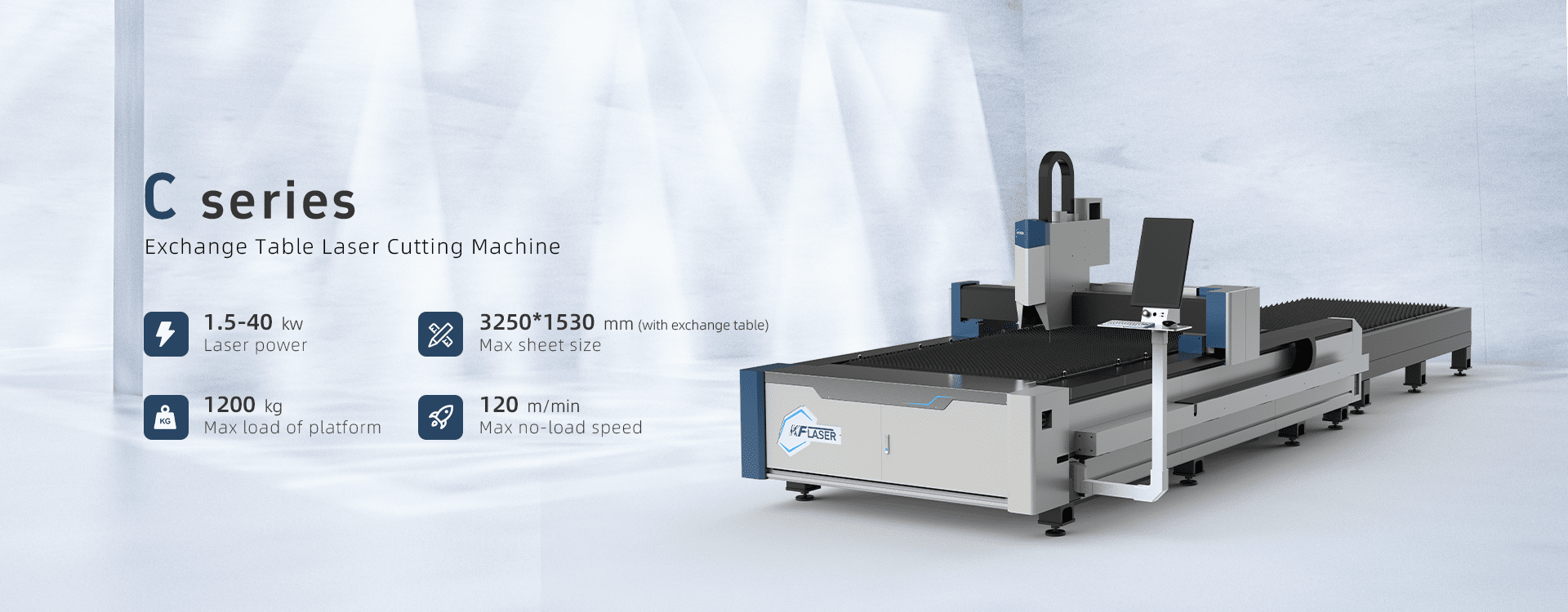

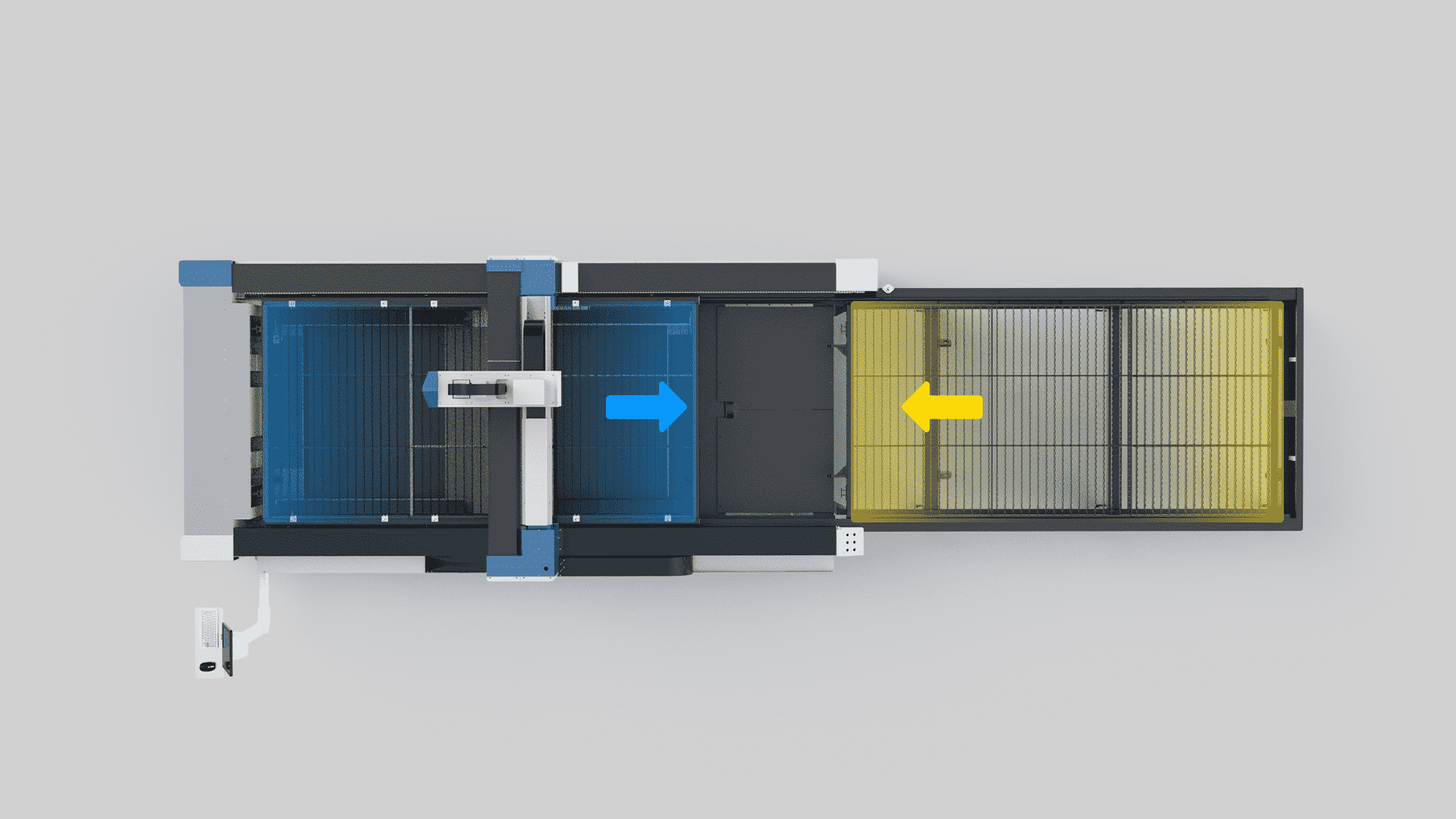

Type C is an open exchange table fiber laser cutting machine,

which can realize front bed cutting and rear bed loading at the same time.

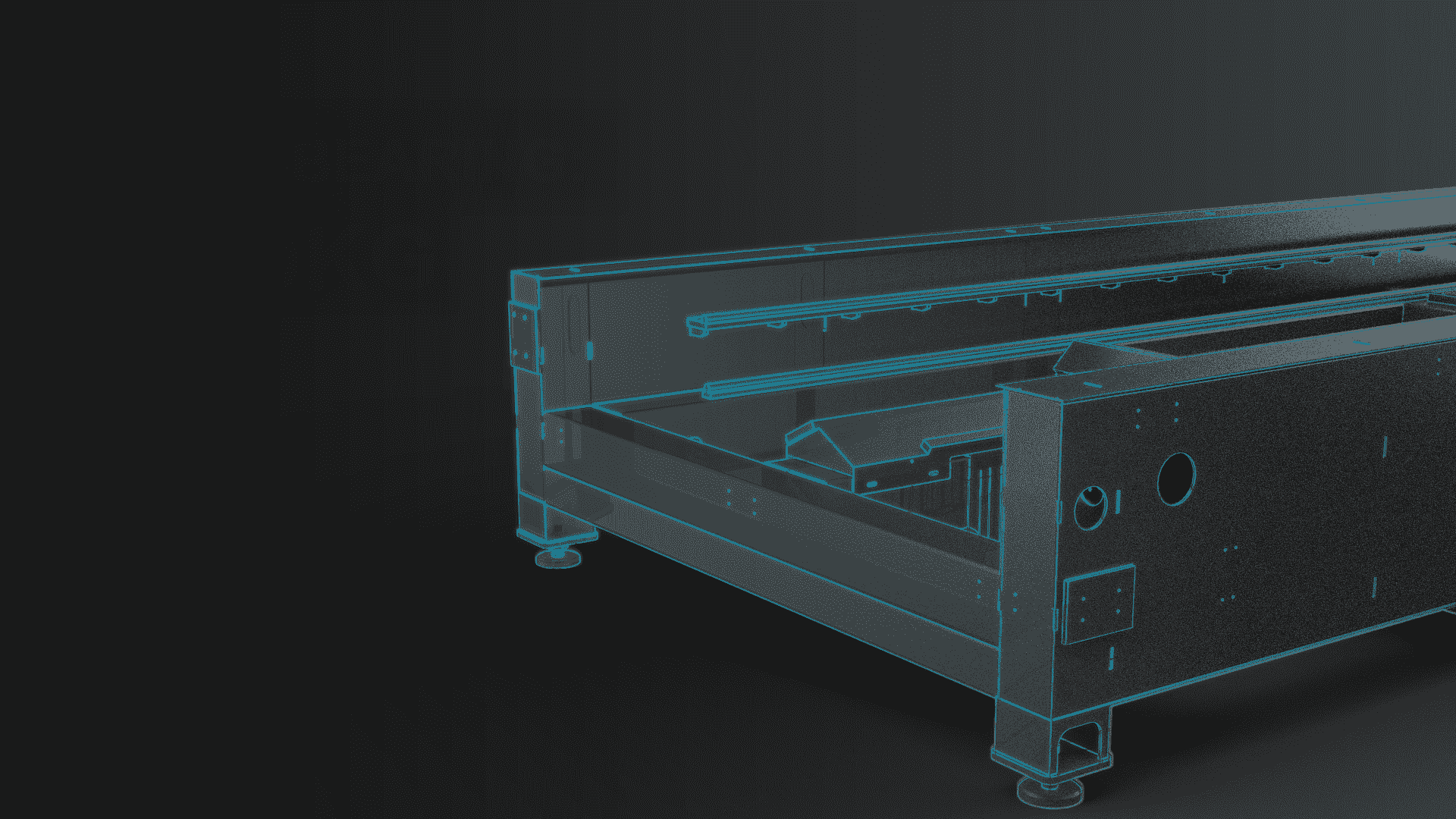

The bed frame is welded using thick square tubes and reinforced internally to enhance structural strength and tensile resistance.It undergoes high-temperature annealing and natural aging treatment to eliminate welding stress, prevent deformation, reduce vibrations, and ensure excellent cutting precision(laser metal cutter)

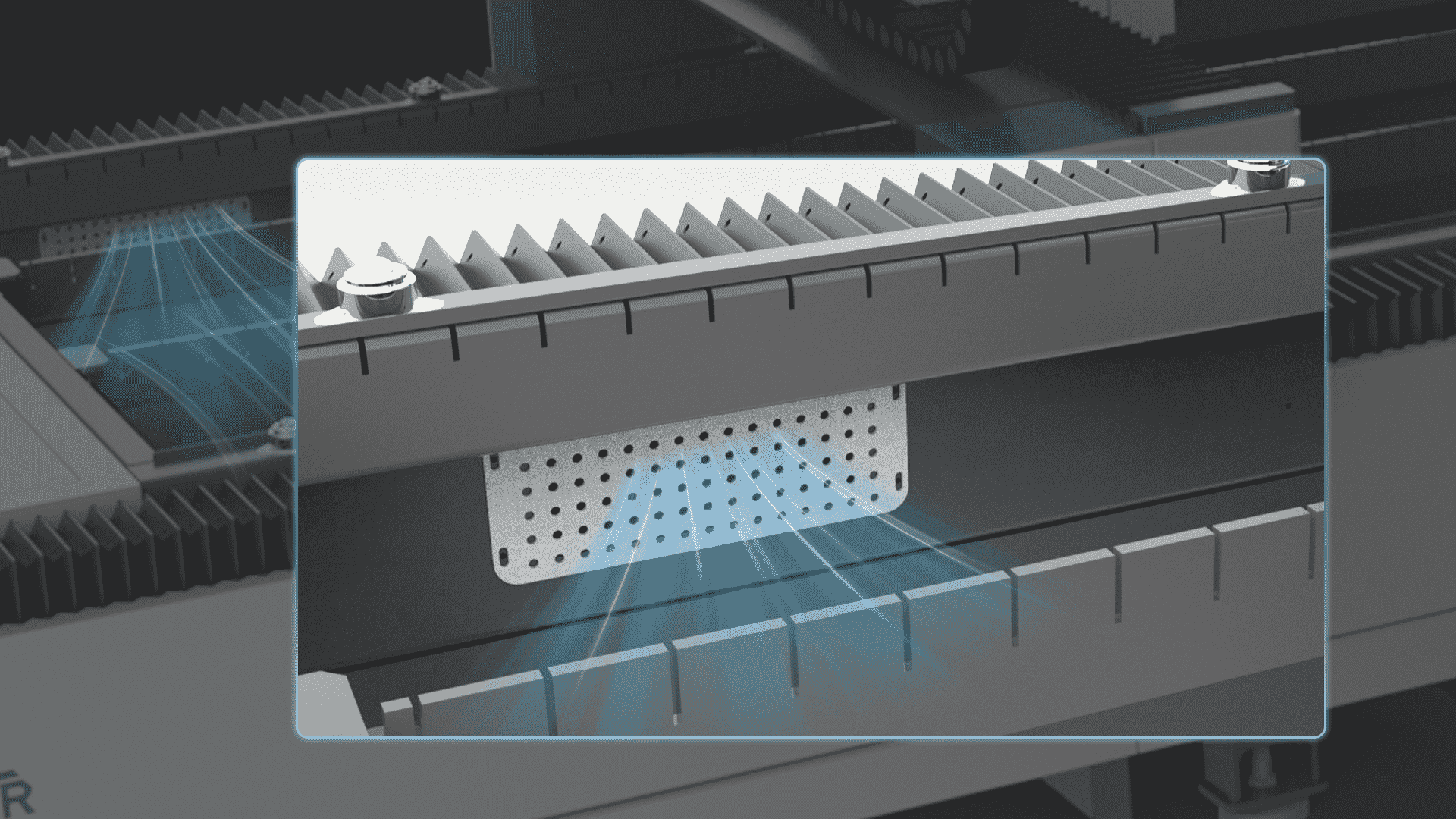

If you attach great importance to environmental protection, this machine is an ideal choice for your business. It has multiple automatic dust removal areas, and the air outlet automatically switches according to the position of the laser head, with precise dust removal, which can seamlessly and efficiently remove dust and smoke generated during the cutting process, meeting your needs for environmentally friendly production.(Laser Sheet Metal Cutting Machine K Series – Details Image

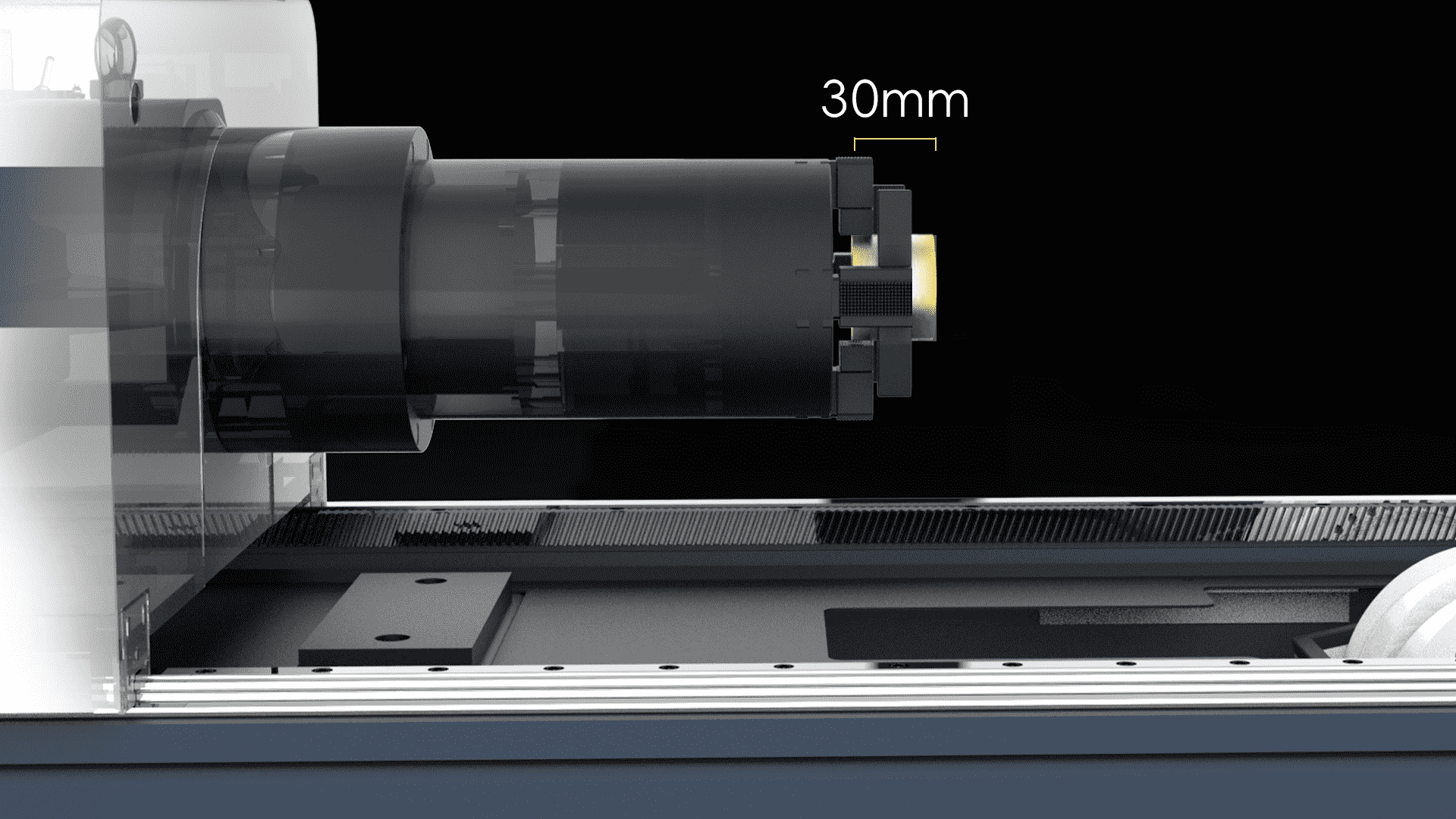

Boci BLT6 series high-power cutting head can achieve precise and stable cutting, meet complex needs and ensure high-quality cutting results. It includes an efficient water cooling system to extend the service life and stable operation. It adopts a multi-functional design with safety enhancement functions such as intelligent obstacle avoidance, collision protection, undervoltage alarm, closed-loop monitoring and intelligent perforation, which can automatically adjust cutting parameters for different materials.

Machine Model | C3 series | C4 series | C6 series |

Working Area | 3050*1530mm | 4100*2050mm | 6100*2550mm |

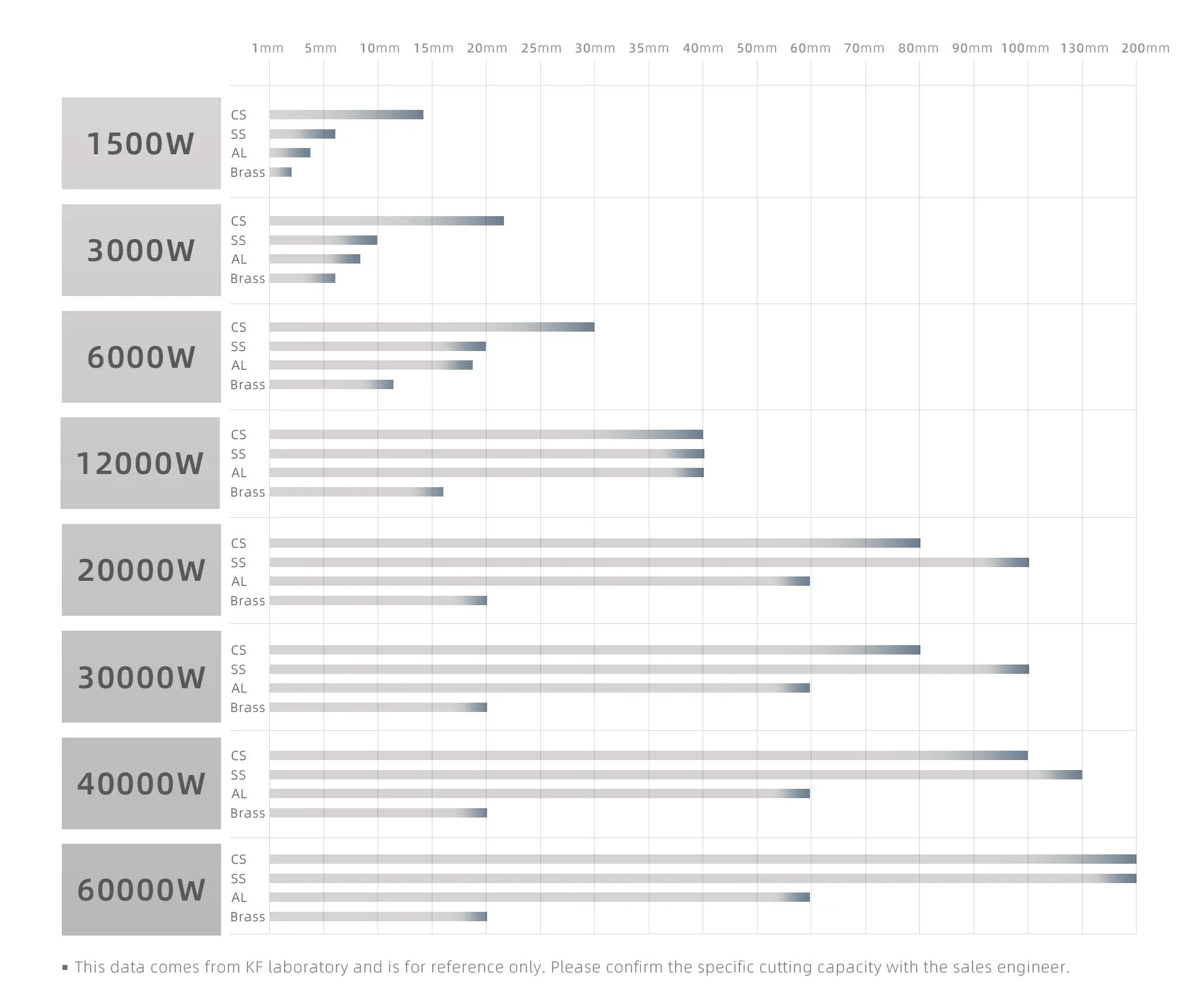

Laser Power | 1500-20000W | 1500-40000W | 1500-40000W |

Dimension | 8020*2600*2100mm | 10020*3100*2100mm | 14200*3600*2100mm |

Weight | 4550KG | 11500KG | 15000KG |

Maximum Idle Running Speed(m/min) | 100m/min-120m/min | ||

Maximum idle acceleration(G) | 1.0G/ 1.2G/ 1.5G | ||

X/Y axis positioning accuracy/mm | ±0.05mm | ||

Repeat positioning accuracy/mm | ±0.02mm | ||

Cutting accuracy/mm | ≤0.1mm | ||

Working Voltage | 380V,three-phase /50Hz-60Hz | ||

Supported image formats | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

A: In order to recommend you the most suitable machine model, just tell us below information

1)What is your material

2)The size of material

3)The thickness of material

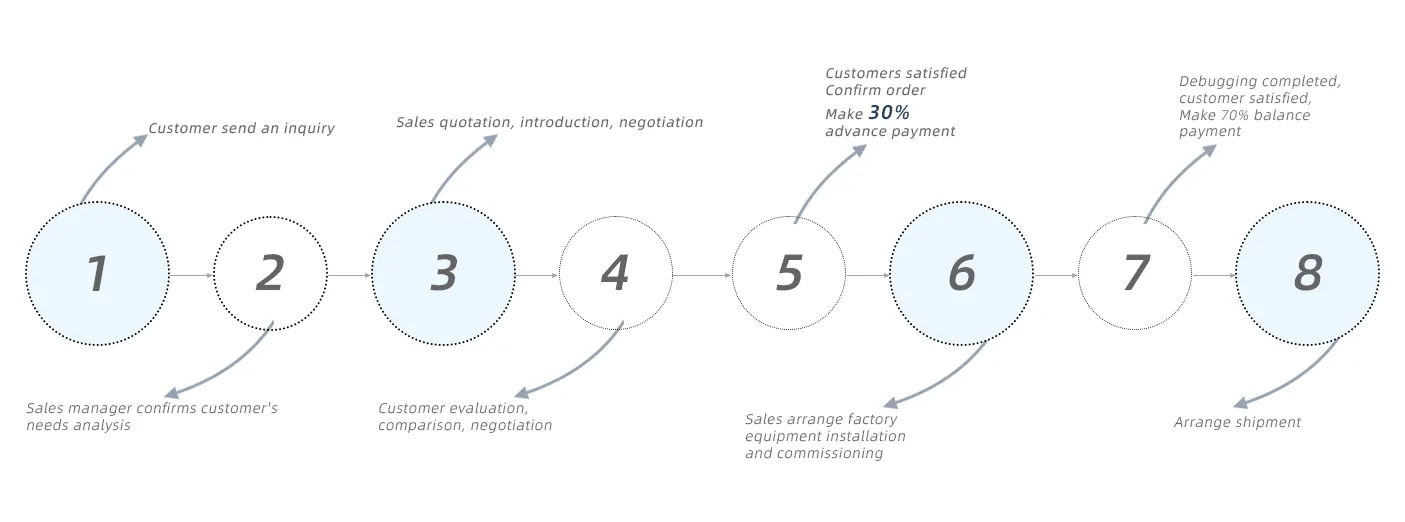

A:1)Alibaba trade assurance/TT/West Union/Payple/LC/Cash and so on.

2)We start making standardized machines after receiving 30% of the payment, inspect the machines after completion, and finally collect the 70% balance before shipping.

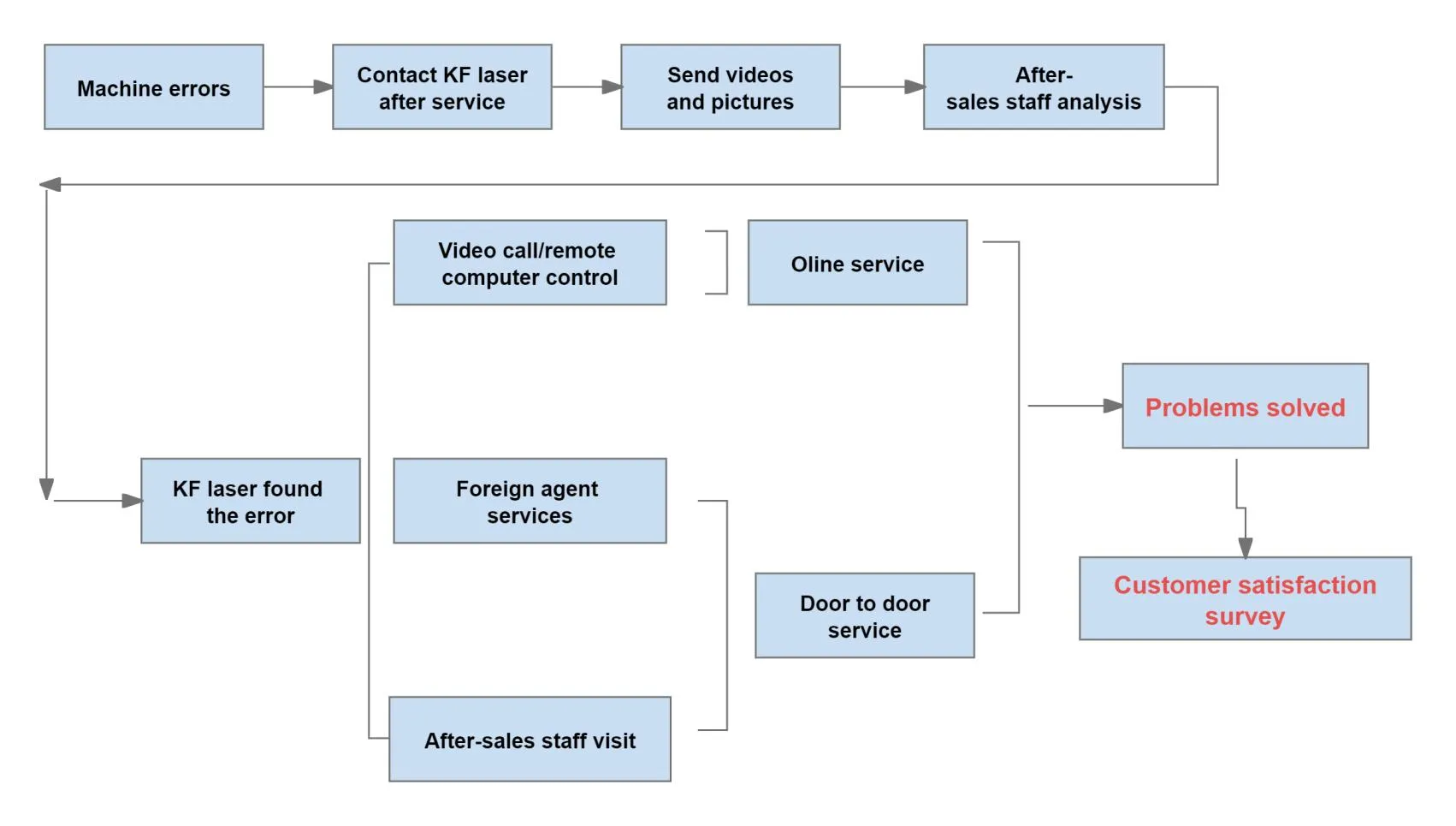

A:1)We provide free training in our factory

2)We provide free online after-sales service

3)We have complete installation instructions and video tutorials

4)Door-to-door service charges are based on region and aircraft model

5)Provide three-year warranty, except for consumable parts, direct replacement for non-human damage

A laser metal cutter is an essential tool in modern manufacturing, offering unparalleled precision, speed, and efficiency for cutting various metals. This comprehensive guide will delve into the intricacies of laser metal cutting technology, its applications, advantages, and considerations when choosing a laser metal cutter machine. The aim is to help you make an informed decision and optimize your metal cutting processes.

A laser cutter machine for metal utilizes a high-powered laser beam to cut through metal sheets, pipes, and rods. The laser beam, controlled by a CNC (Computer Numerical Control) system, melts, burns, or vaporizes the material, producing a precise cut. The technology is widely used across different industries due to its ability to handle various types of metals, including steel, stainless steel, aluminum, copper, and brass.

Laser metal cutting machines are used across numerous industries due to their versatility and efficiency. Common applications include:

There are several types of laser cutters used for metal, each with its specific advantages and suitable applications:

When selecting a laser cutter machine for metal, consider the following factors to ensure you choose the best machine for your needs:

Different techniques can be employed when laser cutting metal, each suited to specific materials and desired outcomes:

To achieve the best results when using a laser metal cutter, consider the following optimization tips:

While laser cutting is generally safe, it involves high-power lasers and potentially hazardous materials. Follow these safety guidelines to ensure a safe working environment:

The cost of a laser cutter machine for metal can vary widely based on several factors, including the type of laser, power, work table size, and the properties of the material to be cut. Understanding these factors can help you choose a machine that fits your budget and meets your cutting needs.

The field of laser metal cutting is continually evolving, with new technologies and advancements improving efficiency, precision, and versatility. Some trends to watch for include:

A laser metal cutter offers numerous advantages, including high precision, speed, and versatility. By understanding the different types of lasers, their applications, and the factors to consider when choosing a machine, you can make an informed decision to enhance your cutting processes. Proper optimization and maintenance will ensure consistent, high-quality results, making laser cutting an invaluable tool in modern manufacturing.