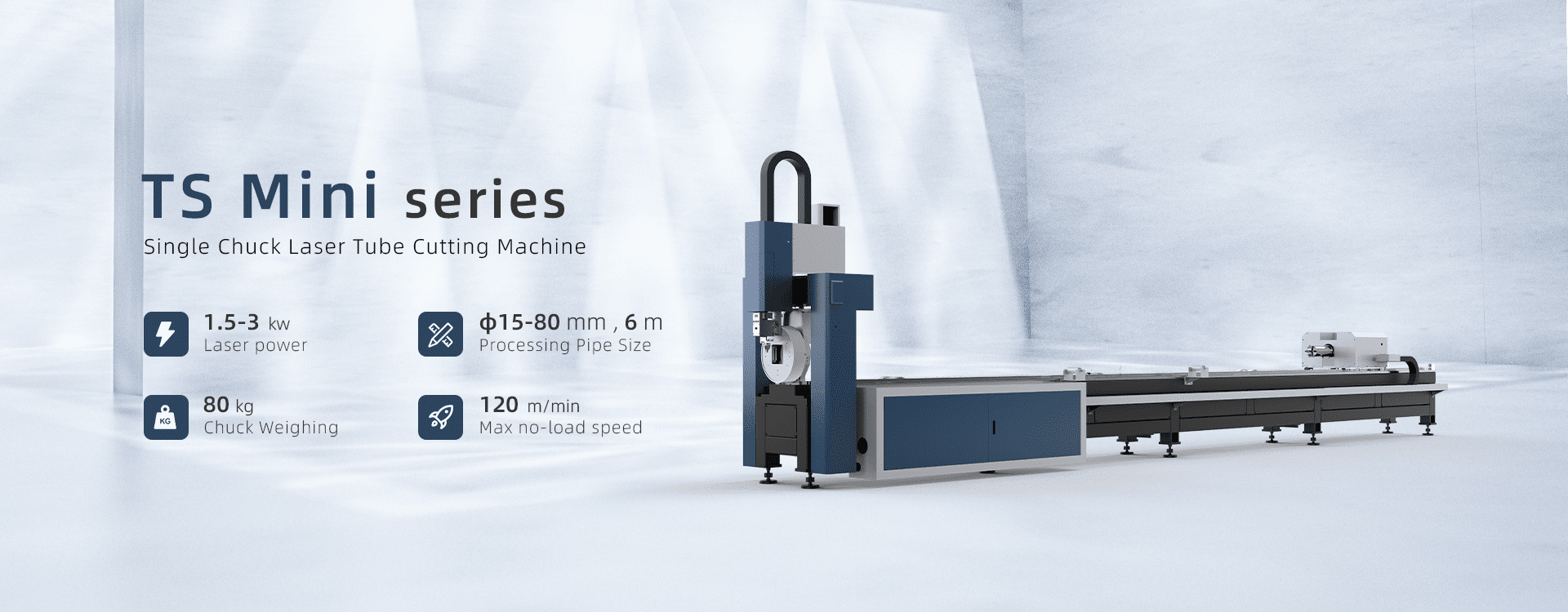

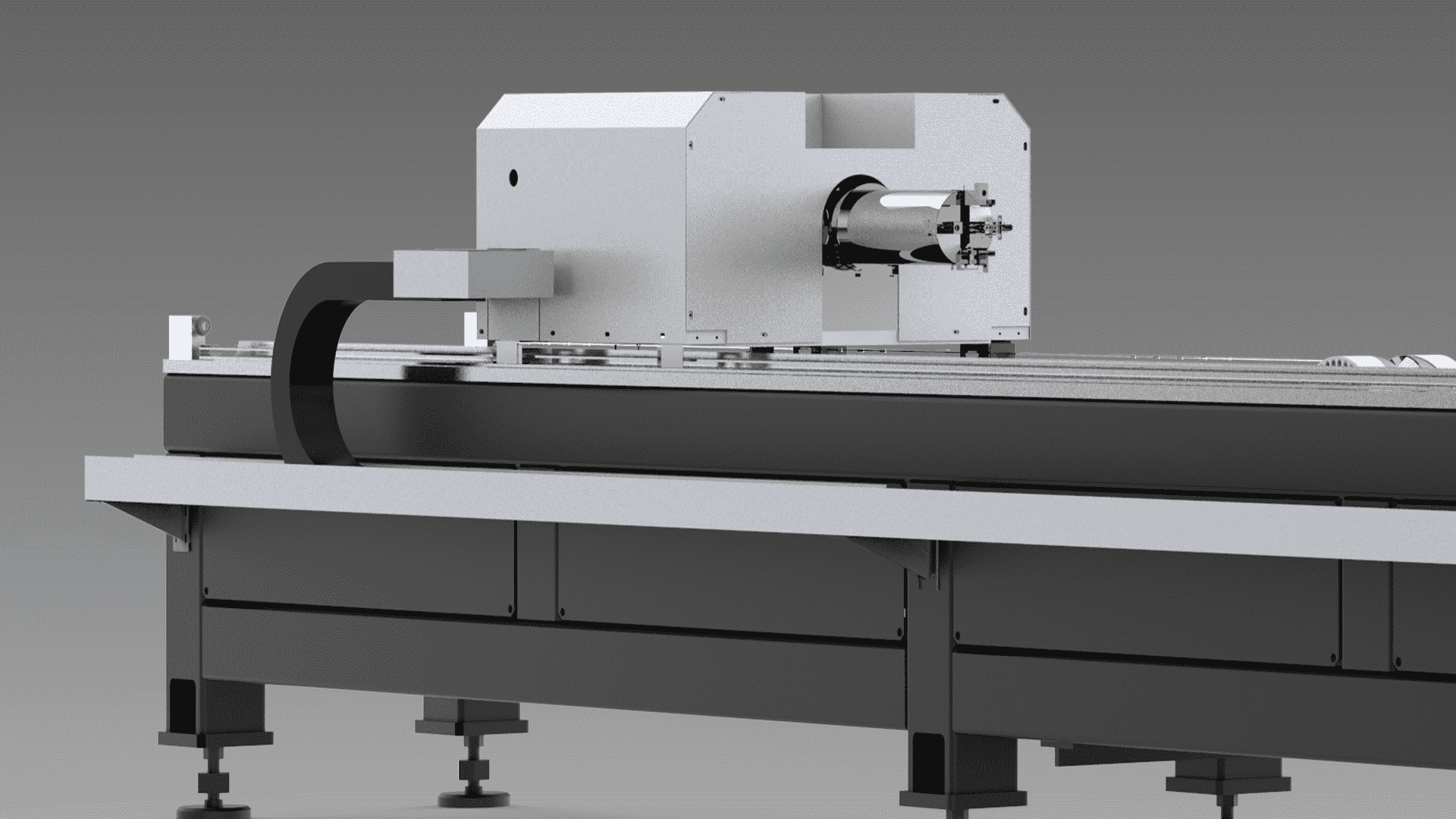

TS Mini series is a more economical and simpler double chuck tube cutting machine with high-speed cutting function for various tubes.

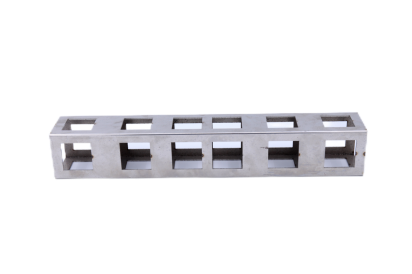

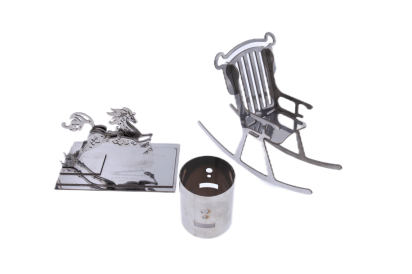

Equipped with efficient cutting, punching and slotting functions, it can quickly meet the processing needs of various profiles such as round tubes, square tubes, rectangular tubes and oval tubes. Whether it is small batch or large-scale production, it can easily cope with it and improve your work efficiency and production flexibility

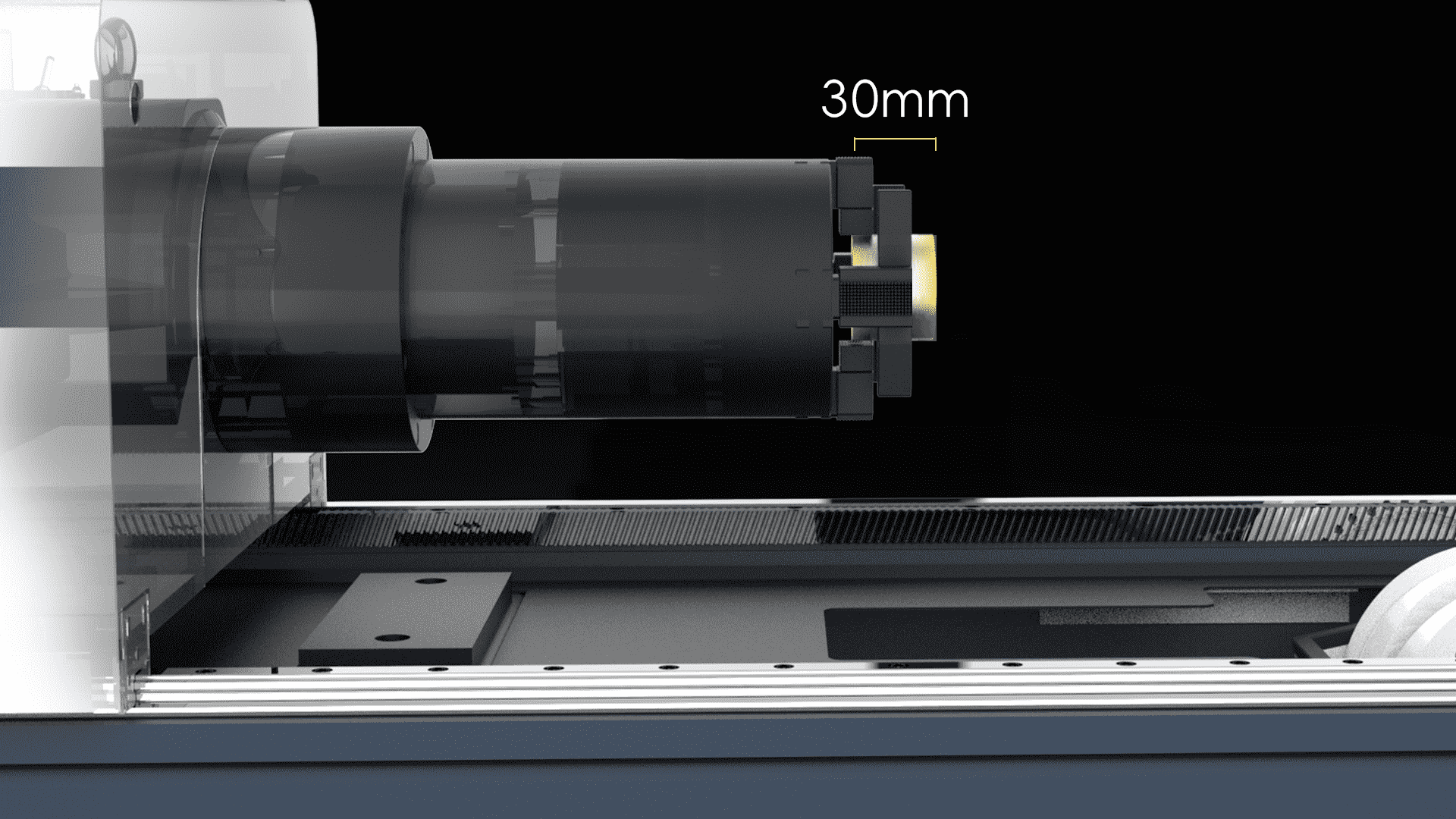

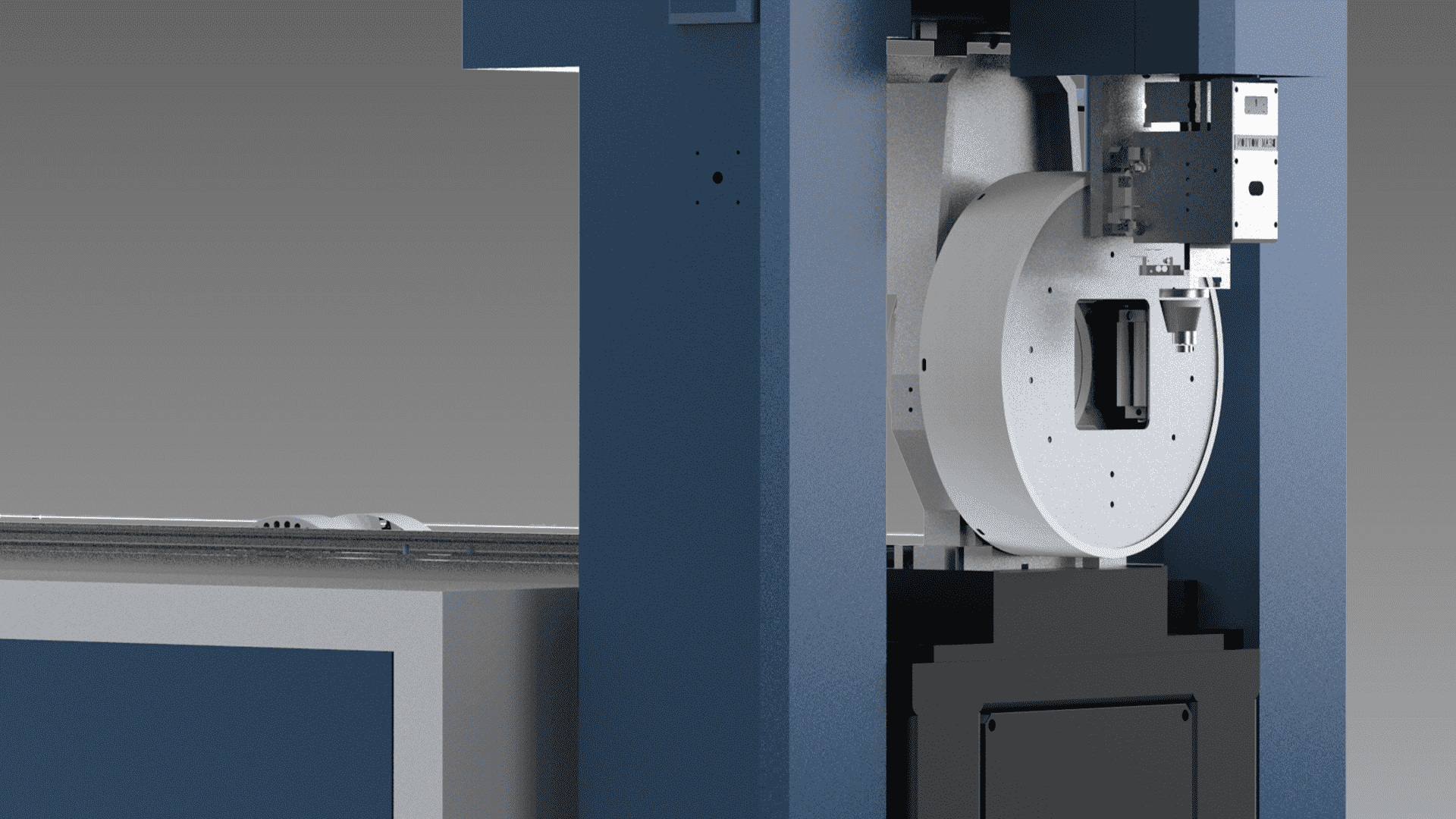

The standard pneumatic chuck specially designed for small tubes provides excellent clamping strength and precise speed control to significantly improve processing efficiency and cutting accuracy. Features include fast response speed, suitable for high-speed operation environments, ensuring more accurate process operations

It has efficient data exchange and coordination capabilities. The system is equipped with an automatic focusing cutting head to improve cutting quality and efficiency. It has multiple cutting modes and parameter settings, a friendly human-machine interface, an intuitive operation interface and real-time monitoring. It is easy to use and has powerful performance.

TQ Series can be packed in 1 40HQ standard container.We can achieve fast delivery and usually charge significantly reduced freight. The whole machine is shipped, no need to assemble other parts again, only the main components laser, chiller, control system need to be connected.

|

Machine Model |

TQ Series |

|

Working Area |

Round tube: φ15-80mm Square tube: □15-60mm 6m length |

|

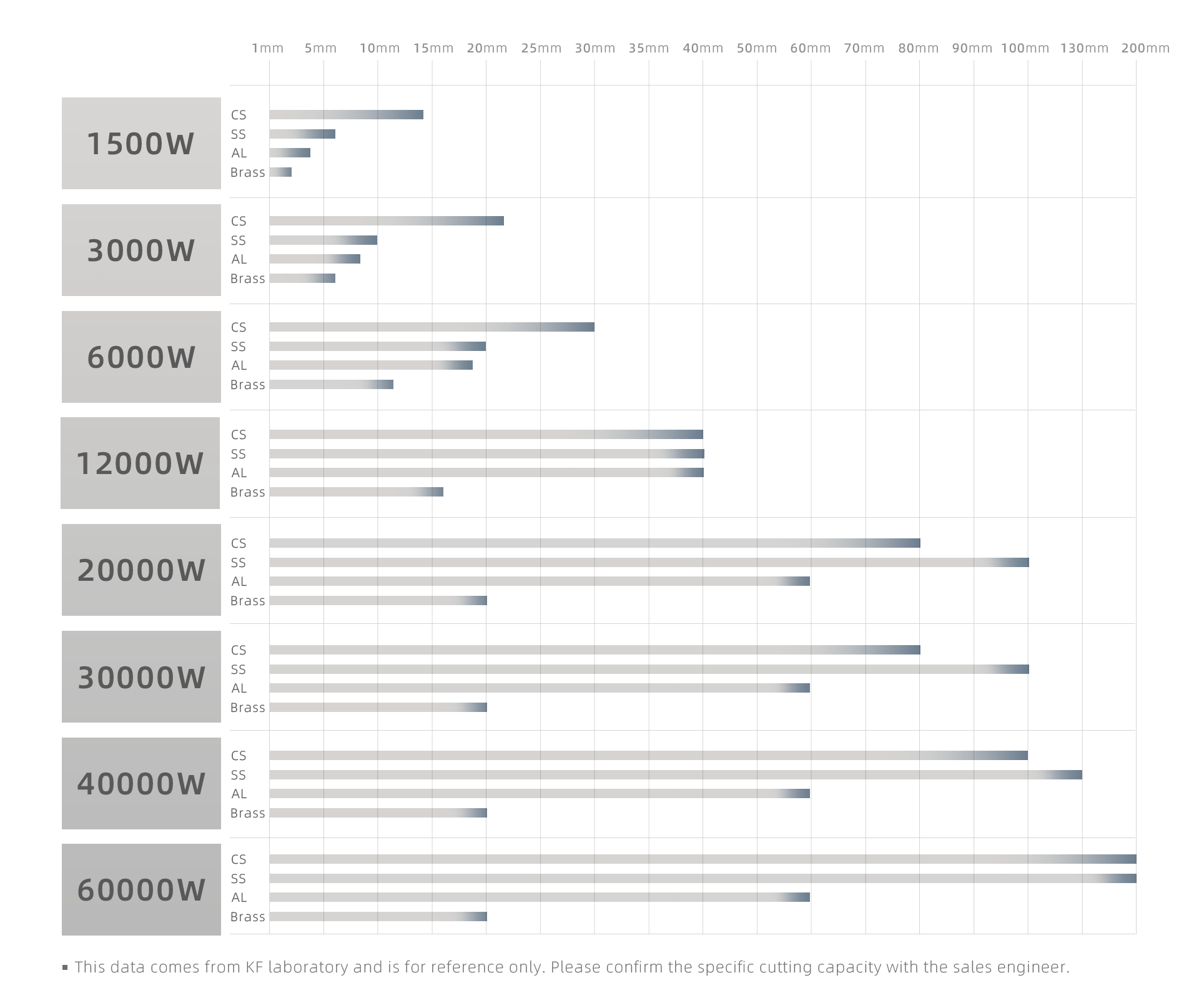

Laser Power |

1.5KW-3KW |

|

Dimension |

9600*3050*2200mmm |

|

Weight |

3000KG |

|

Loading configuration |

Standard configuration: Automatic loading |

|

Maximum Idle Running Speed(m/min) |

100m/min-120m/min |

|

Maximum idle acceleration(G) |

1.5G |

|

X/Y axis positioning accuracy/mm |

±0.05mm |

|

Repeat positioning accuracy/mm |

±0.03mm |

|

Cutting accuracy/mm |

≤0.1mm |

|

Working Voltage |

380V,three-phase /50Hz-60Hz |

|

Supported image formats |

LXD/.DXF/.PLT/.AI/.Gerber/.DWG |

A: In order to recommend you the most suitable machine model, just tell us below information

1)What is your material

2)The size of material

3)The thickness of material

4)Fiber laser cutter for metal

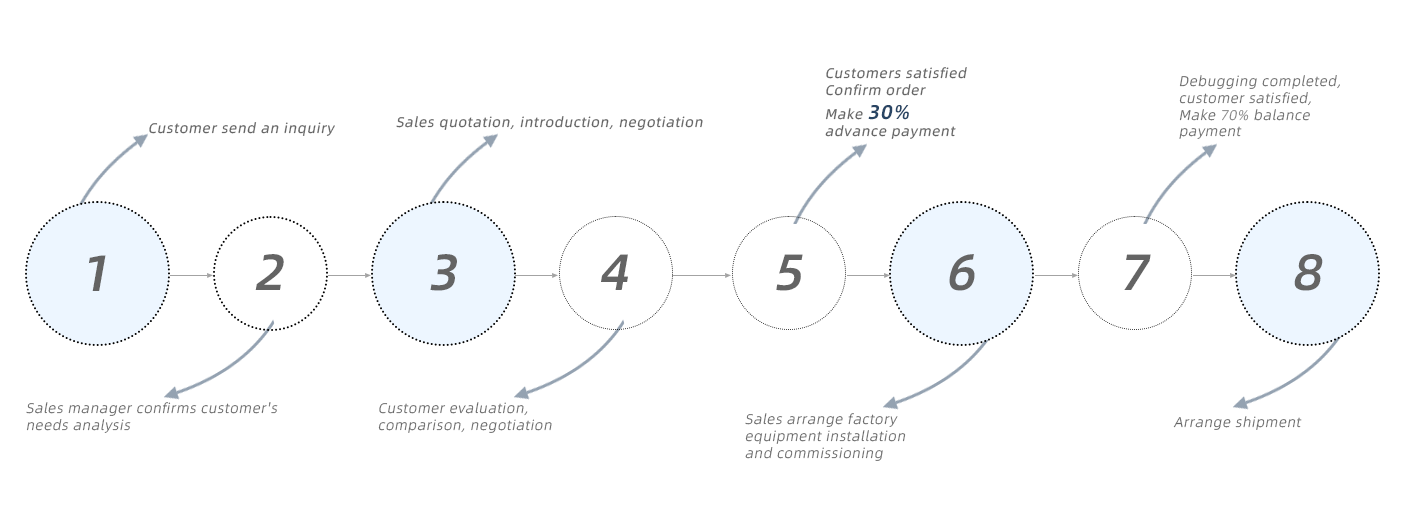

A:1)Alibaba trade assurance/TT/West Union/Payple/LC/Cash and so on.

2)We start making standardized machines after receiving 30% of the payment, inspect the machines after completion, and finally collect the 70% balance before shipping.

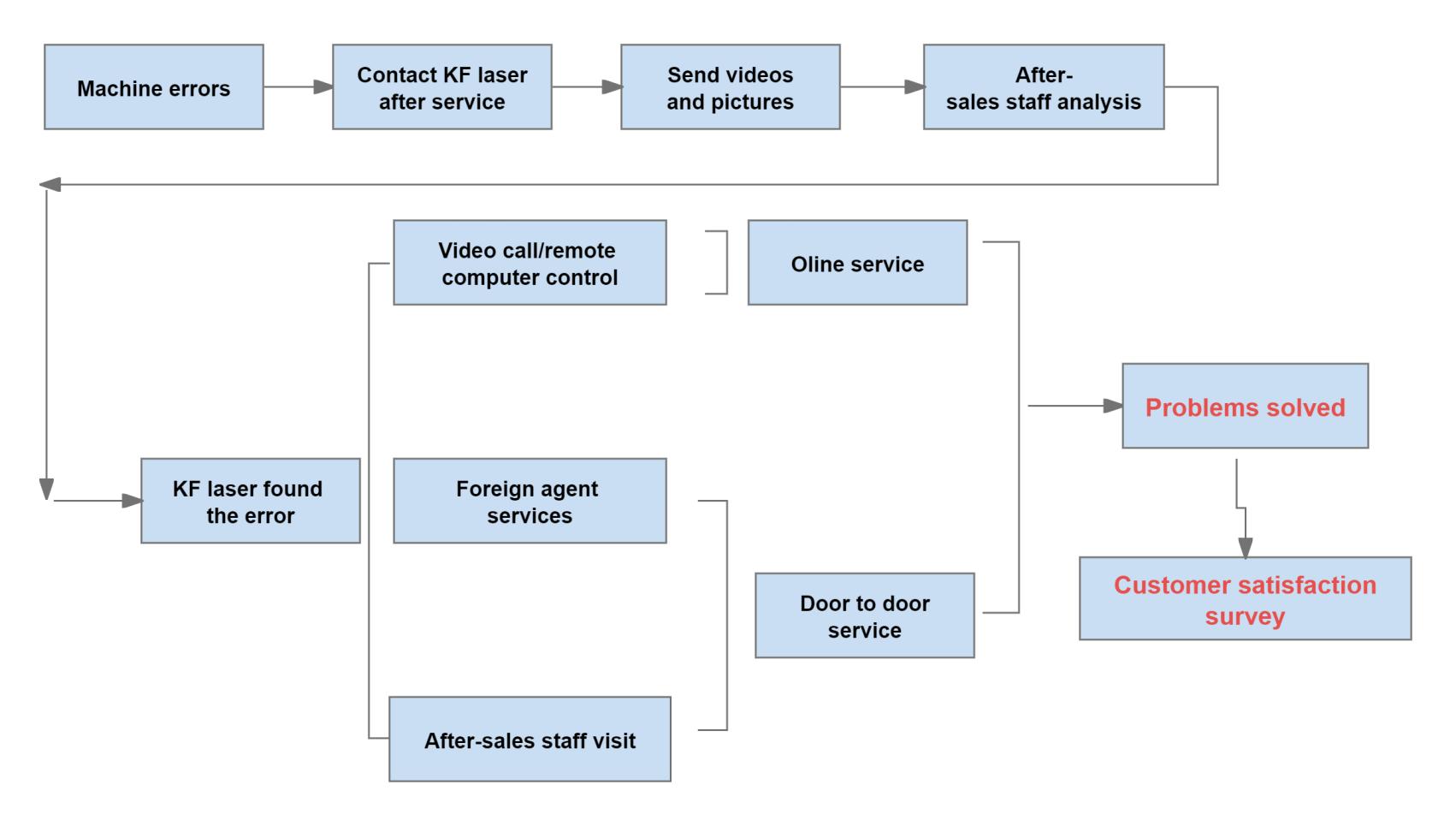

A:1)We provide free training in our factory

2)We provide free online after-sales service

3)We have complete installation instructions and video tutorials

4)Door-to-door service charges are based on region and aircraft model

5)Provide three-year warranty, except for consumable parts, direct replacement for non-human damage

1):Clean the optical lens: Clean the optical lens regularly to maintain the beam quality.

2):Check the gas supply: Make sure the gas supply system is normal to prevent the cutting quality from being affected.

3):Lubricate the moving parts: Lubricate the guide rails and lead screw regularly to ensure the smooth operation of the moving parts.

4):Replace the chiller’s purified water every month. If it’s below zero in winter, remember to add antifreeze.

A laser tube cutter is a cutting-edge technology used to cut tubes and pipes with high precision and efficiency. The tube laser cutter uses a focused laser beam to cut through the material, providing clean and accurate cuts. This technology has revolutionized the way manufacturers handle tube and pipe cutting, making it faster and more efficient than traditional methods. The pipe laser cutter can handle a variety of materials and shapes, making it a versatile tool in the manufacturing industry.(laser tube cutter)

Laser tube cutting involves using a laser beam to cut through tubular materials. The process starts with the laser beam being generated and directed through an optical path system. The beam is then focused on the surface of the tube, where it melts or vaporizes the material to create a cut. The process is controlled by computer numerical control (CNC) systems, ensuring high precision and repeatability.

Tube laser cutters can handle a variety of tube shapes, including round, rectangular, and square tubes, as well as complex profiles. They are widely used in industries such as automotive, aerospace, construction, and furniture manufacturing due to their ability to produce complex shapes and designs with high precision.

Laser tube cutters are used in numerous industries, including:

There are several types of laser cutters used in the industry:

When selecting a tube laser cutter, several factors should be taken into account:

There are several techniques used in laser cutting, each suitable for different materials and requirements:

To achieve the best results with a pipe laser cutter, consider the following optimization tips:

While laser cutting is generally safe, it involves high-power lasers and potential hazards. Follow these safety guidelines to ensure a safe working environment:

The cost of a laser tube cutter depends on several factors, including laser type, power, work table size, and material properties. Understanding these factors can help you choose a machine that fits your budget and cutting needs.

The field of laser tube cutting is continually evolving, with new technologies and advancements improving efficiency, precision, and versatility. Some emerging trends include:

Laser tube cutters offer numerous advantages, including high precision, speed, and versatility. By understanding the different types of lasers, their applications, and the factors to consider when choosing a machine, you can make an informed decision to optimize your cutting processes. Proper optimization and maintenance will ensure consistent high-quality results, making laser cutting an indispensable tool in modern manufacturing.