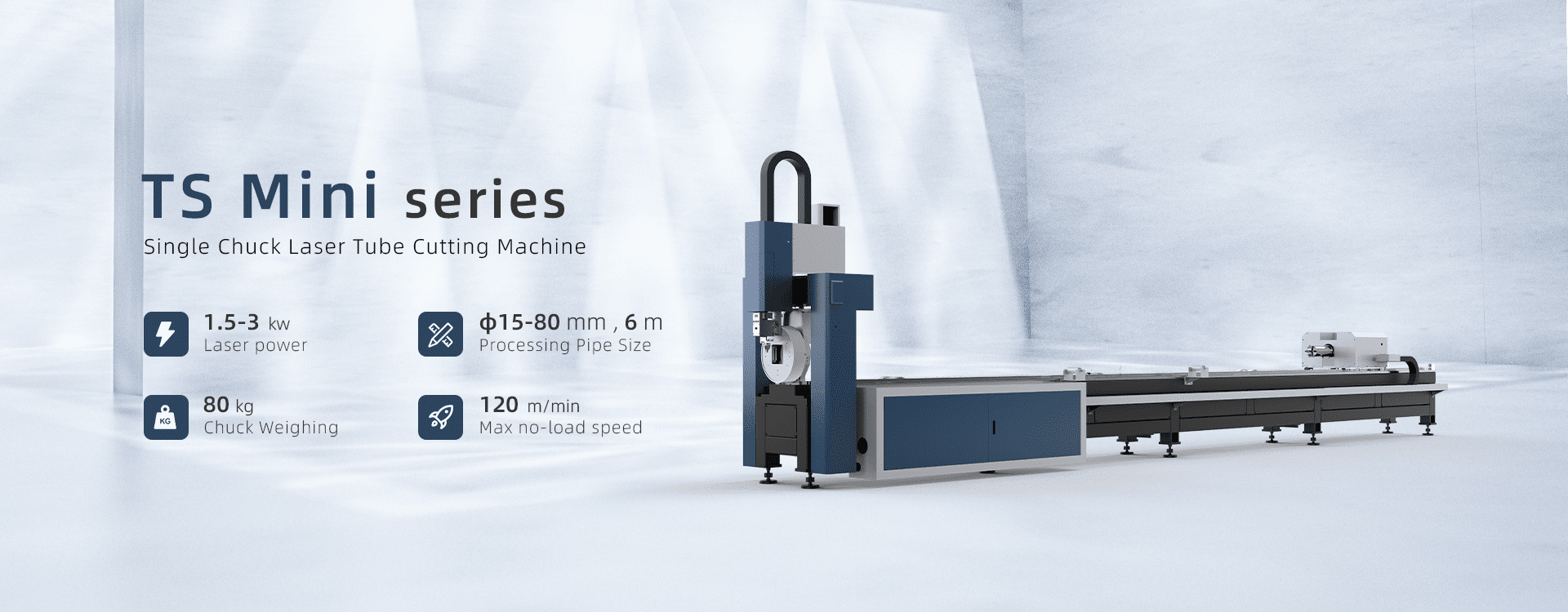

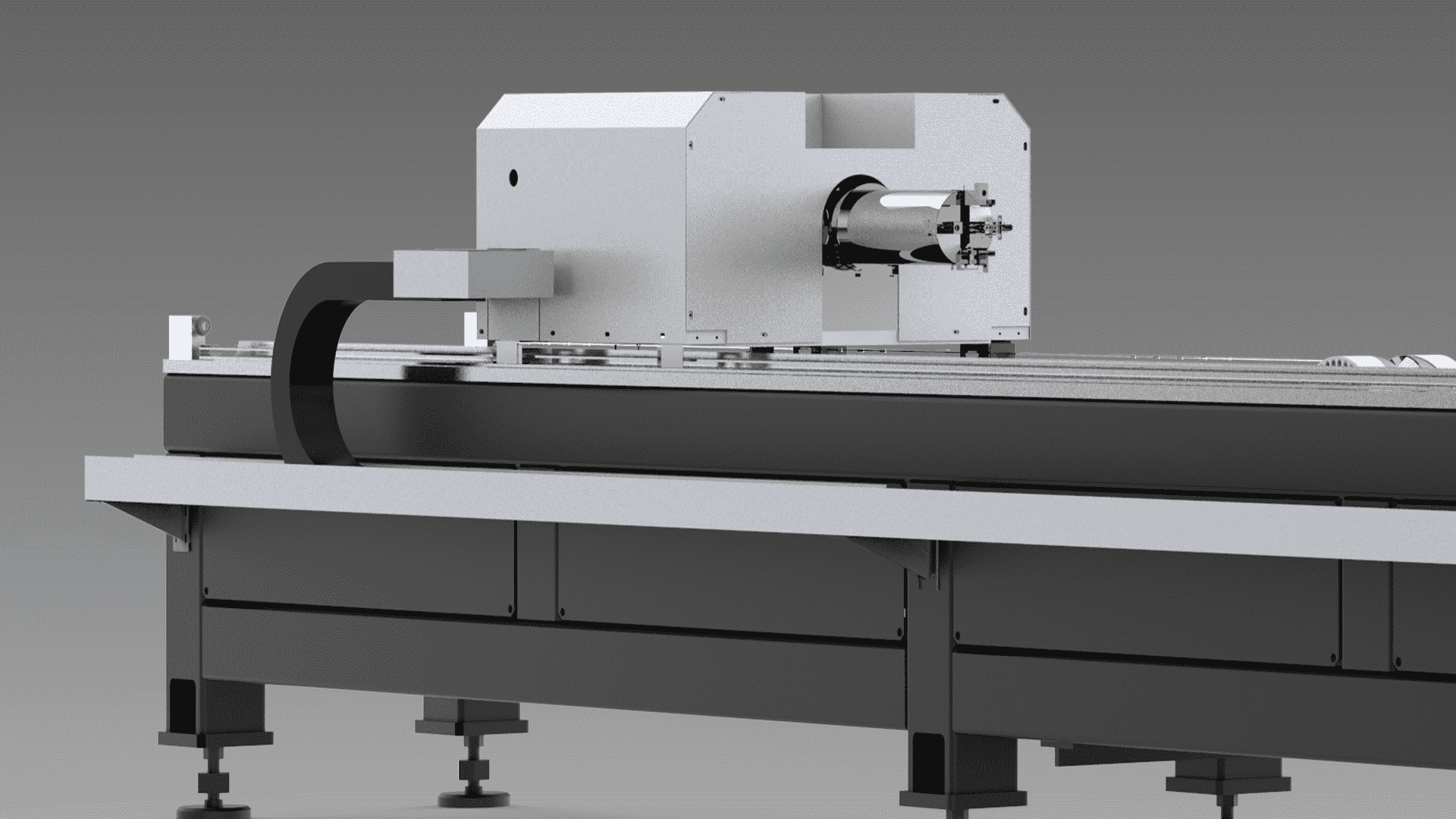

A série TS Mini é uma máquina de corte de tubo de mandril duplo mais econômica e simples, com função de corte de alta velocidade para vários tubos.

Equipado com corte eficiente, funções de perfuração e ranhura, pode atender rapidamente às necessidades de processamento de vários perfis, como tubos redondos, tubos quadrados, tubos retangulares e tubos ovais. Quer se trate de pequenos lotes ou produção em grande escala, ele pode lidar facilmente com isso e melhorar sua eficiência de trabalho e flexibilidade de produção

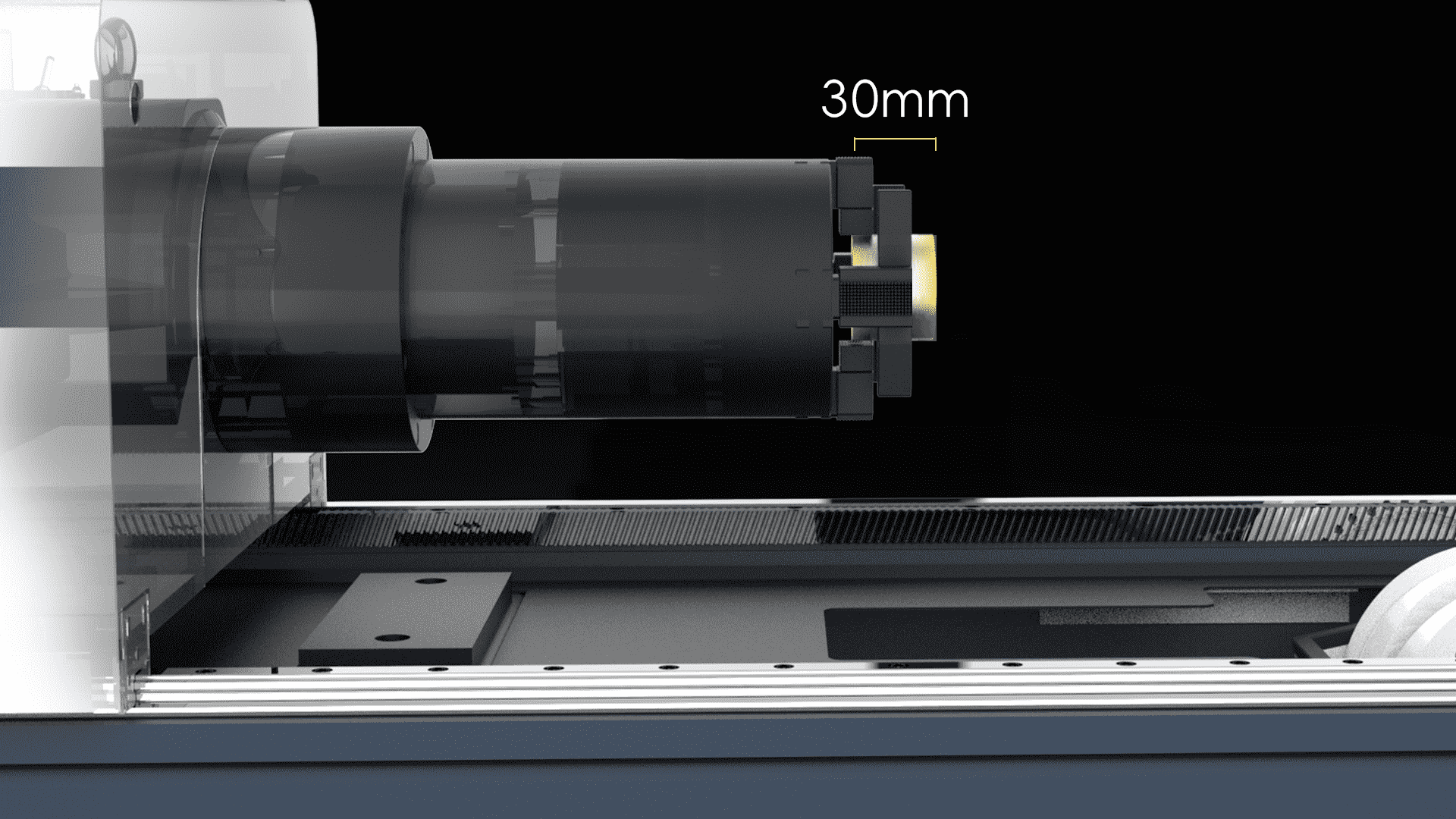

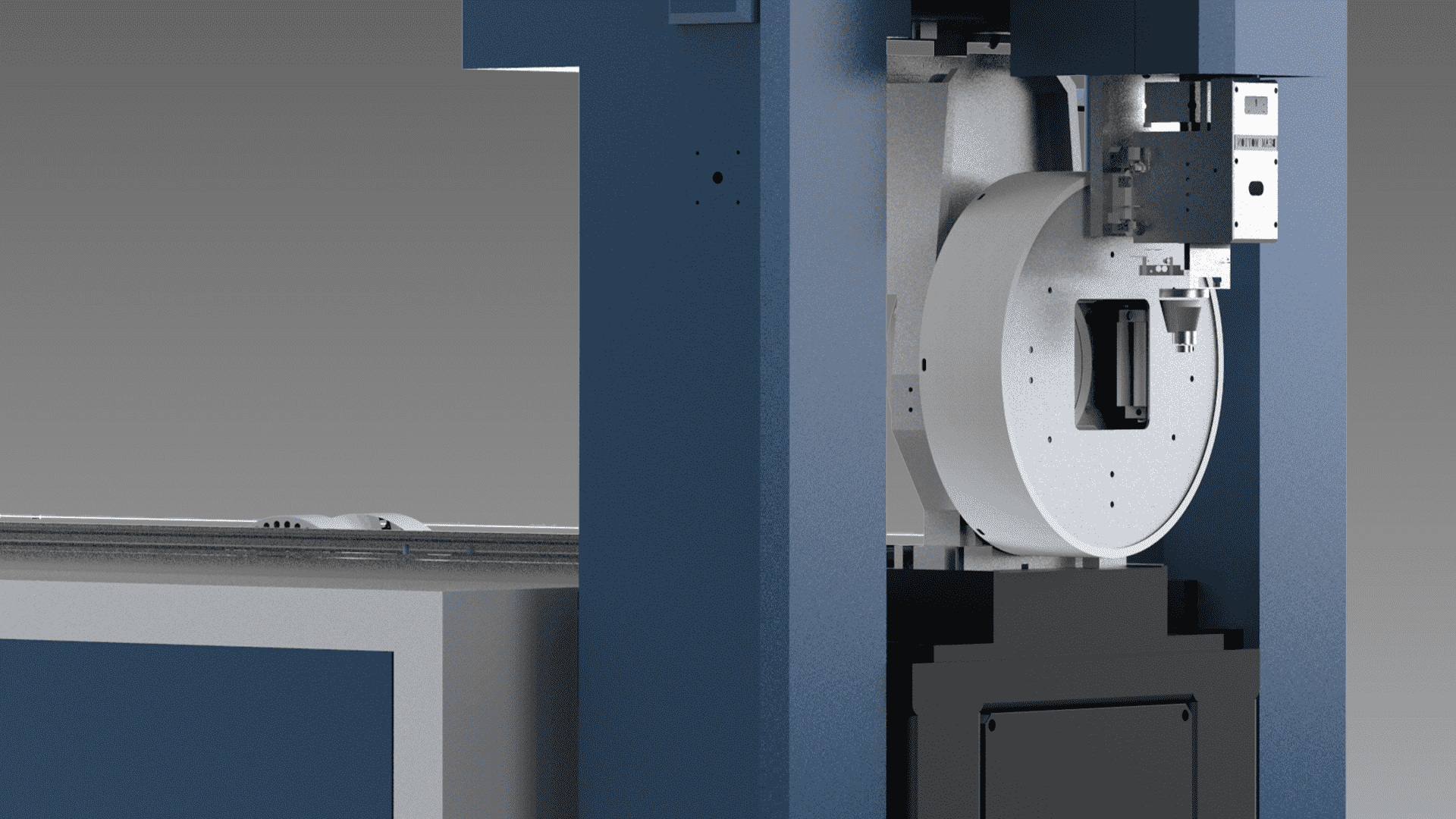

O mandril pneumático padrão especialmente projetado para tubos pequenos oferece excelente resistência de fixação e controle preciso de velocidade para melhorar significativamente a eficiência do processamento e a precisão do corte. Os recursos incluem velocidade de resposta rápida, adequado para ambientes de operação de alta velocidade, garantindo operações de processo mais precisas

Possui capacidade eficiente de troca de dados e coordenação. O sistema está equipado com uma cabeça de corte com foco automático para melhorar a qualidade e eficiência do corte. Possui vários modos de corte e configurações de parâmetros, uma interface homem-máquina amigável, uma interface de operação intuitiva e monitoramento em tempo real. É fácil de usar e tem desempenho poderoso.

A série TQ pode ser embalada em 1 40Contêiner padrão HQ. Podemos obter entrega rápida e geralmente cobrar frete significativamente reduzido. A máquina inteira é enviada, não há necessidade de montar outras peças novamente, apenas os principais componentes do laser, resfriador, sistema de controle precisa ser conectado.

|

Modelo de máquina |

Série TQ |

|

Área de Trabalho |

Tubo redondo: Tubo quadrado de φ15-80mm: □15-60mm 6m de comprimento |

|

Potência Laser |

1.5KW-3KW |

|

Dimensão |

9600*3050*2200mmm |

|

Peso |

3000KG |

|

Carregando configuração |

Configuração padrão: Carregamento automático |

|

Velocidade máxima de marcha lenta(m/min) |

100m/min-120m/min |

|

Aceleração máxima em marcha lenta(G) |

1.5G |

|

Precisão de posicionamento do eixo X/Y/mm |

±0,05 mm |

|

Precisão de posicionamento repetido/mm |

±0,03mm |

|

Precisão de corte/mm |

≤0,1 mm |

|

Tensão de trabalho |

380V,trifásico /50Hz-60Hz |

|

Formatos de imagem suportados |

LXD/.DXF/.PLT/.AI/.Gerber/.DWG |

UM: Para lhe recomendar o modelo de máquina mais adequado, basta nos dizer as informações abaixo

1)Qual é o seu material

2)O tamanho do material

3)A espessura do material

4)Cortador a laser de fibra para metal

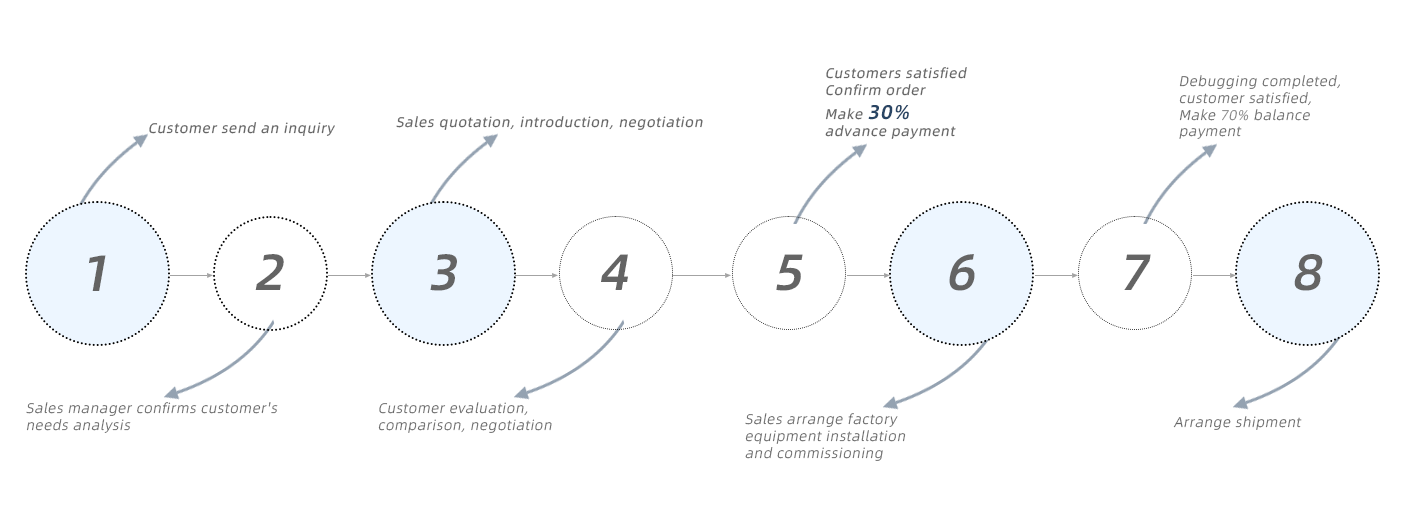

UM:1)Garantia comercial Alibaba/TT/West Union/Payple/LC/Cash e assim por diante.

2)Começamos a fabricar máquinas padronizadas após recebermos 30% do pagamento, inspecionar as máquinas após a conclusão, e finalmente coletar o 70% saldo antes do envio.

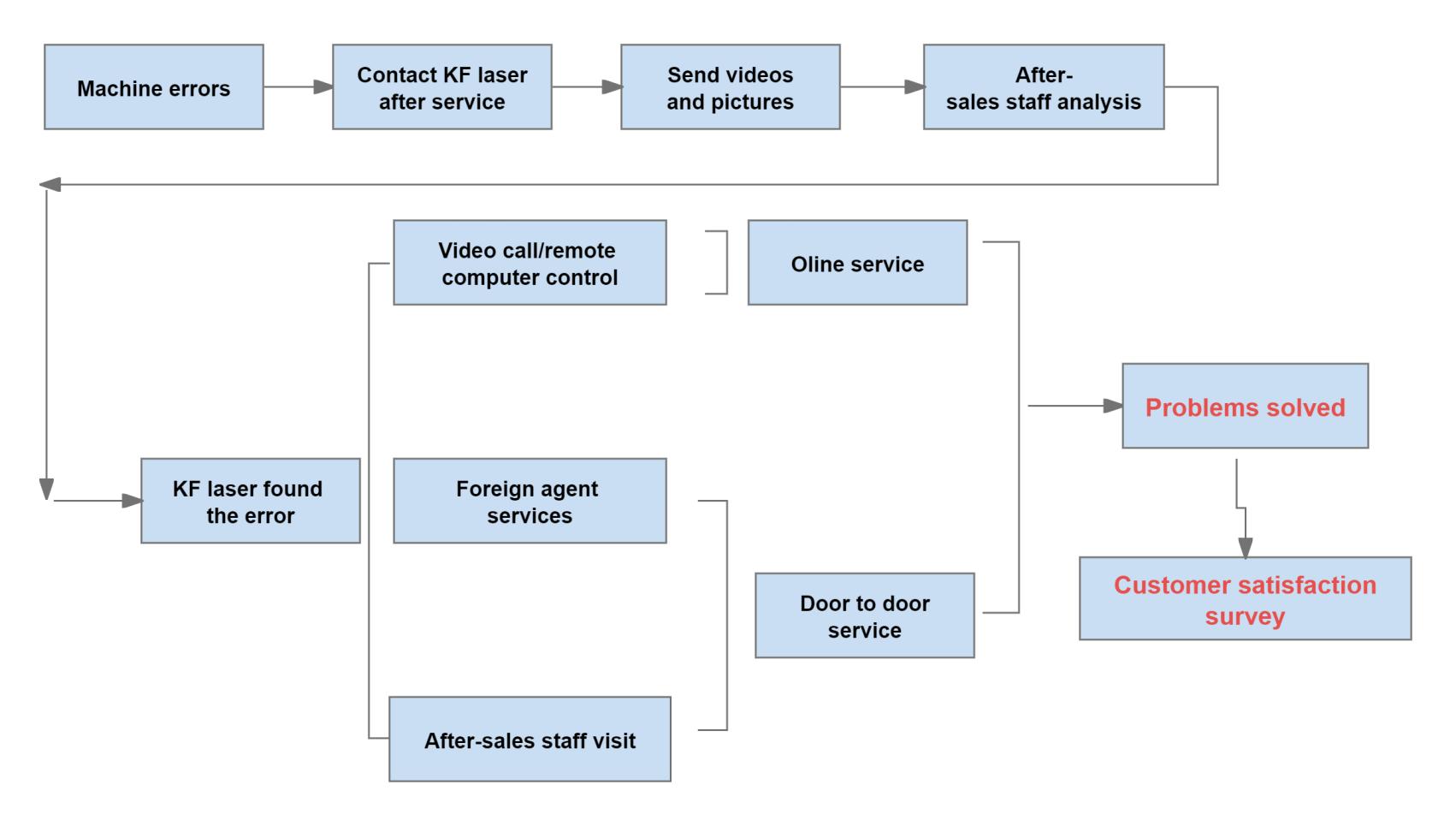

UM:1)Oferecemos treinamento gratuito em nossa fábrica

2)Oferecemos serviço pós-venda on-line gratuito

3)Temos instruções completas de instalação e tutoriais em vídeo

4)As taxas de serviço porta a porta são baseadas na região e no modelo da aeronave

5)Fornece garantia de três anos, exceto peças consumíveis, substituição direta por danos não humanos

1):Limpe a lente óptica: Limpe a lente óptica regularmente para manter a qualidade do feixe.

2):Verifique o fornecimento de gás: Certifique-se de que o sistema de fornecimento de gás esteja normal para evitar que a qualidade do corte seja afetada.

3):Lubrifique as peças móveis: Lubrifique os trilhos-guia e o parafuso de avanço regularmente para garantir o bom funcionamento das peças móveis.

4):Substitua a água purificada do chiller todos os meses. Se estiver abaixo de zero no inverno, lembre-se de adicionar anticongelante.

Um cortador de tubos a laser é uma tecnologia de ponta usada para cortar tubos e tubulações com alta precisão e eficiência. O cortador a laser de tubo usa um feixe de laser focado para cortar o material, proporcionando cortes limpos e precisos. Esta tecnologia revolucionou a maneira como os fabricantes lidam com o corte de tubos e tubulações, tornando-o mais rápido e eficiente do que os métodos tradicionais. O cortador a laser de tubos pode lidar com uma variedade de materiais e formas, tornando-o uma ferramenta versátil na indústria de manufatura.(cortador de tubo a laser)

O corte de tubos a laser envolve o uso de um feixe de laser para cortar materiais tubulares. O processo começa com o feixe de laser sendo gerado e direcionado através de um sistema de caminho óptico. O feixe é então focado na superfície do tubo, onde derrete ou vaporiza o material para criar um corte. O processo é controlado por controle numérico de computador (CNC) sistemas, garantindo alta precisão e repetibilidade.

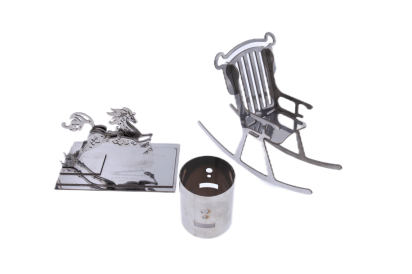

Os cortadores a laser de tubos podem lidar com uma variedade de formatos de tubos, incluindo redondo, retangular, e tubos quadrados, bem como perfis complexos. Eles são amplamente utilizados em indústrias como automotiva, aeroespacial, construção, e fabricação de móveis devido à sua capacidade de produzir formas e designs complexos com alta precisão.

Os cortadores de tubos a laser são usados em inúmeras indústrias, Incluindo:

Existem vários tipos de cortadores a laser usados na indústria:

Ao selecionar um cortador a laser de tubo, vários fatores devem ser levados em conta:

Existem diversas técnicas utilizadas no corte a laser, cada um adequado para diferentes materiais e requisitos:

Para obter os melhores resultados com um cortador a laser de tubos, considere as seguintes dicas de otimização:

Embora o corte a laser seja geralmente seguro, envolve lasers de alta potência e perigos potenciais. Siga estas diretrizes de segurança para garantir um ambiente de trabalho seguro:

O custo de um cortador de tubo a laser depende de vários fatores, incluindo tipo de laser, poder, tamanho da mesa de trabalho, e propriedades dos materiais. Compreender esses fatores pode ajudá-lo a escolher uma máquina que atenda ao seu orçamento e necessidades de corte.

O campo do corte de tubos a laser está em constante evolução, com novas tecnologias e avanços melhorando a eficiência, precisão, e versatilidade. Algumas tendências emergentes incluem:

Os cortadores de tubos a laser oferecem inúmeras vantagens, incluindo alta precisão, velocidade, e versatilidade. Ao entender os diferentes tipos de lasers, suas aplicações, e os fatores a serem considerados ao escolher uma máquina, você pode tomar uma decisão informada para otimizar seus processos de corte. A otimização e manutenção adequadas garantirão resultados consistentes de alta qualidade, tornando o corte a laser uma ferramenta indispensável na fabricação moderna.