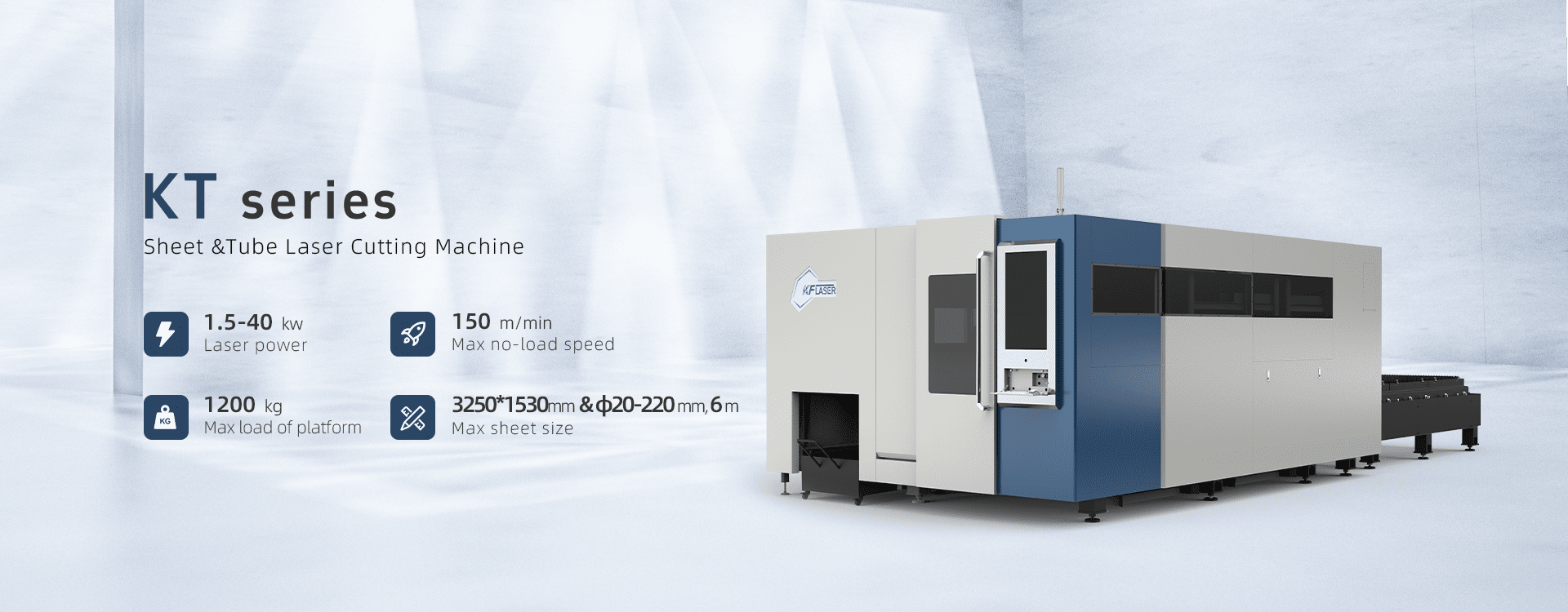

The KT series is a high-eficiency processing equipment that

integrates the plate and tube cutting functions.

It has an enclosed appearance and can achieve zero

pollution cutting with the purifier.

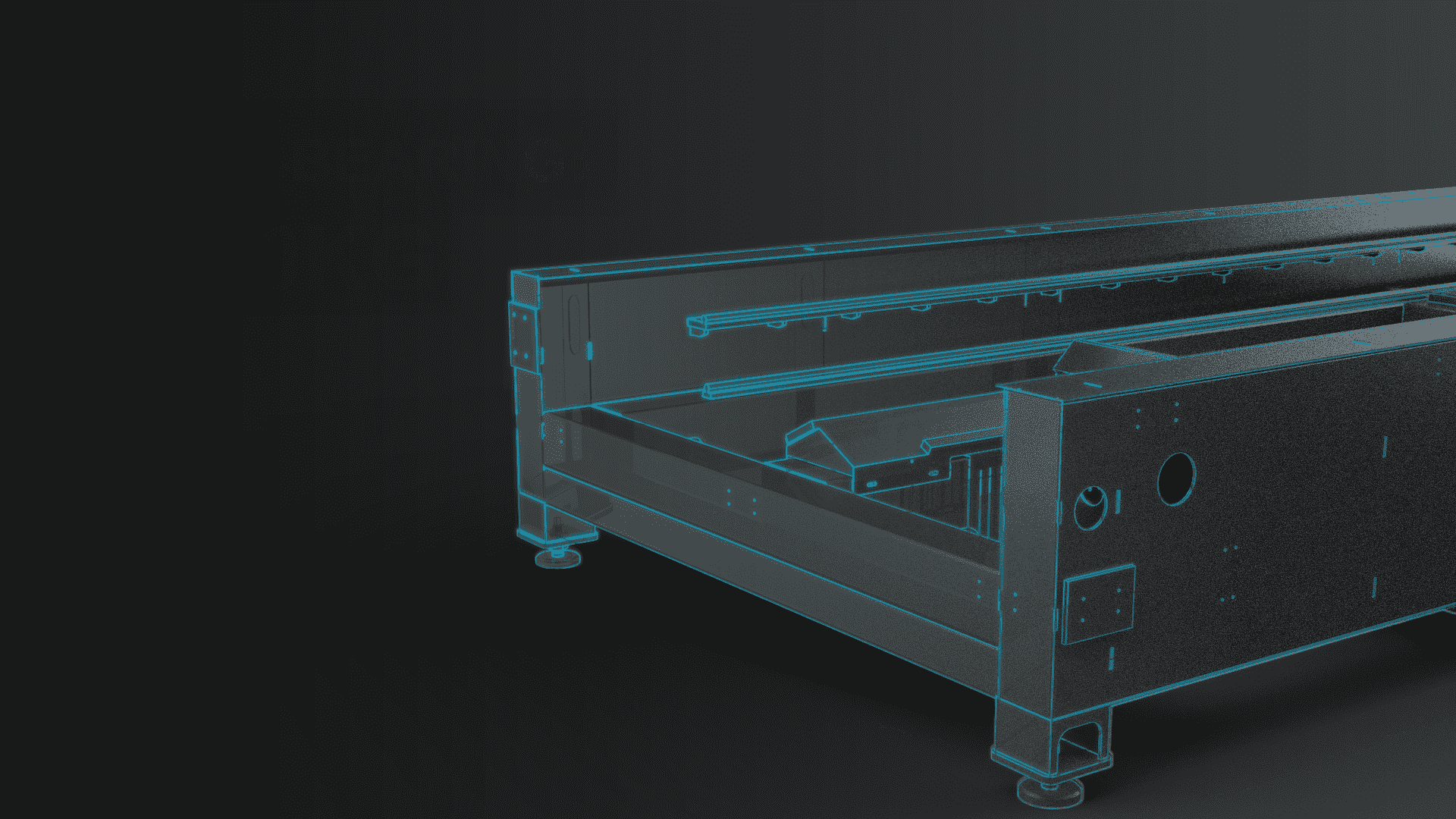

A cama O quadro é soldado usando tubos quadrados grossos e reforçado internamente para melhorar a força estrutural e a resistência à tração., impedir a deformação, reduzir vibrações, e garantir uma excelente precisão de corte.

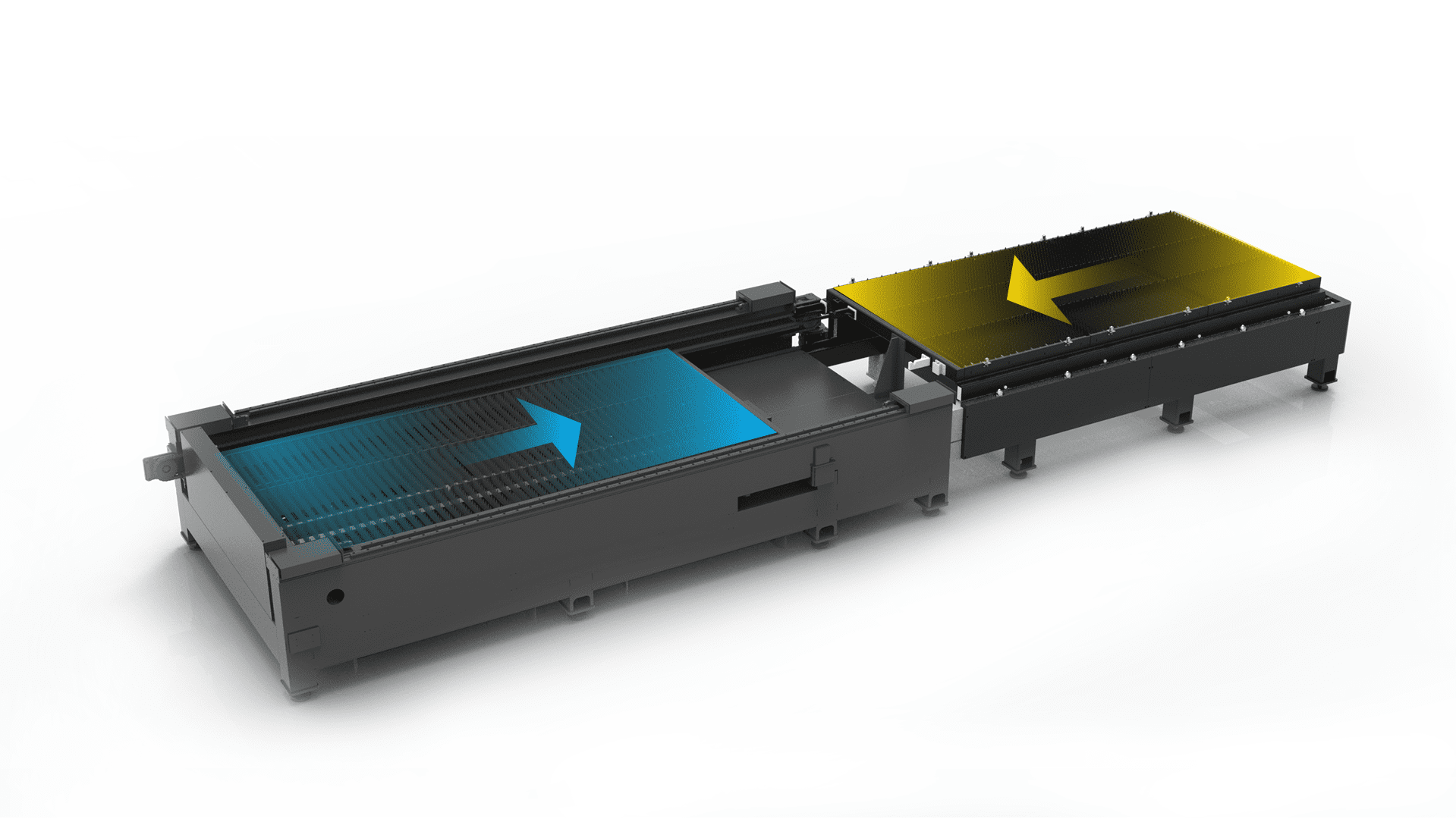

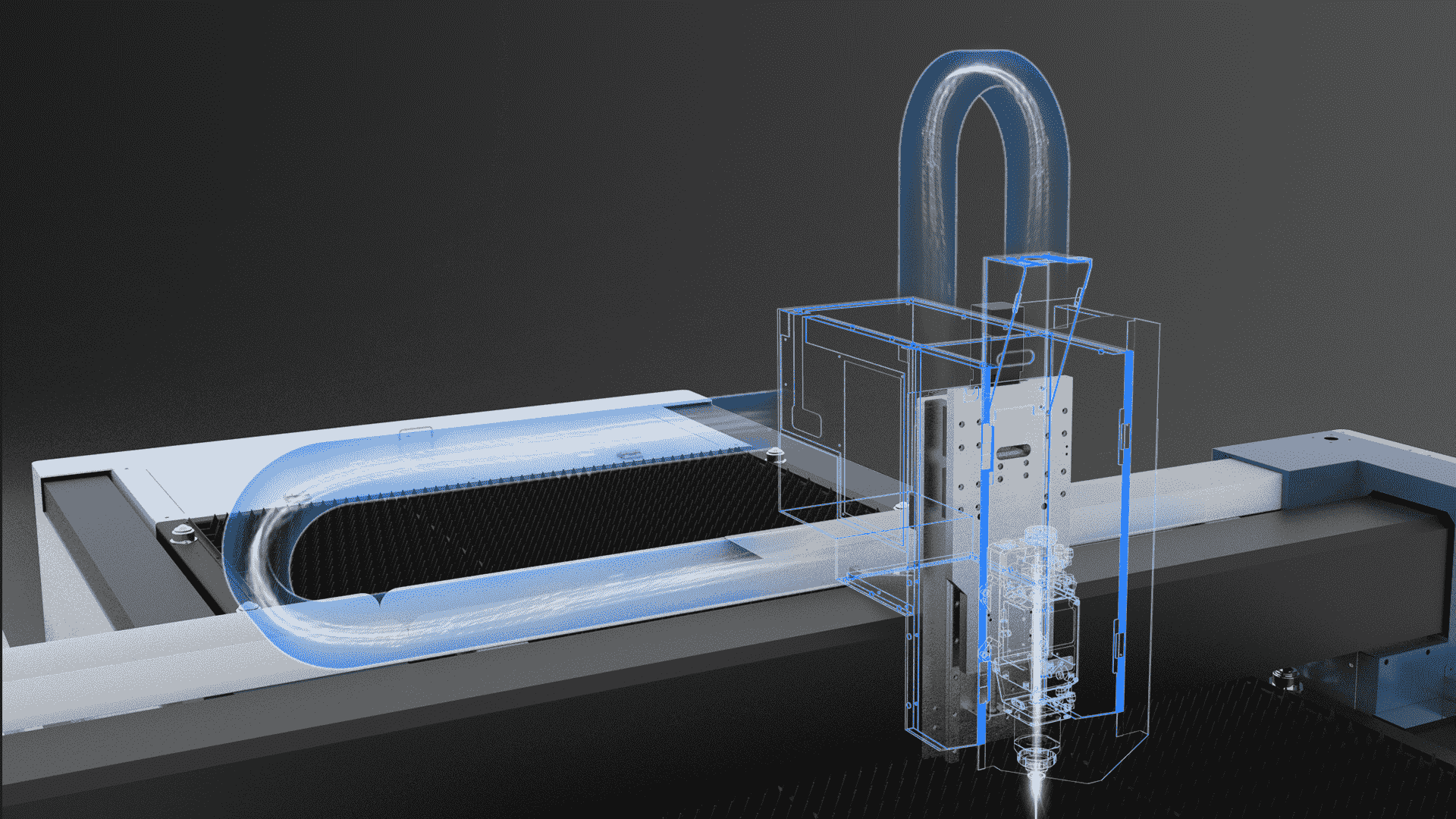

Se você atribuir grande importância à proteção ambiental, Esta máquina é uma escolha ideal para o seu negócio. Possui várias áreas automáticas de remoção de poeira, e a saída de ar muda automaticamente de acordo com a posição da cabeça do laser, com remoção precisa de poeira, que pode remover de maneira perfeita e eficientemente a poeira e a fumaça geradas durante o processo de corte, Atendendo às suas necessidades de produção ecológica.

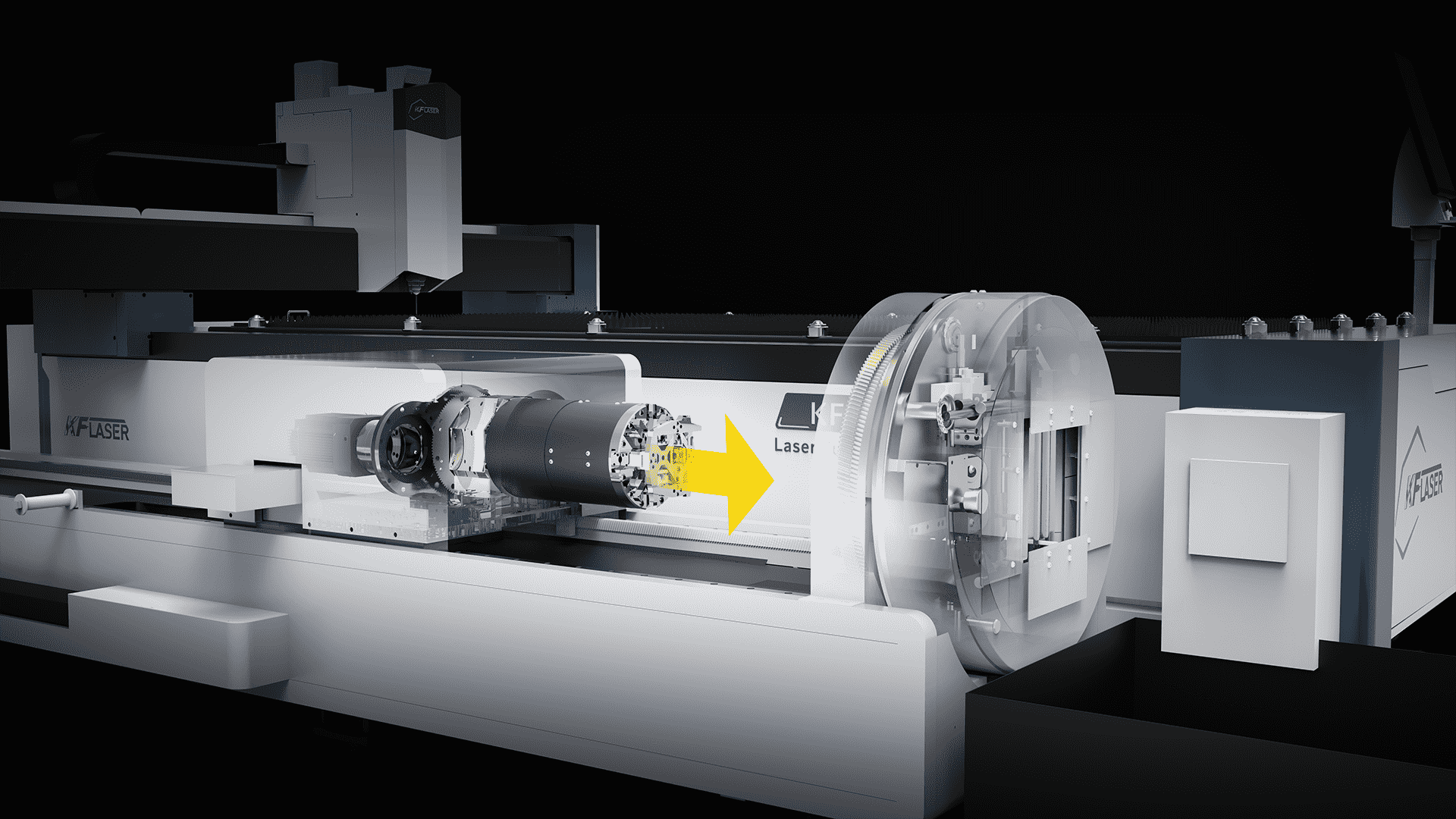

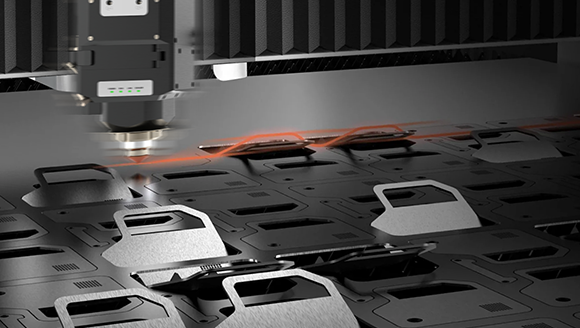

A cabeça de corte de alta potência da série Boci BLT6 pode obter corte preciso e estável, atender necessidades complexas e garantir resultados de corte de alta qualidade. Inclui um sistema eficiente de resfriamento de água para prolongar a vida útil e operação estável. Adota um design multifuncional com funções de aprimoramento de segurança, como prevenção inteligente de obstáculos, proteção contra colisão, alarme de subtensão, monitoramento de circuito fechado e perfuração inteligente, que pode ajustar automaticamente os parâmetros de corte para diferentes materiais.

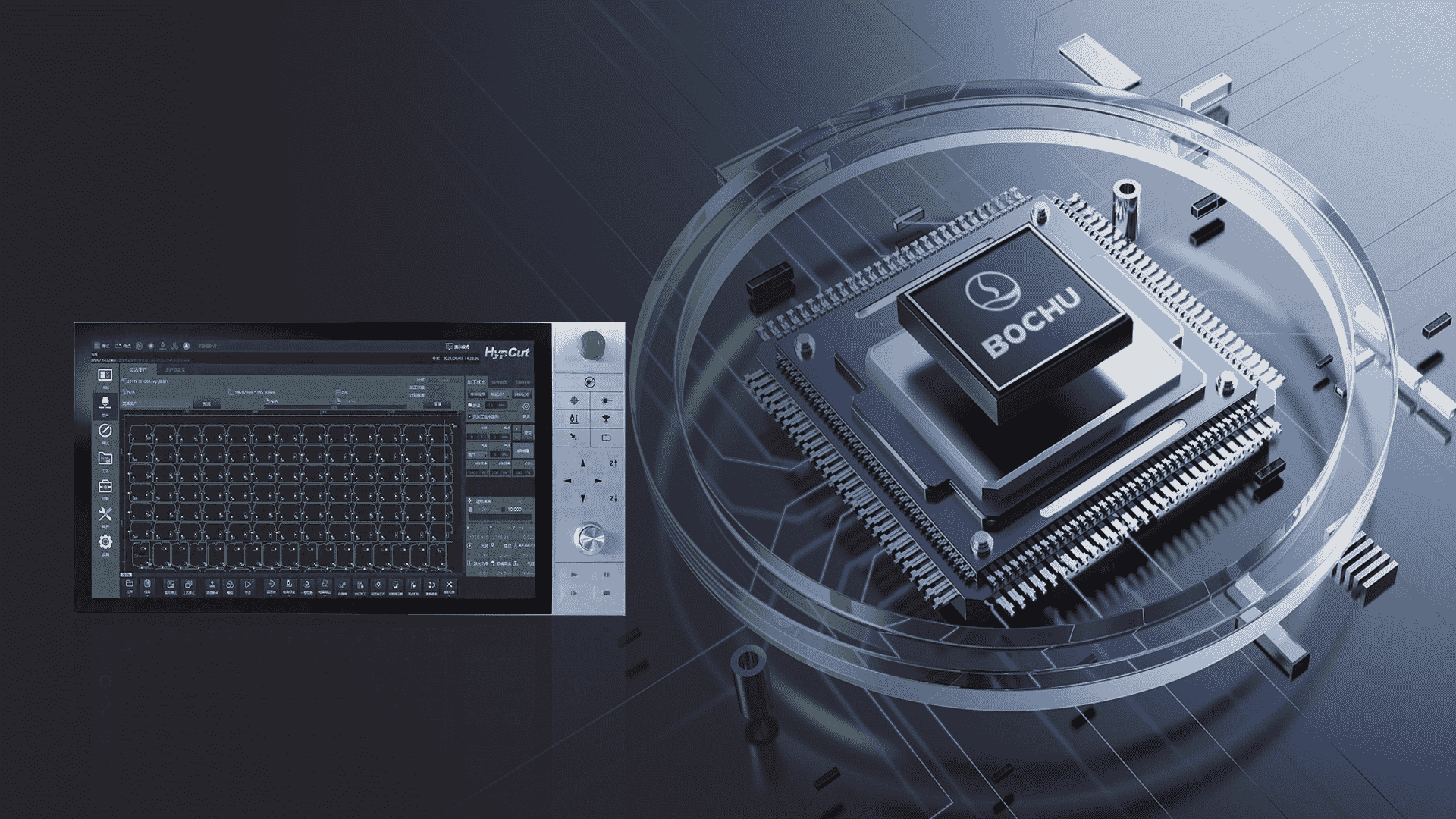

O sistema de controle avançado de Bochu, projetado especificamente para a máquina de corte a laser integrada do tubo de placa, possui suporte de corte multifuncional, Controle de movimento de alta precisão, Interface amigável e recursos de monitoramento e ajuste em tempo real. Sua função de automação e estabilidade garantem produção e eficiente de qualidade, E é adequado para todos os tipos de necessidades de processamento de metal, e é uma escolha ideal para melhorar a eficiência da produção e a precisão do corte.

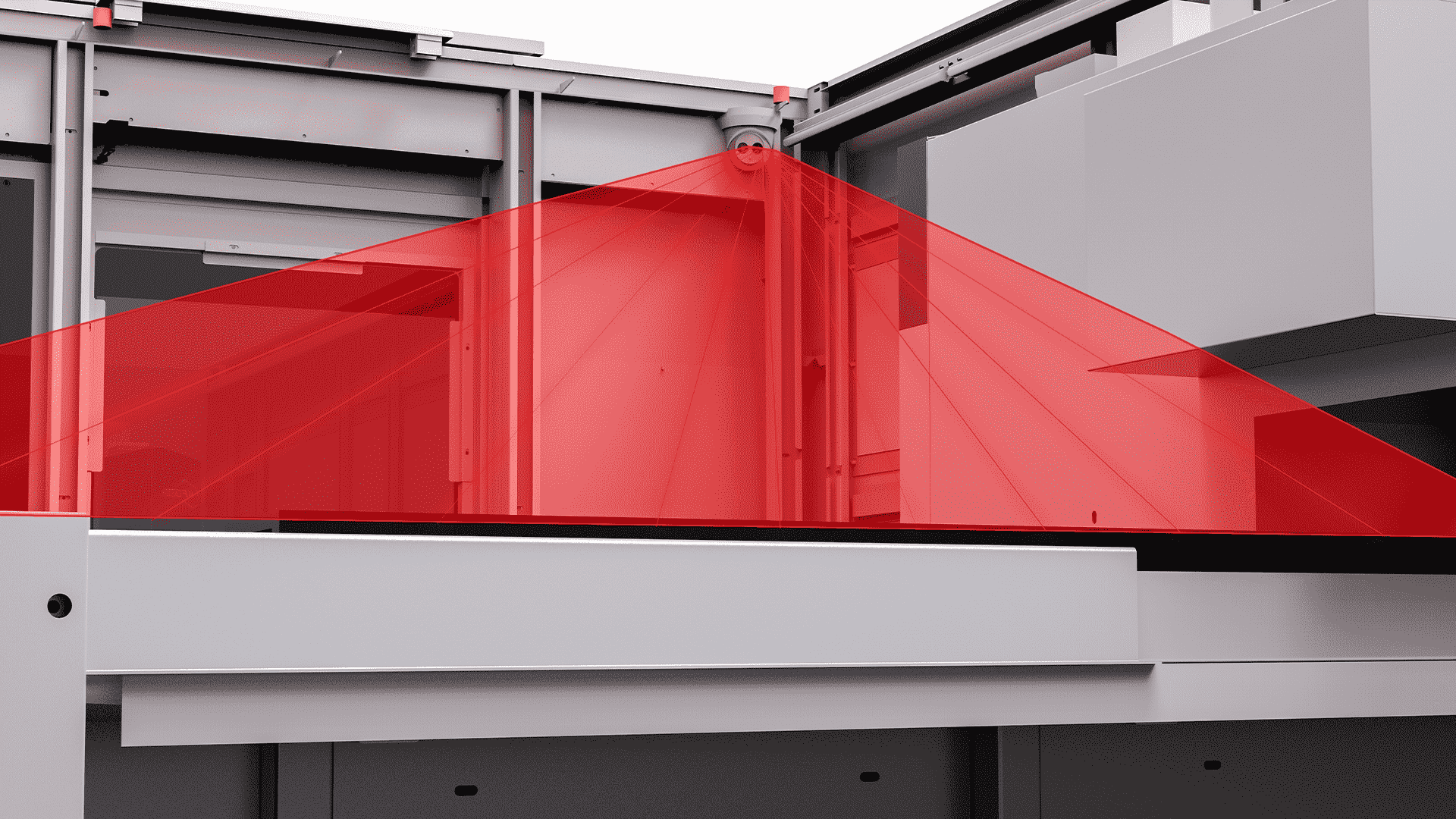

A máquina está equipada com câmeras internas, permitindo a observação em tempo real de suas operações através do painel de controle.

Modelo de máquina | Série KT3 | Série KT4 | Série KT6 |

Área de Trabalho | 3050*1530milímetros | 4100*2050milímetros | 6100*2550milímetros |

Potência Laser | 1-12KW | 1-20KW | 1-20KW |

Dimensão | 8800*4500*2180milímetros | 10800*5000*2180milímetros | 14800*5500*2180milímetros |

Tamanho do tubo de processamento | 6M φ20-220mm / □ 20-220 | ||

Peso | 8500KG | 15000KG | 19000KG |

Velocidade máxima de marcha lenta(m/min) | 100m/min-120m/min | ||

Aceleração máxima em marcha lenta(G) | 1.0G/1,2G/1,5G | ||

Precisão de posicionamento do eixo X/Y/mm | ±0,05 mm | ||

Precisão de posicionamento repetido/mm | ±0,03mm | ||

Precisão de corte/mm | ≤0,1 mm | ||

Tensão de trabalho | 380V,trifásico /50Hz-60Hz | ||

Formatos de imagem suportados | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

UM: Para lhe recomendar o modelo de máquina mais adequado, basta nos dizer as informações abaixo

1)Qual é o seu material

2)O tamanho do material

3)A espessura do material

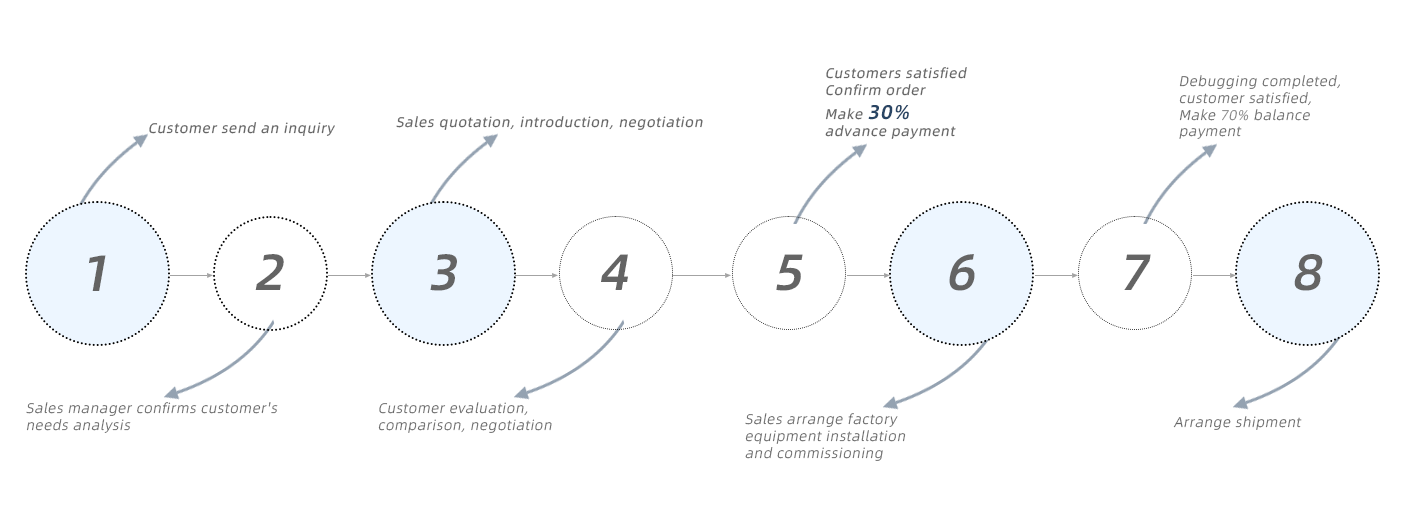

UM:1)Garantia comercial Alibaba/TT/West Union/Payple/LC/Cash e assim por diante.

2)Começamos a fabricar máquinas padronizadas após recebermos 30% do pagamento, inspecionar as máquinas após a conclusão, e finalmente coletar o 70% saldo antes do envio.

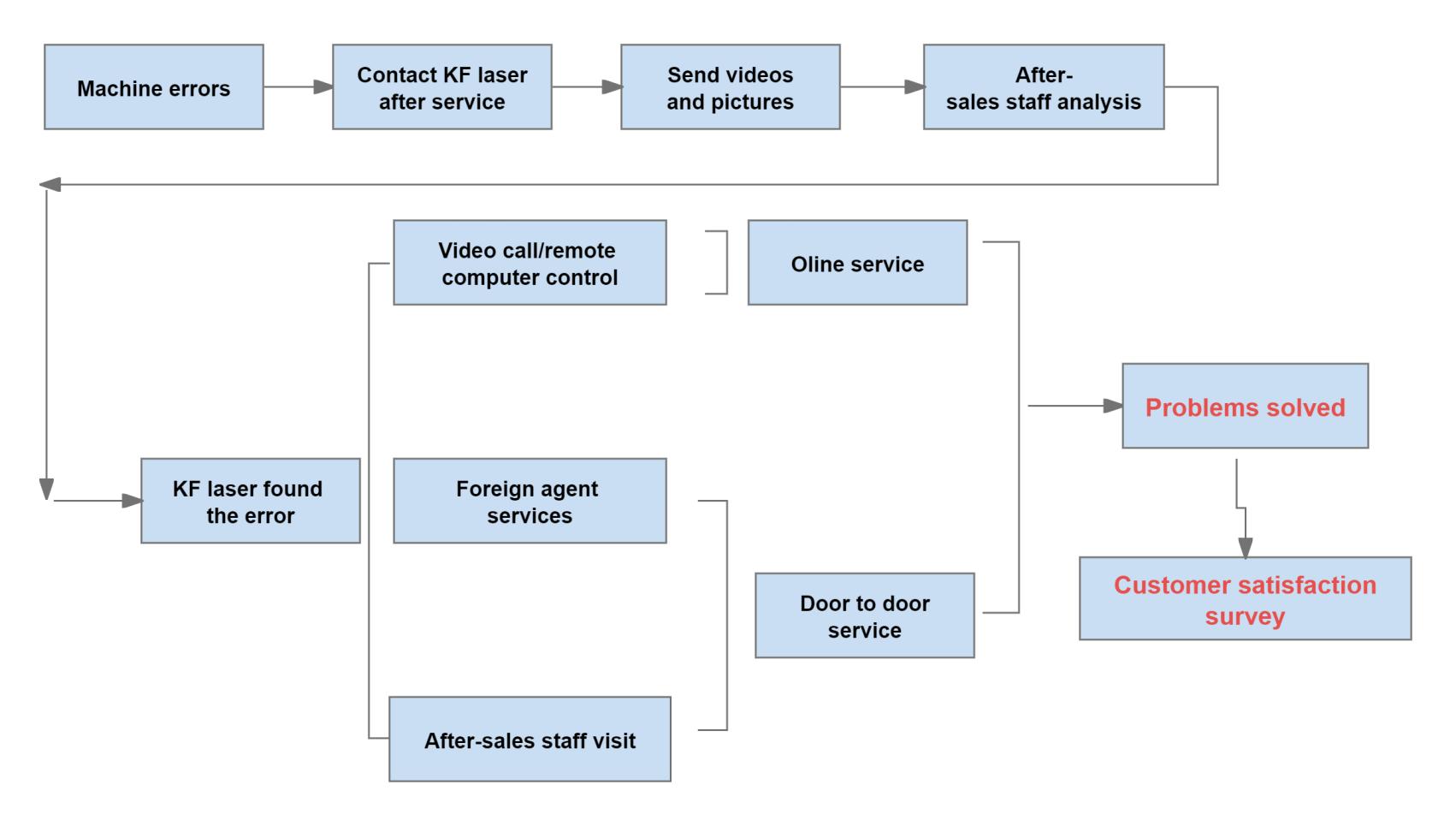

UM:1)Oferecemos treinamento gratuito em nossa fábrica

2)Oferecemos serviço pós-venda on-line gratuito

3)Temos instruções completas de instalação e tutoriais em vídeo

4)As taxas de serviço porta a porta são baseadas na região e no modelo da aeronave

5)Fornece garantia de três anos, exceto peças consumíveis, substituição direta por danos não humanos

Cortador de laser de metal para venda: Um guia abrangente

Quando se trata de comprar um cortador de laser de metal à venda, Existem muitos fatores a serem considerados para garantir que você obtenha a melhor máquina para suas necessidades. Se você é um pequeno negócio, uma grande operação industrial, ou um hobby, Compreendendo os tipos de cortadores a laser, seus custos, e seus benefícios podem ajudá -lo a tomar uma decisão informada.

As máquinas de corte a laser vêm em várias variedades baseadas no tipo de laser usado. Aqui estão os quatro principais tipos de lasers comumente encontrados em máquinas de corte a laser de metal:

- CO2 (Dióxido de carbono) Os lasers são o tipo mais tradicional e consistem em uma mistura de gás em um tubo de vidro. Quando a eletricidade flui através da mistura de gás, Ele excita as moléculas, produzindo um feixe de laser.

- Esses lasers são adequados para cortar metais e não metais, mas lutam com materiais reflexivos como latão e cobre.

- Garnet de alumínio Yttrium dopado com neodímio (Nd: Yag) Os lasers usam um cristal como meio a laser. Eles são menos comuns para o corte industrial, mas são usados em algumas aplicações médicas e cosméticas.

- Os lasers de fibra usam um cabo de fibra óptica para amplificar o feixe de laser. Eles são altamente eficientes e adequados para cortar uma ampla gama de metais, incluindo reflexivos como alumínio e cobre.

- Os lasers de diodo são compactos e eficientes em termos de energia, mas geralmente não são poderosos o suficiente para cortar metais espessos. Eles são usados principalmente para gravar e cortar materiais finos.

Ao selecionar um cortador de laser de metal para venda, considere os seguintes fatores:

- Verifique se o cortador de laser pode lidar com os tipos de materiais necessários para cortar. Os lasers de CO2 são versáteis, mas podem lutar com metais reflexivos, Enquanto os lasers de fibra são mais adequados para uma variedade de metais, incluindo aço inoxidável e alumínio.

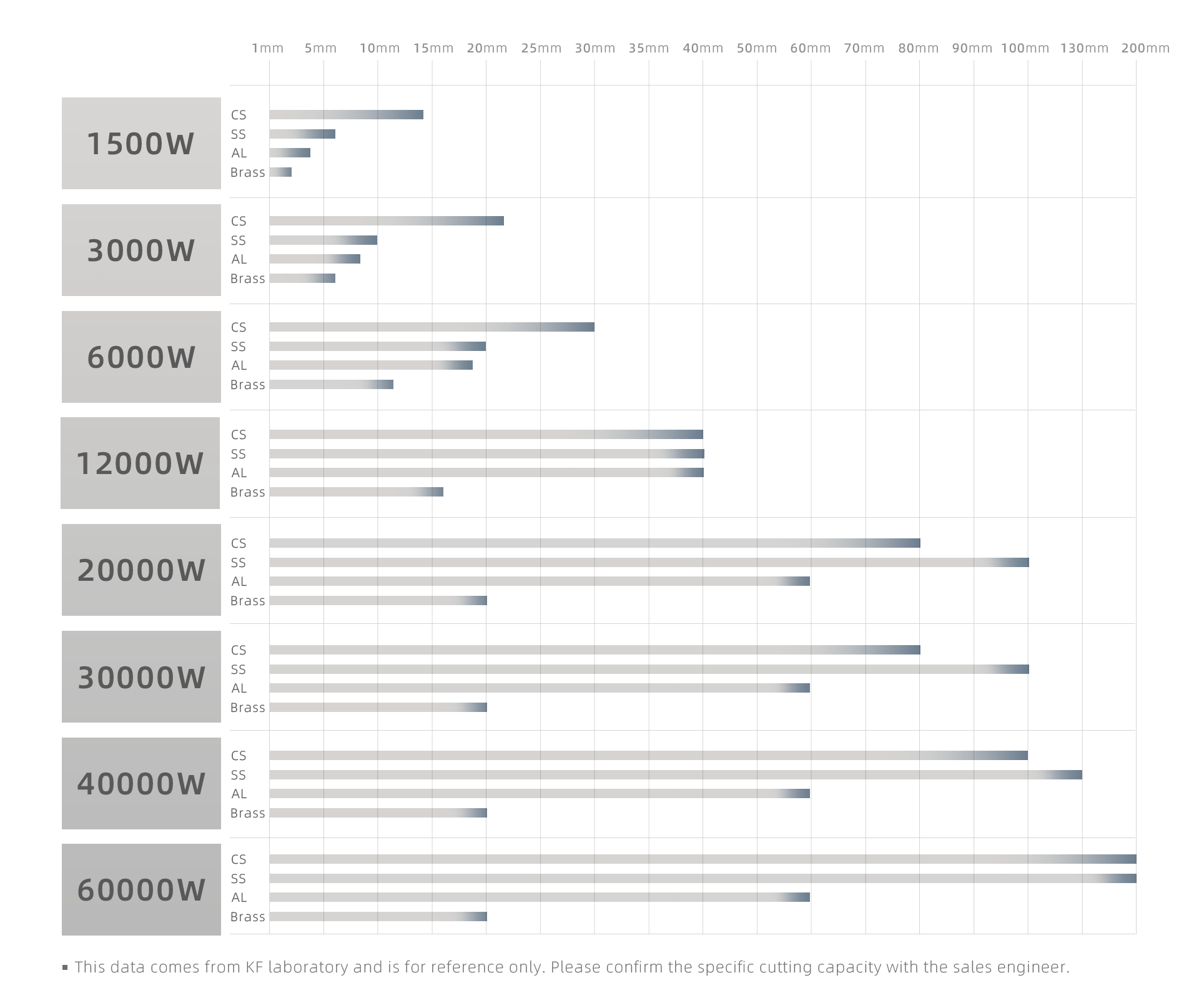

- O poder do laser afeta sua capacidade de cortar diferentes espessuras de metal. Os lasers de maior potência podem cortar materiais mais espessos, mas são mais caros.

- Considere o tamanho do cortador de laser e verifique se ele se encaixa no seu espaço de trabalho. Máquinas maiores podem lidar com folhas maiores de metal, mas exigem mais espaço.

- Avalie os custos de longo prazo, incluindo consumo de energia, manutenção, e potencial tempo de inatividade. Os lasers de fibra geralmente são mais eficientes em termos de energia do que os lasers de CO2.

O custo de um cortador de laser de metal à venda varia amplamente, dependendo do tipo, poder, e recursos. Aqui está uma quebra geral de preços:

- Os cortadores de laser de diodo começam em torno $500 mas normalmente não são adequados para cortar metais.

- Os cortadores a laser de metal de CO2 para iniciantes variam de $2,000 para $3,000.

- Os cortadores a laser de fibra de nível básico começam aproximadamente $15,000. Essas máquinas podem lutar com metais mais espessos, mas são adequados para a maioria das operações de tamanho médio a médio.

- Cortadores profissionais de laser de CO2 variam de $30,000 para $100,000.

- Cortadores de laser de fibra de ponta podem custar mais de $200,000, com modelos especializados e cortadores de assistência robótica de braço que excedem esta quantidade.

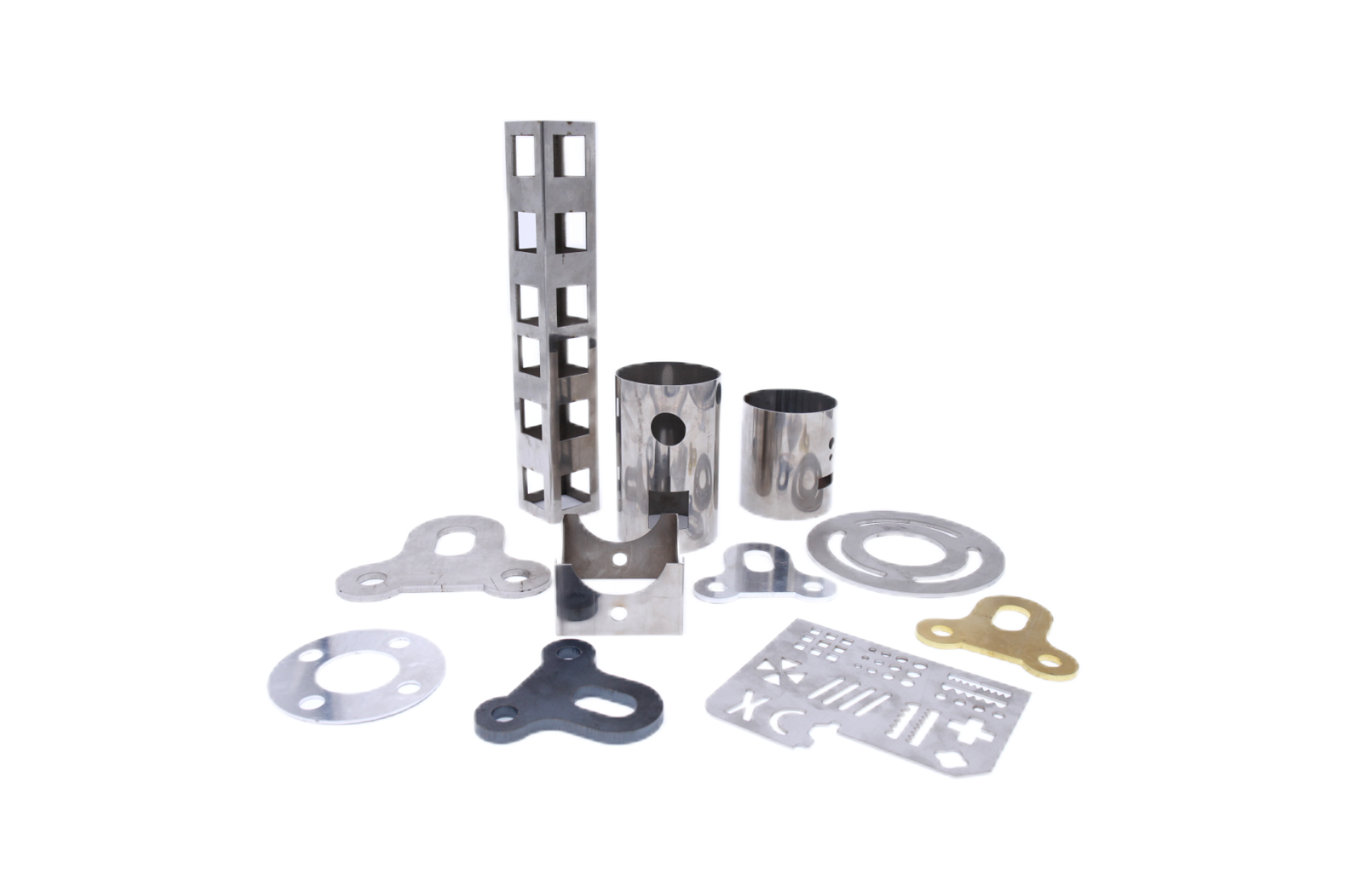

A compra de um cortador de laser de metal para venda oferece várias vantagens:

- Os cortadores a laser fornecem cortes altamente precisos, reduzindo a necessidade de processos de acabamento secundário.

- O corte a laser é mais rápido que os métodos tradicionais, melhorando a produtividade.

- Os cortadores a laser podem lidar com uma ampla gama de materiais e espessuras, tornando-os adequados para diversas aplicações.

- Possuir um cortador a laser pode reduzir a dependência de serviços de corte externos, reduzindo os custos de produção ao longo do tempo.

Aqui estão algumas dicas essenciais a serem consideradas ao comprar um cortador de laser de metal à venda:

- Determine os materiais e espessuras específicos que você precisa cortar para escolher o tipo certo de cortador de laser.

- Contas de custos operacionais em andamento, como consumo e manutenção de energia, em seu orçamento.

- Verifique se o vendedor oferece suporte confiável ao cliente, treinamento, e disponibilidade de peças de reposição.

- Considere a velocidade de corte e o tamanho da cama da máquina para garantir que ela atenda aos seus requisitos de produção.

A indústria de corte a laser continua a evoluir, com novas tecnologias e avanços melhorando a eficiência e as capacidades. Aqui estão algumas tendências para assistir:

- A integração com sistemas de automação e robótica aumentará a precisão e reduzirá o trabalho manual.

- Os avanços no software simplificarão a otimização dos parâmetros de corte, melhorando a eficiência geral.

- Desenvolvimento de lasers de alta potência permitirá um corte mais rápido de materiais mais espessos.

- Haverá um foco crescente no desenvolvimento de tecnologias de corte a laser ambientalmente amigáveis para reduzir o consumo e o desperdício de energia.

Investir em um cortador de laser de metal para venda pode beneficiar significativamente seus negócios, fornecendo alta precisão, eficiência, e versatilidade no corte de vários materiais. Ao entender os diferentes tipos de lasers, seus custos, e suas aplicações, Você pode tomar uma decisão informada que atenda às suas necessidades e orçamento específicos. Certifique-se de avaliar custos de longo prazo e suporte pós-venda para maximizar o retorno do seu investimento.