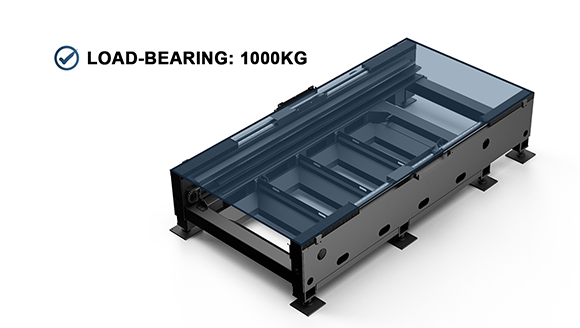

A cama O quadro é soldado usando tubos quadrados grossos e reforçado internamente para melhorar a força estrutural e a resistência à tração., impedir a deformação, reduzir vibrações, and ensure excellent cutting precision.

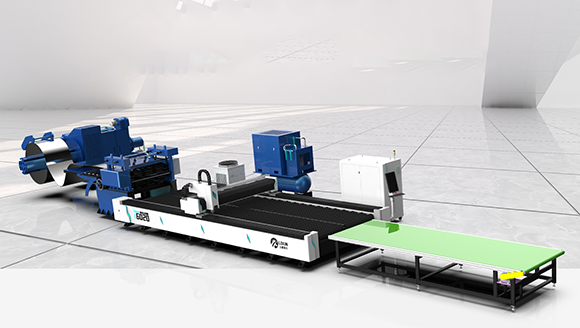

Independent open automatic feeding system

Automatic transmission operation platform

Completely eliminate the disadvantages of manual feeding

Higher degree of automation and significantly improved efficiency

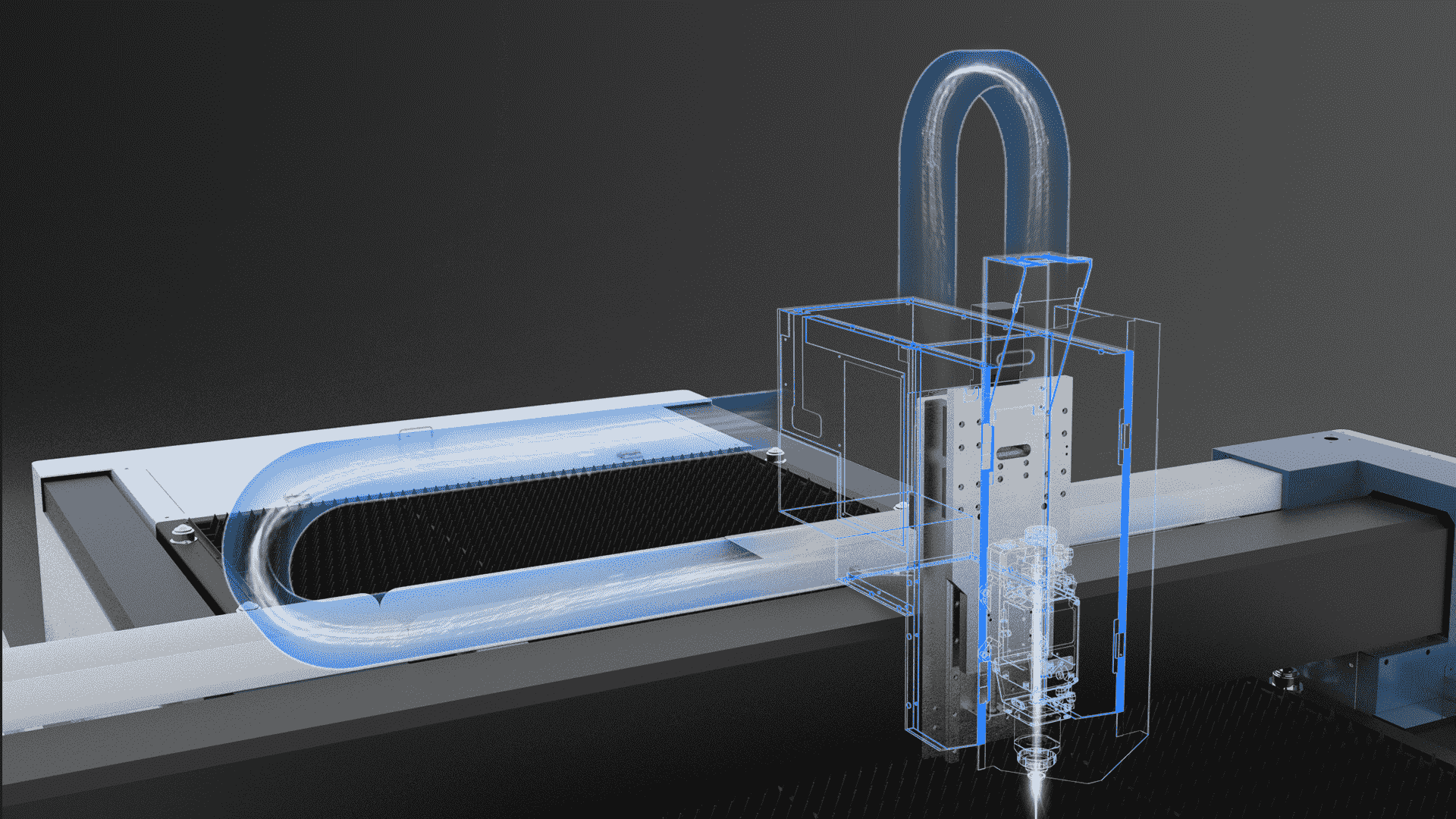

Usando o japonês Yaskawa Electric, MOTOR ELÉTRICO DE FUJI JAPONES, alta precisão, sem perda de etapa, alto torque, baixo ruído, Usando Taiwan YYC/Alemanha Herion Gear e Shimpo Japonês/Redutor de Cíder de Motovario/Alemanha, A precisão do posicionamento da máquina atinge 0.02 milímetros

Modelo | SR3 |

Trabalhando área(milímetros) | 3250*1530milímetros |

Dimensão (L*W*H) | 17000*2500*2600milímetros |

Outer diameter of metal coil | Φ1200-φ1500mm |

Inner diameter of metal coil | Φ510 φ600 |

Maximum weight of single roll | ≤8T |

Material thickness(milímetros) | 0.6-2 |

Feeding accuracy(milímetros) | ±2 |

Feeding speed(m/min) | 0-10 |

X/Y Eixo Posicionamento de Accuracsim | ±0,05 mm |

Precisão de posicionamento repetido | ±0,03mm |

UM: Para lhe recomendar o modelo de máquina mais adequado, basta nos dizer as informações abaixo

1)Qual é o seu material

2)O tamanho do material

3)A espessura do material

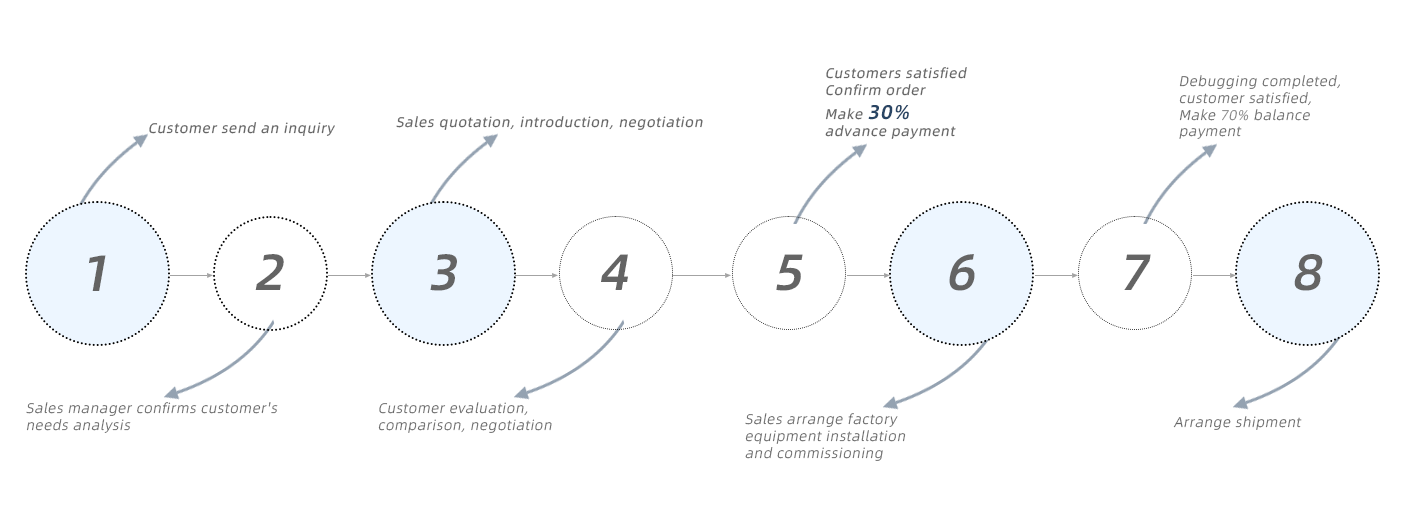

UM:1)Garantia comercial Alibaba/TT/West Union/Payple/LC/Cash e assim por diante.

2)Começamos a fabricar máquinas padronizadas após recebermos 30% do pagamento, inspecionar as máquinas após a conclusão, e finalmente coletar o 70% saldo antes do envio.

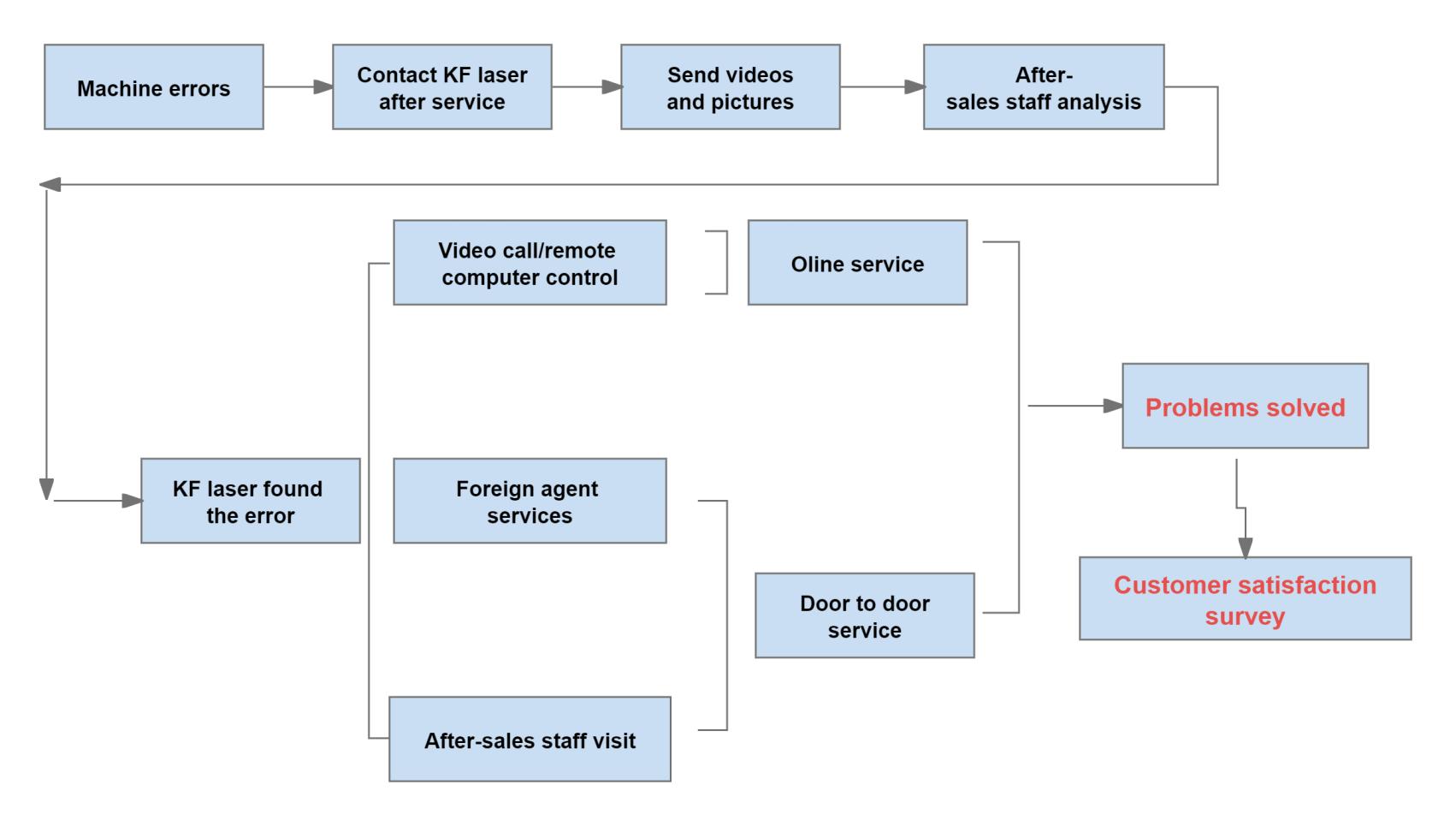

UM:1)Oferecemos treinamento gratuito em nossa fábrica

2)Oferecemos serviço pós-venda on-line gratuito

3)Temos instruções completas de instalação e tutoriais em vídeo

4)As taxas de serviço porta a porta são baseadas na região e no modelo da aeronave

5)Fornece garantia de três anos, exceto peças consumíveis, substituição direta por danos não humanos

Laser cutting is an advanced technology widely used across various industries due to its precision and efficiency. When it comes to stainless steel, a material known for its durability and corrosion resistance, laser cutting offers a clean, accurate, and efficient method for shaping and engraving. This comprehensive guide explores the intricacies of using laser cutters for stainless steel, covering the types of lasers suitable for this material, the process involved, and the benefits of using laser technology.

Fiber lasers are highly efficient and offer excellent precision, making them ideal for cutting stainless steel. They operate by generating a high-power laser beam, which is focused onto the material, melting and vaporizing it along a precise path. The key advantages of fiber lasers include:

- Alta eficiência: Fiber lasers convert electrical energy into laser light with great efficiency, leading to lower operating costs.

- Precisão: They produce a smaller spot size, enabling finer cuts and intricate designs.

- Velocidade: Fiber lasers can cut through stainless steel quickly, enhancing productivity.(Stainless Steel Laser Cutters)

CO2 lasers are another popular choice for cutting stainless steel. They use a gas mixture to produce the laser beam and are known for their versatility. Key features include:

- Broad applicability: CO2 lasers can cut a wide range of materials, including various grades of stainless steel.

- Lower initial cost: These lasers generally have a lower purchase cost compared to fiber lasers.

- Smooth cuts: CO2 lasers produce clean and smooth edges, especially on thicker stainless steel sheets.(Stainless Steel Laser Cutters)

For specialized applications, such as cutting very thin stainless steel sheets or foils, UV (ultravioleta) and IR (infrared) lasers can be used. These lasers are less common but offer specific benefits:

- Lasers UV: Ideal for very fine and detailed work, they are used in applications requiring extremely tight tolerances.

- IR lasers: Suitable for slightly thicker materials, they provide a good balance between precision and speed.(Stainless Steel Laser Cutters)

The first step in the laser cutting process is creating a precise design, typically using CAD software. This design guides the laser cutter, ensuring that the cuts are made accurately.

Once the design is ready, the next step involves setting up the laser cutting machine. This includes selecting the appropriate laser type, adjusting the power settings, and calibrating the focus and assist gas (commonly nitrogen or oxygen) to optimize the cutting process.

The laser cutter follows the programmed design, cutting through the stainless steel with high precision. The focused laser beam heats the material to its melting point, and a gas jet removes the molten metal, leaving behind a clean cut.

After the cutting is complete, the parts may require additional finishing, such as deburring or polishing, to achieve the desired surface quality. This step is crucial for applications where aesthetic or functional precision is critical.

Laser cutting offers unmatched precision, allowing for the creation of complex shapes and intricate patterns that would be challenging with traditional cutting methods. The high accuracy ensures minimal waste, which is particularly important when working with expensive materials like stainless steel.(Stainless Steel Laser Cutters)

Compared to mechanical cutting methods, laser cutting is significantly faster, especially for thin and medium-thickness stainless steel sheets. This speed, combined with the ability to automate the process, enhances overall production efficiency.(Stainless Steel Laser Cutters)

Laser cutting minimizes the heat-affected zone (HAZ) around the cut edges, preserving the material’s mechanical properties and reducing the risk of warping or distortion. The process also results in smooth, burr-free edges, reducing the need for post-processing.

Laser cutters can handle a wide range of stainless steel types and thicknesses, making them suitable for various industries, from automotive and aerospace to medical device manufacturing and decorative arts.(Stainless Steel Laser Cutters)

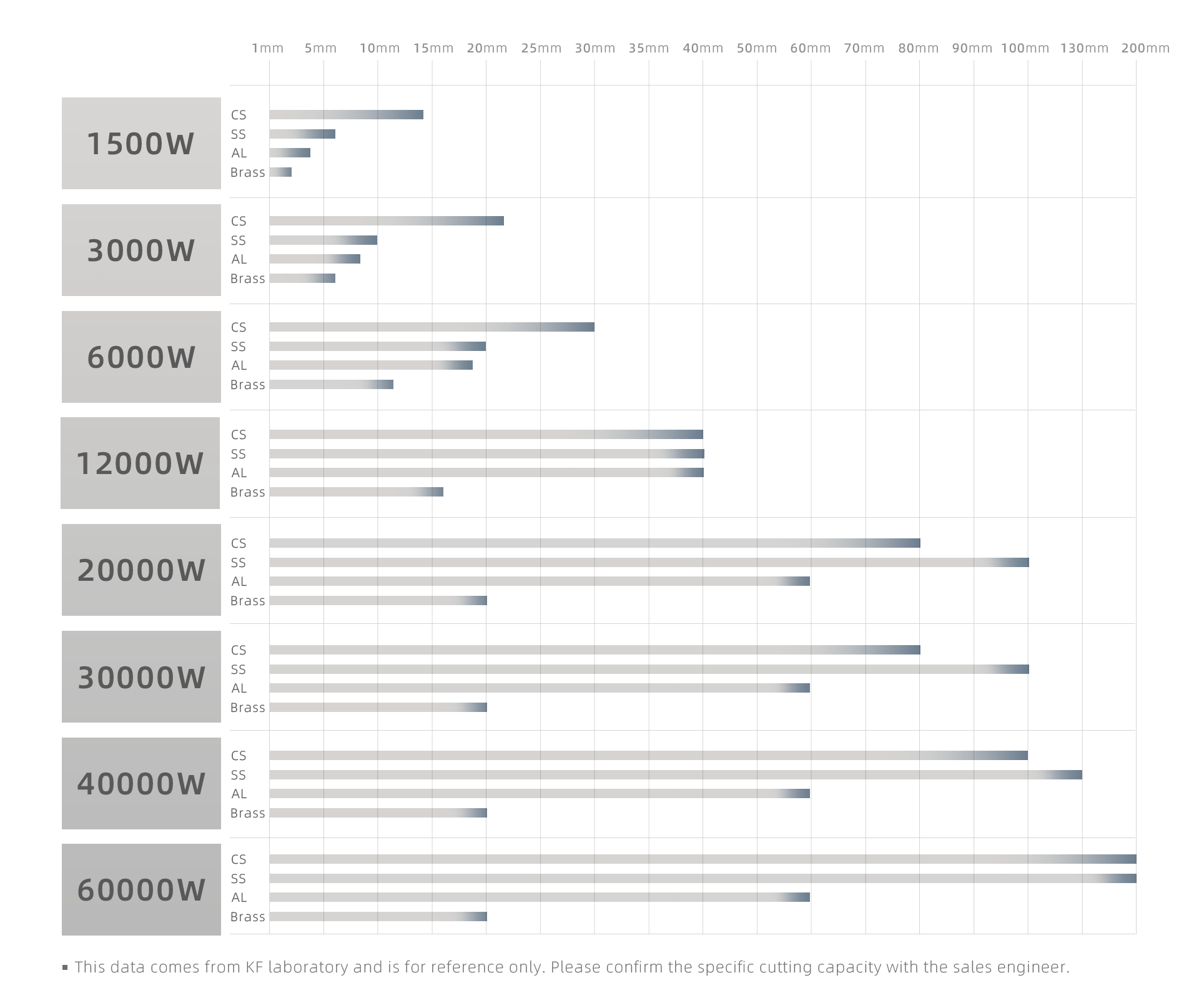

The type and thickness of stainless steel being cut are critical factors in determining the appropriate laser cutter and settings. Thicker materials may require higher power lasers and slower cutting speeds, while thin sheets can be cut quickly with lower power settings.

Selecting the right laser power is crucial for achieving high-quality cuts. Too much power can cause excessive melting and a rough edge, while too little power may not penetrate the material. The focus of the laser must also be adjusted precisely to match the material thickness.

The choice of assist gas affects the quality of the cut and the speed of the process. Nitrogen is often used for cutting stainless steel as it prevents oxidation and ensures a clean cut. Oxygen can be used for faster cuts but may result in an oxidized edge.

Regular maintenance and calibration of the laser cutting machine are essential to ensure consistent performance. This includes cleaning the optics, checking the alignment, and replacing consumables like lenses and nozzles as needed.

Na indústria automotiva, laser cutting is used to create precise components and parts, such as exhaust systems and body panels. The ability to cut complex shapes quickly and accurately makes it a valuable tool for automotive manufacturers.

The aerospace industry demands high precision and quality in its components. Laser cutting is ideal for producing intricate parts from stainless steel, such as turbine components and structural elements, where tolerances are critical.

Stainless steel is commonly used in medical devices due to its corrosion resistance and strength. Laser cutting is used to manufacture surgical instruments, implantes, e outros dispositivos médicos, ensuring high precision and cleanliness.

Laser-cut stainless steel is also popular in architectural and decorative applications. From intricate railings and facades to detailed signage and art pieces, laser cutting offers designers the freedom to create unique and complex designs.

One of the challenges in laser cutting stainless steel is managing the heat generated during the process. Excessive heat can lead to warping and other defects. Using proper assist gas, optimizing cutting speed, and using cooling systems can help manage heat effectively.(Stainless Steel Laser Cutters)

Achieving a clean edge without burrs is crucial for many applications. Adjusting the laser settings, such as power and focus, and selecting the right assist gas can help improve edge quality. Post-processing techniques like deburring may also be necessary for high-precision requirements.(Stainless Steel Laser Cutters)

While laser cutting offers many benefits, it can also be costly, particularly for high-power machines and thick materials. It's important to balance the costs with the benefits, such as reduced material waste and increased production speed, to determine the overall value.(Stainless Steel Laser Cutters)

Fiber laser technology continues to evolve, with improvements in power, eficiência, and beam quality. These advancements are expanding the range of applications for laser cutting and improving the quality and speed of the process.(Stainless Steel Laser Cutters)

Automation is becoming increasingly important in manufacturing, and laser cutting is no exception. Integrating laser cutting machines with other automated systems, como braços robóticos e correias transportadoras, can streamline production and reduce labor costs.(Stainless Steel Laser Cutters)

À medida que as preocupações ambientais crescem, the industry is looking at ways to make laser cutting more sustainable. This includes improving energy efficiency, reducing emissions from assist gases, and recycling waste materials.(Stainless Steel Laser Cutters)

Stainless steel laser cutting is a versatile and efficient process that offers numerous advantages, incluindo alta precisão, velocidade, and the ability to handle complex designs. With the right equipment and settings, laser cutting can produce high-quality results for a wide range of applications. À medida que a tecnologia avança, we can expect even greater capabilities and efficiencies from laser cutters, making them an increasingly valuable tool in various industries.(Stainless Steel Laser Cutters)