Notícias

Máquina de corte de chapa metálica para venda: Guia do comprador final

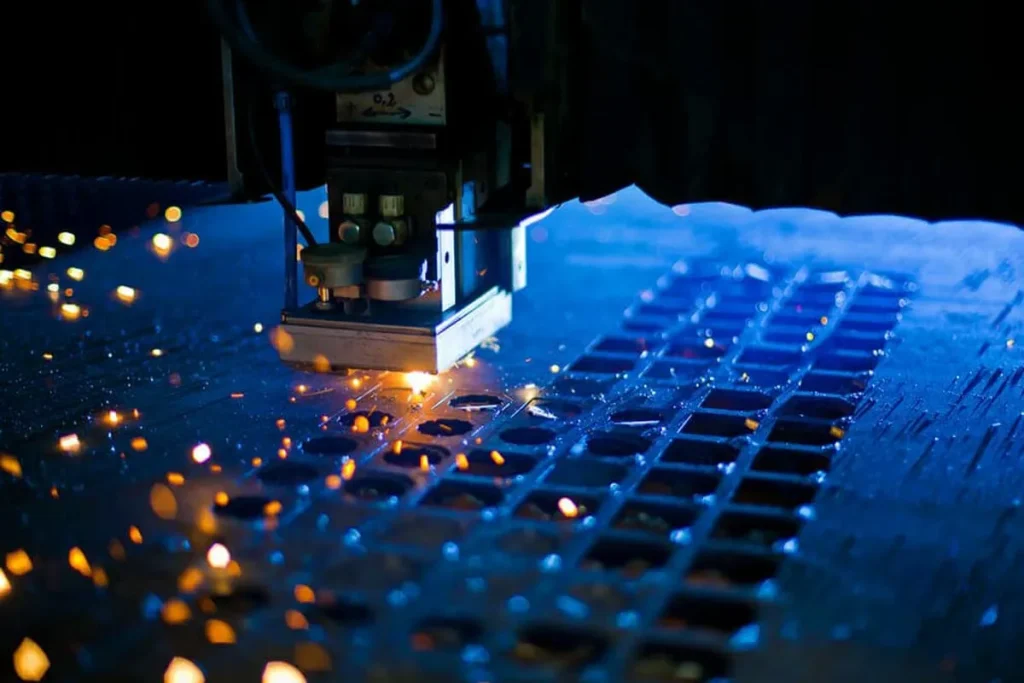

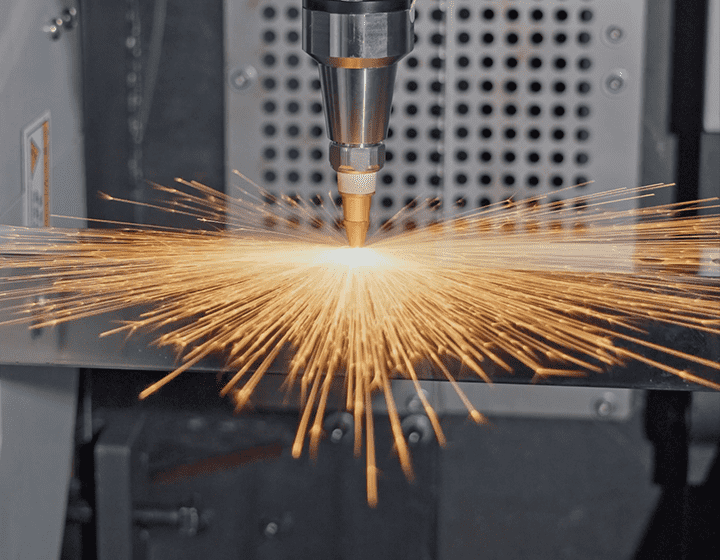

Imagine transforming raw metal into intricate components with surgical precision. Picture slashing production costs while doubling output speed. Envision a workshop where complex cuts happen flawlessly, repeatedly, relentlessly. This is the revolution ignited by modern sheet metal cutting machine for sale technology – a game-changer for fabricators battling deadlines and demanding clients. The leap from manual tools to automated cutting isn’t just an upgrade; it’s survival in today’s hyper-competitive manufacturing landscape.

Why Power Density Dictates Performance

When evaluating a sheet metal cutting machine for sale, photon concentration separates hobbyist tools from industrial beasts. Higher wattage (por exemplo, 12kW systems) enables:

- Thickness Mastery: Cut through 40mm stainless steel in one pass, eliminating multi-stage processing 2.

- Blistering Speeds: Alcançar 50+ meters/minute on 3mm mild steel – ideal for high-volume orders.

- Edge Perfection: Advanced gas dynamics (N₂/O₂) minimize dross and heat distortion, reducing post-processing by 70% 2.

Cutting-Edge Technologies Redefining Value

Lasers de fibra: The Efficiency Kings

- Speed vs. CO₂: Fiber lasers operate 3x faster on thin metals while consuming 50% less power.

- Maintenance Wins: Solid-state designs avoid mirror alignments and gas replenishment.

Plasma Systems: Budget Powerhouses

- Eficiência de custos: Ideal for shops cutting ≤25mm aluminum without laser-level precision.

- Portability: Compact units fit space-constrained environments.

5 Critical Purchase Considerations

Material Profile

Stainless/aluminum: Prioritize lasers with nitrogen assist.

-Mild steel >15milímetros: High-power fiber lasers (≥8kW) prevent beveling.

Throughput Demands

-Low-volume: Opt for open-table configurations.

-Mass production: Automated load/unload systems slash idle time.

Precision Thresholds

-±0.1mm tolerance: Fiber lasers with capacitive height control.

-±0.5mm acceptable: Plasma/waterjet alternatives.

Hidden Ownership Costs

Expense | Laser | Plasma | Waterjet |

Energy/operation | $$$ | $$ | $$$$ |

Consumables/hour | $8 | $15 | $40+ |

Maintenance/month | $200 | $350 | $500 |

Preparado para o futuro

-Modular designs allowing power upgrades

-IoT-enabled machines for predictive maintenance

Operational Pitfalls to Avoid

- Underpowered Lasers: Struggling with 20mm+ steel causes tapered edges and recast layers.

- Gas Mismanagement: Using oxygen on stainless steel induces oxidation pitting.

- Neglecting Nozzle Health: Worn nozzles increase kerf width by 30%, wasting material.

The Smart Buyer’s Action Plan

- Audit Current Workflows: Track your thickest cuts and tightest tolerances over 30 dias.

- Demand Live Demos: Test vendors with your actual material samples – not standardized trials.

- Verify Support Networks: Ensure local technicians can service advanced optics within 24hrs.

- Calculate ROI Holistically: Include scrap reduction (lasers average 3% contra. plasma’s 8%).

The right sheet metal cutting machine for sale doesn’t just slice metal – it carves profit margins. While 12kW+ systems dominate aerospace applications, mid-range 6kW lasers satisfy 80% of automotive needs 2. Lembrar: Over-specing drains capital; under-specing strangles growth. Your perfect match balances today’s jobs with tomorrow’s ambitions.

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa