News

Tube and Plate Laser Cutting Machine: Revolutionizing the Manufacturing Industry

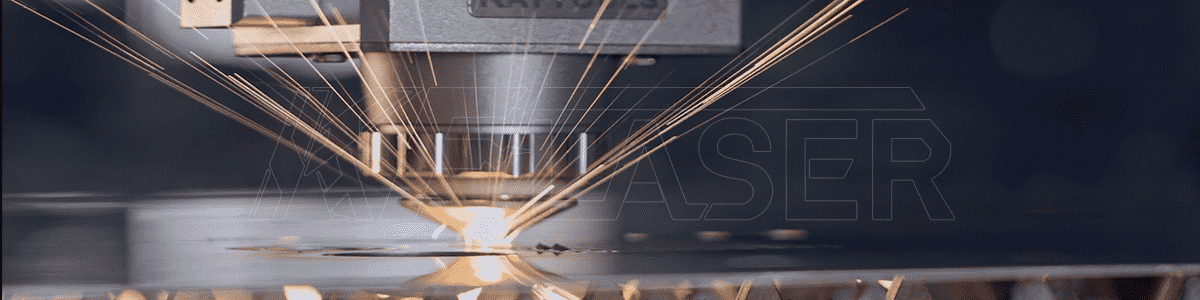

When it comes to precision and versatility in industrial cutting, tube and plate laser cutting machine have emerged as a groundbreaking solution. The ability to handle complex geometries and deliver fine, accurate cuts with minimal material waste has transformed various sectors, from aerospace to automotive, construction, and beyond. But what exactly makes these machines stand out in the competitive field of laser cutting technology? Let’s dive deeper into the world of tube and plate laser cutting machine, uncovering the benefits, applications, and reasons they’re considered a game-changer for manufacturers.

A Leap in Cutting Technology

The fusion of tube and plate laser cutting technology represents a significant leap forward in machining. It’s no longer just about cutting through metal or other materials. It’s about providing unparalleled precision, reducing production times, and minimizing the environmental footprint.

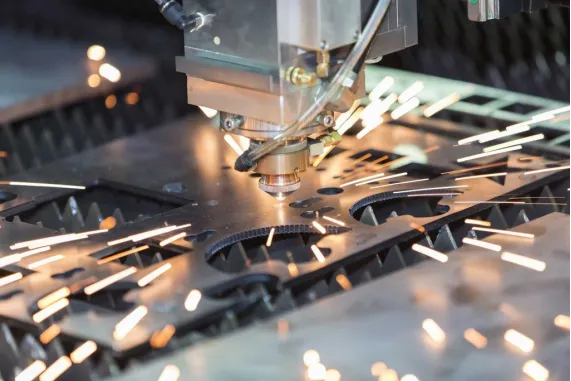

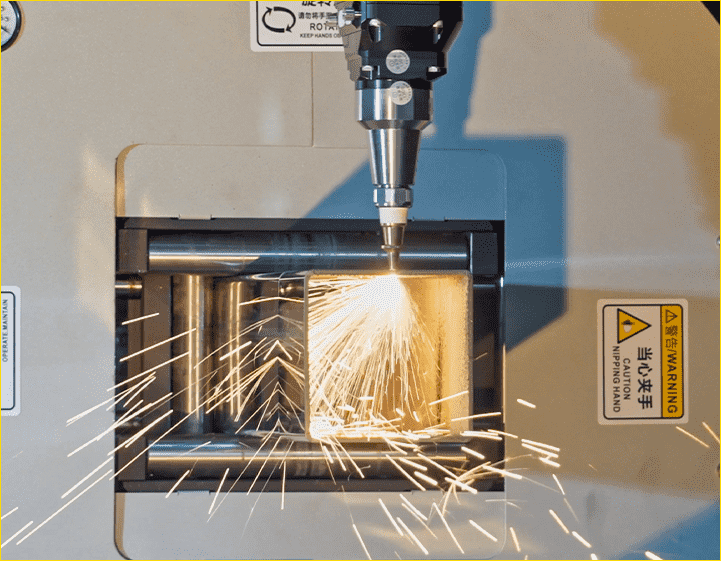

The laser cutter is widely regarded for its capability to perform intricate cuts that are virtually impossible with traditional methods. Whether cutting through steel plates or tubular materials, these machines provide exceptional accuracy, ensuring that even the most complex designs are executed flawlessly.

Why Choose Tube and Plate Laser Cutting Machine?

- Speed and Precision:

Laser cutting machines are known for their rapid processing time, which is a major advantage in high-volume manufacturing. The tube and plate laser cutting machinecan make intricate cuts in record time, all while maintaining a level of precision that traditional methods cannot achieve. This level of accuracy is vital for applications in fields like automotive manufacturing, where every millimeter matters. - Reduced Waste and Cost Efficiency:

Traditional cutting methods, like punching or shearing, can result in significant material waste. A laser cutting machine, on the other hand, uses focused energy to cut the material, leaving very little scrap behind. This makes the tube and plate laser cutting machinenot only a more cost-effective solution but also a more environmentally friendly option for manufacturers concerned about sustainability. - Versatility in Material Handling:

Laser cutting technology can handle a variety of materials beyond metal, including plastics, wood, and ceramics. However, its true potential shines when cutting metals, particularly stainless steel, carbon steel, aluminum, and brass. Whether you need to cut thick plates or delicate tubes, laser cutters provide the flexibility to work with various shapes and thicknesses. - No Tool Wear and Minimal Maintenance:

Unlike traditional cutting methods that rely on physical tools like blades and dies, laser cutting uses light energy to make cuts. This eliminates tool wear and reduces the maintenance cost associated with replacing or repairing cutting tools. This can be a game-changer for businesses looking to reduce downtime and extend the lifespan of their equipment.

The Applications of Tube and Plate Laser Cutting Machine

The range of applications for tube and plate laser cutting machines is broad, and they’re employed in various industries where precision is paramount.

- Aerospace Industry:

In the aerospace sector, components require exact dimensions and flawless precision. The ability to cut complex shapes in both plates and tubes allows manufacturers to produce lightweight yet durable components for aircraft and spacecraft.

- Automotive Manufacturing:

Laser cutting technology is widely used in the automotive industry to create everything from structural components to exhaust systems. The precision and speed of tube and plate laser cuttingmake it ideal for cutting parts used in engine systems, bodywork, and chassis.

- Construction and Architecture:

In construction, laser cutting machineare used to fabricate intricate steel or aluminum components that are both functional and aesthetic. Whether for structural beams, support columns, or decorative facades, the versatility of laser cutting ensures that no design is too complex to bring to life.

- Medical Device Manufacturing:

The medical industry demands high-precision cutting when creating surgical instruments, implants, and medical equipment. Laser cutters are the perfect solution for ensuring that each part meets stringent safety and performance standards.

- Energy Industry:

In sectors like wind and solar energy, precise cutting of materials is crucial for the production of turbine blades and energy-efficient components. Tube and plate laser cutting machineallow manufacturers to create intricate designs that improve energy efficiency and sustainability.

The Future of Laser Cutting Technology

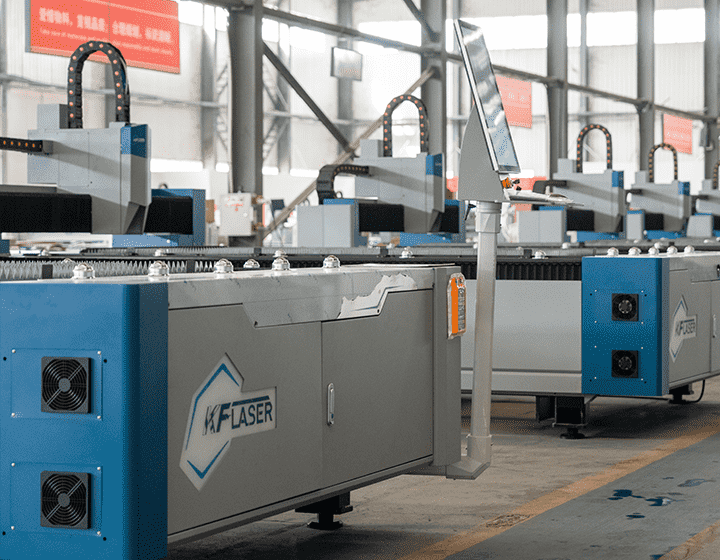

The future of tube and plate laser cutting machine is bright, with continuous improvements in laser technology driving innovation. Fiber lasers, in particular, are becoming more common due to their efficiency and ability to cut a wider range of materials with higher precision. As automation becomes more prevalent in the manufacturing world, laser cutting machine will continue to evolve, offering enhanced speed, improved precision, and better integration with Industry 4.0 systems.

Furthermore, 3D laser cutting technology is pushing the boundaries even further, enabling complex geometries and intricate three-dimensional cuts. These advancements open up new possibilities for industries such as aerospace, automotive, and beyond, where intricate parts are critical to performance.

Conclusion: Why Embrace Tube and Plate Laser Cutting Machine?

In a world where precision, efficiency, and sustainability are increasingly important, the tube and plate laser cutting machine is revolutionizing manufacturing processes across industries. Its ability to cut complex shapes with minimal material waste, paired with its unmatched speed and precision, makes it the ideal tool for modern manufacturers. As technology continues to evolve, the versatility and efficiency of laser cutting will only increase, opening the door for even greater innovations in product design and manufacturing.

By embracing the power of tube and plate laser cutting technology, businesses can stay ahead of the curve, streamline their production processes, and maintain a competitive edge in an ever-changing marketplace.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine