Laser cutting is a versatile and precise method of cutting various materials with the help of focused laser beams. This technology has gained popularity across industries like manufacturing, automotive, aerospace, and even art due to its accuracy, efficiency, and ability to work with complex designs.

One of the greatest advantages of laser cutting is its ability to process a wide range of materials, making it suitable for numerous applications. But what exactly can a laser cutting machine cut? In this article, we’ll explore the different materials that can be cut by laser technology, their applications, and the factors that influence the cutting process.

When determining the cost of a laser cutting machine, it’s important to consider multiple variables that can significantly impact the final price. Here are the key factors that influence laser cutter pricing:

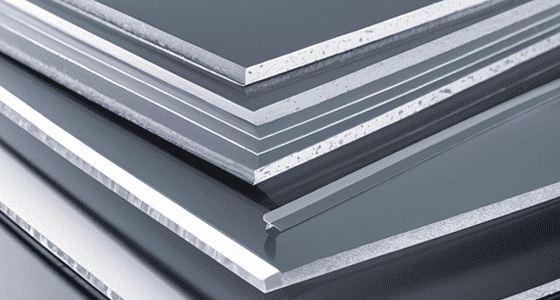

Laser cutting is widely used for cutting metals, thanks to its precision and ability to cut through thick sheets with ease. The type of metal and its thickness will determine the type of laser cutter used and the settings for optimal cutting performance.

Stainless Steel: Laser cutting is ideal for cutting stainless steel sheets with clean edges and minimal distortion. It is commonly used in the automotive and kitchen appliance industries.

Carbon Steel: Carbon steel, often used in heavy-duty applications, can be cut quickly and precisely with a laser. This material is typically used in manufacturing industries that require robust and durable parts.

Aluminum: Although cutting aluminum with a laser requires higher-powered machines due to its reflective properties, it is still a common application in the aerospace and automotive industries.

Brass & Copper: Non-ferrous metals like brass and copper can also be cut by laser. However, these materials require specialized lasers due to their higher reflectivity compared to steel.

Laser cutting of metals allows for precise shapes and edges, with minimal heat-affected zones, which means less material warping and better quality finishes. Fiber lasers are particularly effective in cutting metals, including stainless steel and aluminum.

Laser cutting is also widely used for cutting wood, especially for creating intricate designs, custom furniture, and decorative elements. The precision of the laser allows for fine detailing, making it a preferred method for woodworkers and artisans.

Plywood: Laser cutters are commonly used to cut plywood, making it easy to create customized designs, from signage to furniture pieces.

MDF (Medium Density Fiberboard): Laser cutting of MDF is popular in crafting and furniture manufacturing, where smooth edges and detailed patterns are essential.

Hardwood: While hardwood can be cut with lasers, the process requires higher power settings due to the denser nature of the material.

Laser cutting wood offers a clean, smooth cut without splintering, making it ideal for intricate shapes and detailed engravings. The technique is also used for etching patterns and designs on wooden surfaces.

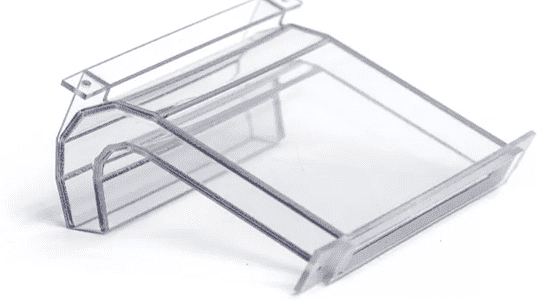

Plastic materials are another category that can be easily cut with laser cutting technology. Plastics are used in a variety of industries, including packaging, automotive, and electronics, and laser cutting provides a clean and precise method of shaping them.

Acrylic (PMMA): Acrylic is one of the most common plastics cut by lasers. It can be cut into complex shapes, and laser cutting can create smooth edges without the need for additional finishing.

Polycarbonate (PC): Polycarbonate sheets, often used in the manufacturing of lenses and safety equipment, can be cut with lasers with high precision. However, special care must be taken as this material can discolor if overheated.

Polyethylene (PE): Although polyethylene can be laser cut, it requires specific settings to avoid the material from burning due to its low melting point.

Laser cutting plastics offers several advantages, including the ability to make intricate cuts without distortion, reduced waste, and the ability to engrave detailed designs.

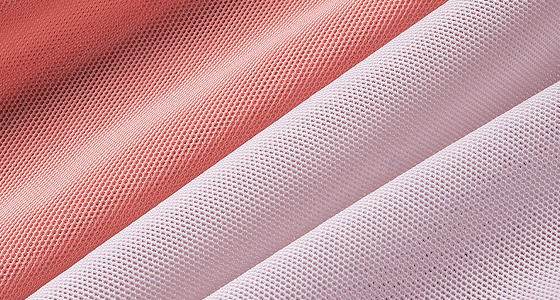

Laser cutting is commonly used in the textile industry for cutting fabric, particularly for custom apparel, upholstery, and design work. Laser cutters can handle everything from delicate fabrics like silk to thicker materials like leather.

Textiles and Fabrics that Can Be Laser Cut:

Cotton: Laser cutting cotton fabric is precise and allows for intricate designs, commonly seen in apparel and fashion items.

Leather: Leather is often laser cut for use in fashion accessories, furniture upholstery, and footwear. The precision allows for intricate detailing without the need for stitching.

Synthetic Fabrics: Fabrics such as polyester and nylon can be laser cut to create clean, sealed edges, preventing fraying and reducing the need for additional finishing processes.

Laser cutting of textiles offers many benefits, including the ability to produce intricate and customized designs with consistent results, all while reducing waste.

While lasers are not typically associated with cutting hard materials like ceramics and glass, advancements in technology have made it possible to cut these materials with precision.

Glass: Laser cutting is often used to make precise cuts or engravings in glass. The technique can be applied to architectural glass, mirrors, and even custom glassware, providing a high-quality, polished finish.

Ceramics: Though it requires high-powered lasers, ceramics can be cut with precision, making it ideal for the creation of custom designs, such as decorative tiles or industrial ceramic components.

Laser cutting of ceramics and glass typically involves using CO2 lasers or ultraviolet (UV) lasers, as they offer the necessary precision to avoid cracking or shattering.

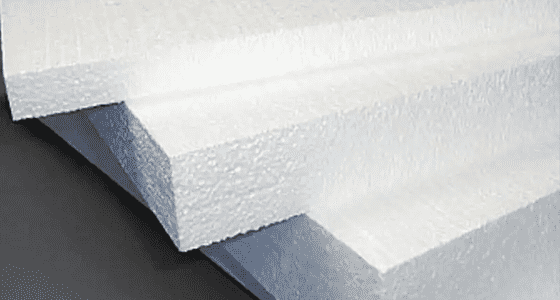

Foam and rubber materials are commonly cut with lasers, especially for industrial applications such as sealing, gaskets, or custom cushioning.

Foam: Laser cutting foam materials, like polyethylene and polyurethane, is widely used in packaging, custom mats, and padding products.

Rubber: Rubber can be cut for industrial purposes, including seals and gaskets, with high precision and minimal distortion. The heat from the laser also helps in sealing the edges, preventing fraying.

Laser cutting of foam and rubber materials allows for high-speed cutting and precise shapes, making it ideal for producing intricate designs used in packaging or automotive industries.

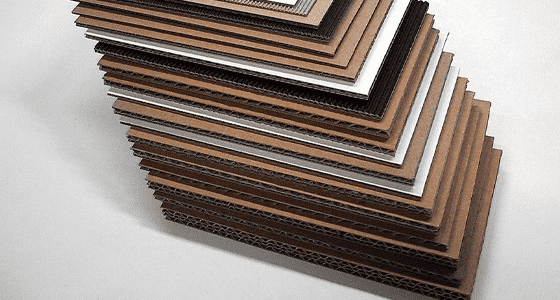

Laser cutting technology is also used for creating intricate designs in paper and cardboard, whether for packaging, custom stationery, or crafts. This is a highly efficient way to create delicate patterns and sharp cuts without needing physical blades.

Cardboard: Laser cutters are often used in the packaging industry to create custom-cut boxes and prototypes with high precision.

Paper: From greeting cards to intricate paper sculptures, laser cutting is a popular method for creating precise and clean paper cuts without damaging the material.

Laser cutting paper and cardboard offers the ability to make complex patterns with ease, providing smooth, burn-free edges and fine details.

Laser cutting is an incredibly versatile technology that can handle a wide array of materials, from metals and plastics to wood, fabrics, and even ceramics. The precision and speed of the process make it suitable for industries as diverse as aerospace, fashion, automotive, packaging, and more. Whether you are a manufacturer or a hobbyist, understanding the materials that can be cut with a laser cutter can help you choose the best equipment for your needs and make the most out of your production capabilities.