Новости

12Мощность лазера, кВт: Революция промышленной резки

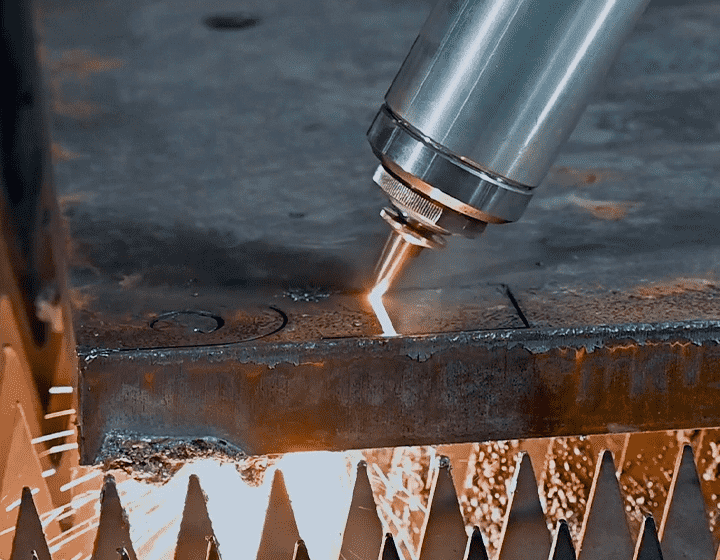

Imagine slicing through solid steel like butter. Picture cutting through thick aluminum faster than ever thought possible. Envision a future where metal fabrication limitations vanish overnight. This isn’t science fiction—it’s the reality delivered by 12kw laser технология, fundamentally rewriting the rules of industrial manufacturing. The leap from 6kW or 8kW systems to the formidable 12-kilowatt threshold isn’t just incremental; it’s a paradigm shift unlocking unprecedented capabilities across aerospace, автомобильный, heavy machinery, and energy sectors.

Beyond Speed: The Physics of Power

The core advantage of a 12kw laser lies in its extraordinary photon density. At this power level, the energy transfer to the material becomes exceptionally efficient, enabling:

- Conquering Extreme Thickness:Where 8kW lasers struggle beyond 25mm mild steel, 12kw laser systems cleanly slice through 40mm and beyond in a single pass. This eliminates multi-pass cutting, secondary operations, and the associated distortions and inaccuracies. Recent industrial trials demonstrated a 70% reduction in processing time for 35mm stainless steel components compared to 8kW systems.

- Unmatched Cutting Velocity on Thinner Gauges:While raw power handles thickness, it also dramatically boosts speed on materials under 10mm. Cutting 3mm mild steel can reach staggering velocities exceeding 50 meters per minute—a productivity surge unattainable with lower-powered lasers. This translates directly to shorter lead times and increased throughput for high-volume production.

- Elevated Edge Quality & Точность:Higher power allows for optimized beam parameter combinations. Using specialized nozzles and advanced gas dynamics (often nitrogen or oxygen at high pressures), а 12kw laser can produce remarkably smooth cut edges with minimal dross and a drastically reduced heat-affected zone (ЗТВ). This reduces or often eliminates the need for costly post-processing like grinding or milling, particularly critical for structural components and parts requiring tight tolerances.

- Material Versatility Expansion:The intense energy density makes previously challenging materials far more viable. Thick-section aluminum (traditionally problematic due to high reflectivity and thermal conductivity), copper alloys, high-strength steels (like armor plate), and even certain reflective composites succumb efficiently to a well-tuned 12kw laser This opens doors to new applications and material choices for designers.

The Economic Equation: Стоимость против. Рентабельность

The substantial investment in a 12kw laser demands rigorous justification. The calculus, однако, reveals compelling returns:

- Throughput Multiplier:Drastically faster cutting speeds and the ability to handle thicker materials in one pass significantly increase parts-per-hour output. Facilities report doubling or even tripling effective capacity without expanding floor space.

- Consumable & Энергоэффективность:While peak power consumption is higher, the dramatic reduction in cutting time per part often results in lower overall energy consumption per component. Более того, optimized cutting parameters at high power can extend nozzle life and reduce assist gas consumption compared to struggling lower-power systems.

- Labor & Post-Processing Savings:Automation integration thrives with the speed and reliability of 12kw laser Reduced manual handling, minimized secondary operations (like deburring thick edges), and lower scrap rates contribute significantly to operational cost reduction.

- Unlocking New Markets:The capability to handle extreme thicknesses and challenging materials allows job shops and OEMs to bid on lucrative contracts previously outside their technical reach, directly impacting top-line revenue growth.

Navigating Implementation: Critical Considerations

Harnessing the full potential of a 12kw laser isn’t merely plug-and-play. It necessitates a holistic system approach:

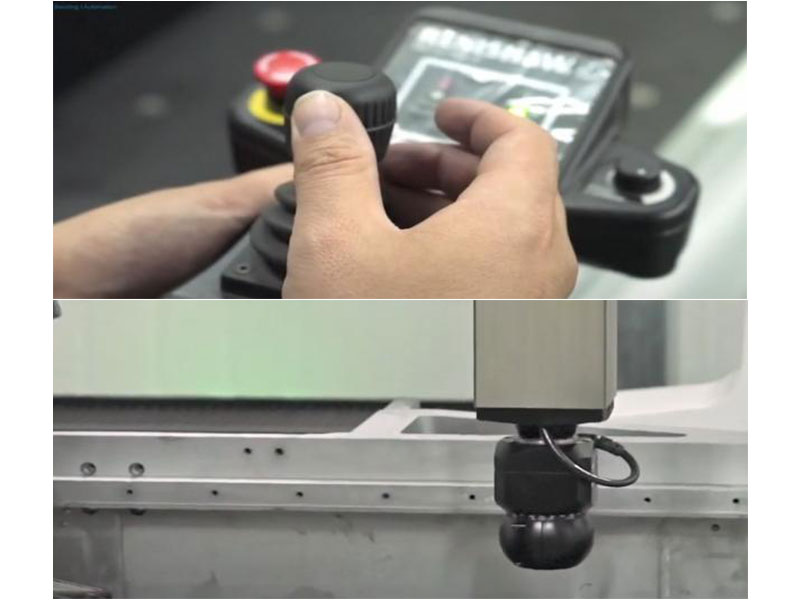

- Robust Machine Foundation:The cutting bed, gantry system, and drives must possess exceptional rigidity and dynamic response to handle the high acceleration and deceleration required at blistering speeds without vibration, ensuring micron-level precision. Linear motor technology is often essential.

- Advanced Beam Delivery:Standard fibers falter at sustained 12kW. Low-loss, process-specific optical fibers and robust cutting heads with optimized collimation and focusing lenses (often water-cooled) are paramount to maintain beam integrity, prevent thermal damage, and ensure consistent focus position. Beam oscillation techniques become crucial for optimal melt ejection in thick sections.

- Sophisticated Process Control:Real-time monitoring systems (like melt pool monitoring or back-reflection detection) and adaptive control algorithms are non-negotiable. They dynamically adjust power, gas pressure, focus position, and cutting speed to maintain quality, especially when piercing thick plate or navigating complex contours at high velocity.

- Exhaustive Fume Extraction:The volume of fumes generated at 12kW is immense. High-capacity, high-static-pressure extraction systems with multi-stage filtration are mandatory to maintain a safe working environment and prevent contamination of optics.

- Laser Source Expertise:Understanding the source technology (fiber laser remains dominant) and its cooling requirements is vital. Redundancy in chillers and power stability are critical for uptime.

The Horizon: Where 12kW Leads

The adoption of 12kw laser technology is accelerating, driven by falling costs per watt and proven ROI. We stand at the threshold of further evolution:

- Hybrid Manufacturing:Integrating 12kw laser deposition (DED – Directed Energy Deposition) with CNC machining for rapid repair or additive manufacturing of large, near-net-shape metal components is gaining traction, particularly in aerospace and energy.

- Ultra-High-Speed Welding:The power enables deep penetration welding at speeds previously unimaginable, revolutionizing processes like battery tab welding or structural seam welding in automotive.

- Smarter Automation:Tighter integration with AI for predictive process optimization, autonomous parameter selection based on material batch variations, and seamless integration into Industry 4.0 workflows will become standard.

The 12kw laser is more than just a more powerful tool; it’s an enabler of radical design freedom and manufacturing efficiency. It pushes the boundaries of what’s possible in metal fabrication, demanding new thinking in machine design, process engineering, and application development. For industries where material thickness, throughput, and precision define competitiveness, mastering the 12kw laser isn’t an option—it’s the imperative next step in the relentless pursuit of manufacturing excellence. The era of compromised speed or thickness is over; the power to redefine production is now concentrated in that intense, focused beam.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина