Новости

Машина для резки лазерной трубки с ЧПУ: Революционный подход к точной резки

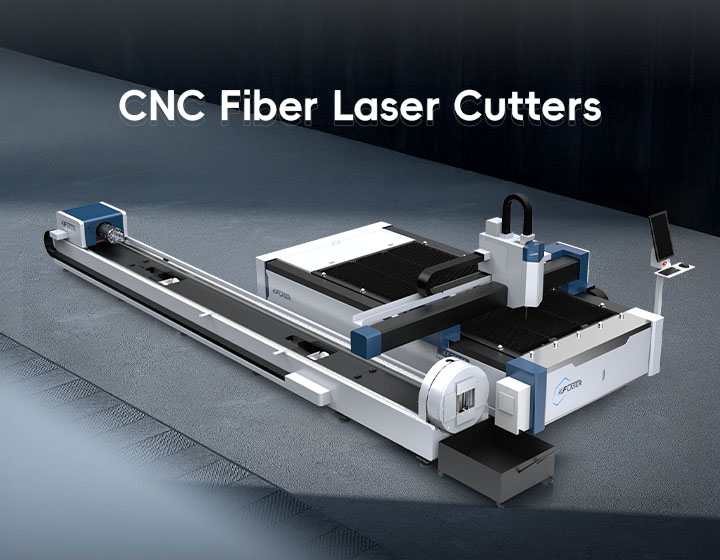

The CNC laser tube cutting machine is transforming the metal fabrication industry, enabling manufacturers to achieve unprecedented precision and speed in cutting metal tubes. Whether in automotive manufacturing, аэрокосмический, строительство, or industrial machinery, this advanced machine is increasingly recognized for its ability to produce high-quality parts with minimal waste. With its efficiency and versatility, it’s not just changing how we cut metals—it’s revolutionizing the entire process.

1. What Is a Машина для резки лазерной трубки с ЧПУ?

A CNC (Компьютерное числовое управление) laser tube cutting machine uses a high-powered laser beam directed at metal tubes to precisely cut them into various shapes and sizes. The CNC system automates the cutting process, allowing manufacturers to produce complex shapes with high repeatability and accuracy. В отличие от традиционных методов резки, например, распиловка или штамповка, laser cutting uses focused light to melt, гореть, или испарить материал, resulting in smooth, clean edges with minimal material wastage.

The core advantage of this technology lies in its precision and versatility. It can handle a wide range of materials—including stainless steel, мягкая сталь, алюминий, and copper—and accommodate various tube shapes like round, квадрат, прямоугольный, and even more complex geometries. The CNC system further enhances this process by ensuring consistency and reducing human error.

2. How Does CNC Laser Tube Cutting Work?

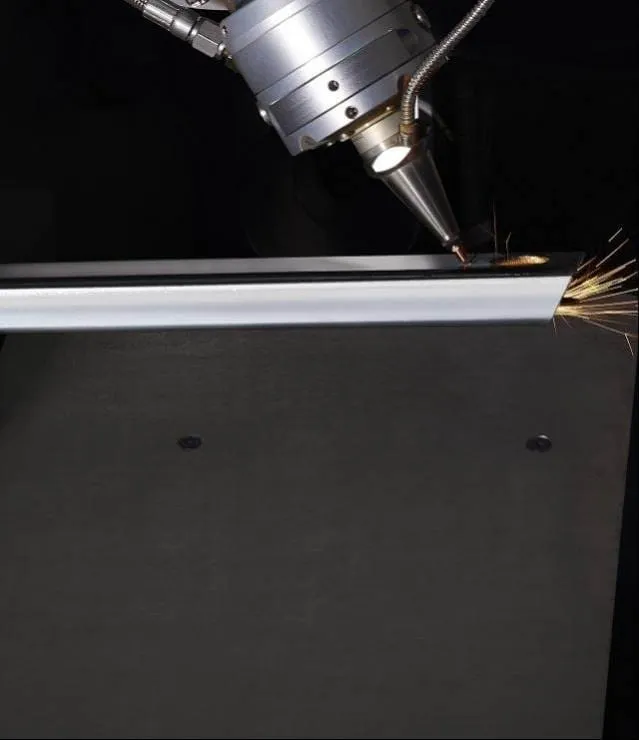

◆ Laser Generation and Focus

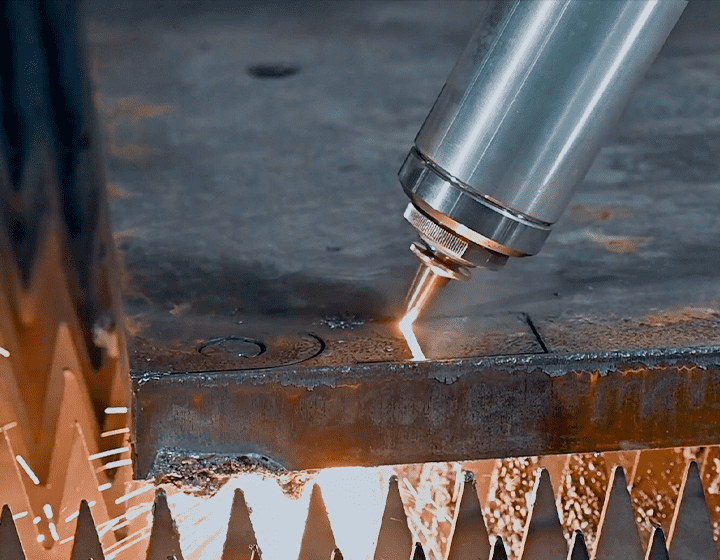

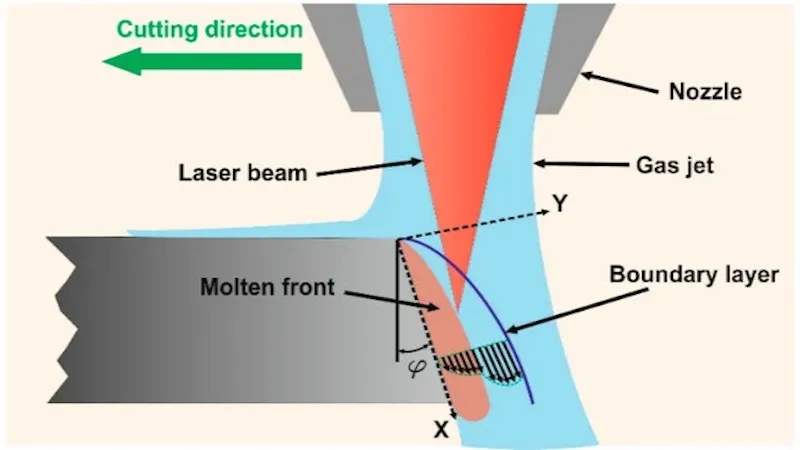

The cutting process begins with a fiber laser that is generated by a fiber optic system. The fiber laser is known for its ability to focus a powerful beam on a small area, allowing it to cut through metals with exceptional accuracy. The laser beam is transported to the cutting head, where it is focused onto the metal tube.

◆ Material Interaction

When the laser strikes the material, the intense heat melts, испаряется, or blows away the material along the desired path. The cutting process is assisted by gases like nitrogen or oxygen, which are used to blow away the molten material and provide a cleaner cut. The precision of the laser also ensures that the cuts are smooth, reducing the need for further post-processing.

◆ CNC Control

The CNC system controls the movement of the laser cutting head along the material. Using a computer program, the system can make precise cuts based on the specific geometry required. The operator can upload design files directly into the CNC system, ensuring that each part is cut with exacting detail and consistency.

3. Key Advantages of CNC Laser Tube Cutting Machines

◆ Exceptional Precision

The main benefit of CNC laser tube cutting machines is their high level of accuracy. These machines can achieve tolerances as tight as 0.1mm, ensuring that each part is manufactured to the exact specifications required. This level of precision is vital for industries that demand the utmost quality, такие как производство аэрокосмических и медицинских устройств.

◆ Increased Efficiency

CNC laser tube cutting machines offer faster cutting speeds compared to traditional methods, значительное сокращение времени производства. The automation provided by CNC systems further increases efficiency by minimizing the need for manual intervention. The precision of the cutting also ensures that there is less material waste, contributing to cost savings.

◆ Material Flexibility

Laser tube cutting machines can handle a wide range of materials and thicknesses. This versatility makes them ideal for industries that require cutting different types of metals, such as the automotive, аэрокосмический, and energy sectors. The machine’s ability to cut through various materials and thicknesses with consistent quality gives manufacturers the flexibility to handle diverse production needs.

◆ Чистые сокращения с минимальными отходами

Laser cutting produces minimal waste compared to traditional cutting methods like sawing, which leaves larger offcuts. Узкий керф (ширина разреза) means that there is little excess material removed, maximizing the yield from raw material. Кроме того, the clean, smooth edges produced by the laser cutting process often eliminate the need for secondary finishing processes, such as deburring.

4. Common Applications of CNC Laser Tube Cutting Machines

◆ Автомобильная промышленность

В автомобильной промышленности, CNC laser tube cutting machines are used to manufacture a wide range of parts, including exhaust systems, Компоненты шасси, and support frames. The ability to produce intricate shapes and parts with high precision helps ensure that each component fits perfectly within the overall vehicle assembly, contributing to both performance and safety.

◆ Аэрокосмическое производство

The aerospace industry relies heavily on precision components, where even the smallest deviations can have serious consequences. CNC laser tube cutting machines are essential in cutting structural parts, топливопроводы, and other aerospace components, where high-quality and precise cutting is non-negotiable.

◆ Construction and Architecture

Laser cutting technology is also used in the construction industry, where it plays a key role in producing decorative metal elements for architectural projects. Whether it’s cutting ornamental designs or structural elements, the ability to produce highly detailed and aesthetically appealing components is a significant benefit for architects and builders.

◆ Medical Devices

In medical device manufacturing, CNC laser tube cutting machines are used to produce parts for implants, medical tubing, and surgical instruments. The cleanliness of the laser-cut edges is critical in ensuring that no contamination occurs, making laser cutting an essential part of the production process for medical devices.

5. Factors to Consider When Choosing a CNC Laser Tube Cutting Machine

When selecting a CNC laser tube cutting machine, several factors must be considered to ensure you choose the right equipment for your needs.

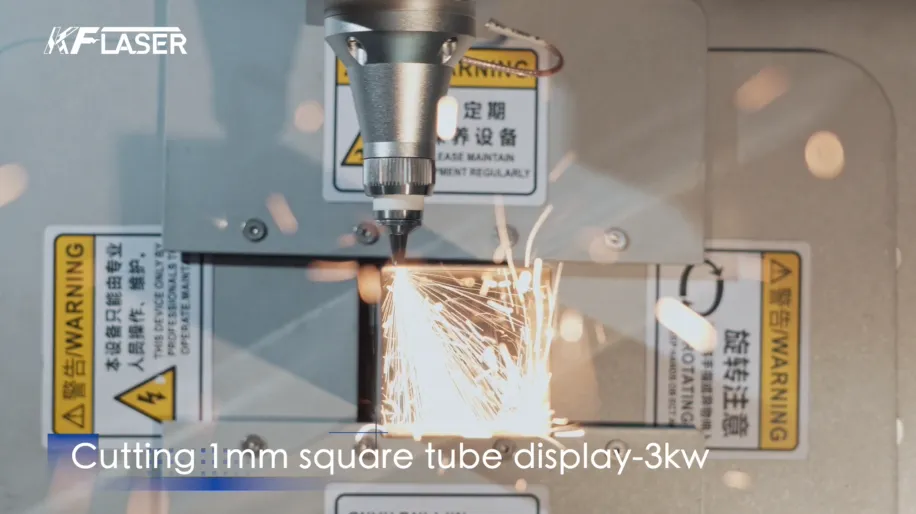

◆ Мощность лазера

The power of the laser determines the thickness of the material that can be cut. Лазеры большей мощности идеально подходят для резки более толстых материалов., while lower-powered lasers are suitable for thinner materials. Be sure to match the laser power with the material thickness required for your application.

◆ Скорость резки и точность

The speed and precision of the machine are crucial for optimizing production. Faster machines can increase throughput, while precision machines ensure that the parts are cut to the exact specifications. Choosing the right balance between speed and accuracy is essential depending on the complexity of the cuts needed.

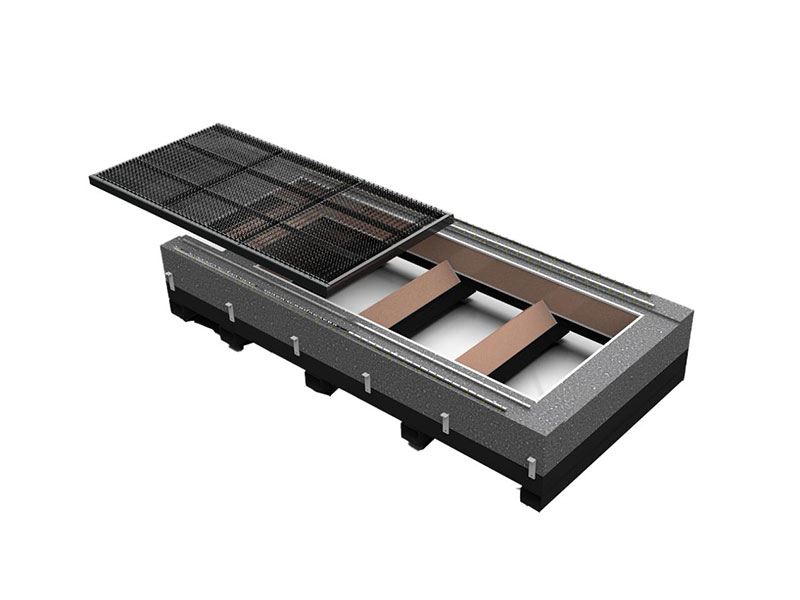

◆ Функции автоматизации

Many CNC laser tube cutting machines come with automation features such as automatic loading, unloading, и системы обработки материалов. These features reduce labor costs, increase production efficiency, and ensure consistent results across all parts.

◆ Техническое обслуживание и поддержка

The reliability of the CNC system and the availability of support services are critical considerations when choosing a laser tube cutting machine. Look for a machine with a solid warranty and access to technical support to ensure minimal downtime and smooth operation.

By choosing a CNC laser tube cutting machine, manufacturers can significantly improve their efficiency, reduce material waste, and achieve higher precision in their metal cutting processes. This technology is driving innovation across multiple industries, and its versatility makes it a valuable asset for businesses looking to stay ahead in the competitive landscape. Whether you’re producing automotive components, медицинское оборудование, or architectural elements, CNC laser tube cutting machines are revolutionizing the way we fabricate metal parts with unmatched accuracy and speed.

Главные новости

-

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025 -

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025 -

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025 -

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025 -

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина