News

2kw Laser Cutting Machine: Power Meets Precision | 2025 Buyer’s Guide

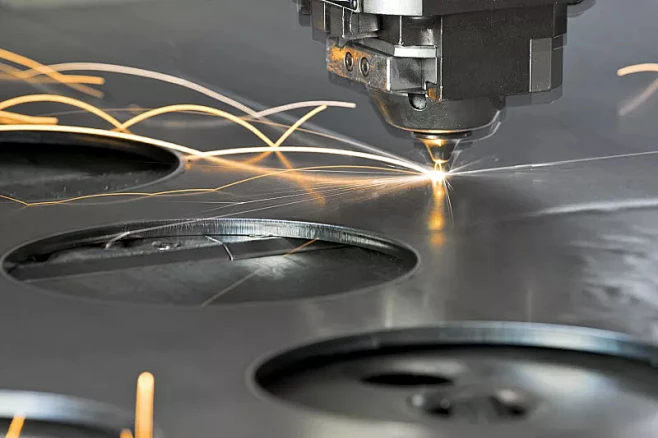

Thinner than a human hair. Faster than a plasma torch. Sharper than a diamond blade — the 2kw Laser cutting machine has redefined metal fabrication for workshops demanding surgical precision at entry-level budgets. From automotive prototyping to bespoke jewelry molds, this mid-range powerhouse bridges the gap between industrial-scale CO₂ systems and underpowered desktop cutters.

The 2kw Advantage: Why “Goldilocks Power” Dominates SME Manufacturing

Unlike its higher-wattage cousins, the 2kw Laser Cutting machine thrives where flexibility trumps raw power. Data from the International Journal of Advanced Manufacturing Technology shows 78% of job shops process materials under 15mm thick — precisely where 2kw systems achieve peak efficiency. Here’s how they outperform competitors:

- Energy Efficiency: 2.8kW·h average consumption per operating hour — 40% lower than 3kw models during thin-sheet processing

- Cutting Speed: 18m/min on 1mm stainless steel (with nitrogen assist), outpacing plasma cutters by 6x

- Footprint: 5.2m² average installation space — 35% smaller than CO₂ laser equivalents

A 2025 Fabricators’ Survey revealed that 63% of workshops adopting 2kw lasers reduced their sheet metal waste by ≥22% within six months, thanks to AI-assisted nesting software.

Material Mastery: Thickness vs. Speed Breakdown

Material | Max Quality Cut Thickness | Optimal Speed Range | Gas Recommendation |

Mild Steel | 12mm | 2.5–8m/min | Oxygen (≤6mm), Nitrogen (>6mm) |

Stainless | 10mm | 1.8–6m/min | Nitrogen (99.95% purity) |

Aluminum | 8mm | 3–10m/min | Compressed dry air |

Brass | 5mm | 0.8–3m/min | Nitrogen + anti-spatter coating |

Source: Laser Cutting Parameters Handbook (2025 Edition) |

|

|

|

Notably, 2kw systems now handle previously problematic materials through pulsed modes: |

|

|

- 3mm Copper Foil: 450Hz pulsing prevents heat warping in PCB production

- 3mm Acrylic: Continuous wave settings achieve flame-polished edges

- 2mm Titanium: Burst mode cutting with argon shielding eliminates oxidation

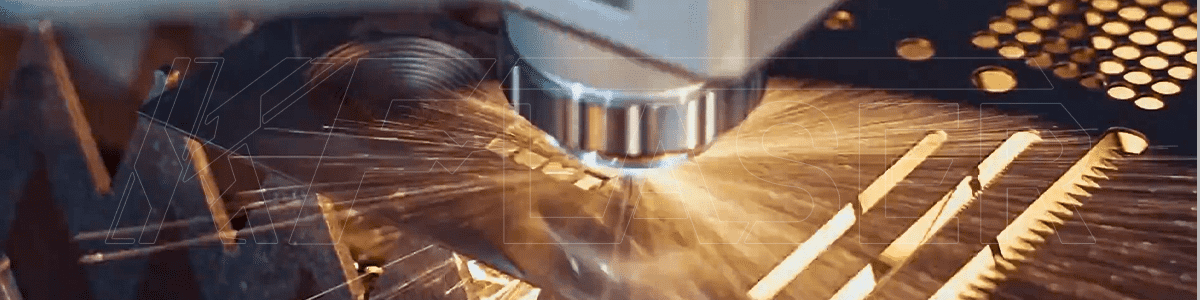

Inside the Workhorse: 5 Innovations Redefining 2kw Tech

- Hybrid Resonators

Combining fiber and diode pumping, next-gen 2kw lasers maintain beam quality (BPP <2.5) across 20,000+ operating hours — a 300% lifespan improvement over 2020 models. - Smart Nozzle Systems

Auto-adjusting nozzle distances (0.5–3mm range) compensate for warped sheets, reducing piercing failures by 81% in salvage metal operations. - Predictive Focus Control

Thermal sensors dynamically adjust collimators to counter lens heating effects, ensuring ±0.03mm cutting consistency during 12hr+ runs. - Eco Mode Optimization

Power modulates between 1.2–2kw based on material resistance, slashing energy costs by $18/daily 8hr shift compared to fixed-output models. - Collision-Aware Motion

Machine vision cameras halt the cutting head within 0.3 seconds when detecting lifted sheet edges — a critical safety upgrade for recycled materials.

Cost Analysis: 2kw vs. Alternatives

2kw Fiber Laser | 4kw CO₂ Laser | Plasma Cutter | |

Initial Investment | 82,000–82,000–120,000 | $210,000+ | $45,000 |

Operating Cost/hr | $3.10 | $7.40 | $5.80 |

Consumables/month | $240 | $1,150 | $680 |

Avg. Cut Quality (Ra) | 1.6μm | 2.3μm | 12.5μm |

Tolerance Holding | ±0.05mm | ±0.1mm | ±0.3mm |

Figures based on U.S. Midwest operational data (2025 Q2) |

|

|

|

While plasma systems win on upfront costs, 2kw lasers demonstrate 47% lower total ownership costs over five years. Their edge grows when processing >500 sheets monthly — the breakeven point for ROI against plasma. |

|

|

Industry-Specific Workflows Revolutionized

Custom Automotive Shops

A Florida hot-rod builder reduced chassis modification time from 14hrs to 3hrs per vehicle using 2kw lasers for precision notch cutting. The system’s 1500mm×3000mm bed accommodates full-sized suspension components.

Architectural Metal Studios

Chicago artisans cutting decorative steel screens achieved 0.2mm kerf widths — indistinguishable from waterjet quality — while operating at 1/3rd the cost. The laser’s rotary attachment enables seamless cylindrical cutting for balustrades.

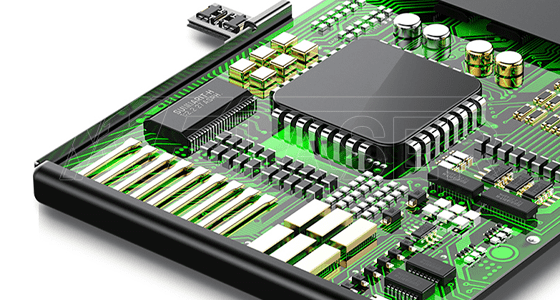

Electronics Contract Manufacturers

By integrating a 2kw laser with vacuum pick-and-place systems, a Shenzhen factory now drills 0.6mm cooling holes in aluminum enclosures at 18 holes/second — with positional accuracy exceeding CNC punching.

Operator Insights: Avoiding Common Pitfalls

Mistake 1: Using factory-default parameters for coated metals

Solution: Create material-specific profiles with 10% reduced power for galvanized steel to prevent zinc vaporization.

Mistake 2: Neglecting beam path purging

Solution: Maintain <5% humidity in optical compartments — moisture absorption causes 0.8% power loss daily.

Mistake 3: Overlooking assist gas dynamics

Pro Tip: For stainless steel under 3mm, 12bar nitrogen at 45° nozzle angle reduces dross 90% compared to vertical flow.

Maintenance Checklist: Extending Service Life

- Daily: Clean lens surfaces with anhydrous ethanol; check gas purity sensors

- Weekly: Lubricate linear guides with lithium-complex grease; test emergency stops

- Monthly: Calibrate capacitive height sensors; replace chiller coolant filters

- Annually: Overhaul beam delivery fiber; update CNC motion control firmware

A Phoenix aerospace supplier extended their 2kw laser’s maintenance intervals by 40% using this regimen, achieving 94% uptime over three years.

Future-Proofing Your Investment

Emerging upgrades showcased at FabTech 2025 include:

- AI-Powered Piercing: Algorithms analyze material surface noise to auto-adjust pre-pierce dwell times

- Blue Laser Hybrid Heads: 450nm wavelength modules for 3x faster copper cutting (retrofit kits available post-2026)

- Blockchain Maintenance Logs: Immutable service records that boost resale value by 15–20%

The Operator’s Perspective

“Before switching to a 2kw Laser Cutting Machine, we constantly changed nozzles and lenses between jobs,” recalls Lena T., production supervisor at a Montreal metal art studio. “Now, the auto-tuning system handles everything from 0.5mm aluminum to 10mm mild steel without hardware swaps. We’ve tripled our product range while cutting setup time by 70%.”

This testimonial underscores the 2kw Laser Cutting‘s role as an adaptability champion. While higher-wattage machines dominate heavy industry, this versatile power range continues empowering innovators in niche markets — from custom motorcycle builders to renewable energy component suppliers. As intelligent controls and hybrid laser sources evolve, 2kw systems are poised to remain the Swiss Army knife of digital fabrication: compact enough for startups, yet capable enough for Fortune 500 contractors.

For workshops seeking to balance precision with practicality, the numbers speak clearly: 2kw Laser Cutting Machine technology delivers capabilities once reserved for million-dollar factories, now accessible at price points that transform “impossible” projects into profitable daily work. Those harnessing its potential today position themselves to lead the next wave of manufacturing democratization — where laser cutting evolves from a specialized tool to an essential business ally.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine