News

The Growing Demand for the 3KW Laser Cutting Machine: Why It’s the Industry’s Game-Changer

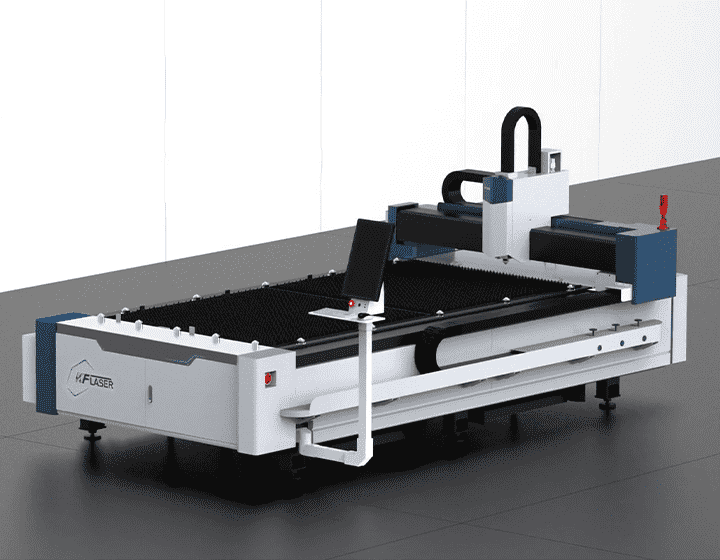

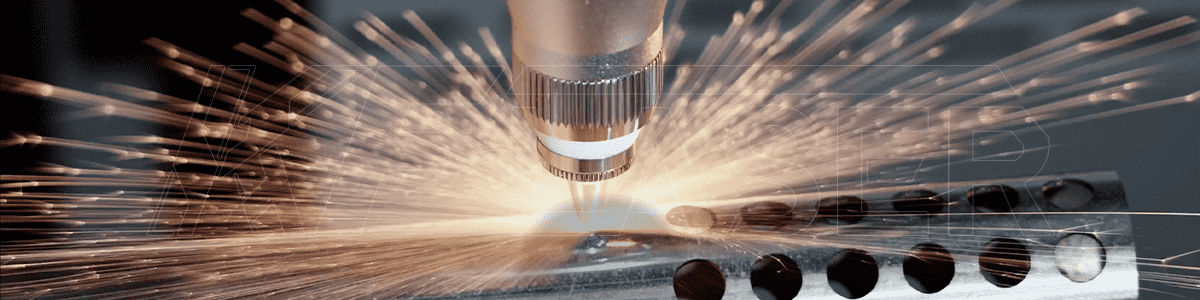

In the evolving world of manufacturing, precision and efficiency are more than just advantages—they are necessities. One technology that is revolutionizing industries globally is the 3KW laser cutting machine. This highly efficient tool offers an unbeatable combination of speed, precision, and versatility. But as demand grows, so do the questions surrounding its price. Why is the 3KW laser cutting machine price a hot topic, and what factors drive this price?

Laser cutting technology is crucial in fields such as automotive manufacturing, aerospace, and metal fabrication. With its ability to cut through thick metals and intricate materials with ease, it’s no wonder that companies are constantly searching for the most cost-effective way to adopt this technology.

Understanding the Value of the 3KW Laser Cutting Machine

A 3KW laser cutting machine combines a moderate power output with the ability to cut a variety of materials with unmatched accuracy. However, with such capabilities come costs that need to be carefully considered. The 3KW laser cutting machine price can vary widely depending on a number of factors, including:

- Laser Type and Quality

- Material Compatibility

- Software Integration

- Brand and Manufacturer

- Maintenance and Support

It’s essential to understand how each of these elements impacts the overall cost to make an informed decision. A 3KW laser cutting machine provides an ideal balance of power and efficiency, suitable for cutting a wide range of metals such as stainless steel, aluminum, and mild steel.

Factors Affecting the 3KW Laser Cutting Machine Price

When considering the price of a 3KW laser cutting machine, various elements come into play. Let’s break down the main factors that will influence the cost:

1. Laser Power

The power output of the laser cutter determines the thickness of materials that can be cut effectively. A 3KW laser cutting machine is ideal for medium-thickness materials and strikes the right balance between power and efficiency. While higher-power lasers can cut through thicker materials, they come at a significantly higher cost.

2. Material Handling and Automation Features

Some machines come with advanced material handling systems, such as automatic loaders or unloaders, and automated positioning systems. These features not only improve workflow but also impact the overall price. More automation typically means a higher price tag.

3. Cutting Speed and Precision

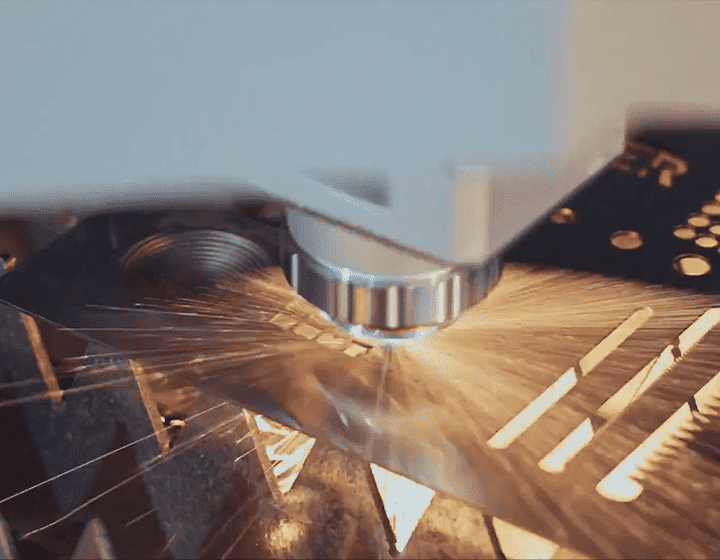

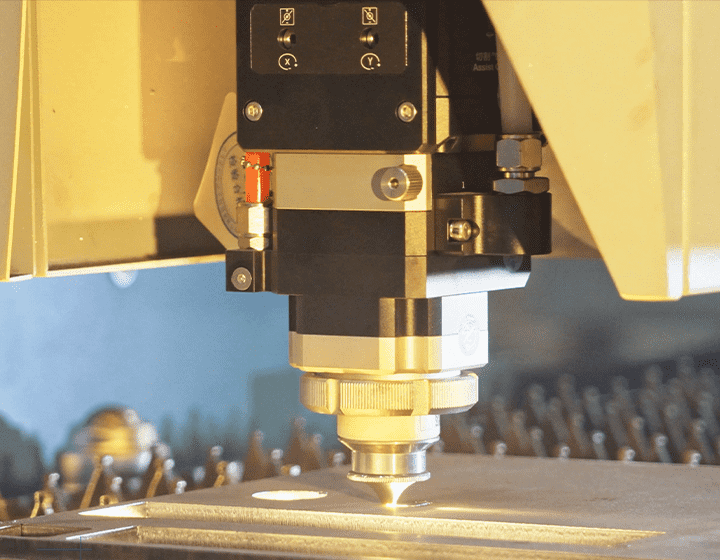

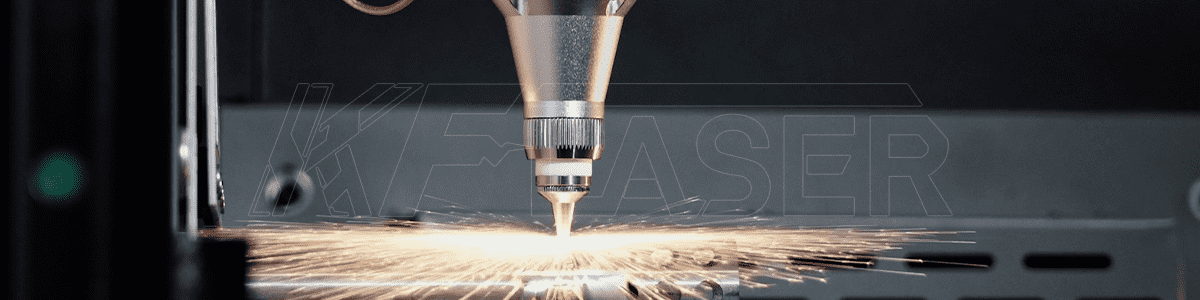

The efficiency of a 3KW laser cutting machine depends on its cutting speed and precision. Machines with advanced cutting technology, such as high-frequency pulsing and advanced optics, often cost more but deliver faster and more precise cuts.

4. Maintenance and Support Services

Ongoing support and maintenance are crucial for keeping a laser cutting machine in top condition. Manufacturers offering extensive after-sale services, including training and maintenance packages, will likely price their 3KW laser cutting machine higher due to the added value of these services.

5. Manufacturer and Brand

Brand reputation plays a significant role in determining the price of a laser cutting machine. Established manufacturers often offer more reliable machines, with better customer support and longer warranties. This reliability can drive the price up, but it’s often worth the investment for companies that rely on their machinery for daily operations.

How to Evaluate the True Cost of a 3KW Laser Cutting Machine

When assessing the 3KW laser cutting machine price, it’s important to factor in both the initial cost and the long-term value. While the upfront price might seem steep, the savings over time from increased efficiency, reduced waste, and improved production speed may offset the cost. Additionally, consider the following:

- Energy Efficiency: Machines that consume less power can lead to lower operational costs.

- Operational Costs: Consider factors such as the cost of consumables (laser heads, lenses, etc.) and the frequency of required maintenance.

- Expected Lifetime: High-quality machines typically offer longer lifespans, which could make them more cost-effective over time.

- Customization: Some manufacturers provide options for customization, allowing you to tailor the machine to your specific needs, but these customizations can also increase the overall price.

What Are the Advantages of a 3KW Laser Cutting Machine?

Investing in a 3KW laser cutting machine brings several significant advantages:

High Precision: Laser cutting is known for its exceptional accuracy, which ensures that the cutting process leaves minimal wastage, enhancing material utilization.

Flexibility: A 3KW laser cutting machine is versatile and can cut a wide range of materials, including metals, plastics, and non-ferrous materials. This makes it a great option for industries with diverse material needs.

Speed and Efficiency: Compared to traditional cutting methods, laser cutting is faster and more efficient, reducing production time and costs.

Automation Compatibility: The machine can be integrated into automated production lines, further enhancing productivity and reducing the need for manual labor.

How to Get the Best Value for Your 3KW Laser Cutting Machine

While the 3KW laser cutting machine price may seem daunting at first, it’s essential to view this investment as part of a larger strategy to enhance your business’s operations. Here’s how you can maximize the value:

Invest in Quality Over Price: Opt for a machine that suits your production needs, even if it costs slightly more upfront. Higher-quality machines may save you money in the long run by offering superior performance and durability.

Understand Total Cost of Ownership: Don’t just look at the initial purchase price. Consider operating costs such as maintenance, energy consumption, and repair costs over the machine’s lifetime.

Negotiate with Suppliers: Many manufacturers offer discounts for bulk purchases, and some may even offer financing options to make the purchase more affordable.

What to Look for When Purchasing a 3KW Laser Cutting Machine

Purchasing a 3KW laser cutting machine is a big decision, and ensuring you’re getting the best deal requires careful research. Some of the key factors to consider include:

Customer Reviews and Testimonials: Look at reviews from other businesses that have used the machine to get an idea of its reliability and performance.

Warranty and Support: Ensure that the machine comes with a solid warranty, and check the manufacturer’s after-sale support options.

Training and Resources: Some manufacturers provide in-depth training and documentation to help you get the most out of your machine. This can be incredibly valuable for businesses that are new to laser cutting technology.

The 3KW laser cutting machine is an essential tool for modern manufacturing, offering precision, efficiency, and versatility. By carefully considering the 3KW laser cutting machine price and the factors that influence it, you can make an informed decision that will benefit your business for years to come.

Tips for Optimizing Your Purchase

When you are finally ready to invest in a 3KW laser cutting machine, it’s important to have a clear understanding of your production needs, budget, and the long-term savings associated with your investment. By doing so, you will be able to select the best option that aligns with your business goals and ensures maximum value.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine