News

The Best Laser for Cutting: Revolutionizing Precision and Efficiency

Cutting has been a cornerstone of manufacturing for centuries, evolving from rudimentary tools to precision-driven technology. But in today’s fast-paced, innovation-driven world, good is not good enough. We seek speed, precision, versatility, and efficiency—qualities that converge in one answer: laser cutting. The question now isn’t whether lasers are the future, but what makes the best laser for cutting stand out among the competition.

1.What Defines the Best Laser for Cutting?

Selecting the “best” laser isn’t a one-size-fits-all solution. It’s a calculated decision based on your specific needs, such as material type, thickness, cutting speed, precision requirements, and budget. A deep dive into these factors reveals why KF LASER machines are a trusted choice for achieving industry-leading results.

2.Types of Lasers for Cutting: A Comprehensive Guide

Before identifying the best laser for your needs, understanding the key types of laser technology is essential:

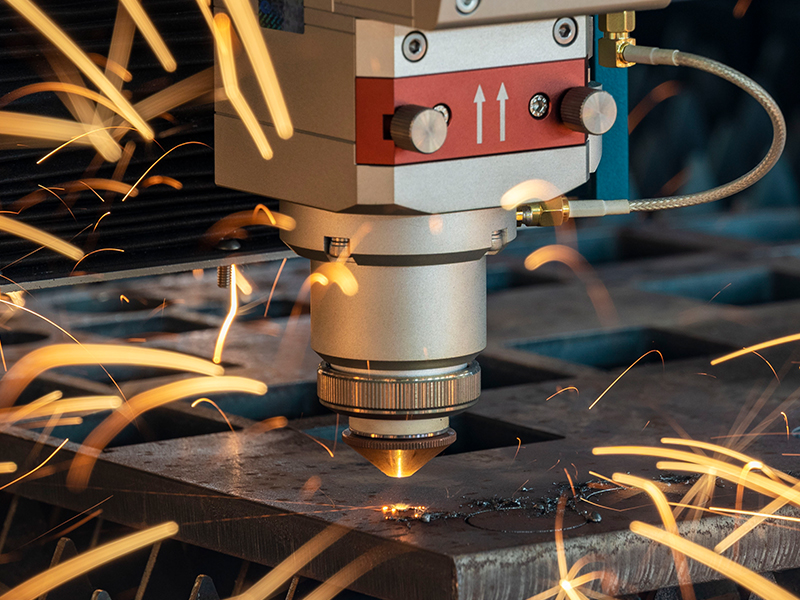

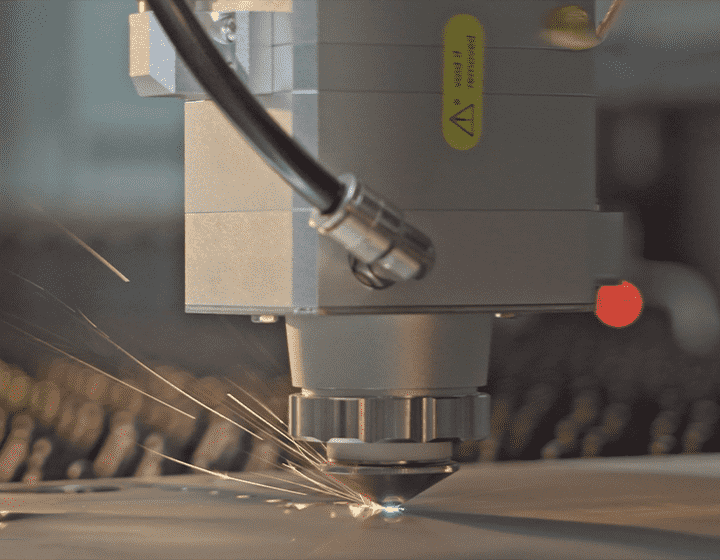

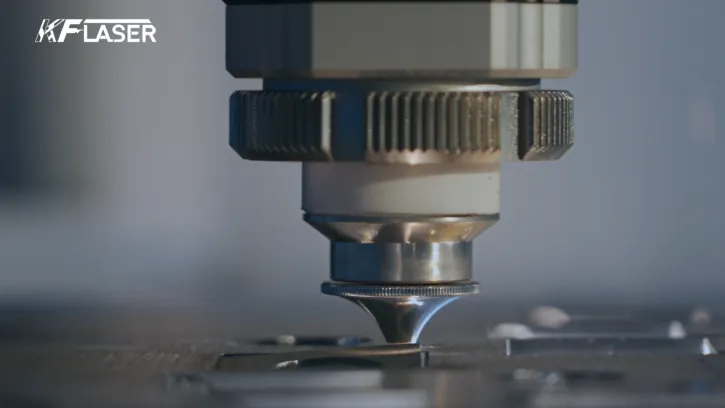

1. Fiber Lasers

Fiber lasers have taken the cutting industry by storm. Offering high power efficiency, they excel in cutting metals such as steel, aluminum, brass, and copper. Their ability to maintain beam quality over long distances makes them the go-to choice for industries requiring precision and speed.

– Best for: Metals, reflective materials, and high-speed cutting.

– Advantages: Energy-efficient, low maintenance, and capable of handling a wide range of materials.

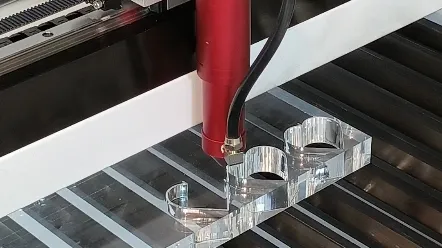

2. CO2 Lasers

A classic choice in the industry, CO2 lasers use a gas mixture to generate a powerful cutting beam. They are highly effective for non-metal materials like wood, plastics, and glass, making them ideal for creative and decorative applications.

– Best for: Non-metals and thicker materials.

– Advantages: Smooth cutting edges and versatility in non-metal applications.

3. Diode Lasers

Although typically used in engraving and marking, diode lasers have evolved to handle light cutting tasks. They are compact, portable, and affordable, making them popular for hobbyists and small-scale operations.

– Best for: Engraving, light materials, and hobbyist projects.

– Advantages: Low cost, user-friendly, and portable.

4. YAG Lasers

YAG (Yttrium Aluminum Garnet) lasers are specialized for applications requiring deep penetration and high power. Often used in welding and drilling, they are suitable for industries such as aerospace and automotive manufacturing.

– Best for: Thick metals and high-strength applications.

– Advantages: High power density and precision.

3.Key Features of the Best Laser for Cutting

When evaluating laser cutting machines, several critical factors distinguish the best systems from the rest:

1. Precision and Accuracy

The best lasers deliver unparalleled precision, ensuring clean cuts with no burrs or rough edges. This is essential for industries like aerospace and medical devices, where accuracy is non-negotiable.

2. Speed and Efficiency

High-speed cutting capabilities minimize production time without sacrificing quality. Advanced laser systems, like those from KF LASER, achieve remarkable efficiency, allowing businesses to meet tight deadlines and scale operations.

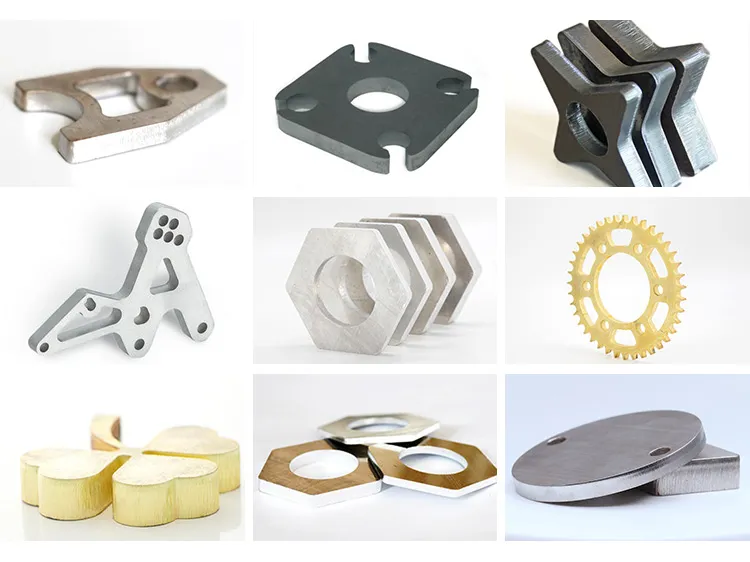

3. Material Versatility

A great laser cutting machine accommodates a wide range of materials, from metals and alloys to wood, plastics, and textiles. This versatility ensures adaptability across multiple industries.

4. Energy Efficiency

Modern lasers emphasize sustainability, consuming less power while delivering high-performance results. Energy-efficient systems reduce operational costs and align with eco-conscious manufacturing practices.

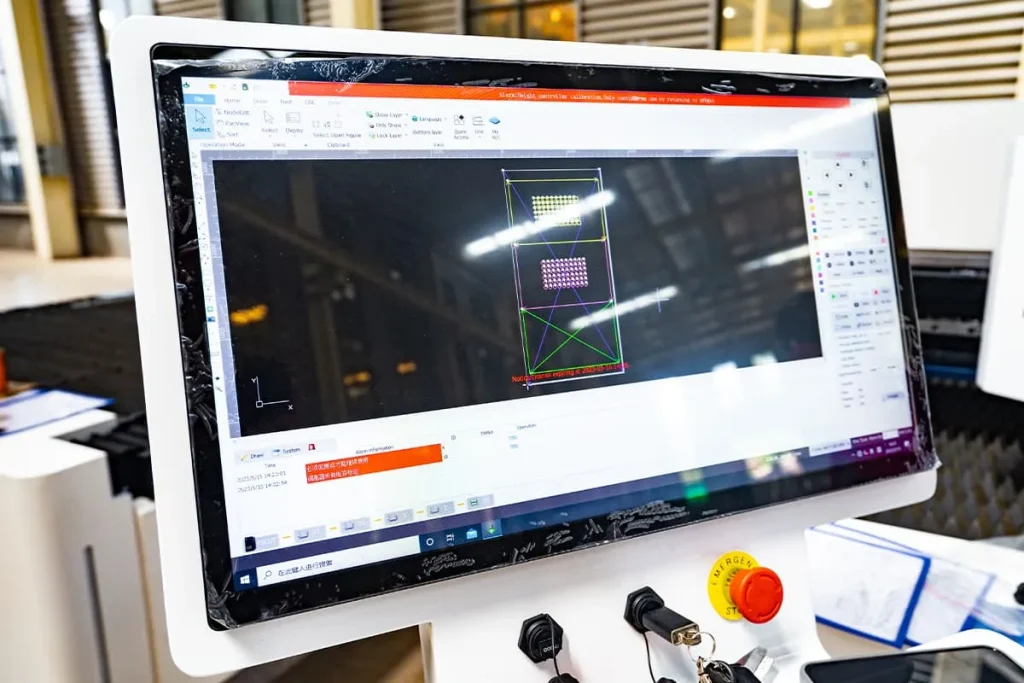

5. User-Friendly Software

State-of-the-art software simplifies the cutting process, enabling operators to design, adjust, and execute cuts seamlessly. KF LASER machines come equipped with intuitive interfaces for hassle-free operation.

6. Reliability and Longevity

Durability is crucial when investing in cutting equipment. The best lasers are built to withstand heavy-duty use, ensuring consistent performance over time with minimal maintenance.

4.Applications of the Best Laser Cutting Systems

The versatility of laser cutting spans across industries, unlocking new possibilities for innovation and creativity:

1. Automotive Industry

From chassis components to intricate engine parts, laser cutting ensures precision and efficiency in automotive manufacturing.

2. Aerospace

High-performance materials like titanium and aluminum demand cutting technology that meets rigorous standards. Fiber lasers excel in delivering the accuracy required for aerospace components.

3. Medical Equipment

Laser cutting produces flawless surgical instruments, prosthetics, and implants, ensuring safety and reliability in medical applications.

4. Architecture and Design

The ability to craft intricate designs makes laser cutting a favorite for architects and designers. From decorative panels to custom furniture, the possibilities are endless.

5. Electronics

Circuit boards, casings, and heat sinks require micro-level precision, achievable only through advanced laser systems.

6. Renewable Energy

The production of solar panels and wind turbine components relies on laser cutting for optimal performance and efficiency.

5.Why KF LASER Stands Out

KF LASER has established itself as a leader in laser cutting technology, delivering machines that balance precision, speed, and reliability. Whether you’re cutting thick metal sheets or delicate non-metal materials, KF LASER systems offer:

– Cutting-Edge Technology: Advanced lasers designed to handle diverse applications.

– User-Friendly Interfaces: Simplified software for streamlined operations.

– Sustainability Focus: Energy-efficient solutions that align with green manufacturing goals.

– Robust Support: Dedicated customer service to ensure smooth integration and ongoing success.

6.Future Trends in Laser Cutting Technology

1. AI-Driven Automation

Artificial intelligence is set to revolutionize laser cutting, enabling predictive maintenance, real-time adjustments, and optimized cutting paths for enhanced productivity.

2. Hybrid Systems

Combining laser cutting with other technologies, such as 3D printing, will open new avenues for innovation and efficiency.

3. Compact and Portable Machines

As businesses prioritize flexibility, compact laser systems will become increasingly popular, empowering small-scale operations without compromising quality.

4. Advanced Material Compatibility

Future advancements will expand the range of materials lasers can cut, including composites and advanced alloys.

7.Choosing the Best Laser for Cutting: A Step-by-Step Guide

1. Define Your Needs: Identify the materials, thicknesses, and precision requirements for your projects.

2. Evaluate Performance: Compare cutting speed, accuracy, and energy efficiency across different systems.

3. Consider Software and Support: Ensure the machine comes with robust software and reliable customer service.

4. Assess Long-Term Value: Factor in maintenance costs, operational lifespan, and scalability.

8.The Bottom Line: Embrace Excellence with KF LASER

The best laser for cutting isn’t just a machine; it’s a tool that empowers creativity, drives efficiency, and transforms industries. KF LASER delivers all this and more, setting the standard for precision and innovation in laser cutting technology.

Whether you’re crafting intricate designs or manufacturing high-performance components, KF LASER offers the solutions you need to excel. The future of cutting awaits—embrace it with the confidence that only the best laser systems can provide.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine