The laser pipe cutting machine is reshaping the future of metal processing, providing a level of precision and speed that was once unimaginable in industries such as automotive, aerospace, construction, and even medical equipment manufacturing. As industrial needs evolve, laser technology has become a critical tool for improving production efficiency and achieving the highest level of precision in pipe cutting applications.

Laser cutting machines for pipes offer substantial benefits over traditional methods like mechanical saws, water jets, and plasma cutting. They can handle complex geometries, provide clean, burr-free cuts, and operate at high speeds, all while minimizing material wastage. These advantages make laser pipe cutting an essential technology for industries striving for higher productivity and quality.

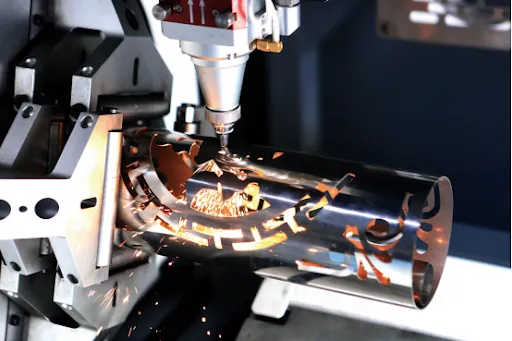

A laser pipe cutting machine uses high-powered laser beams to cut through metal pipes with exceptional precision. The process involves directing a focused beam of light onto the surface of a pipe, where it generates enough heat to melt, burn, or vaporize the material. The result is a precise, clean cut with minimal thermal distortion. CNC technology is employed to control the laser head’s movement, ensuring that even the most complex designs are executed with ease.

Unlike traditional mechanical methods, which rely on physical contact with the material, laser cutting involves no such contact, reducing the risk of damage to the material. This contactless process also minimizes wear on the cutting tools, extending their lifespan and reducing operational costs.

Precision and Accuracy

One of the most notable features of laser pipe cutting machines is their ability to make highly accurate cuts. The precision of laser cutting is unparalleled, especially when it comes to intricate designs or tight tolerances. This is crucial in industries such as aerospace or automotive, where even the smallest error can affect the performance and safety of the components.

Speed and Efficiency

Laser pipe cutting machines can cut metal pipes at impressive speeds, significantly outpacing traditional methods. High-speed operations, coupled with the ability to cut complex shapes without the need for additional finishing processes, result in a faster turnaround time. This efficiency translates into reduced production costs and a quicker time-to-market for products.

Reduced Material Waste

Laser cutting machines minimize material waste by providing precise cuts with very little kerf (the width of the cut). This is particularly valuable when working with expensive materials, as the reduced waste leads to significant cost savings. Additionally, laser cutting generates less heat compared to other cutting methods, reducing the risk of warping or distortion that might require further material adjustments.

No Need for Post-Processing

The clean and precise cuts produced by laser machines often require little to no post-processing. For industries dealing with tight tolerances and critical applications, this eliminates the need for additional finishing steps such as deburring, which saves both time and labor costs. The smooth edges produced by the laser process are often ready to use without the need for further refinement.

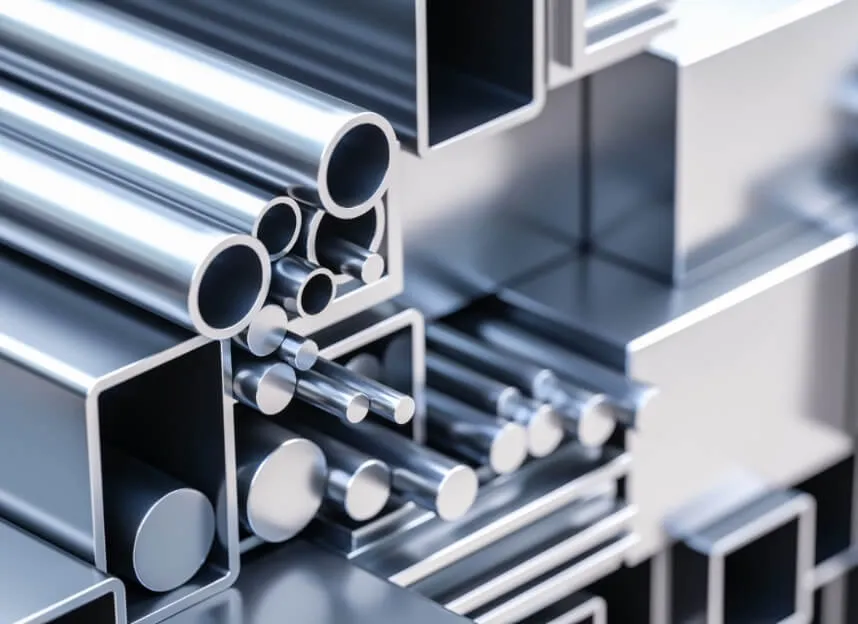

Versatility in Materials and Thickness

Laser pipe cutting machines can handle a wide range of materials, from stainless steel to aluminum, and even more exotic metals like titanium and copper. These machines can also cut pipes of varying thicknesses, making them adaptable to different types of projects. Whether you’re working with thin-walled pipes for delicate components or thick-walled pipes for heavy-duty machinery, laser cutting provides the versatility needed to tackle both.

The versatility and benefits of laser pipe cutting machines make them indispensable in a wide range of industries. Some of the most common applications include:

Automotive Industry

Laser pipe cutting machines are widely used in the automotive industry to manufacture parts such as exhaust systems, frames, and structural components. These machines can produce highly precise cuts and complex geometries, ensuring that components fit together perfectly and meet the strict quality standards of the automotive sector.

Aerospace and Defense

The aerospace industry relies on laser cutting technology to produce components that require tight tolerances and high performance. Parts like engine components, frames, and brackets made from various metals such as titanium, stainless steel, and aluminum are often cut using laser pipe cutting machines. The ability to handle materials with varying thicknesses and to cut complex shapes makes laser technology indispensable in this field.

Construction and Heavy Machinery

In construction, laser pipe cutting machines are used for manufacturing pipes, supports, and structural elements that must be both durable and precisely fabricated. Whether it’s large-diameter pipes for plumbing systems or smaller pipes for HVAC systems, laser cutting ensures high-quality results with minimal waste.

Medical Equipment Manufacturing

Laser pipe cutting machines also play a key role in the medical device industry, where precision is paramount. Surgical instruments, implants, and diagnostic equipment often require exacting cuts that are difficult to achieve with traditional methods. Laser cutting technology allows manufacturers to produce these delicate parts with high precision, reducing the risk of defects and ensuring safety.

Energy and Oil & Gas

In the energy sector, particularly in oil and gas production, laser pipe cutting machines are essential for cutting pipes used in drilling, transportation, and energy generation. The ability to cut through tough materials like steel and stainless steel makes these machines a crucial part of maintaining the infrastructure for oil and gas extraction and delivery.

As technology continues to evolve, laser pipe cutting machines are becoming even more advanced. The integration of fiber lasers, which are more energy-efficient and capable of cutting thicker materials, has already revolutionized the industry. In the future, we can expect further innovations, such as AI-powered automation, which will allow these machines to optimize cutting paths, detect and correct potential issues in real time, and increase overall efficiency.

Laser pipe cutting machines are poised to play an even greater role in manufacturing as industries demand more precise, efficient, and sustainable production methods. The combination of faster cutting speeds, reduced material waste, and improved energy efficiency positions laser technology as the cutting method of choice for the modern world.

The laser pipe cutting machine has become an indispensable tool for manufacturers seeking high-quality, efficient, and precise fabrication. From automotive to aerospace, medical to energy, this technology is transforming how industries handle metal pipe cutting, enabling companies to meet the growing demands of today’s fast-paced manufacturing environment.